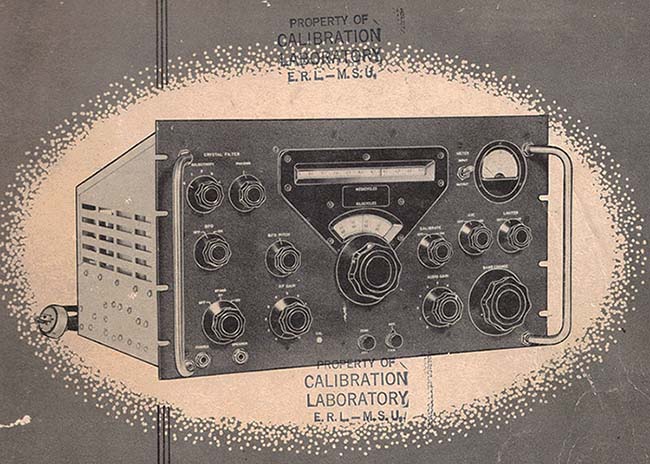

| IF/RF Alignment -

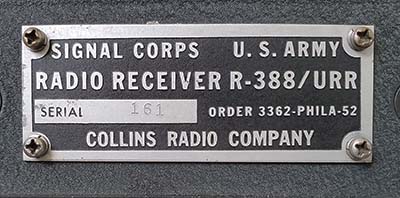

Apparently, reading what I wrote in the 2022 section of this write-up on

Collins SN:9108, I didn't perform an alignment then. The last alignment

must have been in 2013, when I serviced it for the fellow I eventually

got it from and that alignment was only a partial one. So, it's probably time

to go

through the alignment again,...thoroughly this time,...and see what I

find.

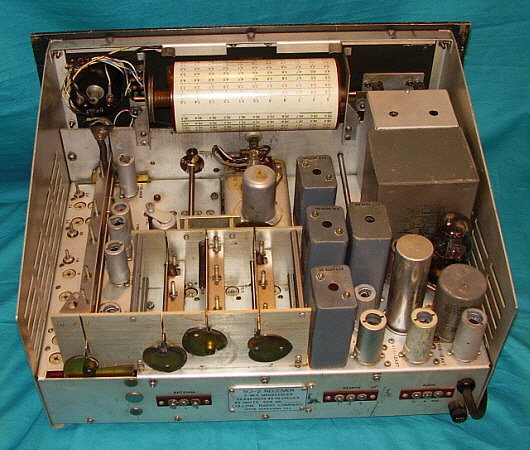

Using modern test equipment really makes performing an IF/RF

alignment fast and easy. I now use synthesized signal generators,

digital frequency counters, digital oscilloscope and a ME-26D military VTVM. With synthesizers,

accurate frequency setting is just a matter of "punching in" the

frequency and amplitude. Accuracy is unparalleled and there is no drift. I know in 2013 I was

still using the HP606B analog RF signal generator and an old Simpson VTVM.

For this IF /RF alignment I'll be using modern (or fairly modern)

equipment,...the HP3325A Synthesizer Function Generator for the IF

alignment (goes up to 20mc.) For the RF alignment I'll use the FNIRSI

DPOS350P RF Generator-Synthesizer (goes up to 50mc,) also this same device provides a DFC,

DVM (works with the 'scope channels) and limited spectrum analyzer functions

(unfortunately, no tracking generator.) The VTVM is an older style that

was found in NOS condition,...the

military HP ME-26D (basically a militarized HP-410-D.) Although the

ME-26D is a relatively old vacuum tube piece of test gear, the analog

meter movement when aligning for "peak" adjustments is very easy to see.

While modern DVMs with visual digital to analog equivalents can be used,

the old ME-26D has a large meter that makes setting peak values easy.

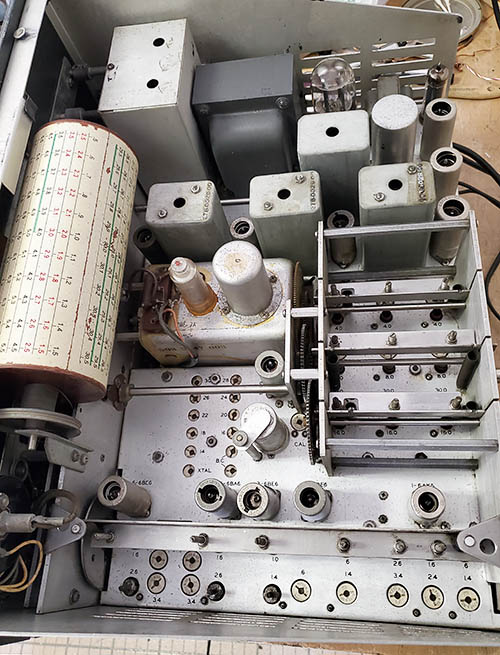

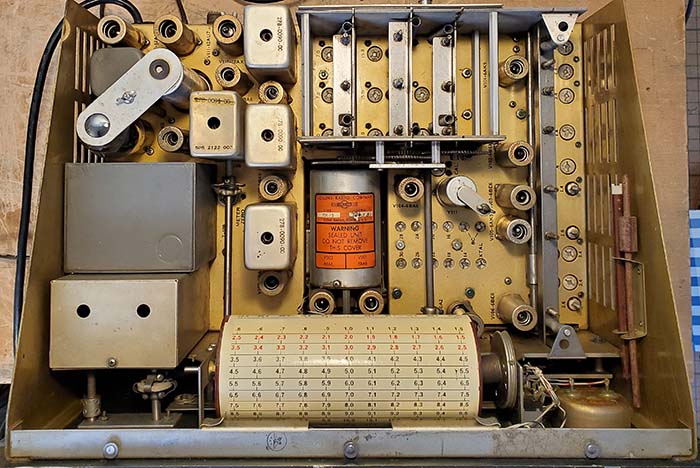

Crystal Oscillator Crystal Socket C

adjustment - The procedure is, with power off, remove one

crystal, select the Band that uses the removed crystal, measure the

socket capacitance using a C-meter, adjust C167 (XTAL) for 32pf. I've

never been able to get this procedure to actually work. I've used two

different types of digital C-meters and neither one will show much C

change as C167 is adjusted. I just assume that if I can adjust all of

the Crystal Oscillator trimmers and all of the Crystal Oscillator

frequencies are correct, then C167 must be adjusted close enough.

It's possible that a crystal and Band has to be selected where the

crystal is only used on that Band. I didn't verify that the crystal I

removed wasn't used both as a fundamental and a harmonic - next time

I'll try that.

Crystal Oscillator Trimmers

- I must not have adjusted these in 2013 because about half of them were set way

too low. These shouldn't be set higher (more negative) than -2.0vdc but some were way

below -1.0vdc.

IF Adjustment - I

probably didn't use the detuning network back in 2013 because, although T104 was

pretty close, T105 was way off and T106 was a little off. T101

was close. BFO close.

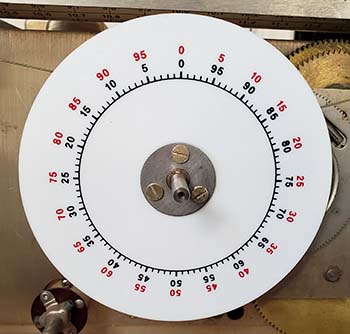

PTO versus KC dial - 6.00mc set exactly 0.00

on the KC dial with the fiduciary straight-up indicates 2.5002mc output

f from the PTO.

Vari-IF Tracking - The

variable IF wasn't off by very much. But a slight tweaking was

necessary on all of the

adjustments.

RF Tracking -

As expected, since I probably didn't use the correct dummy antenna back

when I performed the earlier alignment, the RF stage adjustments were

quite a bit off. The dummy antenna will allow a fairly consistent

impedance on the Antenna input as the frequency is changed. Except for

the RF stage adjustments, all other adjustments were fairly close.

Summary - Since SN:9108

worked quite well before the alignment, I didn't really expect to find

any of the adjustments to be radically off. The Crystal Oscillator

trimmers were off but anything under -2.0vdc is probably okay. I set

them all to -1.9vdc. T105 was off quite a bit which was unexpected but I

probably didn't use the detuning network in 2013. PTO was right-on but

that was only at center-band. Vari-IF

only needed a little adjustment. Only the RF stage was off and that was

probably due to using a different type of RF signal generator, actually a

synthesizer, and using the correct dummy antenna. What about

post-alignment performance? Tuned in Trenton Military on 15.035mc USB,

went to 15mc WWV and the CL meter indicated +50db and the tuning was

right-on 0.00kc with the fiduciary straight-up. Went up to 15M and heard

a ZL station on SSB about Q5 S6. 20mc WWV indicated +40db exactly on

20.00mc with the fiduciary straight-up. I'll need to do some more

listening,...this was right after the alignment was completed. These stations were heard about 1100hrs PST Nov 27, 2025.

In the afternoon, I tuned in XSG 16.898mc, this is a Chinese Marine

CW Beacon out of Shanghai. It's fairly difficult being much weaker than XSQ,

the other Chinese CW Marine Beacon

located in Guangzhou, China (XSQ is on 16.880mc and on 16.850mc.)

|