|

This happens to me a lot,...after I've gone through a receiver

and I'm actually using it on a regular basis, I begin to notice

little problems or quirks that I either missed or I thought were

minor, so they were ignored. When the receiver actually works

pretty well and it's obvious it's not going to be another "shelf

queen," a return to the workbench is inevitable. The following is

what was found after the "30-day sea trials" and on the

subsequent "Workbench Revisit."

|

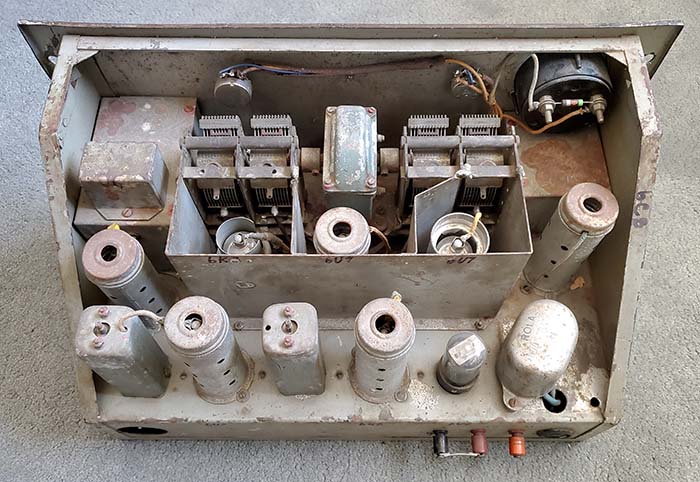

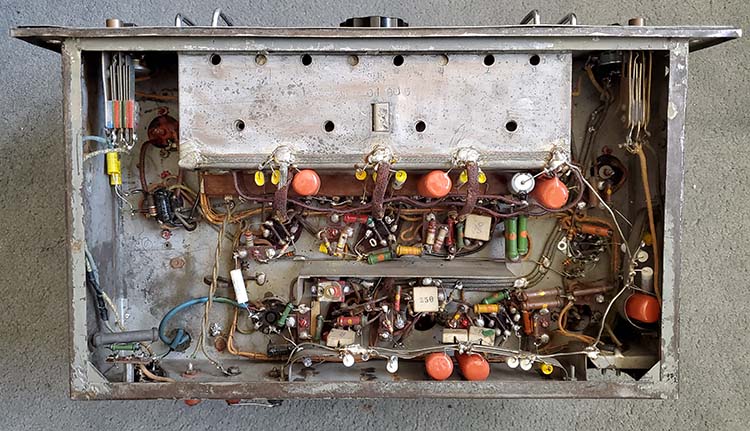

Oct. 29, 2020 - Workbench Revisit

- After using the C.R. 300/1 as a station receiver for about one month,

a few minor problems required returning the receiver to the workbench for

further "tuning up." The return work was going to require some

disassembly mostly involving cabinet and

bottom cover removal (and front panel dismount later in the "revisit.")

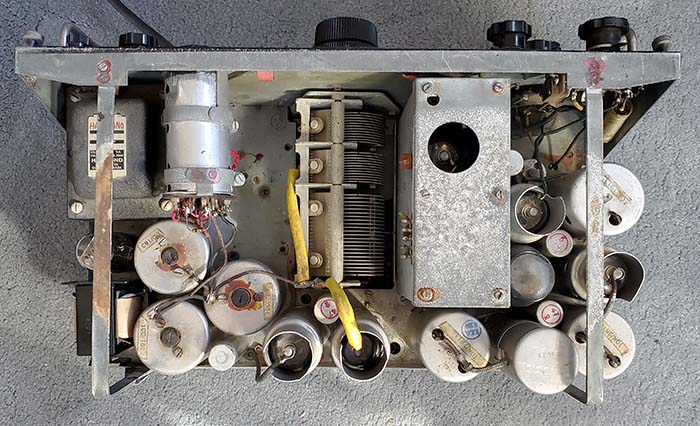

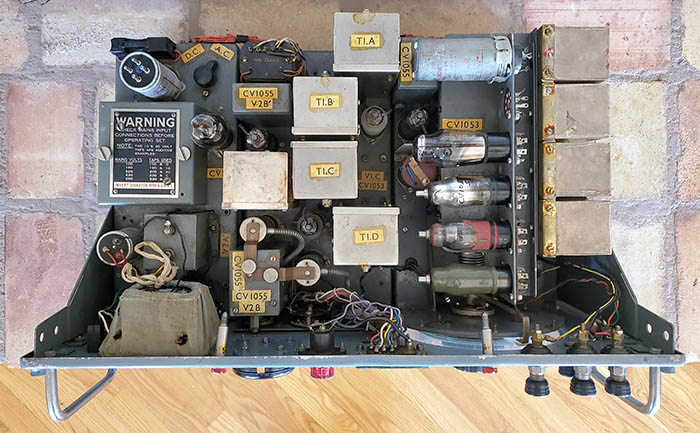

Installation of Tube Socket

Shroud/Shield for DH63 - The

first problem was mechanical because I had replaced the metal 6Q7 tube

with the proper DH63 glass tube and that now required installing the

correct tube socket shroud and tube shield. These parts had been removed

years ago when the 6Q7 was installed. Installation was just a matter of

tube socket screw removal, installing a correct style shroud and then reinstalling the screws.

LF Gain Pot Problem - The second problem was a noisy AF Gain control (LF Gain) that seemed to

be more intense since installing the DH63 (more info on this tube's

performance, or lack of, in "DH63 Problem" below.) Access to the LF

Gain pot was easy. I removed its back cover and cleaned with a DeOxit

dampened Q-tip. The pot was reassembled and remounted.

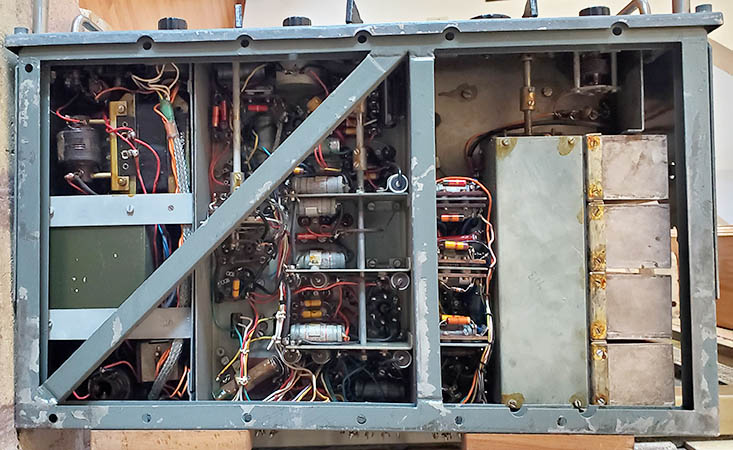

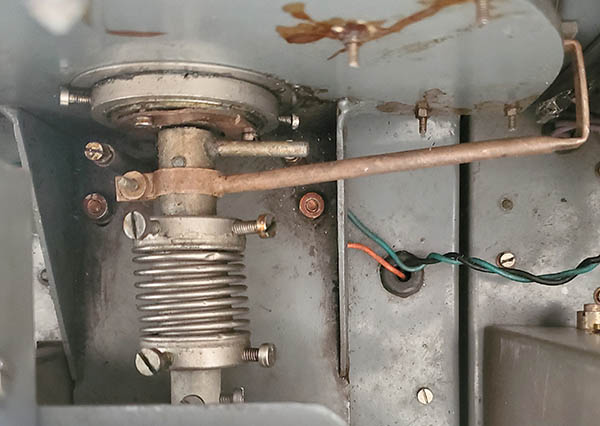

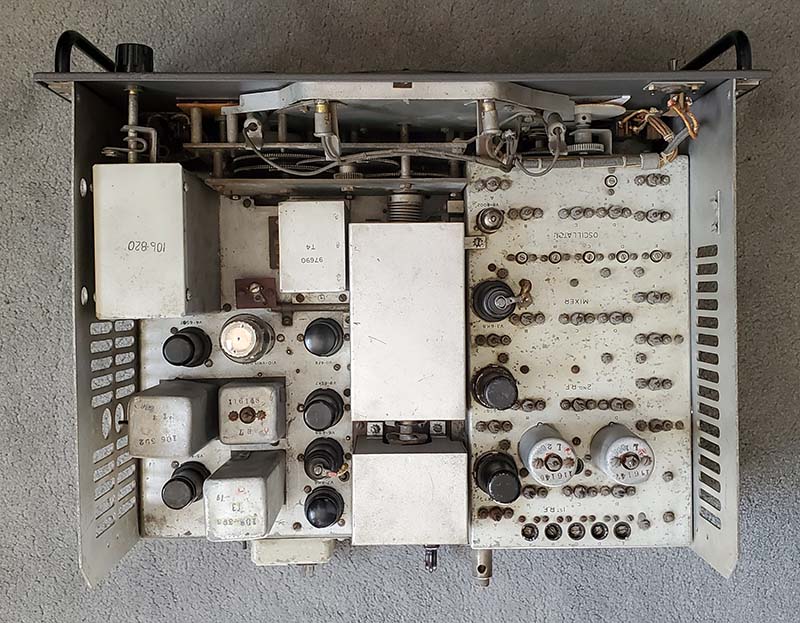

Band Switch Problem - Third problem was

that I had to "rock" the band switch on Bands 6 and 7 to get full

sensitivity. I hadn't cleaned the band switch, so that was done using a

small paint brush and DeOxit. When doing the cleaning I discovered that

the RF/ANT section bandswitch mounting screws were extremely loose. Both mounting

screws required considerable tightening to have the switch always

"inline" and to not move around when the bandswitch was operated.

All of the other Bandswitch mounting screws were tight. The RF/ANT

switch movement probably resulted in the misalignment in position 6 and

7 which the "rocking" of the Bandswitch knob would get the

loose switch into the proper position. The IF band

switch and the Passband switch were also cleaned.

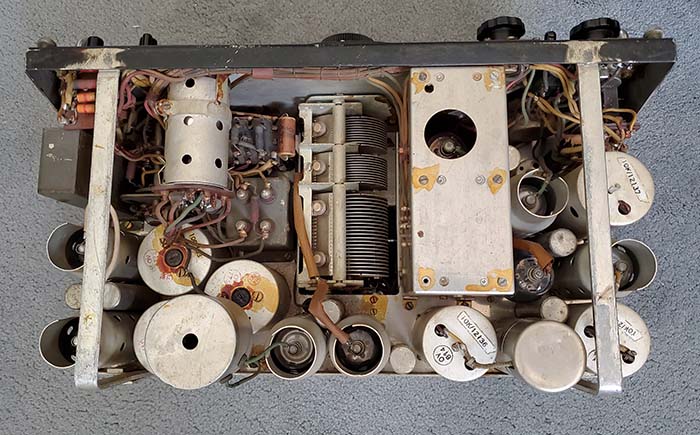

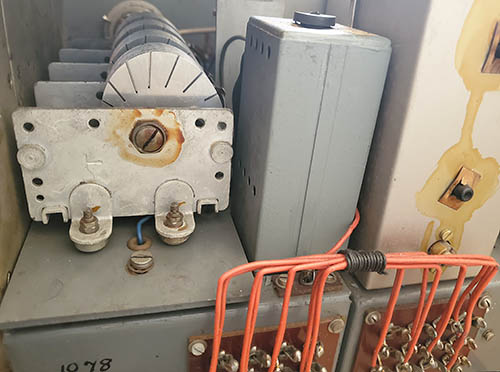

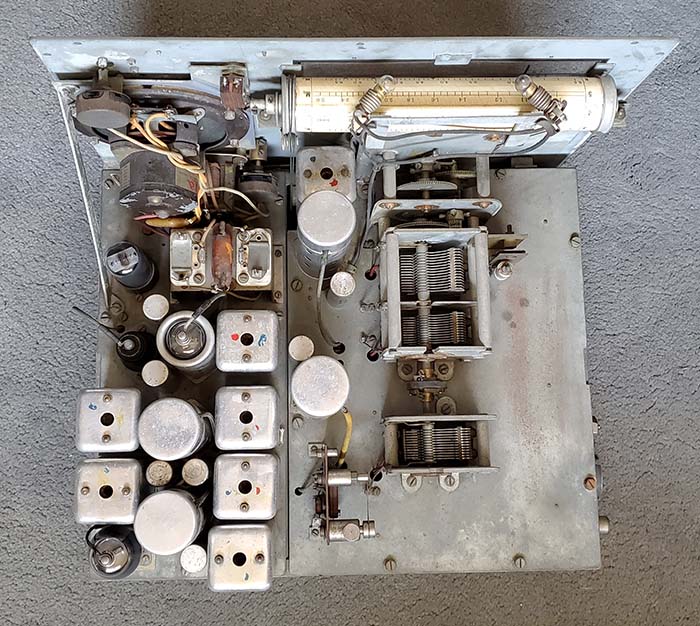

Re-Alignment of the RF Tracking

- Since I had

changed the RF amp tube from a KTW61 to the proper ARTH2, I performed a

second complete RF tracking alignment. Since the installation of the

ARTH2 improved the high frequency sensitivity so much I thought that the

tube must have slightly different characteristics and a RF tracking

alignment might show more improvement. Also, the first alignment was

just a "quickie" - kind of a "roughed-in" alignment to make sure

everything worked okay. I had used the slide rule frequency dial

settings for tracking and that dial doesn't have any accuracy at all

(even the manual states that the slide rule frequency dial is just for

"reference.") The manual provides exact frequencies that correlate to

23.00 on the logging dial for the low end and 1.00 on the high end for

each of the eight bands. To

align the tracking accurately one has to use the logging dial since that

is mechanically driven along with the tuning condenser. One has to use a 200pf

dummy antenna load between the receiver and the signal generator on

Bands 1, 2, 3 and 4. On Bands 5, 6, 7 and 8 a 100 ohm CC resistor is

used for the dummy antenna load. The tracking adjustments were off by

quite a bit, probably because of the way I did the initial alignment (a

"quickie" alignment.) After alignment, I've noticed that the

relationship of the logging dial/f versus the slide rule dial indication

is that the upper and lower ends of the slide rule dial are off at the

specified logging dial numbers but the majority of the

slide rule dial indication is relatively accurate.

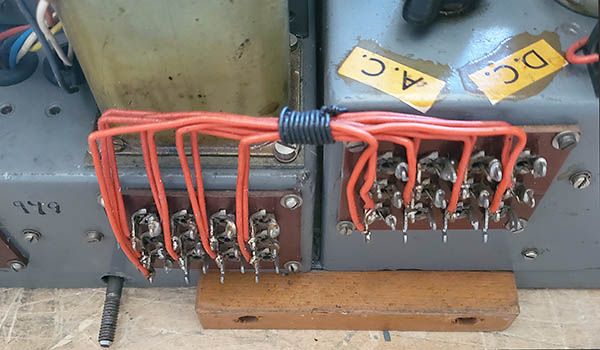

RF/Ant Coil #8 Problem

- Another problem found while doing the alignment was that the RF/ANT

adjustments wouldn't work on BAND 8. I found that one of the terminals

on coil #8 had three different wires "wrapped and stacked" but the bottom wire

in the stack wasn't

soldered. I cleaned the non-soldered wire and then flowed new

solder on the entire joint. Afterwards BAND 8 RF/ANT adjustments worked

and could be aligned (and they were.) This improved BAND 8 sensitivity

noticeably since before the RF/ANT coil wasn't "tuned." It's probable

that this connection had been unsoldered since the receiver was built

and the function of BAND 8 had relied on the wrapped mechanical connection

but with decades of minor oxidation and dirt accumulation that

mechanical connection had become non-conductive.

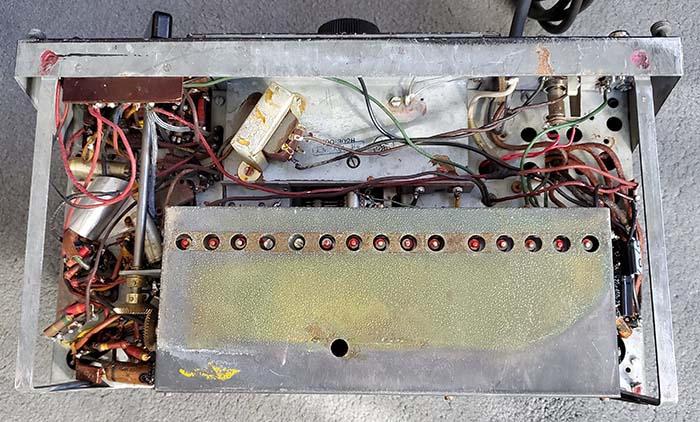

HF Gain Pot Problem -

The HF Gain pot had been giving erratic contact at the the top end of

travel. Since the LF Gain pot cleaning had turned out so well I decided

to do the same to the HF Gain pot. After dismounting the pot and

removing the back cover an inspection revealed some surface cracking on the carbon element

near end of travel. I cleaned the element and reinstalled the pot then

set-up a temporary

operation of the receiver which showed that the HF Gain still had a problem. Replacement of the HF Gain pot was unfortunately necessary.

The junk box provided a very close look-alike 10K pot that was installed

which corrected the HF Gain adjustment problems.

The Front panel had to be dismounted for the HF Gain pot work so at

this time I

also lubed the IF switch cam with viscous grease.

DH63 Problem - It was

noted that when the receiver was connected to the station antenna

the CW sensitivity seemed okay but when the BFO was switched off for AM

reception the background noise totally disappeared and only very strong

signals could be heard and they were badly distorted. This problem had

developed while the receiver was on the workbench and it seemed to progressively

get worse each time the receiver was operated. While I had thought the

DH63 was a good tube (after all, it was sold as "used-tested good,") I replaced the

DH63

with a glass 6Q7G. With the 6Q7G installed, the AM reception then had the usual background noise and

sensitivity in both CW or AM was "back to normal." DH63 tubes have to be

purchased from the UK and all examples that I've seen for sale are in "used-tested

good" condition. I'm sure that this DH63 "tests good" but

tube operation in a

tube tester is usually just long enough to perform the test and that's

all,...maybe one minute,...tops. It's quite

different from the tube's operational performance in a receiver where the circuit parameters

are quite different and

length of time "powered up" might be measured in hours. For now,

the 6Q7G will do fine. It looks absolutely correct since the "G" version fits through the

tube socket shroud, it has the original style tube shield installed and

most important - the 6Q7G is the recommended substitute for the DH63 in

the receiver manual.

570kc IF Alignment versus Bandwidth

Performance - In the copy of the C.R. 300 manual that I have

the "Receiver Alignment - page (18)" is missing. This page details the

IF alignment procedure. I had to experiment with some different

adjustments to see what worked best. The best performance for the IF

bandwidth function requires accurately aligning the 570kc IF with the

receiver in the "N" Bandwidth position. The IF circuit boosts the gain

when in "N" to compensate for the narrow bandwidth. If the 570kc IF is

aligned in

either the W or the M position then the gain boost for N is not

apparent and the bandwidth doesn't seem to widen or narrow per the

Bandwidth selection. The 570kc IF accurately aligned in the "N" position

gives the user a wide bandwidth response in W, slightly narrower

bandwidth in M and very

narrow bandwidth but with boosted gain in N. This works out very well for CW,

which was the commonly used mode during WWII. Since only a stronger AM

Voice signal audio bandwidth would benefit in the M or W position, the slight reduction in

IF gain is

expected (but not really all that apparent) when these types of signals are

tuned.

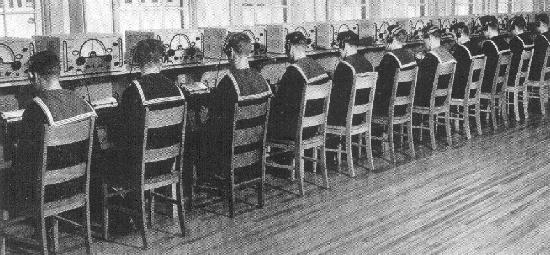

Workbench revisit completed on November 6, 2020 and the C.R. 300/1

was returned to the operating position paired with the Navy ART-13 transmitter.

Combo used for Nov. 7th - MRCG net on 3.985mc with no problems. This

combo has been used many times since then and the receiver is an

excellent performer on 75M Phone. I've also listened to the various

Chinese and Korean Frequency Marker Beacons on several different

frequencies. Also, Gander Air on 10mc and Trenton Military on 15mc, both

VOLMET aviation weather stations. So, the C.R. 300/1 is a good, dependable

receiver that is able to provide reception many different types of

transmissions. |