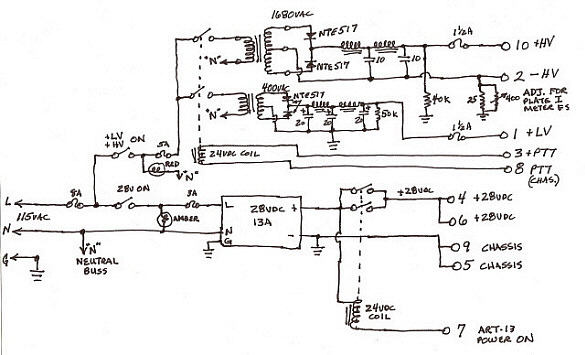

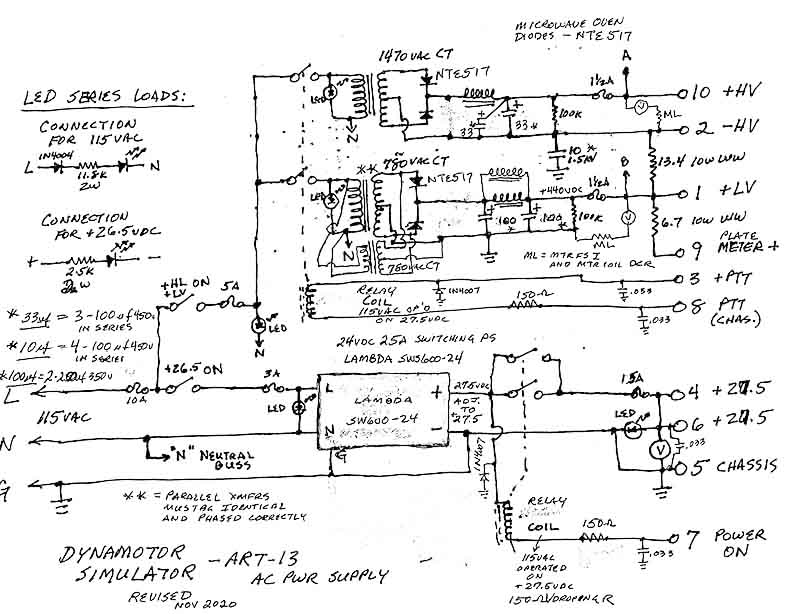

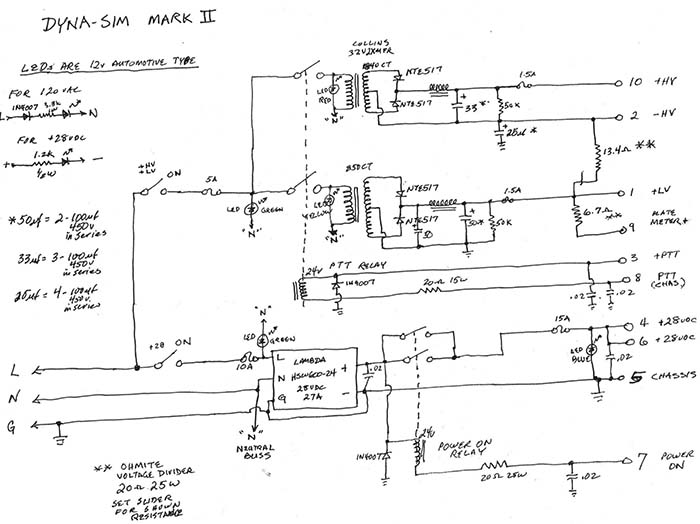

| For many months now, every few weeks I've been switching

in and out of the operating position one of my two ART-13 transmitters

because only one AC power supply was available. After I finished the

restoration of the ART-13A "Basket Case," I didn't design and build a

power supply for it. This situation needed to change. I decided that I

didn't want to go the huge, immoveable type of power supply but that I

would rather design a power supply that was small and lightweight. I

wasn't concerned about maximum power output since I had the "Hommage a

le Valve" power supply that easily allowed running 150 watts output from

the transmitter. This new power supply would be like the dynamotor in

that two lower voltage supplies would be connected in series to provide

the +HV and I would shoot for about +1150vdc as the dynamotor supplied.

The original dynamotor circuit provided +400vdc for the +LV and +750vdc

(+HV) in series with the +LV to achieve +1150vdc plate voltage. A

barometric pressure switch separated the two supplies above 25,000 feet

altitude to prevent arc-over by reducing the plate voltage to +750vdc.

It is very easy to use this same approach in designing an AC operated

power supply, excluding the barometric pressure switch, of course. The

advantages are that the components used will be rated at lower voltages

which reduces expense and generally makes locating them easier. One

thing to keep in mind is that the +LV supply must be able to handle not

only its own current requirements but must also be able to carry the

current required by the +HV since the negative return for the +HV is

connected to the +LV and then to chassis. This means that the +LV will

have to be capable of about 500mA maximum current. The original

dynamotor spec for the +LV is 750mA but this is the dynamotor capability

not the actual +LV current requirement of the ART-13.

To handle the additional current the +LV transformers are actually

two identical transformers that are connected in parallel. When

operating transformers in this manner they must be exactly the same,...

identical. Also, their connections must be "phased." This means that

primary and the secondary windings must be connected so the AC applied

and the AC output are in phase in each transformer. This is easy to test

ahead of the building and mark the primary and secondary windings so

there will be no confusion at assembly time. I only used the parallel

transformers because I didn't have a single 400-0-400vac that had enough

current capacity for the +LV (+LV and +HV current combined) requirement. If you can find a 500mA rated

transformer then going with the single, although large, transformer is

much easier. Same reason for the parallel chokes in the +LV supply.

There are some changes that have to be made in the general design

that allows for the proper operation of the Plate Current meter since

the -HV is connected to +LV. This is basically done by providing a

bridge circuit using a 13.4 ohm series load from -HV (negative meter

connection) to pin 1 (+LV) and a 6.7 ohm series load from pin 1 (+LV) to

pin 9 of U7 (positive meter connection.) This duplicates the circuit

used in the original dynamotor. The advantage to this bridge resistor

set up is that the Plate Current meter reads accurately regardless of

the actual level of +HV and +LV as long as the ratio of +HV to +LV

remains approximately 2:1 (actually, the ratio of +750 to +400 is 1.87:1

but the bridge resistor ratio is 2:1.)

Since a minimum of +750vdc is used for +HV, the filter capacitors

can be series-connected 100uf 450wvdc type electrolytics with 510K

resistors across each cap to equalize the voltage drop across the series

connections. Three capacitors are used resulting in a working voltage of

about 1350vdc at a capacitance of about 33uf. Since we are using

Pi-filtering, in an "unloaded" condition the +HV could soar to around

+1035vdc.The extra "head-room" is protection in case the power supply is

operated without a load. The same type of "head-room" is used in the +LV

section, where the unloaded voltage could rise to around +600vdc. Using

two series-connected 350wvdc electrolytics results in around +700vdc

capability. In normal operation, the power supply design is such that

the +HV and +LV are actuated with the PTT from the ART-13 which would

also be in the powered-up condition thus presenting full load to both

the +HV and +LV instantly. However, in some testing situations (or

perhaps in an ART-13 failure mode) the power supply might be operated

"lightly loaded" (or "unloaded") and this capacitor "hook-up" gives us

the necessary head-room to survive this possibility without component

damage to the power supply.

Solid-state microwave oven type diodes can be used in both supplies

connected as full-wave rectifiers. These diodes are type NTE517 rated at

15kv PIV. These diodes are relatively expensive at about $8.00 each. The

advantage of SS diodes is higher output voltage from the power supplies.

To take advantage of the smaller size and lighter weight

possibilities, a 24vdc 13 amp Meanwell Switching Power Supply is used

for the +28vdc requirements. This supply can be adjusted up to +27.0vdc

maximum which will provide sufficient voltage to operate the filaments,

relays and the Autotune. Though the Meanwell PS is RFI quite as a

+27.0vdc source for the ART-13, it can cause interference in receivers

unless the cable from the power supply to the ART-13 is fully shielded.

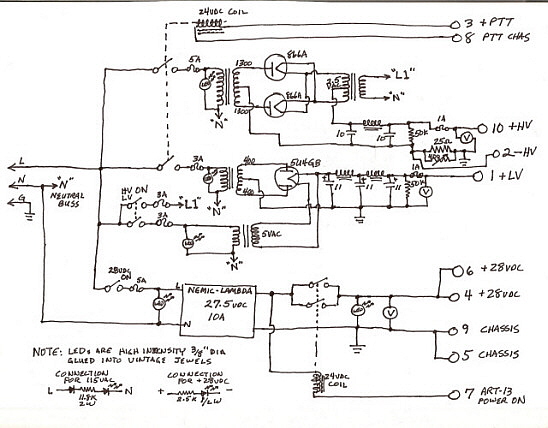

NOTE: I used the Meanwell PS for several years without any

serious problems. But, I noticed that when operating 630M with the

receiver on a loop antenna, I could pick up some noise being generated

by the Meanwell PS. HF didn't seem to pick up the noise, just MW. There were other issues with a switching spike on

the transmitter output (not audible but seen on a 'scope.) Also, the Meanwell PS would "drop out" on initial power up causing the ART-13 to

"chatter" for a few cycles before it would become stable. I eventually

rebuilt the Dyna-Sim to use an external +28vdc 25A Lambda linear power

supply to correct the problems that were caused by the Meanwell PS.

8-3-20. This power supply also had some issues in that it would "trip

its breaker" when PTT was actuated or released. After a ten minute

warm-up, the "tripping" was only an occasional nuisance.

NOTE: Nov. 26, 2020 - I purchased a Lambda 24vdc 25A

switching power supply. It's twice as wide as the Meanwell, slightly

taller but about the same length. I've

installed it onto the Dyna-Sim chassis where the Meanwell had been mounted.

All wiring changes that were made for the external power supply were returned to

original for internal connections to the new Lambda. A few

different "vent holes" had to be cut into the cabinet since the Lambda fan

is in a different location than the Meanwell's was and it's larger size

required a top vent to allow air intake. The Lambda was

mounted using two aluminum brackets rather than mounting the power

supply directly onto the chassis.

This was to make installation easier and not require major disassembly

of the underneath of the Dyna-Sim. The new Lambda easily adjusts up to over +30vdc output. I

set the voltage output to +27.5vdc. The schematic of the Dyna-Sim

shown to the lower right is the latest revision from November 26, 2020.

|

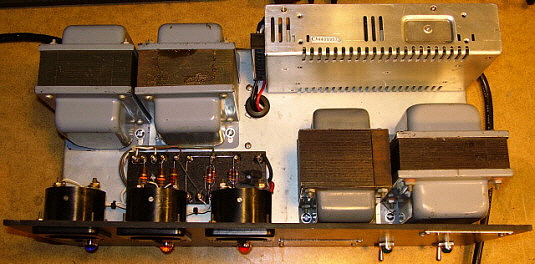

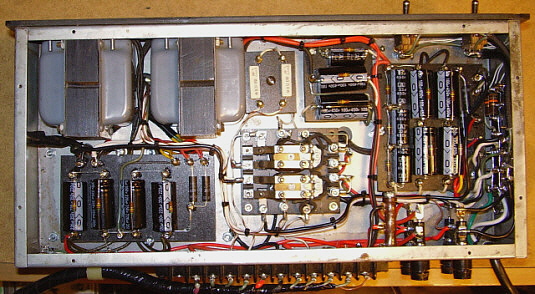

>>> I decided to build the Dyna-Sim into a BC-348 cabinet. This cabinet

had been destroyed by a former owner who drilled out all of the pop

rivets that mount the bottom plate which has all of the engagement pins

for the shock mount. Rubber feet were installed to take the place of the

engagement pins, thus ruining the cabinet for proper use with a BC-348

and FT-154 shock mount. The back of the cabinet had have a wide

rectangular opening cut to provide access to the fuses, line cord and

the output terminal strip. A round hole was also cut to provide

ventilation for the fan in the Meanwell PS. The front panel is made from

type of black hard plastic called delrin. Three panel meters are

provided to allow constant monitoring of the output voltages during

operation.

As with the "Hommage a le Valve" power supply, the only reason

I used three meters is because I found three matching meters in the junk

box. Setting up any DC current meter to act as a DC voltage reading

meter is quite easy and only involves knowing the meter coil resistance,

the meter full scale current requirement and then calculating a series

dropping resistor based on the supply voltage to be measured versus the

FS voltage scaling desired. For example, if the meter to be used is a

1mA FS DC Current meter and it is going to be used to measure the

+400vdc and the FS DC voltage scaling desired is +1000vdc. The DCR of

the meter coil in a 1MA FS meter is usually around 50 ohms (but measure

it to be exact when actually doing your calculation.) Since the meter is

1mA FS, the total current through the series dropping resistor and the

meter will be 1mA. The meter coil resistance is 50 ohms, so E = I/R

indicates that the voltage drop across the meter at FS will be

.00002vdc. FS DC voltage will be 1000vdc, so 1000 - .00002 = 999.99998

drop required in the series resistor. R=E/I so 999.99998/.001 =

999,999.98 ohms. You might as well use a 1 meg resistor. Dissipation

equals I² x R = P or (.001 x .001) x 1,000,000 = 1.0 watt. 2X the

dissipation is standard practice and allows the resistor to operate in

the middle of its rating. So, a 1 meg ohm 2 watt resistor can be used

and the 1mA DC Current meter will read accurately the +400vdc at .4mA on

the scale. You can usually alter the actual meter scale so that

"MILLIAMPS" is painted over and leave the "DC." If you have suitable

"rub-on" lettering, you can add "VOLTS" to complete the meter

transformation. To take advantage of the existing meter scale, the +HV

meter actually indicates the +700vdc supply measured to -HV rather than

measuring to chassis which would indicate +HV plus +LV, or the actual

voltage (~ +1100vdc) applied to the 813 and two 811 plates.

Two 24vdc relays are required for the PTT and

Power On functions. The junk box turned up a very nice heavy-duty dual

relay with 0.25" contacts. The problem was that the coils were for

115vac operation. Since these are solenoid coils, the operation doesn't

really change whether AC or DC voltage is used. When using DCV on an ACV

rated coil, you will have to significantly reduce the voltage. In testing the

relay, it was found that good switching occurs with about 15vdc. A 150

ohm dropping resistor in series with the +27vdc supply provided around

+18vdc to the relay and allowed fast, positive switching.

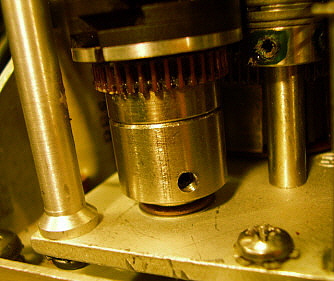

A construction technique employed in the Dyna-Sim is the use of

"component boards." The boards were made of 3/16" thick delrin and the

terminals were made from 4-40FH brass screws secured with brass nuts.

The use of brass allowed soldering directly to the terminal stud.

Unfortunately, component boards require a lot of planning for proper

layout and routing of the wiring (which is via a harness.) This prolongs

the design phase and ends up with the project taking much longer to

complete. If you're in a hurry then the use of standard tie points is

easier and allows for quick construction. The upside of component boards

is that the appearance of the wiring and construction looks like a

professional job. See photos below of the finished Dyna-Sim.

+750vdc (+HV) - This

is supplied by a 1475vac CT Plate transformer rated at .25A. Since no

other windings are on the frame, this transformer is relatively small.

Pi-filtered. Actual voltage is close to +900vdc under load. Total +HV is

approximately +1300vdc. NOTE: This was changed to a choke input filter for

better voltage stability under load. This reduced to voltage to about

+700vdc with the resulting total being about +1100vdc. 8-3-20

+400vdc (+LV) - This

is supplied by two identical parallel-connected 780vac CT Power

Transformers and two identical parallel connected filter chokes. Actual

voltage is around +440vdc under load. Total current available is 500mA.

Pi-filtered.

+27.0vdc - This is

provided by a Meanwell Switching Power Supply rated at 13A. Very small.

Apparently not all Meanwell 24vdc power supply maximum voltage outputs

are the same. Usually +26.5vdc is the specification for the maximum

adjustment but this one adjusts to just over +27vdc. Fully shielded

wires for RFI quite operation. NOTE: Too much switching noise

appears on output waveform. Rebuilt Dyna-Sim to use an external +28vdc @

25A Lambda linear power supply. 8-3-20 Rebuilt again 11-26-20 to use

a Lambda SWS600-24, a 25A switching PS that could be mounted inside the cabinet.

Relays, Fuses & Meters

- Two 24vdc relays are used for PTT and Power On functions. These relays

are 115vac coils operated on +28vdc with 150 ohm series resistor. The AC input

and all outputs are fused. Three meters allow for constant monitoring of

the voltages during operation.

Plate Current Meter Bridge

Resistors - This is an original combination WW resistor from

a junk DY-17A dynamotor base.

Pilot Lamps - High

intensity LEDs with vintage-type jewels are used. Red = +HV, Yellow =

+LV, Blue = ART-13 Pwr ON, Green = AC power ON to +28 supply and to +HV

& +LV supplies.

Cabinet-Chassis - Derelict

BC-348 cabinet with black delrin front panel. The "cool" tags were

donated by KØDWC and KE7MFW. Cabinet was painted with VHT Black Wrinkle

Finish paint. The chassis is steel.

NOTE ON CABINET: Since the BC-348 cabinet is aluminum (and the Dyna-Sim panel is delrin)

and the case of the ART-13 is aluminum, no protection is provided for

magnetic coupling from the non-potted transformers in the power supply.

When installing the power supply be sure it is not placed directly next

to the right side of the ART-13. Since this is where the ART-13 Audio

Module is, very likely magnetic coupling will occur and cause some 60Hz

hum to appear on the signal in the VOICE mode.

Read Aug 3, 2020 updates in the section below the schematic. The

schematic of the Dyna-Sim is the latest revision from November 26, 2020.

|

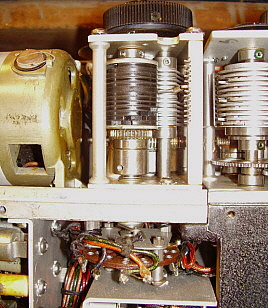

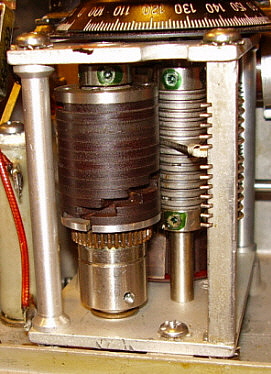

photo above: The

Dyna-Sim ART-13 Power Supply in operation |

|