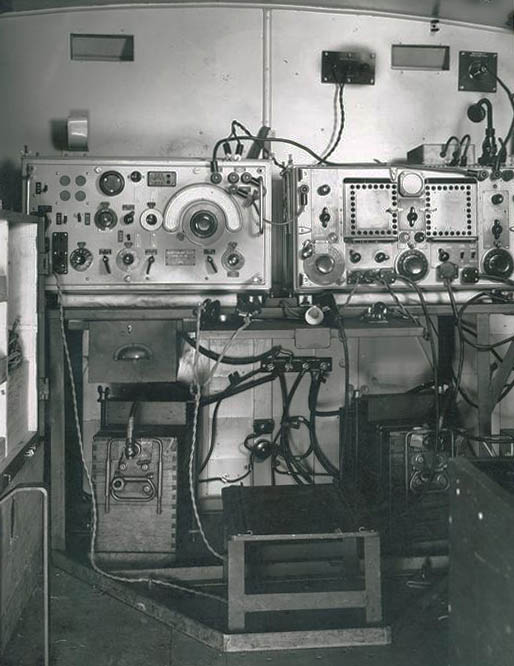

| The Equipment - All electrical and electronic

equipment in the D.F. hut had to operate on DC provided by a storage batteries.

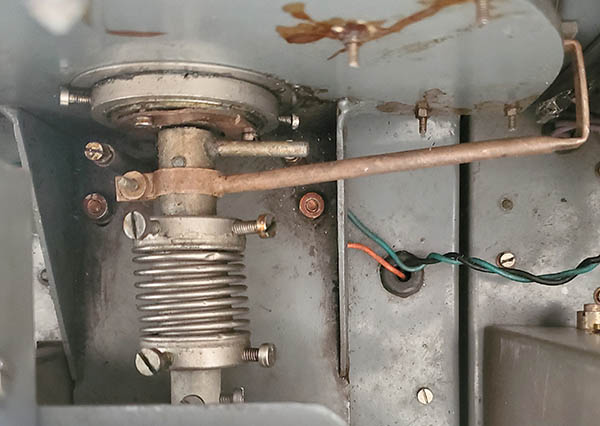

A six volt vibrator type power supply was used for the R106. Although it can't be

seen in the drawing because its likely location was in the corner near

the R.107 operator position, there must have been a set of dual six volt

storage batteries

connected in series to supply the R.107 with its 12vdc power

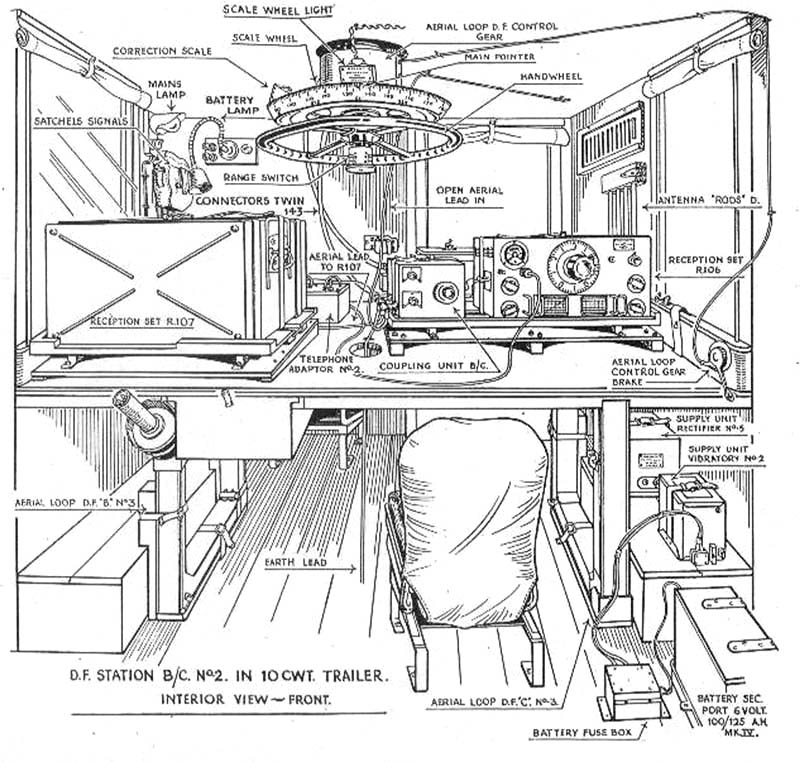

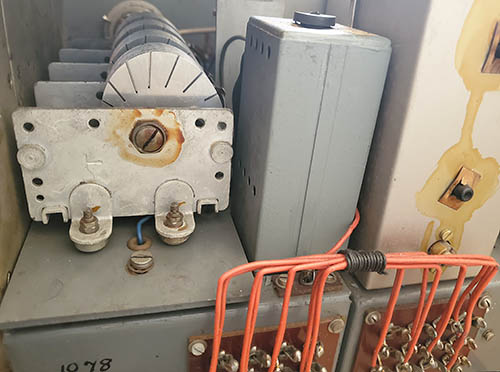

requirement. Three types of loop antennas were used and two of loop antennas and the

vertical "Sense" antenna were carried in disassembled form

inside the hut. The loop antenna in use was rotated with a

Handwheel

that was located above and mounted to the

ceiling of the hut. Above the handwheel was the loop azimuth compass,

called "Scale Wheel"

that, when set up accurately, would measure the bearing (direction in

degrees from magnetic north) of the signal being received. There was a

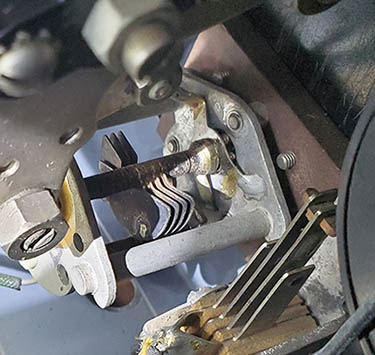

Range Switch at the bottom of the handwheel

that possibly was a impedance matching network that was switched to

match the particular loop being used (three different loops could be

installed.) Two receivers were set

up in the hut, the National Company, Inc. Reception Set R106,

a HRO-M receiver, and the British Army

Reception Set R.107 built by

Radio Transmission Equipment Ltd. or by Ferguson Radio Company (there

may have been other contractors that built these sets.) In the

drawing above, the R.107 is shown from the rear. Note in the drawing

that both receivers are "strapped" to their respective mounts by leather

belts to prevent movement while the trailer is being towed along bumpy

dirt roads or in fields with no roads. Both receiver mounts were slightly elevated at the front for

a better operator's view of each receiver panel. The loop antennas were diamond

shaped with a vertical antenna (built up from four "rods") to act as the "Sense" antenna.

Two antenna leads were routed to the Coupling Unit B/C.

with one lead coming from the Loop and the other lead was from the Sense

antenna. The Coupling Unit B/C would have the circuitry to combine the

signals from the Loop and Sense antennas into one output that was

connected to the Antenna input of the D.F. receiver. There's another antenna lead shown as "Open

Aerial Lead In" and the assumption would be that it was an

auxiliary antenna not associated with the D.F. Loop and Sense antennas

but still connected to the Coupling Unit B/C. The "Open Aerial" was

probably connected to the receiver that wasn't being used for the D.F.

operation so that receiver could then operate in an "enemy signals

search" (intercept mode) or for receiving communications

from D.F. Headquarters. The Coupling Unit B/C

had switches on its front panel that could have allowed the operator to select

the routing of the antennas to the two receivers and to also select

the Loop and Sense antennas' configuration. The operator would have needed to be

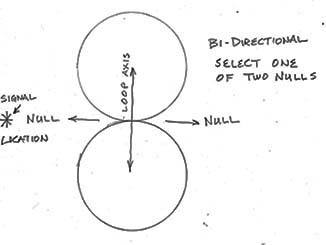

able to select just the Sense Antenna

for an omni-directional pattern

used when searching for signals. Then

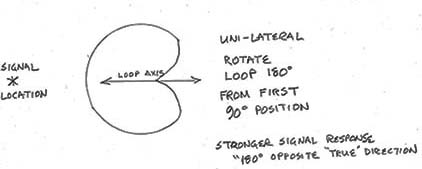

just the loop could be selected for a bi-directional pattern

(a "figure-8" pattern) to find the

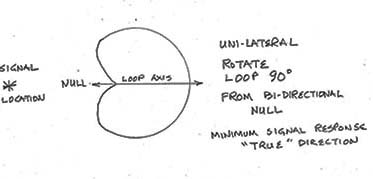

general direction of the signal. Finally, the combination of the Loop

antenna and the Sense antenna, sometimes called

Uni-lateral Direction or

True Direction, could be selected to create a

cardioid pattern to determine

True Direction. True Direction required that the radio operator tune in

the desired signal but the ultimate indication of direction was to

rotate the loop antenna for the minimum signal from the receiver, called

"the null." The loop compass would then indicate the direction in

degrees from magnetic north (provided the hut and loop plus the loop

compass had been physically aligned correctly.) The operator would have to know the correct Magnetic

Variance (also called Magnetic Declination) for the area to allow

calculating "True Direction." Magnetic Variance is different

in areas all over

the Earth so it was normally shown for the area on special charts used

for direction finding. The Coupling Unit B/C. could be switched to

either receiver and allow one receiver to become the direction finding

receiver. Additionally, most D.F. systems had some way to "balance" the

antenna response differences of the Loop compared to the Sense antenna.

The Coupling Unit B/C might have had a gain control (generally on the

Sense antenna) that allowed the operator to equalize the two antenna

responses (usually to a test signal.) It was also possible during the

set-up of the D.F. station hut to orient its position and adjustment of

the loop and loop compass to compensate for the magnetic variance of the area and

have the D.F. compass read "True Direction" without the need for the

additional calculation. Since magnetic variance could be either easterly

or westerly, the operator had to know whether to subtract or add the

magnetic variance from or to his "Magnetic Direction" bearings. To eliminate

this possible source of error, sometimes the loop-compass was set up to

read "True Direction." In most cases, bearings were "radio

transmitted" to a communications D.F. center (usually not far away) that

performed the transfer of the radio direction bearings to maps that could then triangulate

the location of the enemy transmitter. This type of D.F.

is called "Aural Null" and implies that the operator was listening

to the receiver output for the signal-loop null using headphones and

that was certainly the primary method used for discerning the

signal-loop null. Sometimes indicating meters were used for

a more accurate null measurement. The R106 S-meter

could be used for a D.F. indicator (the null.) This would have required

the AVC to be used and would only provide carrier level indications in

the AM-Voice mode. The R.107 didn't have a

Carrier Level meter so, if an external indicator would have been needed,

it might have been possible to use an audio output meter to indicate the null but it

would have depended on the

type of signal. The modulated carrier output of an AM-Voice signal would

have the audio meter needle "bouncing" following the modulation and that

would make finding a minimum null difficult. The same problem would

happen when CW was received since the signal plus BFO would result in

the same "bouncing" audio meter indication. Only a constant carrier

signal would have provided a stable audio signal that would allow

finding the null via an audio meter indication. This type of signal would only

occur during "tune up" or during pauses in voice modulation. It's possible that the

Telephone Adaptor No.2 was

provided with external sensitive audio response meters that had

damped-response circuitry to act as D.F.

indicators (this device is mostly hidden by the R.107 in the drawing.) It might be possible that the Telephone Adaptor No.2 could

have provided some type of usable null indicator since the typical Audio Output Meter

really wouldn't have worked. Note that

the Reception Set R106 has a cord running from the receiver's headphone

output jack to the Telephone Adaptor No.2. In the HRO circuit, the

headphone jack is capacitor-coupled from the first audio amplifier plate

so the audio signal isn't particularly "high level." However,

for rapid D.F. bearing measurement a meter indication wasn't actually necessary. Since the

loop-null is very

sharp (very narrow) it can easily be discerned quite accurately by

just listening.

|

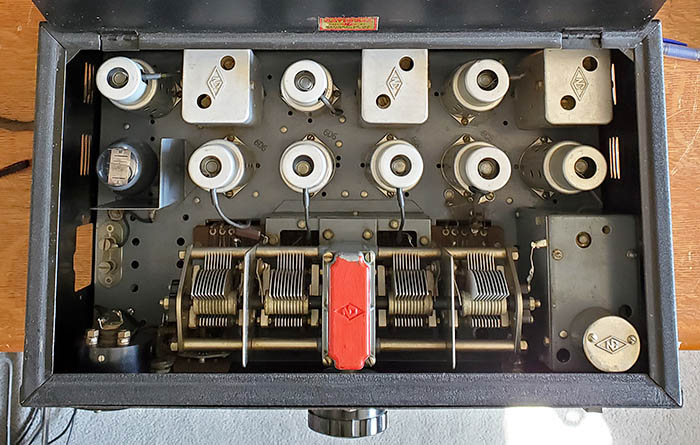

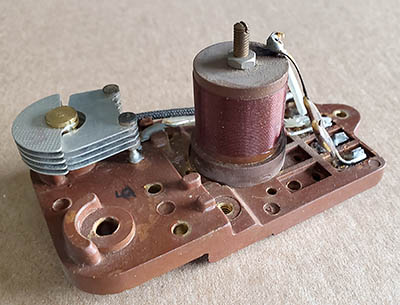

Reception Set R106

|

|

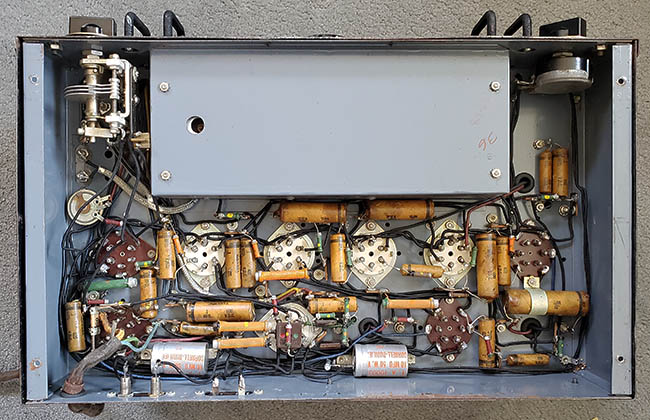

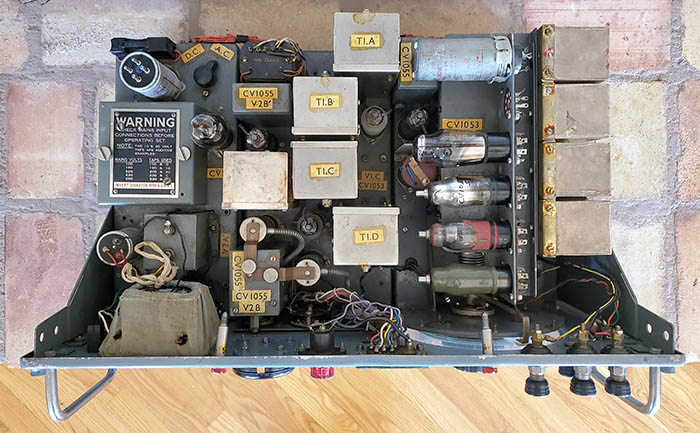

Reception Set R.107 |

When transporting the hut to the field location, the two Loop antennas

were stowed inside the hut.

Aerial Loop D.F. "B"

No. 3 and Aerial Loop D.F. "C" No. 3.

were installed in compartments by the wheel wells of the trailer.

The implication of the drawing is that

Aerial Loop D.F. "A" No. 3 is installed on the roof

of the hut since it's not shown. That would be a total of three Loop antennas

available depending on the frequency range of interest. The "Sense Antenna" was a

vertical antenna comprised of the four rods shown as "Antenna Rods D"

that mounted to the wall of the hut.

If the drawing is studied carefully, it can be seen that there's a chair

bolted to the floor behind the Telephone Adaptor No.2. This second chair provides for two radio operators to

be in the hut simultaneously. Since all of the connections for the R.107 are on the

front panel, it's obvious that the drawing shows the R.107 from the rear.

This also implies that what looks like a window on the rear wall is

actually another access door. Without a door on both the front and back

how would each operator get to their respective positions? The drawing

indicates that it's showing the

D.F. hut from the "FRONT" but that designation might be dependent

on which operator you were talking to.

The ability to change loops would allow a greater frequency coverage

for the entire B/C No.2 station although its specified use was D.F. for 480kc up to

10mc. However, the R.107 tuning range didn't go below 1.2mc therefore

the R106 had to be used for frequencies below 1.2mc. This would have

necessitated having HRO coil set E and HRO coil set F to allow frequency

coverage of 480kc to 900kc on coil set F and 900kc to 2.0mc on coil set

E. Between the two receivers, the specified frequency coverage of 480kc

to 10mc would be easily accomplished. Actually, if all of the R106 coil

sets were available, coil sets JD (1.8mc to 4.0mc,) JC (4.0mc to 7.3mc)

and JB (7.0mc to 14.4mc) would allow tuning to be extended up to 14mc.

Coil set JA tuned 14mc to 30mc, although that wasn't in the D.F. Station

B/C No.2 frequency

coverage specifications. It's possible that while one receiver was

operating in the D.F. mode the second receiver was tuned to receive

orders or deployment details from the military command and that's why

there's a separate antenna and an extended frequency coverage on the

R106. However, it's also quite likely that one receiver was used for

D.F. while the other receiver was used for enemy signal intercept. Use

of the second receiver may have been variable depending on the

installation and the task that had to be performed. From the drawing

that implies the view is from the "Front" of the hut and the fact that

the "Aerial Loop Control Gear Brake"

is adjacent to the operating position of the R106, it appears that the

R106 was the primary D.F. receiver and the R.107 was for intercept or

for receiving communications. No transmitting

capability is shown in the drawing. If the towing

vehicle had radio T/R capabilities, then any two-way communications with D.F.

Headquarters could have used that set up.

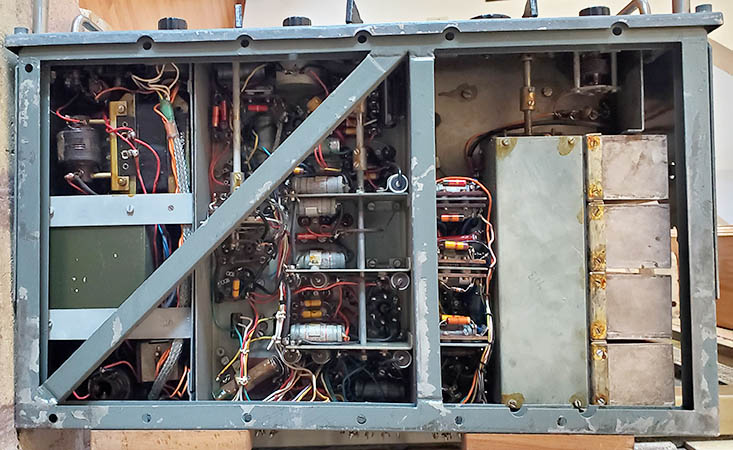

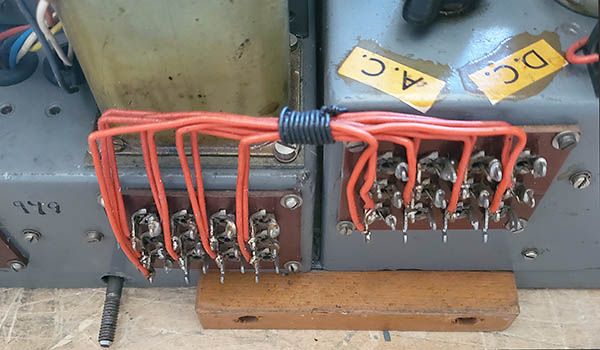

In the upper left rear part of the hut are two lamps. One is shown as

"Battery Lamp" and the other is

shown as "Mains Lamp." The

implication is that the D.F. hut ran on DC voltage when deployed in the field

but

it was possible to use the "AC Mains" as a power source if it

was available. However, it looks like the radio equipment was normally

set up for DC operation only. To switch the R.107 to AC operation would

require pulling the chassis from its cabinet to move the power supply

switch from "DC" to "AC." To convert the R106 to AC would require

operating the R106 from a different power supply. Possibly the Supply

Unit Rectifier was the AC operated power supply for the R106 and the

Power Unit Vibratory No.2 was the DC operated power supply (more

details on R106 power options are in the R106 section description

further down this write-up.) It would seem that the AC Mains

operation might be for convenience when troubleshooting or changing set

ups at a depot and then DC operation was normal for power in the field.

The length of operational time, of course, would depend on the current

draw from the storage batteries. No charging system is shown but it

certainly had to be possible to charge the batteries, or even operate

the D.F. hut using an external motor-driven DC generator. It might have

also been possible to power the hut in the field using some sort of

motor-driven AC alternator-generator. It's interesting that the storage

battery is shown as "Battery Sec. Port. Six

Volt 100/125AH" with the emphasis on "Sec Port" implying a

"secondary" and "portable" use for the battery, even though it's shown

as the power source for the Reception Set R-106 when operated with the

Power Unit Vibratory No.2. However, since that six volt storage

battery is the "secondary"

where's the "primary" battery? It could be out-of-view in the

drawing and located in the corner near the R.107. It would have to

supply 12 volts and probably consisted of two six volt storage batteries

connected in series.

Another piece of equipment not shown is a radio transmitter for

communication of bearings for triangulation information or other

observations to the D.F. Headquarters. Usually, these were small battery

operated "handie-talkie" types of transceivers if the distance involved

wasn't very far. It could be that the towing vehicle would have had

T/R communications equipment installed for that purpose and the range of

that type of communications equipment would be far greater than the "handie-talkie"

type. It's certainly possible that other items like

maps, set-up compasses, parts, tools and other necessities might have

been in the vehicle that towed the D.F. Station B/C. No. 2 to its

operating location. There were several other pieces of auxiliary

equipment such as satchels signals, various lamps and

window shades that were part of the D.F. hut but it's obvious that not

all of the parts and pieces could be shown in just one drawing.

Wrap-up and Disclaimer

- All of these descriptions are somewhat speculative and are based on the analysis of the D.F.

Station B/C No.2 drawing and examination of an actual R106 receiver and

an actual R.107 receiver. Some procedures or purposes of the support

equipment are assumptions based on other types of "aural null" D.F. equipment and how

that equipment was used. Some D.F. equipment that was used for

comparison were "field" D.F. measuring devices while others were for

airborne "search and rescue" operations. Certainly some errors in how

the support equipment in D.F. Station B/C No.2 worked are to be expected

since I don't have the actual support equipment in front of me to

examine (or even schematics of the support equipment.) However, most "aural null" D.F. stations worked on the same principles and

most of the assumptions will be found to be essentially accurate or, at

least, plausible.

Estimates are that about 200 of the D.F. Station B/C. No.2 mobile

trailer-huts were built during WWII. It's thought that none have

survived completely intact although there are on-going efforts in Europe

to restore a couple that have survived in

less-than-complete condition. |