|

The

Contractor Companies, Contract Numbers, Build-Years and Production

Quantities for R-390 &

R-390A Receivers

R-390

1951, 1952 - Collins Radio Co.

- contract 14214-PH-51 (contract 14214-PH-51 was used for multiple

orders of different types of receivers over a period of three years.

Collins used contract 14214-PH-51 for R-390, R-389, R-391 and a quantity

of 1027 R-390A receivers. Also, Motorola use this same contract number

for R-390 receivers.)

1951, 1952 - Motorola Inc. -

contract 14214-PH-51 Motorola used this contract number for their early

R-390 receivers with data plate indicating "Manufactured by Motorola

Inc. for Collins Radio Co.", contract 26579-PH-52 was used on later

Motorola R-390 receivers.

R-390A

1954, 1955 - Collins Radio Co.

- contracts 375-PH-54 or 08719-PH-55 (1027 R-390As built on

14214-PH-51 contract) '54 - 310 receivers, '55 - 4982 receivers

1955, 1956, 1958 - Motorola

Inc.

- contracts 63-PH-54, 14-PH-56, 14385-PH-58

'54 - 3427 receivers, '56 - 4909 receivers, '58 - 6537

receivers

1959, 1960 - Stewart-Warner

Corp.

- contracts 42428-PC-59, 20139-PC-60-A1-51

'59 - 2120 receivers, '60 - 4511 receivers

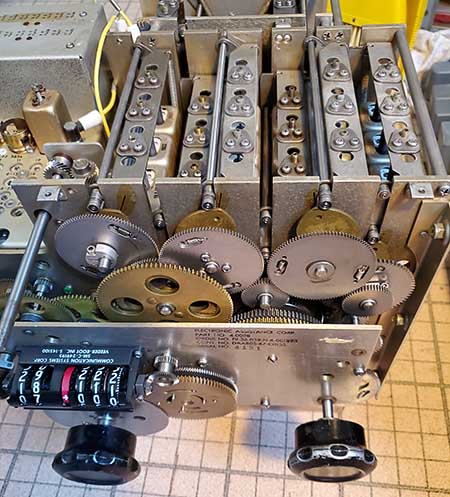

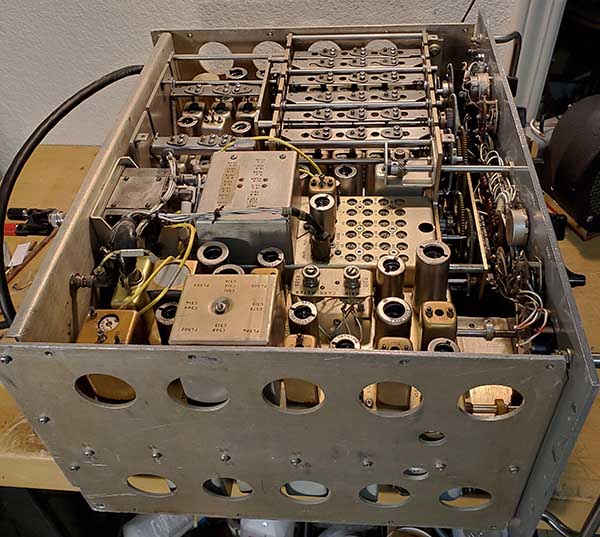

1960 - Electronic Assistance

Corp. - contract 23137-PC-60 (may have been for modules only)

1961 - Capehart Corp. -

contract 21582-PC-61 4237 receivers

1962 - Amelco Corp. -

contract 35064-PC-62 3982 receivers

(Amelco was owned by Teledyne)

1963 - Teledyne Inc. or Imperial

Electronics Inc. - contract 37856-PC-63 3976 receivers (some

data plates show Imperial, others show Teledyne, who owned Imperial)

1963 - Stewart-Warner Corp. -

contract DA-36-039-SC-81547 (may have been for modules only)

1966 - Communications Systems

Inc.

- contract FR-11-022-C-4-26418 (this is an order number and have been for modules only)

1967 - Electronic Assistance

Corp. - contract DAAB05-67-C0115 (some data plates have the

order number FR-36-039-N-6-00189(E) shown instead of the contact number)

10,717 receivers plus 151 consumer (rocket tag) receivers

1968 - Dittmore-Freimuth/EAC

- contract DAAB05-68-C-0040 215 receivers built by

Electronic Assistance Corp. for Dittmore-Freimuth

1984 - Fowler Industries -

contract N 00024-84-C-2027 5 receivers

NOTES:

The first

1027 R-390A receivers built by Collins will have long data plates

with 14214-PH-51 contract number. This contract was also used for R-390, R391

and R-389 receivers and early Motorola R-390 receivers. After the

initial 1027 receivers, Collins R-390A receivers have short

data plates with either 375-PH-54 or 08719-PH-55 contract numbers.

Shortly after Teledyne Inc. was formed, in June 1960, they purchased Amelco

Corp. (they had invested in Amelco's initial start-up.) Imperial Electronics was also an early

purchase by Teledyne.

Electronic Assistance

Corporation owned Hammarlund in

the 1970s. It's often reported that Hammarlund owned EAC but, confirmed

with a 1970 Hammarlund flyer advertising the R-390A*, that states at the

bottom that Hammarlund was a subsidiary of Electronic Assistance

Corporation. Earlier, in the 1960s, Hammarlund was owned by Guianini Scientific Corp. and

Hammarlund Mfg. was located in Mars Hill, NC.

There are a few other contractors that were

involved in producing R-390A receivers and modules but those listed produced the

greatest quantity of receivers with Electronic Assistance Corporation

building the largest number of R-390A receivers on a single contract at 10,717

and Motorola building the largest total quantity of R-390A receivers,

although requiring

three different contracts, ultimately producing 14,873 receivers.

It's generally believed that a combined total of at least 55,343

R-390A receivers were built by the various contractors.

Estimates for R-390 production range from around 15,000 to as high as

20,000 receivers.

Receiver quantities from: www.navy-radio.com

* Starting in 1968, EAC did sell 151 R-390A receivers to the civilian

market. These 151 receivers have a special data plate with the depiction

of a rocket and no military reference. |