|

Horace G. Martin

|

Vibroplex Company History

Horace G. Martin

was the earliest of the bug manufacturers, producing the Autoplex

semi-automatic keys in 1903. The Autoplex used battery-operated

solenoids to power the dot stream but dashes were produced manually. In

1904, Martin developed the basic idea for all "modern" bugs - the

"Vibroplex" which utilized a horizontal, weighted, swinging

pendulum to create a dot stream with manual creation of dashes, although

a somewhat similar, earlier patent filing had been submitted by William

O. Coffe

(owned by Mecograph Co.)

The patent for the Martin's Single Lever was granted in 1904. Coffe's

patent had been filed almost four months earlier than Martin's.

However, Coffe's patent processing was delayed for two years because of

questionable claims and vague mechanical drawings used in his application. Coffe's patent was

granted in 1906. Martin's Single Lever was the first (or

earliest) model "bug" offered for sale. Later, in 1907,

Benjamin Bellows (Mecograph's owner) sued Martin and lost the initial suit,

however in the 1908 appeal, the court handed Mecograph a victory,...of sorts.

Mecograph claimed 12

infringements by Martin but the court only granted them their "Claim #11"

- the mechanically energized swinging pendulum. The court rulings were conflicting because the

initial finding claimed that Martin's Autoplex used a swinging pendulum

giving him priority (Martin's Autoplex patent application even uses the

terms "pendulum" and "weight" in the description.) The later court's finding was that the Autoplex

needed a

secondary power source (a battery) to operate where Coffe's pendulum

operation was entirely mechanical. Obviously, the second court thought that both

the Martin Vibroplex and Coffe Mecograph

were using an entirely mechanical weighted

swinging pendulum for dot formation and therefore Coffe's submission for

a patent proceeded Martin's in that one aspect alone. However, because

of the precise patent drawings and the mechanical design of Martin's key

was so far advanced beyond that of Coffe's amateur contraption (along with

the earlier ruling that Martin's Autoplex with its

concept of using a

weighted swinging pendulum proceeded Mecograph's claim,) the court's ruling

didn't enforce any capitulation on Martin's part. Since the court

essentially gave Martin the "go ahead," he continued to

build his Vibroplex keys.

"Vibroplex"

and "Autoplex" keys were originally sold through United Electrical Manufacturing Co. in

New York. U.E.M. was formed in February 1904 by several individuals,

including Edward Buchanan and Horace Martin. Most of U.E.M.'s time was

spent in court, however they handled most of the sales of the Autoplex

and the Single Lever. Although U.E.M. had started in New York, they

ended up moving to Norcross, Georgia. Martin lived in Norcross during

this time. The parts for these keys were made elsewhere as U.E.M. was

just an assembly operation.

The U.E.M. Company failed in 1908.

After 1908, Martin moved back to New York City and continued to build

keys in his own workshop (probably in Brooklyn.) |

|

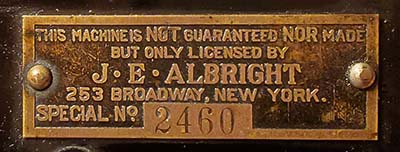

Ultimately, Martin partnered with James E. Albright in

1911. Albright sold "Martin's Vibroplex" keys initially as an agent as there was

no specific company at that time. Martin was not a businessman, he left

that to Albright. Martin was the inventor and spent all of his time in the

shop.

Albright was aggressive at defending Martin and his Vibroplex. He was successful in obtaining all other applicable patents to the Vibroplex (if not already assigned to Martin)

when he purchased the Mecograph Company in 1913 from founder Benjamin

Bellows' widow, Nellie Bellows. The purchase of Mecograph included

Coffe's patent and therefore freed Martin-Albright from any further litigation since they

now owned all of the patents. However, it didn't stop the many other

companies that were building "knock-off" imitation Vibroplex keys.

Albright won a suit

against Max Levey (ATOZ Elect. Novelty Co.) over ATOZ's blatant "Single Lever" copy

called "The Improved Vibroplex" in March 1914. After

that ruling, all Vibroplex "knock-offs" had to be licensed (by Albright) or the user

(along with his employer) could be held

liable for "unlicensed use." Albright sold the licenses for $2

and the licensee had to have a special metal tag affixed to their non-Vibroplex

key in order to avoid threatened prosecution. Licenses were sold through

1914 up to the formation of the Vibroplex Company in 1915.

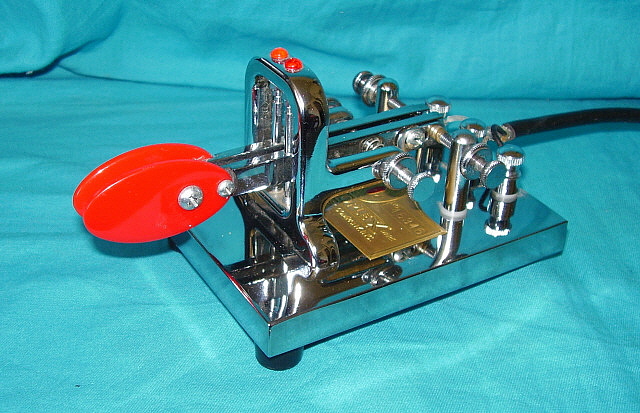

Martin had designed the Single-Lever (Original,) the

Double-Lever, the Direct-Point (Model X) and the No. 4 (Blue

Racer) by the time

"The Vibroplex Company" was officially formed,

in 1915, with James E. Albright as president.

Between 1915 and 1920, Martin designed the

Vertical (Upright) and the Midget.

Martin left Vibroplex in 1920

when he was "bought out" by Albright for a little under $7000. Martin had

a ten-year "non-competition" clause in the arrangement but continued to offer

improvements to Vibroplex and after the ten-year period expired provided

collaborations with other key manufacturers thru his sons' company,

Martin Research & Mfg. Co. After Martin's departure, Vibroplex

introduced an Original with a reduced base size and with

increased contact size bug that became known as the Junior

(1921.) The

No. 6 or Lightning Bug was introduced in the mid-twenties. The

Champion came along in 1939. These post-Martin keys were

designed by John LaHiff.

Vibroplex continued on

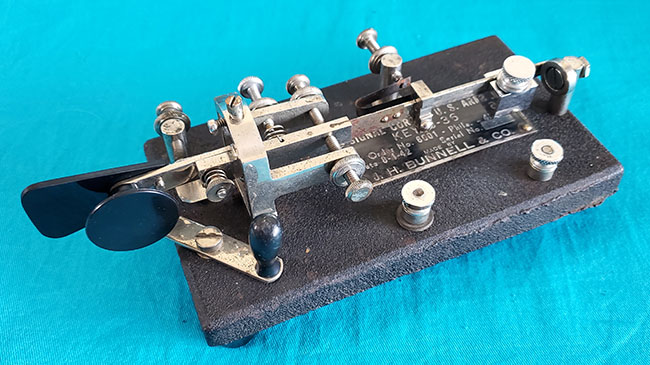

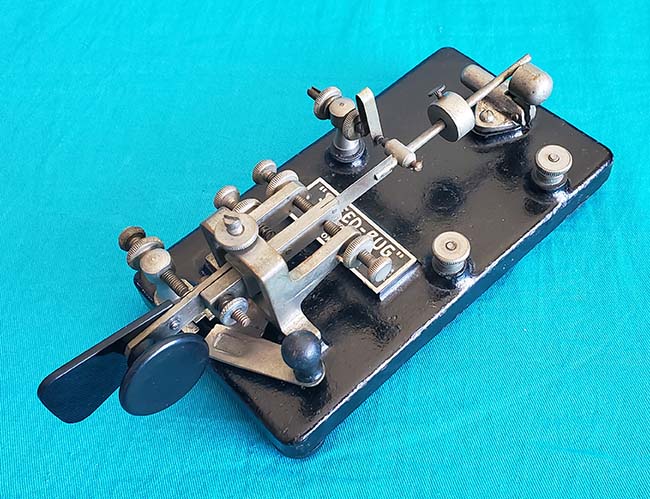

supplying bugs to telegraphers, hams and even the military. Vibroplex

started building J-36 bugs, which were essentially copies of the

Lightning Bug, for the Signal Corps in 1936. Actually, a small company

called Brooklyn Metal Stamping Co. built the first J-36 bugs in the

early thirties (based on their "Speed-Bug.") Demand for

the J-36 bug was so high during WWII contracts were also awarded to the Lionel

Corporation to build the quantity of keys that were required. The J. H. Bunnell

Company also built J-36 keys during WWII (as did the Australian company, Buzza.) |

|

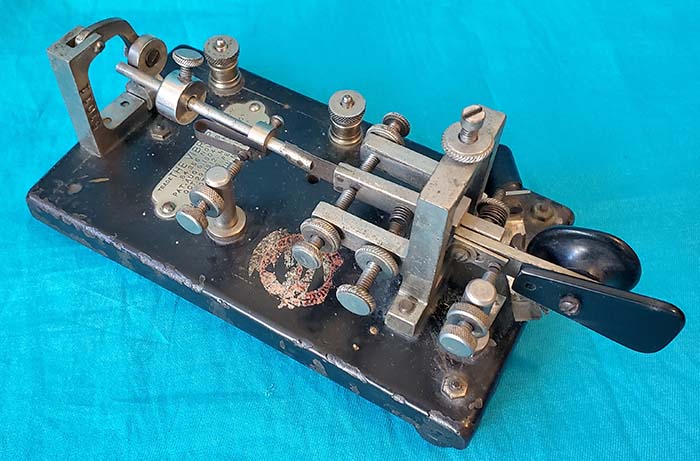

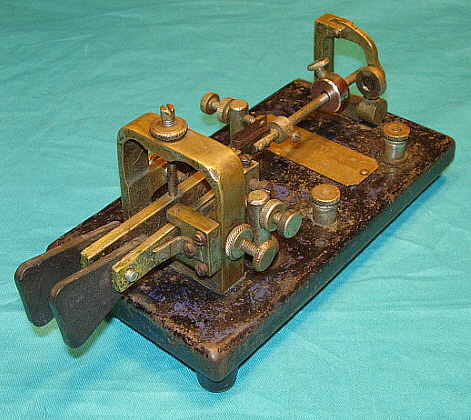

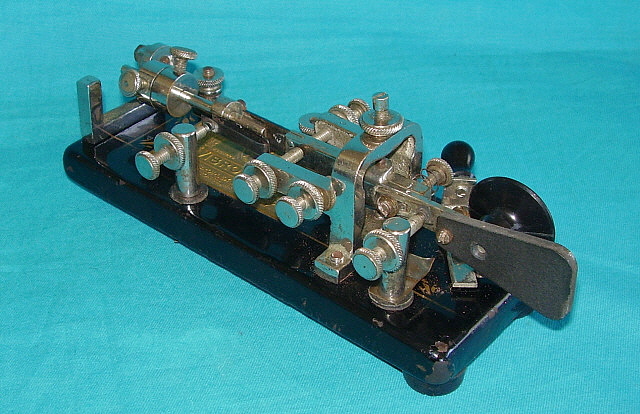

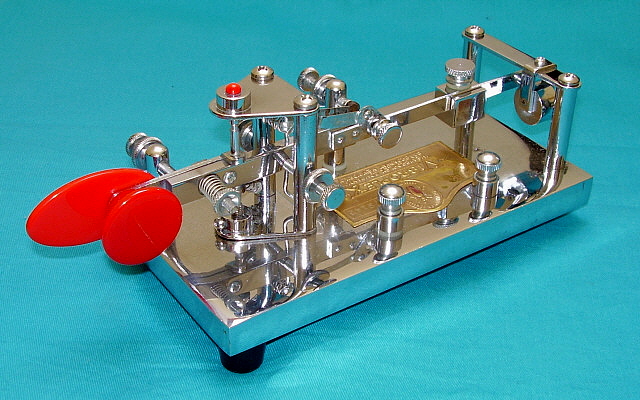

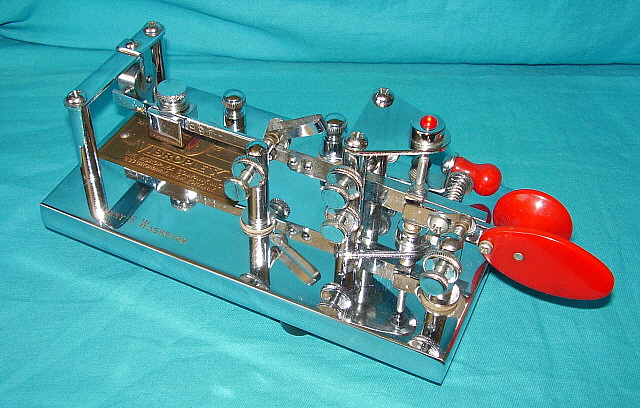

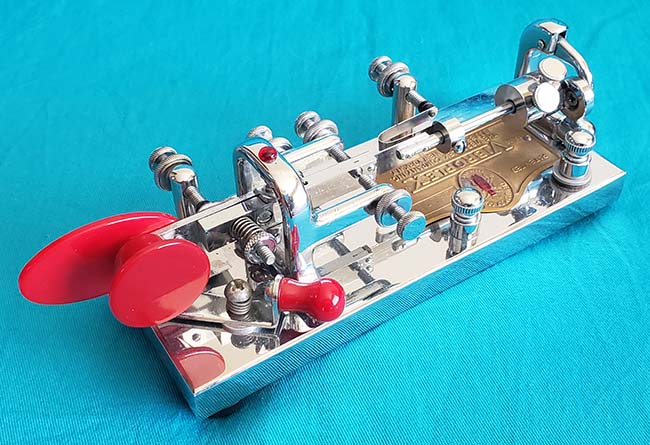

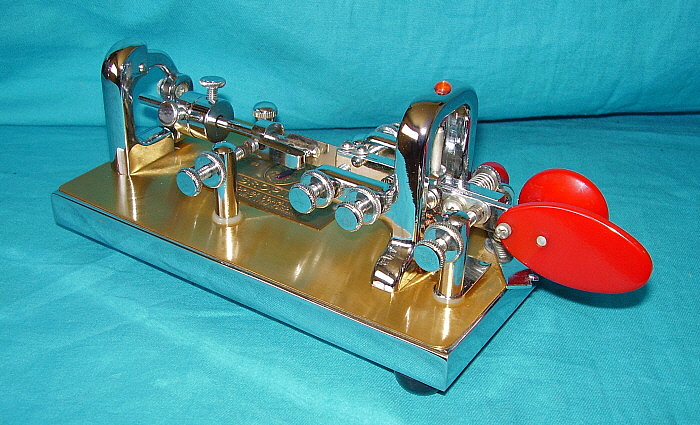

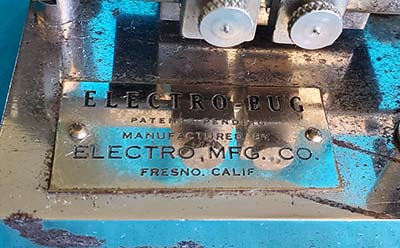

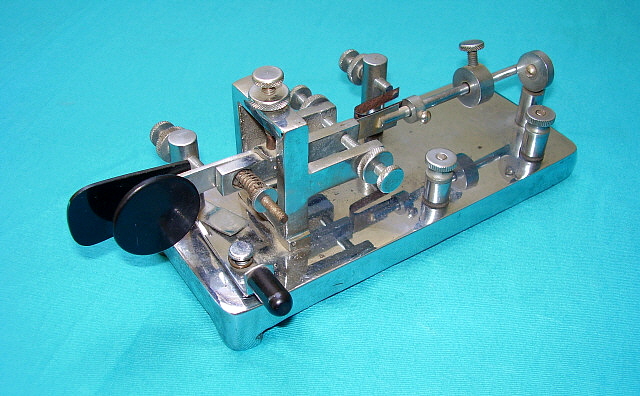

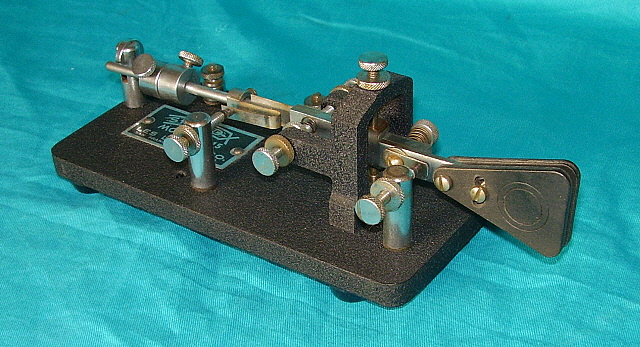

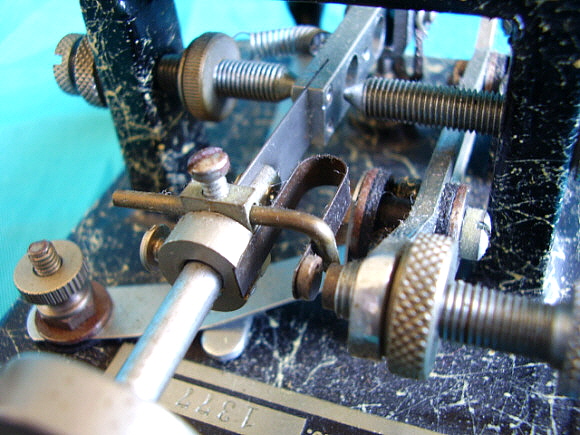

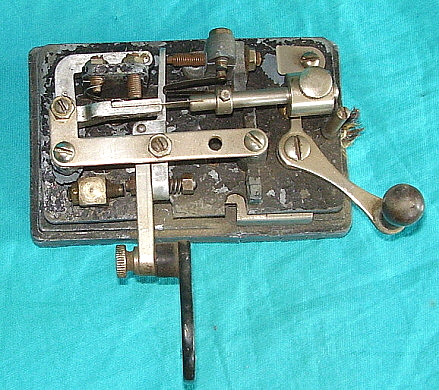

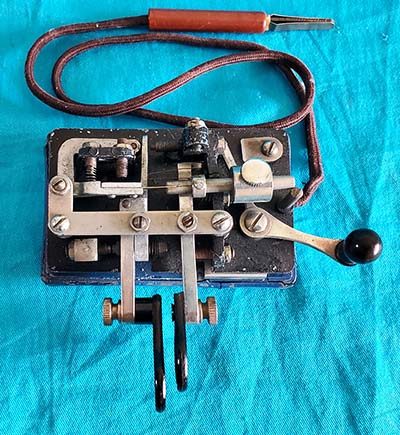

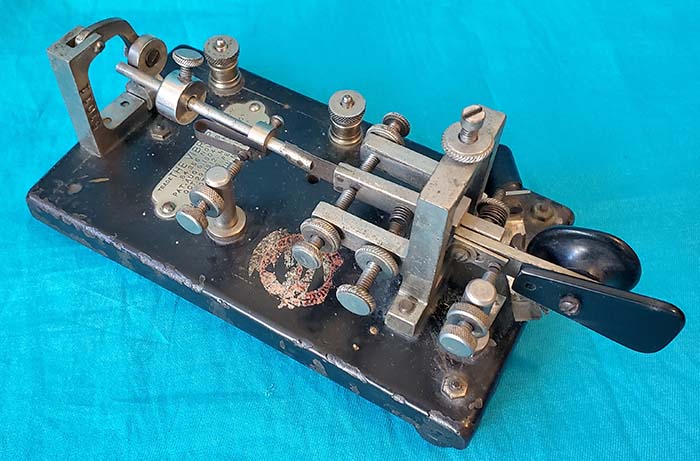

| photo above: This is a Single-Lever that was

built before the Vibroplex Company was formed. It's

more-or-less typical of the early Single-Lever in that

it has the nickel-plated data plate with patent numbers

and dates

along with Horace Martin's name and "TRADE

THE VIBROPLEX MARK" as

the key identification. The serial number on these

early, pre-Vibroplex Company Single-Lever bugs was stamped into the

damper frame. In this case, the serial number 51011

dates from 1914. Also of note, the "J.E.

Albright - Vibroplex" decal that was applied to bugs

starting around 1914 to 1915 is still present on this key, a

little worn, but still readable. |

|

In 1947, J.E.

Albright passed the presidency of Vibroplex to his brother, W.W.

Albright. John LaHiff had been with the company for many years and

designed several keys, specifically the Lightning Bug and the Champion

(and probably the Zephyr.) LaHiff became the new owner of Vibroplex in 1965.

Upon his death in the early seventies, his son took over but he eventually

sold Vibroplex to Peter Garsoe in 1978. Garsoe moved Vibroplex from New

York to Maine where Garsoe had other business interests. Around 2000, the Vibroplex company was

sold to Mitch Felton who moved the company to Alabama and Georgia.

Felton sold his interests to the current owners in 2009. And, in 2009, Vibroplex

moved to Knoxville, Tennessee, where they currently operate from.

Besides a nice selection of Vibroplex models, they now also handle

Bencher keys, W7FG Vintage Manuals, DX Covers, various types of antennae

and many other ham items.

|