| BC-348 Operation on LF with

the CU-32 Loading Coil Tuner - The BC-348 was always

connected to the ART-13's RECEIVER (J110) terminal. With LF selected on

the ART-13, the vacuum switch inside the CU-32 toggles back to "HF" when

the PTT line is deactivated (key up) and that then allows the BC-348 to

connect to the aircraft antenna via the ART-13's "HF" routing through

the CU-32. When PTT is actuated (key down,) the CU-32 vacuum switch

toggles to LF which connects the ART-13 J-117 terminal to the CU-32 LF

input. The ART-13 output is routed through the CU-32 to the selected

aircraft antenna. The BC-348 is further isolated during "key down" via

the ART-13's vacuum T-R switch. With PTT deactivated (key up,) the

ART-13 and CU-32 return to "HF - Receive" mode. Since the BC-348

isn't routed thru the CU-32 tuner, the receiver's match to the particular

aircraft antenna used would be dependent on its LF alignment on the Q, N

and J versions. The other BC-348 versions have a front panel antenna

trimmer for antenna matching although its effectiveness might be limited

somewhat on LF. The BC-348 does tune 630 meters on its 200kc to 500kc band.

However, successfully using the BC-348 on 630M will require some

specific noise reduction changes to the typical HF setup. Of

course, your LF receiver doesn't have to be a BC-348. Any LF receiver

can be connected to the ART-13 RECEIVER terminal and utilize the ART-13

remote standby function (U-8/U connector) for fully integrated operation

on LF with the ART-13. Or, you can use an entirely separate receive

antenna such as a tuned loop (highly recommended.) On 472kc, the use of a tuned loop receive

antenna will greatly increase the signal to noise ratio so weaker

signals can be received in somewhat noisy conditions.

Directivity of the loop is also an advantage. However, loops don't

produce any gain. Signals will always be weaker on a loop when compared

to a large wire antenna. The advantage is the reduction in noise that

allows you to advance the receiver's RF gain and extract the weak signal

out of that lowered noise condition. In rural areas, large wire antennae

will many times out-perform a tuned loop but often atmospheric noise in

these rural areas can limit how often you can use the large wire

antenna. Tuned loops always work,...well, almost always. Shielded

magnetic loops are even more advantageous. In noisy urban areas they

provide

better signal to noise improvements. In rural areas, a shielded magnetic

loop will provide dramatic improvement in detection of very weak signals. The

disadvantage is that shielded magnetic loops are difficult to homebrew

and commercially built versions are fairly expensive.

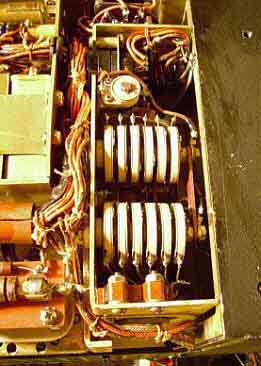

Operation of the ART-13 with

the CU-32 on 630 Meters - Operation must be on CW. This

mode of operation utilizes a keying relay in the ART-13 that essentially

is "keying" the PTT line. The keying of the ART-13 also provides keying

to the vacuum switch in the CU-32 via the U-11/U connector/cable on the

ART-13 (U-11/U is only operational if LF is selected on the ART-13.)

Since there are three relays involved, the ART-13 keying relay, the

ART-13 vacuum T-R switch and the CU-32 relay/vacuum switch, all working

with the radio operator's keying, the maximum CW speed will probably be

limited to around 15 WPM. I tried a bug and, even at slow speeds (for a

bug,) it's too fast for the relays to follow and allow the ART-13 to key

"dits" properly. A hand key must be used and top speed seems to be

around 15WPM.

Be sure to do your initial testing on LF with the ART-13 in the

"TUNE" mode. This limits the power output to prevent excessive current

flow when the PA is out of resonance. With a short end-fed wire of about

100 feet in length, you'll probably find that the two LOADING controls

will be at maximum and the "plate dip" is fairly sharp. A 200 feet long

wire will perform much better and will load up easier.

Running CW signal on 473.5kc from my ART-13/CU-32 combo running into

a 163ft end-fed wire I've worked two-way QSOs with NO3M in Pennsylvania,

WØSD in So. Dakota, KI6R in California and others. I've copied a few

stations in receive with no problems but they can't copy me. I'm sure my

transmitting set-up works fine on 630M but many ops don't have a low noise QTH that

allows for MW DX reception which is why they don't hear my signal.

Go to "Vintage Longwave Receivers - Part 4" for more details on

operating the ART-13 and CU-32 Loading Coil on 630M including a log of

stations I've worked on 630M CW.

Operating CW on the ART-13 with CU-32 is a very noisy experience.

There are three relays "clacking along" with your sending. While the

airplane was aloft there was so much other noise going on the sending

relays were seldom heard, especially since the radio op normally was

using 'phones. Not much can be done about the noise if you want to run

the ART-13 and CU-32 as they were originally operated. Modifications to

change any of the method of operation seems to go against the entire

idea of collecting, restoring and operating WWII vintage military radio

gear in the first place. Sure, it's noisy, but if you use a set of

'phones for "sidetone" monitoring, as the old WWII ops did, it's not too bad. For Sidetone to monitor your sending, the ART-13 provides two jacks

to access the sidetone circuit. There is a volume control that is

located under the tuning chart. Use a 600Z ohm load, either phones or

loudspeaker. You can also listen to the receiver if you're using a

separate antenna. Since I'm using a remotely tuned loop on the receiver,

I just turn the RF gain down and use the SP-600VLF receiver as the CW

monitor. Actually, with this method, I'm listening to the

transmitted signal which is probably better since any problems would

become quickly apparent.

Utilizing "Fixed Ant" and

"Trailing Ant" for HF and LF Antenna Selection - The

original intent of this switch was to select between a trailing wire

antenna or a short vertical antenna, with both antennae being utilized

for HF or LF operation. A more useable purpose for this switch is to use

the "Fixed" position for the HF antenna. Then the "Trailing Ant" can be

used for the LF antenna. When the ART-13 is NOT in LF, the CU-32 is

bypassed except for the Antenna Selector switch. So, when operating HF

switching to "Fixed Ant" will allow the HF antenna to be connected to

the "Fixed" output terminal with the coax shield connected to chassis.

Selecting LF on the ART-13 activates the PTT switching of the CU-32 and

the antenna selector can be switched to "Trailing Ant" and a LF antenna

used. I'm assuming that most ops are going to have a separate LF antenna

such as a 200 ft end-fed wire but will use their regular HF antenna for

80M or 40M operation.

Effective Isotropic Radiated

Power - The EIRP limit of 5 watts is somewhat difficult

to determine with any accuracy. This regulation seems to be in place

mainly to limit the size of the antenna versus the amount of RF power

used and thus to control the effectiveness of the transmitted signal.

For example, a full-size 630 meter half-wave antenna is over 1000 feet

long. This type of "full-size" antenna would actually exhibit a slight

gain when compared to an isotropic radiator (+1.6db.) Therefore, the

power input to the antenna would have to be < 5 watts to stay within the regulations

(assuming there were no other losses.) With a full-size antenna, even

just 5 watts input would result in a formidable signal on CW. However,

small, "city-lot-size" antennae will be very inefficient at 630 meters

and therefore would exhibit considerable loss rather than gain. That's

how the RF power input to a "small" antenna can be very high and yet

only result in 5 watts EIRP. Think of the small, inefficient antenna as

acting like a "dummy load." You can input lots of RF watts and it does

radiate somewhat (a few feet) but it isn't an efficient radiator.

So, to stay within the regulations, one has to know the efficiency of

their antenna which is determined by the antenna's input resistance and

its size. From efficiency and power input you can then calculate EIRP.

Antenna resistance usually has to be estimated based on several physical

factors with antenna size being the most important. The best information

for answering the EIRP question can be found at

www.472kHz.org in their

section on"630M Antennas" and "EIRP." Their formulae and examples

indicate that the "average" ham antenna takes several hundred watts

input to achieve 5 watt EIRP.

Propagation and Successfully

Receiving LF Signals - A lot of the conversations about

prospective 630 meter operation seem to be concerned about the

transmitted signal. Very little is written about how to successfully

receive CW DX signals in "real time" on the lower frequencies. Propagation

on 630 meters isn't ground wave only. At night, skywave propagation

dominates this region of the spectrum. It's easy to receive medium wave

Airport NDBs that run 25 watts out to distances of 1500 miles. Regional

NDBs that run 100 to 400 watts can be received out to the east coast.

Transoceanic NDBs will run up to 1KW and can be received well over 3500

miles distance. All of the NDB stations operate into relatively small

antennae and therefore their actual EIRP is considerably less than the actual

transmitter output power. But, the incredible DX and great nighttime conditions don't last. Long wave

enthusiasts consider the "season" to be from the Autumnal Equinox to the

Vernal Equinox, or about mid-September to about mid-March. Actually, the

best part of the "long wave season" is from mid-November to

about mid-January. This is when the conditions are the least noisy

allowing very weak DX signals to be heard. So, fall and winter nights or

very early mornings work best on 630M. Summer is good for testing or for local QSOs.

Your physical location is another important part of successful 630

meter operation. In noisy urban areas the RFI is so intense that

virtually nothing can be heard below the AM BC band. In these locations,

a shielded magnetic loop is about the only type of antenna that might

allow for some reception. These loops are shielded with a non-ferrous

metal tube and, generally, the antenna only responds to the magnetic

portion of the electromagnetic signal. A broadband amplifier is necessary

with these loops (usually part of the loop design.) Since most RFI is

electrical in nature, the shielded magnetic loop provides some relief

in noisy areas. Less noisy areas can usually receive DX using a remotely

tuned loop. These are just a fairly large coil of wire that's tuned with varactor diodes in parallel with the loop. A pick up loop is mounted

within the loop field and that connects to the receiver. Usually, an

amplifier isn't required on a remotely tuned loop. In quiet rural areas,

it might be possible to use a wire antenna with good results. I use both

a large wire antenna and a shielded magnetic loop. I find that I can

always use the loop antenna. Most of the time, only from "mid-Nov

to Dec to

mid-Jan"

are conditions quiet enough to allow DX reception on the large wire

antenna. One has to remember that the weak signals are always stronger

on the large wire antenna but the atmospheric and RFI noise is also

quite strong. With the shielded magnetic loop, weak signals are not as

strong but the noise is greatly reduced. This results in a better

signal-to-noise ratio when using the loop antenna and usually the weak

signal can be heard because of that. Unfortunately, in some large metropolitan areas,

the RFI noise is so intense, nothing helps,...not even the shielded

magnetic loop. In these areas, it might be possible to use Internet

accessible remote SDR stations. These types of stations are always

located in rural or at least RFI-quiet areas. Some SDRs do have MW

capability. For metro-areas, the SDR might be the only solution for MW

reception.

For a complete write-up on how to successfully receive DX longwave

signals using vintage radio equipment, go to my article "Vintage

Long Wave Receivers - Part 4" - use the Home/Index for

navigation. UPDATE: 630 Meter CW

Operation in 2025 - All of this 630M activity that I've

written about was when the band first opened up. There were lots of CW

signals at that time. Many CW CQs were heard from all over the USA. It

lasted about one year before the various types of data transmissions

"took over" the puny 9kc that comprises the limited size of the 630M band.

Operating CW on 630M did require experience in being able to copy weak

CW signals and having experience in how to receive signals in a noisy part

of spectrum. Most hams didn't want to learn how to do this.

Consequently, the data transmissions started up. These modes allowed

operating in noisy areas and didn't require copying CW. The data mode

signals sound like a solid carrier that is a few kc wide. With the 630M

band only being 9kc wide, that doesn't leave much room for anything else

other than data mode signals. That's where 630M operation is today.

There are several different types of data mode transmissions that all require

special equipment and special computer interfaces. Unfortunately, CW communication is a

"thing of the past." Calling CQ in CW on 630M is a futile effort that

results in nothing. It might be possible to set up a schedule in CW with

someone but even that's sometimes difficult due to data mode usage of

the band. |