Radio Boulevard

Western Historic Radio Museum

Vintage Long Wave Receivers

Restoration and

Performance Testing

Various Models of Vintage LW Receivers

featuring LW Receivers from 1923 up to 1961

in Four Parts

"Long Wave," or LW,

is a commonly used term that refers to all of the EM spectrum below the AM-BC Band.

Proper terminology is Medium Wave, or MW, f range of 300kc to 3000kc,

Low Frequency, or LF, f range of 30kc to 300kc

and Very Low Frequency, or VLF, f range of 10kc to 30kc

by: Henry Rogers WA7YBS

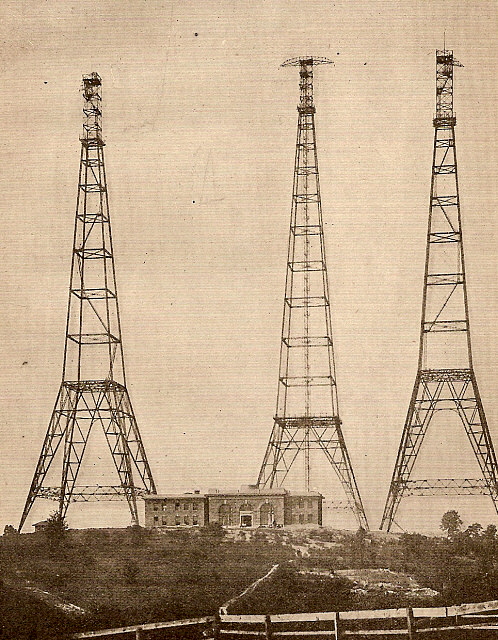

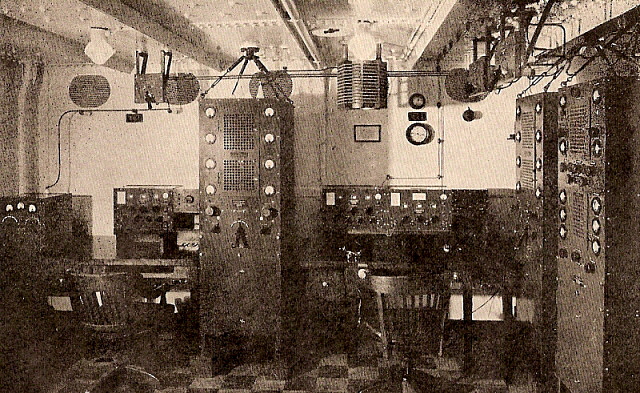

"The Three Sisters" Radio Towers and the NAA Station House at Arlington,

VA ca: 1920

The Navy wireless station at Arlington, Virginia was built in 1912, at

the southwestern end of Ft. Myer, on land that was given to the Navy by

the War Department. After the construction, the

area became known as "Radio, Virginia" but the NAA location was

also often referred to as "Ft. Myer" or "Arlington." The main tower was 600 ft tall

(center in the photo) and two towers flanking the station house were 450 ft tall. The

antenna was a triangular wire array suspended and tilted from the towers. The initial transmitter was a 100KW

rotary spark type but it was soon joined by a more efficient 35KW arc

transmitter. In Sept.

1915, NAA radio-communicated with the Mare Island Naval Shipyard in

California becoming the first direct transcontinental two-way radio communication.

Shortly after that, NAA exchanged a short message with Pearl Harbor becoming

(at that time) the longest distance direct two-way radio communication

at just under 5000 miles. In 1923, two additional towers were added

(250' tall.) In the 1930s, the towers were painted orange due to an

increase in airplane traffic and several "close-calls." Air traffic only

increased and "The Three Sisters" were razed in 1941 due their hazardous

location near the new and very busy Washington National Airport. Prior

to the shutdown, all of the equipment and duties were moved to NSS (built in

1918,) the Navy station at Annapolis. In 1961, the call NAA was

reassigned to the Navy VLF Submarine Communications station at Cutler, Maine.