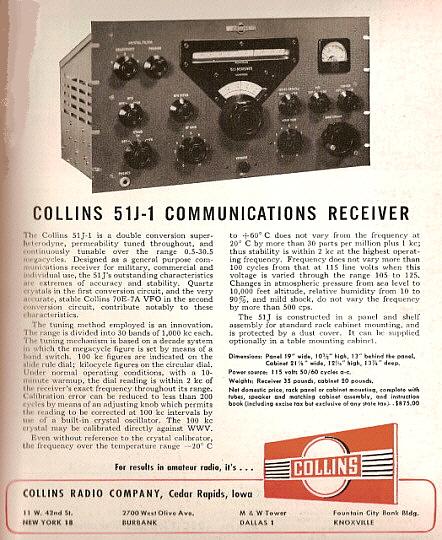

|

A Quick Reference Guide to the Standard Versions |

51J-1 - 1947? but probably late-1948

up to early-1950

- Officially available in 1949 but perhaps supplied to the Signal Corps

and a few other commercial users somewhat earlier. Collins (well,...the

CCA) says the receivers were "available in 1945" but, if true, this must

have been in prototype-form when the design was nearing completion. The

basic electronic design concept is certainly obvious in the 1947 75A-1

ham receiver, so it might be possible that the general coverage 51J was

concurrently available with the 75A-1 although the sparse quantity of

51J-1 receivers seen today indicates that very few were produced

(usually the 51J-2 is seen much more often.) Most sources indicate 1949

as the date of availability to the civilian commercial market and this

is when advertising first appears and probably when most of the

production took place. When a complete and

original 51J model is found it will be equipped with an illuminated

amber scale S-meter, the Collins "winged emblem",

a metal

dial bezel painted satin-black with "51J RECEIVER" silk-screened

in white above the kilocycle dial,

the 70E-7A PTO, the megacycle dial featured green highlighted amateur bands,

"100 KC CRYSTAL"

nomenclature was used for the Calibration Oscillator switch only on the

prototypes, "CALIBRATE" replaced "100 KC CRYSTAL" on panel nomenclature

on all production receivers, the bottom of

chassis had a small cover for the RF sections only with the rest of the

chassis bottom uncovered, no grab handles were used, no skirt was on

Megacycle Change knob but it did feature a crank to ease band changing,

a single phone jack on front panel and the circuit used 16 tubes. The

antenna input impedance was fixed at 300 ohms nominal Z with no Antenna

Trim control used. Each Antenna coil had a primary winding on the J-1

and J-2 receivers. Production level was very low, estimates are less

than 1000 receivers were built (including R-381/URR versions.) The 51J-1

I have has crystals installed (all ten) that are dated 12-49 and the

serial number appears to be 652. Unfortunately, of the surviving 51J-1 receivers I've seen,

ALL

examples had at least several electronic modifications and most had many extensive

physical modifications.

Unfortunately, almost all of the 51J-1 examples I've seen had been

destructively modified in past attempts to "upgrade" the receiver and

usually the destruction was beyond any restoration.

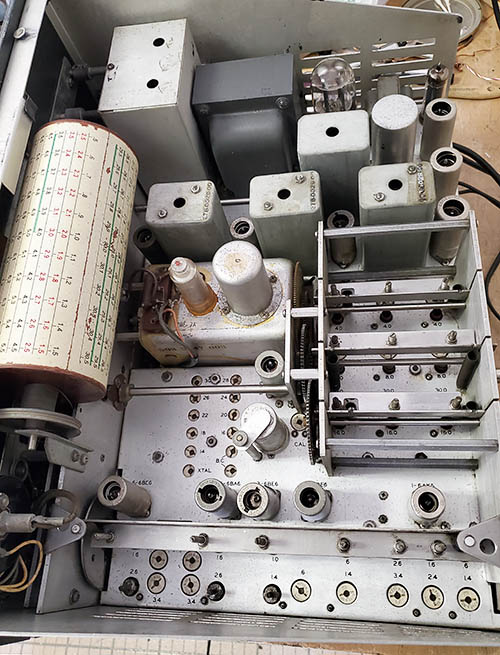

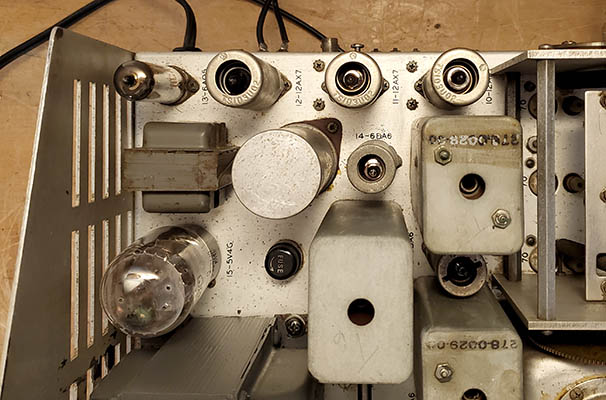

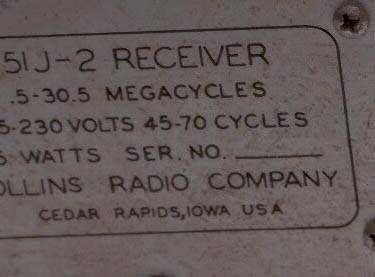

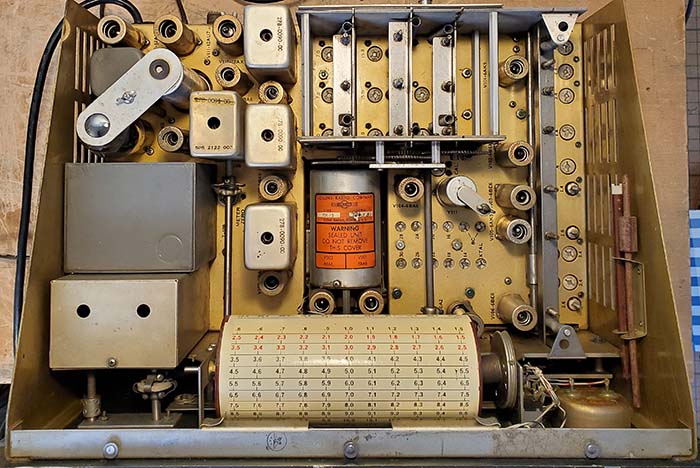

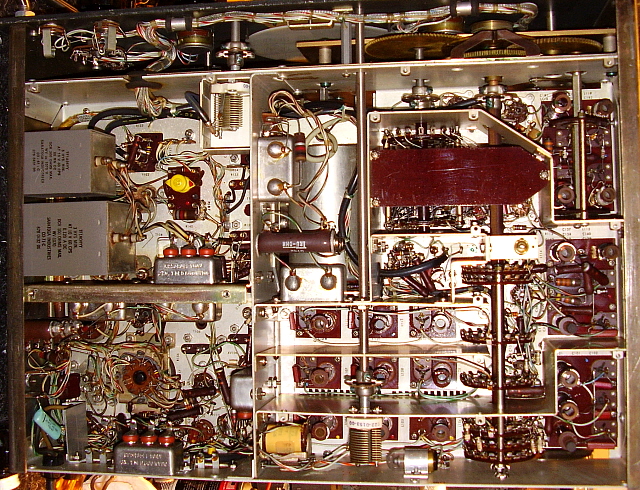

51J-2 -

1950 - The 51J-2 models had essentially the same

characteristics as the J-1 with these following exceptions; the meter was changed to a Carrier Level/Audio

Output Level meter with

appropriate scaling but meter was still the square front bakelite

housing model with illumination. A switch was added to the meter circuit

to allow measuring either carrier level or audio output, marked "METER -

INPUT - OUTPUT." Beginning with 51J-2 serial number 501, the IF

transformers were moved further back towards the rear of the chassis.

This required moving the three 12AX7 tubes to the left (viewed from the

front) and moving the

6AQ5 tube next to the 5V4 rectifier. The AC fuse was moved from the top

of the chassis near the 5V4 to the rear chassis apron near the AC power

cable. All subsequent 51J receivers have

this same tube-chassis layout. It might be possible that the green

highlighted amateur bands were removed from the megacycle drum dial but

this is more likely the result of a recent replacement (R-388) drum

being installed. A few examples have 70E-15 PTOs installed. Production level of 51J-2 receivers was well over 2000 receivers (2233 highest serial

number seen.) Very few of the 51J-2 receivers have survived

in totally original condition. All

examples found seem to be modified in some manner but generally not as

extensively as the J-1.

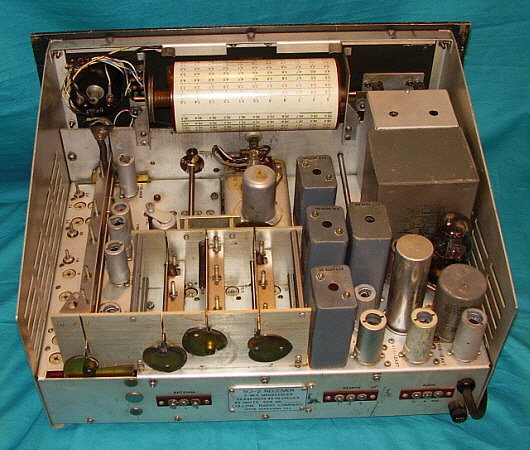

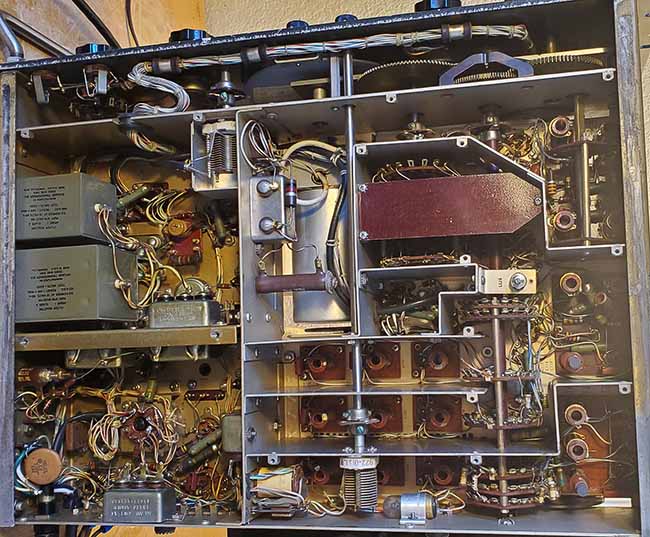

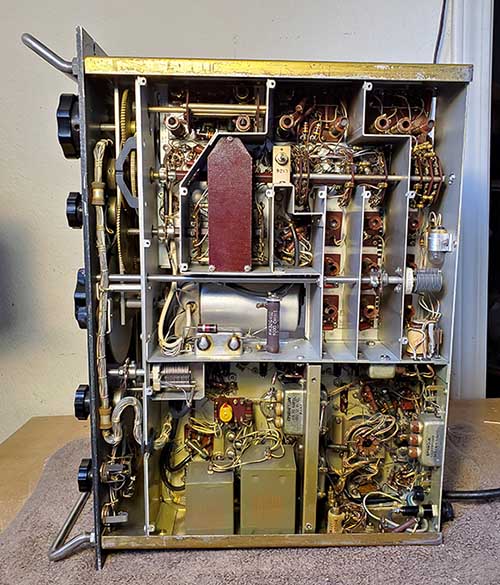

R-388/URR

- late-1950 through 1962 - This is the military version 51J receiver that

featured major changes to the original 51J receiver design. The

antenna input impedance changed from fixed 300 Z ohms to low-Z 50 ohms adjustable by

eliminating the primary winding on the antenna coils and adding an

antenna trimmer capacitor with front panel control. The dial bezel was

changed to a black bakelite piece and "51J RECEIVER" nomenclature

eliminated, the megacycle dial drum no longer had the green

highlighted amateur bands, the carrier level meter was now a non-illuminated, sealed

unit made by Burlington Company (field replacement meters made by Marion

Electric and other companies, DeJur and Simpson are often found as

original installations,) audio

outputs on the front panel allowed for phone (4Z) or speaker (600Z)

connections (pre-1953,) grab handles were now installed on the front

panel, a skirted-knob used for megacycle change, an 0A2 voltage

regulator tube was installed, the entire bottom of receiver chassis was

now protected with a slide-in aluminum bottom cover, the

side panels are made of steel and finished with gold color cadmium-based

chemical treatment, the schematic was usually applied to the inside of

the top cover, all

receivers were MFP-coated (very late contract versions were

not MFP'd - 1957 and 1962 contracts,) remote standby or Break-in now required +12vdc to be

applied to a relay via rear terminals. All R-388 receivers used the new

but problematic 70E-15 PTO which added the PTO buffer output tube. This PTO was cylindrical

in shape and has two tubes. All R-388 PTOs are identified with a "M" as a prefix for the

serial number. An

SO-239 connector on rear chassis, "IF OUTPUT," was provided for driving RTTY TUs and other

data devices. 1953 and later receivers have a "Break-in" on-off switch

added to the front panel in the same location as the SPEAKER jack which

was removed. Diode Load and AVC pin jacks are added to the rear chassis

on last of production (1957 and 1962 contracts.) The R-388 was supplied to Army Signal Corps at various times

from 1950 up into the early 1960s. Most (all?) USN R-388 receivers are

considered as AN/URR-23-A but data plate has "R-388/URR" as the

receiver ID (on a USN data plate.) At least 11,000 R-388s were produced (as indicated by PTO

serial numbers.)

Finding all-original, complete and unmodified R-388 receivers is

becoming more and more of a rare occurrence. Many of the R-388s found

today suffer from

incompetent workmanship that seems to have been perpetrated ever since

the receivers became easily available and reasonably priced on the surplus market and from

other sources. But, even now in 2023, finding an "all original,

unmolested" example

is still not impossibly difficult.

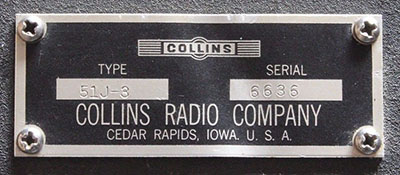

51J-3 - 1951 through late-1953

- The 51J-3 is electronically identical to the R-388/URR but the ID tag will

show that the receiver is a 51J-3

rather than R-388/URR (there is increasing evidence that many 51J-3

receivers were sold without ID tags and used the Collins production

ink-stamped number on the front panel as the serial number.) As far as

the circuit and the components used, the civilian 51J-3 receivers are exactly the same as the

R-388/URR. Even the 51J-3 chassis was MFP coated. But, the 51J-3 receiver's

PTO will have a serial number without a letter prefix or suffix, just a

number. It could be possible that the last of 51J-3 production receivers

might have a "C.R." suffix

on the PTO serial number. 51J-3 receivers were sometimes installed in a Collins

cabinet. 51J-3 receivers wouldn't have any military inspection stamps. Check for Signal Corps acceptance

stamps or other mil-stamps for confirmation. Navy stamps indicate the receiver is the AN/URR-23-A but it would have

been tagged as "R-388/URR" on a Navy data plate. 51J-3 serial numbers in the 12000 range

indicate that the data plate is a reproduction and calls into question

the authenticity of the receiver as a true 51J-3. While many "radiophiles"

consider the R-388 is a 51J-3 (electronically they are identical) the subtle

physical differences are very apparent

to Collins enthusiasts. Authentic civilian 51J-3 receivers are scarce.

But, the 51J-3 receivers that were sent out without data plates had no

overt identification (actually, no identification at all) so it's

possible that many 51J-3 receivers might be misidentified as a "tag-less

R-388" receiver.

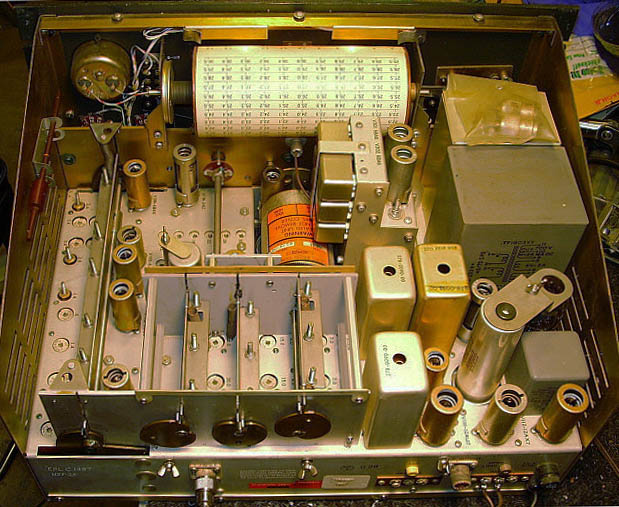

51J-4 - 1954 through 1964

- Civilian, Commercial, Military versions are all the same with the

receiver itself being very similar to the R-388 with the following

exceptions. The 51J-4

added three mechanical filters to the IF by installing the Collins

354A-1 Mechanical Filter Kit into the R-388/51J-3 chassis. Examine the 51J-4 chassis and

it will be seen that the chassis is punched for the standard IF strip of

the R-388 but that a mechanical filter assembly package has been

installed which converts the receiver to a 51J-4. The front panels were

also changed to add 1KC, 3KC and 6KC nomenclature for the mechanical filter selector

switch lever which is located behind the BFO knob. The MF assembly adds an

additional IF amplifier tube bringing the tube total to 19. All 51J-4

receivers have a 70E-15 PTOs with "CR" as a suffix for the

PTO serial number. Majority of

production receivers have St. James Gray wrinkle finish front panels

with white silk-screened nomenclature. A small quantity of 51J-4

receivers were produced with

front panels painted light-gray smooth finish with black nomenclature,

possibly built for laboratory or test facility users. Some 51J-4

light-gray panel receivers are marked "Beckman - Receiver Model 7700" or

sometimes "Beckman/Berkeley." The Beckman/Berkeley receivers were a

component of a Frequency Measuring System that was a rack with several

other components that functioned with the Model 7700/51J-4. The

light-gray panel 51J-4 receivers are sometimes found with a variety of

Collins-type knobs installed.

51J-4 receivers

are not usually MFP coated. AVC and Diode Load pin jacks are on

the rear chassis. IF Gain control is on later receivers and is mounted

on upper chassis between MF assembly and power transformer. "FCC Part 15" information is silk-screened on the rear of

the chassis on later production receivers. When supplied to the military as the

R-388A/URR or R-388B/URR it's possible that the ID plate had "51J-4"

stamped on it. Serial numbers go up to about 7500. 51J-4 receivers with

serial numbers higher than 7000 are typically found with two difference

sizes of "S-line" knobs and sometimes slightly smaller KC/MC knobs. Good examples of "all original and complete" 51J-4

receivers are still very easy to find but, of course, "good ones" will

be expensive. There are several J-4 variations that

might be considered rare or scarce when compared to the standard J-4.

R-388A/URR and R-388B/URR -

With this designation, these receivers should have been Signal Corps receivers.

These are versions of the 51J-4 but it's unknown if the data plate actually

identified the receiver as a

"R-388A/URR." Same with

the R-388B. At this time, no examples of a receiver identified by the

data plate as "R-388A/URR" are known to exist (navy-radio.com also

indicates the lack of any known examples.) The designation is shown as

"R-388A/URR" in Federal Procurement Books. It could be that

this was just an identification for ordering the 51J-4 receiver and the

receivers shipped from Collins may have

actually had the "51J-4" designation on

the ID tag (or maybe no data plate at all.) Since the R-388A/URR was shown in Federal Procurement Books

as a purchasable receiver (purchase price was about $1200,) the

implication would be that it was a new receiver. As for military

conversions using the Collins 354A-1 Mechanical Filter Kit, there

doesn't seem to be very much evidence that this conversion was performed

in military depots. The common use of "R-388A" to describe a R-388 with

the 354A-1 installation is of radio amateur origin and not an official

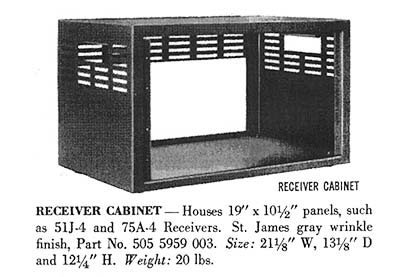

designation. AN/URR-23 and

AN/URR-23-A - These are U. S. Navy designations for the 51J-2

and 51J-3 installed in a Collins cabinet designated as CY-1235/U

with Collins speaker designated as LS-199/U. According to the USN manual

for the AN/URR-23-A, the receiver IS a R-388/URR and this is

shown many times throughout the manual.

It's possible that the AN/URR-23-A identification was on the data plate

that was mounted on the CY-1235/U cabinet. The LS-199/U loudspeaker also

had a data plate installed.

The contract was issued for the AN/URR-23-A on June 22, 1951,

NObsr-52527. There was another 1960 USN contract, NObsr-81258.

R-381/URR and R-381A/URR - These are Signal Corps

designations for the 51J-1 and 51J-2. These receivers don't have the

Collins Winged Emblem but have typical mil-style data plate installed.

|

Raytheon modified 51J-3

receivers for the USAF and USMC designated AF-30 or R-645

photo from: eBay |

AF-30 or R-645 -

Special modified version of the 51J-3 used for ionospheric backscatter

research. Modified by Raytheon for the USAF or USMC. Has a blue panel

and no grab handles. Supposedly a very small quantity of only seven

modified receivers were produced. Several photos

on navy-radio.com

Since these receivers were sold to Raytheon, a commercial

electronics manufacturer (who did a lot of military contracts

themselves,) as far as Collins was concerned, they weren't

selling the receivers on a military contract. The AF-30/R-645 receiver is not

a R-388 since those receivers were on military

contracts for the Army and the Navy. Because of the civilian purchase by

Raytheon, Collins installed the civilian 70E-15 type of

PTO. Note that the PTO serial number doesn't have a prefix or suffix

letter, only the number 727. Only R-388 receivers have the "M" prefix PTOs

(however, the very last contracts of R-388 receiver don't have the

"M" PTO installed - 1957 and 1962 contracts.)

Collins Mfg. SN on this receiver is 3803, stamped on the rear

chassis. |

Civilian 70E-15 PTO

installed in the AF-30/R-645

photo from: eBay |

Light-Gray Panel 51J-4 - The

most often heard reason for the light-gray panel 51J-4 were that they

were for use in laboratories or in test facilities. Some say that they

were for Collins "in-house" labs (and evidence seems to confirm this.)

But, did Collins supply light-gray panels to other end-user

laboratories? See Receiver Model 7700 next. Were light-gray panels ever

advertised as an option? I don't think so.

Receiver Model 7700

- This identification is on the Beckman-versions of the 51J-4 with

light-gray, smooth-finish painted front panel. One Beckman/Berkeley

51J-4 has been found with a greenish-gray wrinkle finish panel with

identification as Model 7700/3. Various "/xx" suffix to most Model IDs,

e.g., Model 7700/2-1. Some of the Model 7700 receivers were components

of a Beckman Frequency Measuring System. The Model 7700 receivers had several modifications

incorporated into the circuitry so they could function as needed

with the other Beckman equipment. Beckman did all of the modifications

to the receivers and probably made the panels themselves. It seems

probable that Beckman purchased standard 51J-4 receivers from Collins

and then incorporated all of the modifications themselves including the

new light-gray front panel with Beckman logos.

Gloss-Black Panel 51J-4 - Two are

shown on navy-radio.com. One is in good shape having been restored, the

other is in rough condition with modifications. Another original

condition one showed up on

an Antique Radio Internet forum. The black panel was a replacement panel in black glossy finish and the top

and bottom corners of the panel were

notched and the grab handles were mounted low on the panel and had

ejector buttons. There are no phone jacks on the front panel. There are two fuse

mounts above the Crystal Filter controls. The nomenclature for the

Crystal Filter was relocated to below the controls. There is a green

indicator lamp by the "ON" nomenclature of the power switch.

Speculation was that it was the forerunner to the LTV-G133F, a modified

51S-1, for airborne intelligence use. Several photos on

navy-radio.com

NOTE: Mar 2023 - One of these

variations of the 51J-4 has been found with a black wrinkle finish front

panel. The receiver appears to be a R-388 with similar modifications

that the gloss black 51J-4 versions had but without a 354A-1 mechanical

filter kit. This receiver has been modified over the years and many

parts are missing so authenticity is difficult to establish (just

examining photographs.)

|