|

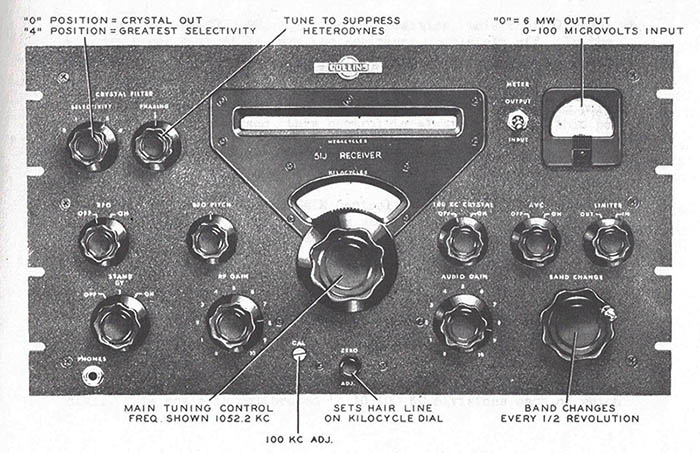

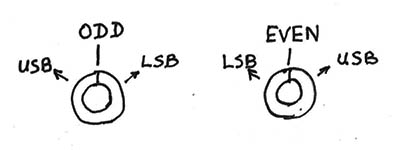

The 70E-15

PTO

The R-388 "M" version

versus the 51J-4 "C.R." version

70E-15

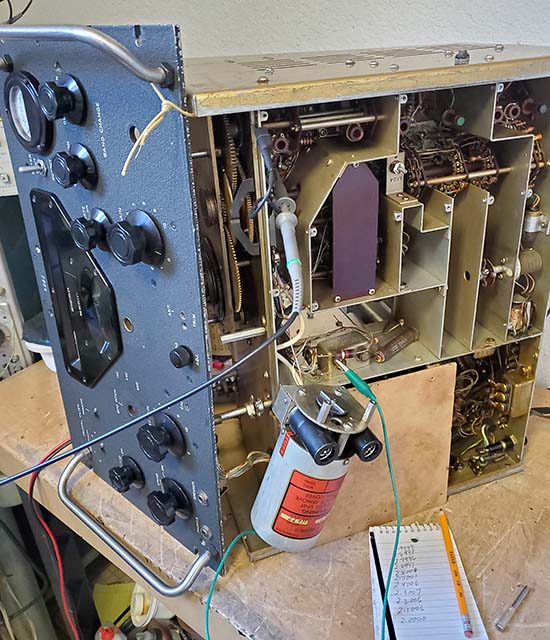

PTO Calibration Procedure - The R-388 and the 51J-3 were the first receivers to use the

new 70E-15 PTO starting in late-1950. Over the years, the 70E-15

has developed a well-deserved reputation of being difficult,

sometimes impossible, to calibrate. To calibrate the 70E-15 PTO

requires that it be dismounted from the receiver but the wires left

connected so the receiver can power the PTO. This required a

fairly involved process of partial receiver disassembly, just to

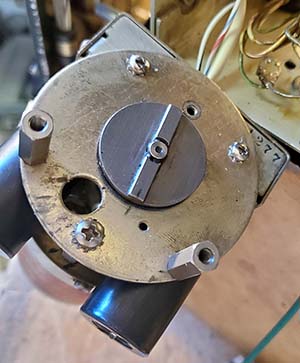

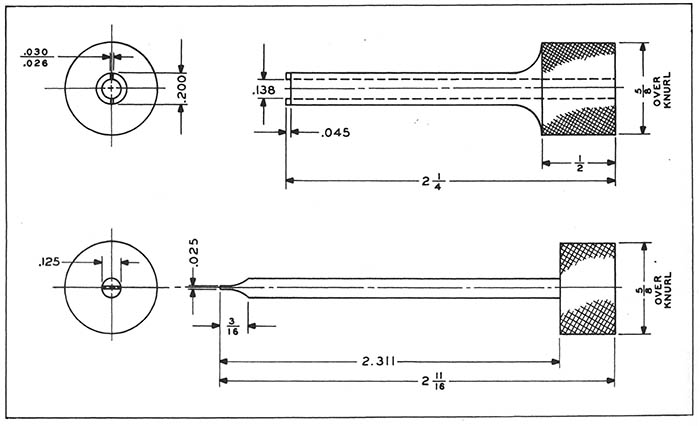

gain access to the front of the PTO in order to remove the hex

screw-plug that covers the calibration trimmer access hole. The

difficult receiver disassembly was a deliberate part of the

receiver's mechanical design that was intended to prevent untrained personnel

from having easy access to casually adjust the PTO's precision

calibration (with the 51J-1 and 51J-2 PTO, the 70E-7A, the calibration

trimmer was easily accessed on top of the PTO body with no

disassembly required other than removing a small cover.) As a further preventative measure against tampering

with the 70E-15 PTO calibration, the adjustment trimmer had a locking

collar that required a special tool to "unlock." The laborious procedure

and special tools necessary to access the 70E-15 PTO

meant that only trained technicians that had a valid reason

would even consider performing the work necessary for a PTO

calibration.

The "M" version versus the

"CR" version - Nowadays, an "as found"

70E-15 "M" version,...that is,...the type only found in the

early R-388 receivers (those built from 1950 up to about 1955,)

will virtually never meet its accuracy specification

due to excessive end-point error that usually can't be corrected with

the L002 trimmer adjustment provided. It was thought that the type or mix of ferrite used for the

PTO core had aging problems that didn't show up immediately.

However, the L002 L-trimmer was provided to compensate for

normal

"aging" changes that happened to all of the Collins PTOs.

But, for some reason, it seemed that the 70E-15"M" PTO changed

a lot

more than expected. Just how long did it take for the

calibration end-point errors to develop? It's very likely that the

70E-15 "M" EPE problems really developed into serious

problems fairly quickly, certainly within a few years. During

the mid-1950s, Collins would slightly modify early 70E-15 PTOs

that were sent back for repair but couldn't be calibrated. The

modification was to remove one turn from the internal trimmer

coil, L002. This allowed the early PTOs to calibrate to

specifications. However, it was only a temporary "fix" and Collins improved the 70E-15 PTO

around the time that the 51J-4 was introduced in 1954. ALL 51J-4

receivers were equipped

with a 70E-15C.R. PTO. These "C.R."

versions rarely have an

uncorrectable EPE and usually can easily be calibrated just

using the L002 L-trimmer provided. Although the schematic never

changed for the 70E-15 PTO, obviously something inside was

changed to make the "C.R." versions maintain their calibration

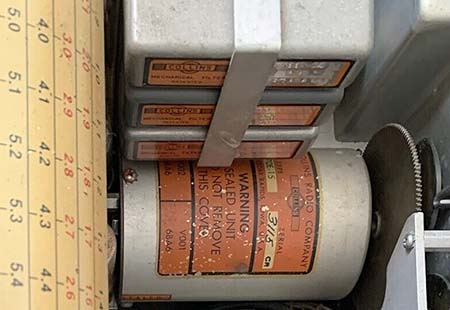

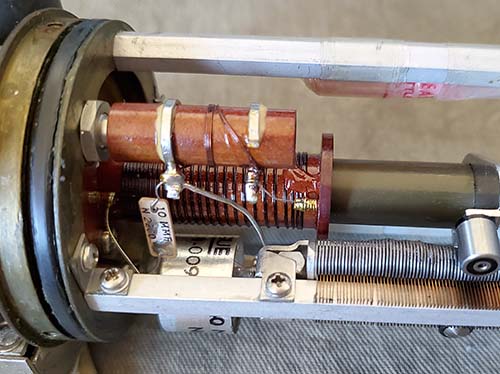

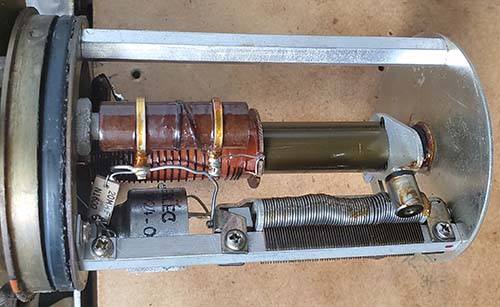

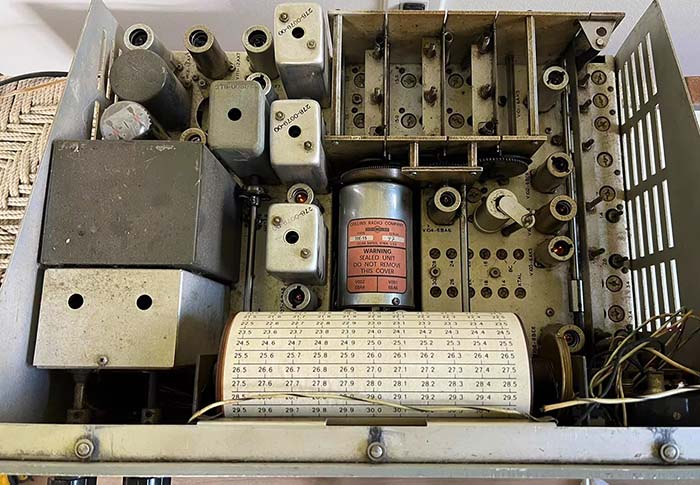

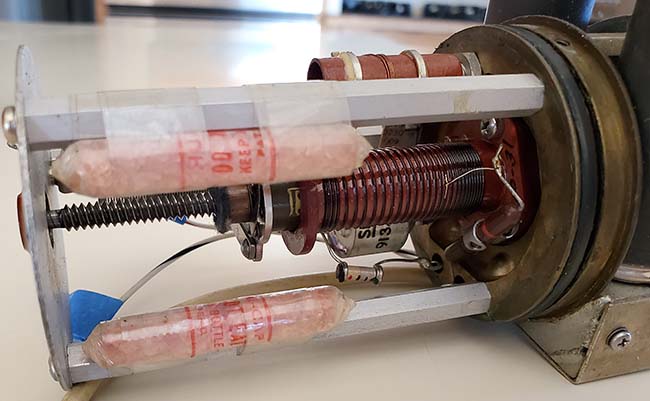

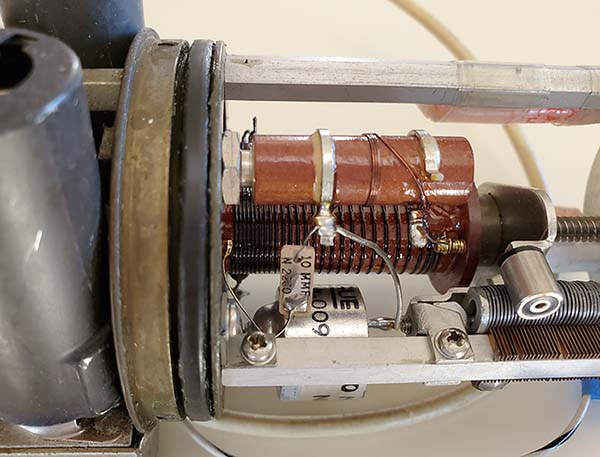

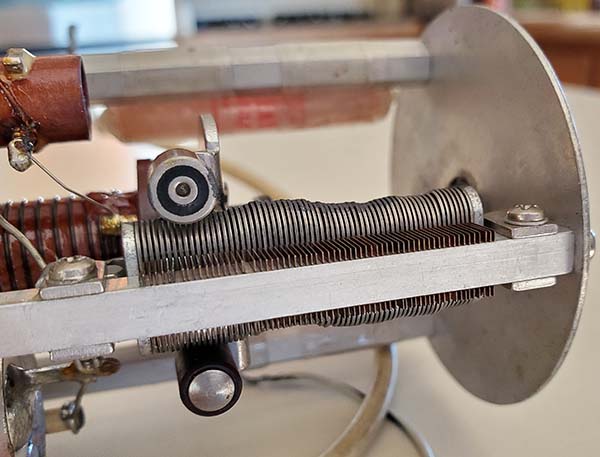

and to maintain their ability to be calibrated much longer. A visual

examination of the "M" versus the "CR" interior construction

will reveal no visible significant changes. A few minor

differences are apparent when examining the PTO

interiors "side-by-side." I've photographed the interiors of the

"M" and the "CR" PTOs and the comparison

photos are further down in this section. I've also included

photos of the interior of a "no prefix-suffix" 51J-3 PTO that

had the "Collins one-turn removal" modification to L002

(performed at Collins in the 1950s.) The last contract for R-388 receivers was a small one in 1962

but the majority of R-388 receivers, those built from

1951 up to about 1955, are considered the "early" R-388 receivers and

those receivers

exclusively used the "M" version PTO. Why "M" versions develop

uncorrectable EPE - As it became apparent that something about

the 70E-15 "M" was causing an ever-increasing number of PTOs to

fairly rapidly develop "uncorrectable" end-point errors, meaning that the normal

L-trimmer adjustment had insufficient range to bring the PTO back

into specification, the first thought (by users and owners) was that the aging of an

unstable mix used in the ferrite

core was

causing the problem. It should be pointed out that all types of

Collins PTOs will change calibration over time and it was

an expected aging factor. That's why the L-trimmer was provided. It's probably

also why the 70E-15 PTO's internal components were "sealed in a

vacuum" and why Collins insisted

that PTOs that had been field calibrated must be returned

to Collins for recalibration

where the vacuum seal was the last step in the process before

the corrected PTO was returned. However, the PTOs weren't

returned to Collins very often and therefore most PTOs had their

vacuum seal lost with the first adjustment for calibrating the

PTO and

thereafter the components inside, including the ferrite, were

exposed to the air and moisture which could then cause "rapid

deterioration" the PTO

components inside (the quote "rapid deterioration" is directly

from the Collins R-388 manual.) It's also possible that slight

seal leakage and a high moisture environment might have

contributed to the rapid development of excessive EPE.

|

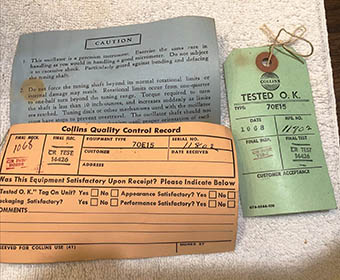

Identifying R-388 "M" PTOs |

|

1951 R-388 PTO with "M" prefix serial

number |

1953 R-388 SN:4991 PTO with "M"

prefix SN |

1953 contract R-388 (no data plate

- break in sw) Late SN PTO with "M" prefix |

Could the uncorrectable EPE have

been caused by the end user? - There weren't any

documented internal changes made to the 70E-15 PTO. The

PTO schematics shown in 51J-3, R-388 and 51J-4 manuals are all

identical. The only obvious external difference is that the

51J-4 regulated +150vdc was provided with better filtering with an added

electrolytic capacitor and a "T" filter on the 0A2 regulator

tube. This filtering change also shows up in the later R-388

receivers (1957 contracts.) Also, these later R-388 receivers

have PTOs that show both the "M" prefix and the "CR" suffix on

the same serial number, e.g., M11254C.R.

or M10816C.R. Since there aren't any differences in the 70E-15 PTOs that can

be shown on schematics and isn't too apparent in comparison

photographs, the difference must be something that's not visual, such as the type or mix of ferrite used in the

cores of "CR" PTOs. But, for the "M" PTOs, it could also be that the

differences were in how the receivers were used in the field.

Collins believed that the problem wasn't something that

happened to every 70E-15. It took a specific set of

circumstances in the field and then a few years for the

uncorrectable EPE to develop. While the ferrite core

might develop a correctable EPE just by aging,

the excessive and uncorrectable EPE problem probably started the first time that

the PTO was calibrated in the field with the removal of

the L002 L-trimmer access hex-plug that then allowed air and

moisture to enter the PTO. In their manuals, Collins even

mentions the possible contamination that could happen with a

field calibration "breaking the vacuum seal" and air-moisture

ingression causing "rapid deterioration" of the PTO's internal

components. In anticipation of possible vacuum-loss problems and

knowing that most customers were not going to return their PTO to

Collins for recalibration and resealing,

starting with the "CR" PTOs, Collins included two desiccant packets inside each 70E-15

"CR" PTO. Since the problem was

almost always with the

"M" PTO in R-388

receivers, it seems that the operational environment, where the

R-388 receivers were often turned on 24/7, could also have been

a factor, perhaps accelerating the

deterioration of PTO components after the vacuum loss.

Collins certainly wouldn't have

put too much time into analyzing a problem that they had plainly

addressed in the receiver manual for the "M" PTOs and had essentially

corrected with the "CR" version of the PTO in 1955.

Collins had been recalibrating 70E-15 PTOs that were returned

(usually inside a "returned for repair" commercial receiver, 51J-3 for

example) by removing one turn on the compensation inductor L002.

Later, when the "CR" PTO version was available,

Collins just replaced the old PTO with a "CR" version (although there might have been an

extra cost for that repair option.) In fact, after 1954 and up to 1962, a total

of only about 1000 R-388 receivers were built on just a few military

contracts in those eight years. And, the 1957 and later R-388

receivers have more 51J-4 characteristics (including the "CR"

added to the serial number of these later PTOs) making these

late-R-388s significantly different than the early-fifties R-388s. Collins did

produce a write-up specifically on the early 70E-15 PTO around 1959 but exactly

what is covered in that document is currently unknown. I suspect

that Collins reiterated the "return to the factory for

calibration" but probably also revealed their "fix" for the the 70E-15 PTO

calibration adjustment that consisted of removing one turn from

the compensation inductor, L002 and then recalibrating the PTO.

It could have also suggested that the older PTO be replaced by

purchasing a new "CR" version replacement. I

can't find the Collins bulletin on the Internet or from the CCA. It's mentioned in a

Hollow State Newsletter but apparently Dallas Lankford couldn't

find a copy of it either. So, it's just speculation as to its

content.

More Experimenting and Speculation - About the only

popularly known research on the 70E-15

"M" problem has been by

a few collectors, starting with Bill Orr back in December 1969 with

Orr's write-up in 73 magazine. Orr's solution

of removing one turn on the L002 L-trimmer has been the commonly used "fix"

necessary to return the 70E-15 "M" to a somewhat useable accuracy.

However, as stated above, there's sufficient evidence that Collins was actually

performing this L002 modification to early PTOs that were

returned to the factory for repair and calibration in the

mid-fifties. Examination of the 70E-15 SN:755 from a 51J-3 that

was used commercially showed that L002 had only three turns but

was heavily recoated with lacquer. Interestingly, this PTO was

easily calibrated from an "as found" EPE of 12kc down to an EPE 3.2kc, which was the best that could be attained

today with the original ferrite core, ample air-moisture contamination

and only one turn removal on L002. Obviously, since the Collins

fix of the mid-50s and Orr's 1969 publication of the Collins

fix, 55 to 70 years have passed and that has allowed further PTO

component deterioration resulting in the fact that the "one-turn

removal" fix probably won't work all that well anymore.

Examples - What I've

noticed, although my examples are certainly limited, is that

nearly all R-388 receivers (14 receivers examined) had

excessive EPE. Interestingly, out of five 51J-4 receivers examined,

three of which I had calibrated their PTOs, none

had uncorrectable EPE (the three cal'd PTOs were "C.R." versions of

the 70E-15 and were cal'd to <1kc EPE

using just L002.) Besides the "CR" PTO correction, perhaps

other factors might be considered, e.g., the 51J-4 being a

civilian receiver was much less likely to be operated 24/7 and

therefore the heat-build up never happened. Also, a 51J-4 being

civilian or commercial, probably never went through a scheduled

maintenance program that routinely calibrated the PTO. One very

important observation is the formidable disassembly

required for PTO calibration certainly resulted in many 51J-4

receivers never having their PTOs calibrated which may have preserved their vacuum environment much longer

than the typical R-388 "M" PTO. The result being

that the 70E-15 C.R. PTOs in 51J-4s are seldom found with excessive EPE that can't be

corrected with just a standard adjustment of the L-trimmer (I've

corrected several 51J-4 CR PTO's EPE just using L002. Also, one

1957 R-388 PTO that had both "M" and "CR" in the serial number.)

I've also calibrated a 51J-3 70E-15 PTO SN:755 that had the

Collins fix done to it in the mid-1950s. The best calibration I

could get with a 3-turn L002 was an EPE of 3.2kc end-to-end. The

implication is that the L002 "one-turn removal" may not work anymore as a

calibration fix although it will improve excessive EPE. However,

I've also recently calibrated a R-388 "M" PTO (SN:M6653) that had

NEVER

been calibrated before (by anyone.) The hex-plug still had its green Loctite

seal unbroken and the L002 trimmer shaft was at the top of its

adjustment range. This "M" PTO had an "as found" EPE of only

3.5kc. I was able to easily calibrate this "M" PTO to <1kc EPE and

<1kc linearity deviation with just one adjustment of the L002

trimmer. This was an important discovery (well,...for me anyway)

in that it was a sort of empirical proof that it was the rapid loss of

vacuum due to removing the hex-plug for a field calibration that

allowed rapid air-moisture ingression and that caused the rapid

deterioration of the PTO's internal components. That didn't

happen with PTO SN:M6653 and the slow leakage over the years

caused a slower change to the components which has nowadays

allowed this PTO to be easily calibrated to specification. The

problem is finding a "M" version PTO that has never been

calibrated. M6653 is the first one I've ever found.

Heat, Vacuum and N2

- This means that nearly ALL

early

R-388 receivers will have a 70E-15 "M" PTO with excessive EPE

and that probably was due to an early PTO field calibration that

caused a vacuum loss followed by moisture

ingression and then the deterioration was further accelerated by 24/7 operation

of the receiver. On the heat factor, a point could be made

that the R-390 and R-390A PTOs, the 70H-12, were designed to operate inside

an oven and these PTOs are never found (okay,...very

rarely found) with excessive EPE that

can't be adjusted out. Collins could and did produce the 70H-12

for a heated environment so why would the 70E-15 be adversely

affected by 24/7 heat build-up? The 70H-12 was "pressurized"

with nitrogen, an almost inert gas, which might have had

something to do with the longevity of the PTO calibration but,

like the 70E-15, the first EPE adjustment releases the N2

pressure and

air enters the PTO (I've only found one 70H-12 that still had

N2 pressure when I removed the plug to adjust the EPE - an

excellent seal that lasted for decades - but still, the EPE

needed a slight "touch-up" after those decades.) For the 70E-15, this again points to the

combination of the ferrite core being susceptible to contamination due to the

rapid loss of vacuum allowing rapid air-moisture ingression and 24/7

operation accelerating the aging and, even then, a problem that

really didn't develop immediately and only affected R-388

receivers built from late-1950 up to 1954.

|

Identifying 51J-4 "CR" PTOs |

|

PTO in 1960 51J-4 SN:4723 showing the "C.R." suffix

|

PTO in 1959 51J-4 SN:3805 |

PTO in 1956 51J-4 SN:1616 Note

pre-printed "CR" not hand-written "C.R." |

Summary - The upshot is that ANY 70E-15 PTO

might be found with excessive EPE problems but almost all

of the "serious uncorrectable EPE problem" PTOs will be 70E-15 "M"

versions found in 1950 to 1954 (early) R-388 receivers. Sometimes a 51J-4 receiver equipped with the 70E-15 "C.R."

version PTO will be found with a "high" EPE but always the EPE can be corrected by calibrating the PTO just using the L002

trimmer provided. This uncorrectable EPE PTO problem will also

affect 51J-3 receivers since the PTOs use the same internal

components. The one 51J-3 PTO (SN:755)

examined

was found to already have the three-turn L002 correction

installed by Collins and this PTO calibrated fairly well,...not

to spec, but acceptable going from an "as found" 11.5kc EPE down

to a 3.2kc EPE (after all, the "fix"

might be approaching septuagenarian status.) Another 51J-3 had

its original PTO changed to a "CR" version and yet another 51J-3

had a very late replacement of a 70E-15 purchased spare with a SN of

>11,000. So, only 51J-3 PTO SN:755 can be used as a reference. The good news is the

Collins three-turn L002 solution is a relatively easy "fix" for the uncorrectable EPE problem found in "M" PTOs in R-388 receivers. But, be aware

that it's not a perfect fix anymore. It will improve a

PTO with excessive EPE to "close to calibration" but there might

also be linearity problems and the adjustment range

will be significantly reduced in the attempt for a better EPE. The "BEST" fix

is to replace a "M" PTO with a "CR" PTO. Collins did that very

thing with 51J-3 SN:1999 which had a "CR" PTO installed at

Collins in 1957. This 51J-3 "CR" PTO recently was cal'd to <1kc

EPE and a linearity deviation of <1kc. THIS IS THE BEST FIX

for the "M" PTO with an uncorrectable EPE problem. The good

news is that ALL 51J-4 receivers have their 70E-15 PTO

identified with a "CR" or "C.R." suffix added to the serial

number. ALL early R-388 receivers have their 70E-15 PTOs

identified with a "M" prefix to the serial number.

There are 70E-15 PTOs that don't have a prefix or a suffix on

the serial number. These PTOs are found in 51J-3 receivers

and also much later as replacement spares (serial numbers are

>11,000.) So, even if the PTO

has been removed from a receiver, it's still possible to tell in

which receiver the PTO was used. The letter suffixes and

prefixes were only an identification that showed in which

receiver that particular 70E-15 was installed. "M" and "C.R."

End-Point Error Comparisons

- Now, I've found R-388 receivers with the "M" PTO that

haven't been worked on and didn't have an EPE that couldn't be adjusted to <1kc, but it's very rare

(2 out of 14 receivers examined.) Nearly all R-388 receivers

(that haven't had the PTO worked on) will have an end-point

error much greater than 10kc which for a "M" PTO might be beyond the

compensation adjustment. Nearly all "M" PTOs that I've tested have been

in the 8kc to 12kc area of EPE. The worst one I've ever tested was barely working and had an EPE

of 30kc! The best 70E-15 I ever tested was a NOS spare that was

found

still in the original box. This PTO was still in calibration and had no EPE!

NOTE: I recently (2025) had an opportunity to retest this

exact same PTO several years later (about 15 years) and I found

that the EPE now is 2kc end-to-end indicating that the aging and

change is very slow.

Confirmation That Loss of

Vacuum Caused "M" PTO Problems - The best

"in the receiver" 70E-15 "M" had an EPE of only 3.5kc (R-388

Collins Mfg SN 9108.) The NOS

PTO mentioned is an example that does

seem to indicate that vacuum loss due to removal of the hex plug

for calibration and the resulting air-moisture ingression could

be responsible for EPE problems since this NOS PTO had never

been calibrated and apparently still didn't require it. As a

confirmation for that hypothesis,...In 2026 I calibrated the "M"

PTO in R-388 SN:9108. As mentioned, this PTO had an "as found"

EPE of 3.5kc. When the PTO was dismounted from the receiver I

discovered that the hex-plug's green Loctite seal had NEVER been

broken. The PTO had NEVER gone through the calibration process

and therefore the vacuum environment was preserved as long as

the seals "held-out." Internally, as expected, the PTO was all

original with the four-turn L002 and with the slotted shaft of

L002 at the top of its adjustment. This PTO was easily

calibrated to <1kc EPE and <1kc linearity deviation with just

one 3/4 turn CW adjustment of L002. Totally atypical of the

normal "M" PTO and a sort of empirical proof that it was the

rapid loss of vacuum and the rapid air-moisture ingression the

caused the rapid deterioration of the PTO's internal components,

likely the ferrite core, that resulted in the uncorrectable EPE

problems.

Good News on "C.R." PTOs

- I just recently (Dec-2025) calibrated four 70E-15 "C.R." PTOs that had EPEs of 15kc,

11.5kc, 8.5kc and 4.5kc. All four of these "C.R." PTOs

were calibrated to <1kc EPE and about 1kc of linearity

deviation just

using L002. An interesting observation was on all but one of these PTOs,

the hex plug still had an "unbroken" green Loctite seal indicating these

three PTOs had NEVER been tampered with and the shield-cover

seal was still present although slightly cracked which is normal

for these fragile decal-type seals. However, the PTO that didn't

have the green Loctite seal on the hex-plug actually had the lowest

"as-found" EPE and

indications were the last calibration was in 1971 at Collins. That implies

that after 54 years, the EPE had only increased to 4.5kc.

However, since this particular PTO is in a Collins Laboratory

51J-4, it might have been possible that the 1971 Collins

calibration also resealed the vacuum environment in that PTO and

that's why it didn't change much in 54 years (again, just more

speculation.) Although an EPE test will show the current

condition of any PTO, actually trying to calibrate the PTO will

reveal how well preserved the internal parts are and, with some

adjustments of L002, it won't take too long to find out IF

the PTO can be calibrated.

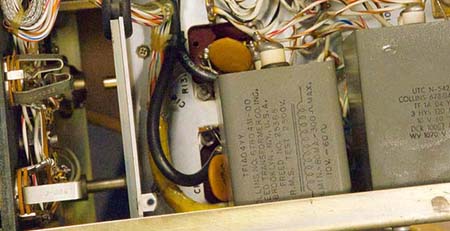

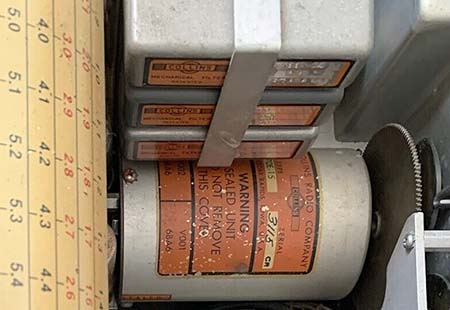

Photographic

Comparison Inside the 70E-15"M" and the 70E-15 "C.R."

and the 70E-15 "no prefix-suffix" 51J-3 PTO with the

Collins L002 fix

- Nowadays, in 2025, with nearly 70 years of aging, even

51J-4 "CR" PTOs are commonly found with a fairly high EPE which seems

to indicate that after decades of existence, the PTO seals have

broken down and allowed a slow ingression of air-moisture into the PTO

body (the desiccant packs have certainly "turned pink.") It's rare to find a "CR" PTO that has had its hex-plug

removed, so the failure of the vacuum seals seems to be a

logical assumption to add to the list of other "factors" for the

PTO EPE issues. It's not unusual for R-388 "M" PTOs to be found with >12kc

of EPE today and 51J-4 "C.R." PTOs generally are found with

4kc to 8kc

of EPE. However, if air-moisture contamination (loss of vacuum) is

the root cause, then Collins was correct in their statement that

accessing L002 to calibrate the PTO was only a temporary

field fix and the

PTO needed to be sent back to Collins as soon as possible for

proper calibration and sealing (restoring the vacuum.)

>>>

|