|

Another UPDATE: "Basket Case"

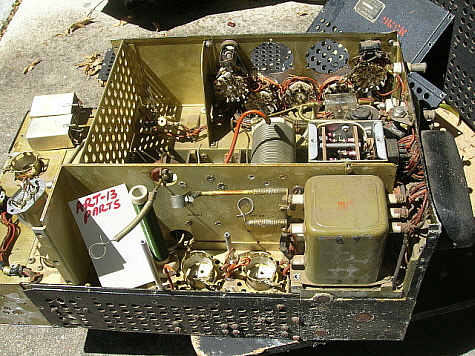

ART-13A aka "The SAAMA Survivor"

August 29, 2021 - Just to let everyone know,...this 75+ year old gear

doesn't run forever without some problems turning up once in a while. During the Vintage Military

Radio Net on August 29, 2021, the "SAAMA

Survivor" ART-13A transmitter

had a failure of the PTT function. Pushing the TEST switch seemed to

operate K-102, the sending relay, but not much else happened. I finished

the net using a different station and

decided to look at the SAAMA Survivor that afternoon. I suspected the Dyna-Sim Mark I had blown a fuse but that wasn't the case. Just to be

sure the Dyna-Sim wasn't at fault, I used it to power up the ATC

transmitter with no

problems. So, the failure was with the ART-13A. A quick check of K-102

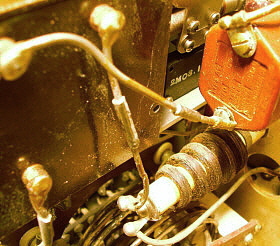

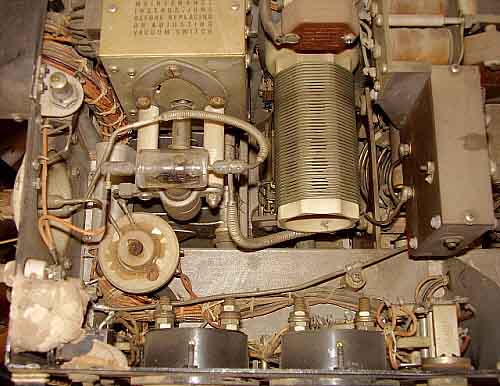

showed that it was indeed operating. The next check was K-104. K-103 and K-104

are both located in the rear bottom section of the transmitter, just below the

813 and 811 tubes. K-103 controls the CW function and K-104 controls the

VOICE parts of the transmitter circuitry which includes parts of the PTT

functions. Luckily, one can

access these two relay's (K-104 and K-103) coil terminals very easily

through the vent holes, so checking is no problem once the ART-13A is

removed from the station set-up. K-103 showed 125 ohms DCR for the coil

which is correct. K-104 showed an open coil which caused the relay not

to function. Both of these relays experience a lot of use when operating

the ART-13, so they are components that are often found defective in

"as-is" ART-13s that haven't gone through a rebuild. But, I haven't

ever had one of these relays

actually fail after a rebuild,...until now. I should mention that the

SAAMA Survivor has worked without a

serious problem

since I did the rebuild on it in 2011, so ten years without a failure is

pretty good reliability. Unfortunately, a check of the spare parts

boxes and the parts sets revealed that the all of the K-104 relays had been

removed earlier and apparently had been installed in other ART-13 transmitters being

rebuilt. I have

rewound these relay coils before. It's not difficult. In fact, there's

photos of the process just up this page a little bit (rewinding the

K-103 solenoid.) Disassembly of the

transmitter is required so it sounds like a winter

project. Update when the rework gets started.

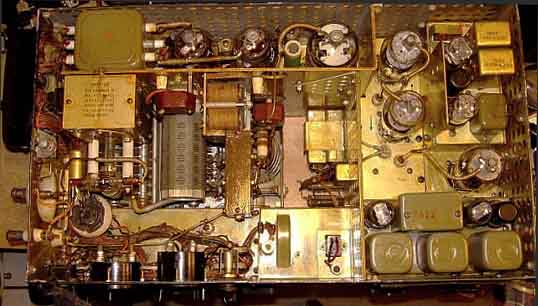

Oct 23, 2021 - While

looking for some C-clamps that happened to be next to my large box of

various types of boxed and bagged pilot lamps I noticed that in the large box of lamps

were two spare ART-13 relays, K-103 and K-104. Why were they in the lamp

box? Who knows. I thought I remembered that both of these relays were

good, usable units. K-103 was operational. Unfortunately, K-104 had an

open coil. Figures. But, I can do the relay rebuild anytime and then

just do a simple R&R on the ART-13A.

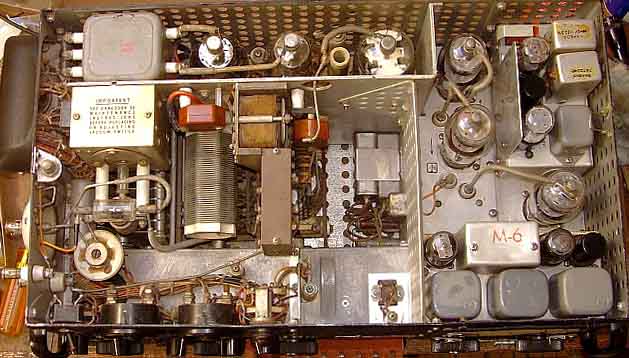

Nov 3, 2021 - I went

ahead and put the SAAMA ART-13A on the bench. To extract K-104 the

bottom cover and the lower back panel have to be dismounted. Once this

is accomplished (easy) then the seven wires that connect to K-104 have

to be unsoldered. I made a sketch that numbered the connections to K-104

and then used masking tape on the individual wires to identify them and

their proper connection. An examination of K-104 confirmed that it

indeed had an open coil. Looking at the coil it's apparent that it had

gotten very hot over the years. The black plastic covering (like tape)

over the coil was slightly melted and I could see that the varnish had also

"bubbled" around the edges indicating a lot of heat. K-104 is energized 100% of

the time when the ART-13 is in the VOICE mode.

Nov 4, 2021 - I

disassembled K-104 to remove the coil. The stranded wires that connect

the coil ends to the terminals were unsoldered and the terminals

straightened. If the terminals are bent they will interfere with winding

the new coil. The only way to remove the old coil is to cut the old wire out. I

use an Ex-acto knife and cut through each layer to remove. It still

takes about 15 minutes to cut through the layers to completely remove

the old wire. I measured a couple of strands of the old wire and got 0.007"

diameter which is 33 gauge wire. The proper measurement of the DCR of

the completed coil should be 150 ohms.

Motorized Coil Winder Problems

- I have an old coil winder I made

using a sewing machine motor and a motor speed control. Belt-driven shaft, bearings and a

chuck for holding the coil form. I made the coil winder about 1980 or so

and have used it many times to rewind lots and lots of audio transformers and solenoid coils. In

fact, I

used it to rewind a solenoid coil to repair K-103 for this SAAMA

ART-13A. That relay was replaced with an original K-103 out of a parts

set sometime later. An operational check of the coil winder was

performed and I discovered that the

"motor speed control" was now non-functional. These are really only a

light-dimmer control so I purchased a new 600 watt version at the local

hardware store. This got the coil winder motor working but the

rubber drive belt didn't stay in position on the shaft now and would

ride-up until it jumped against the motor shaft front bearing mount. I'm

going to have to fit a guide onto the 3/8" diameter shaft to keep the

belt in position. One of these days, I'll be able to rewind the K-104

solenoid.

|

Nov 22, 2021

- More Coil Winder Issues

- Though I haven't spent too much time on this project lately, I'm sure

that I've spent the majority of time trying to fix or redesign this

motorized coil winder. I added a rubber grommet on the 3/8" shaft to act

as a guide for the belt and that works quite well. I had to install a longer AC power

cord so I could do away with extension-cords. Then the rubber belt broke. That required finding something that

would work as a belt, like a super heavy-duty rubber band. I had trouble with

the method I had used to limit the shaft thrust movement. I finally

removed the screw that had been acting as a thrust limit and replaced

it with two rubber grommets on the shaft - one on each side of the back

bearing housing. Simple - and it works. Limits the shaft thrust movement very well without

placing any load on the shaft. I had to use a wrap of friction tape on

the shaft to increase belt traction. After spending several hours

redesigning this coil winder (that I had used many times before without

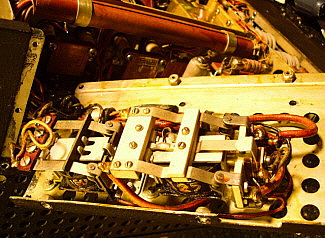

any problems) I finally was ready to wind the solenoid coil. The coil

winder did perform really well and I had the

solenoid coil wound in about five minutes. I wound a little extra wire to be sure

I could trim the DCR by removing wraps. I measured 230 ohms at first.

After several wrap-removals, I was at 175 ohms, which was close enough*.

I finished off the solenoid with several wraps of black electrical tape.

I then used a rubber stamp with gray paint and added "150" to the side

of the solenoid as the originals had. I painted the solenoid with

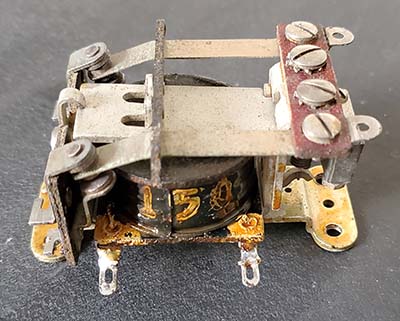

yellow-tinted lacquer to simulate MFP coating. I completely reassembled K-104 and tested its operation using a DC power supply set to +26vdc. K-104

operated as it should (I thought.) It's now ready to reinstall into the SAAMA

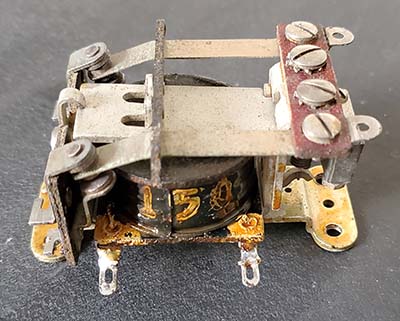

fugitive. The rebuilt K-104 is shown in the photo to the right. |

|

Nov 23-24, 2021 - I was

so confident of the rewind-repair of K-104 that I completely reassembled

the ART-13A and even moved it into the operating position only to find

out that it still didn't work in VOICE,...bummer. I moved the ART-13A

back to the bench and disassembled it,...again. I had to bring the

Dyna-Sim Mark I along to power-up the transmitter so I could

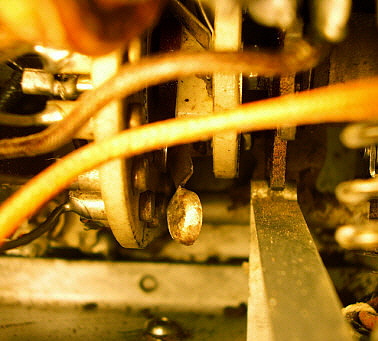

troubleshoot the problem. A few voltage checks and it looked like K-104

was actuating as it should but the PTT contacts weren't "making"

although it looked like they were. I cleaned the contacts with DeOxit on

a paper strip pulled through the contacts and then adjusted them for

good contact. The ART-13A now had full output on VOICE and the PTT

functioned correctly. I must have slightly bent or "tweaked" the contact

arm on K-104 with all of the rework performed on it. I did check its

functionality but I didn't check the contact resistance before

installation, hence the "bench re-visit." So, everything was put back together again and the SAAMA

Fugitive was put into the operating position and tested hooked-up to the

antenna - 110 watts carrier output and ready to use. "On the Air" for

the MRCG net had the SAAMA Fugitive in VOICE mode for one and a half

hours (100% continuously energized K-104) with no problems.

* The original

solenoid DCR was 150 ohms. As mentioned, the original wire measured as

33 gauge and I had to use 34 gauge. Since there's slightly less current

carrying capability using 34 gauge, I purposely increased the DCR

slightly to compensate. It's not critical since it's just an

electro-magnet but operating a solenoid coil on DC does build up more

heat than if it operated on AC and K-104 is 100% energized while in the

VOICE mode. |