| Teleprinters go back to 1849 when a loop circuit between

Philadelphia and New York City was started. The machines were crude and

had many problems that seemed to delay any significant developments

until about 1902. At that time, engineer Frank Pearne approached Joy Morton (Morton

Salt Co.) with the idea of financing a mechanical reading and

writing

telegraph machine. Morton did supply the money and also brought

in Charles Krum to assist in the development. Shortly after that

(about one year) Frank Pearne left for a university teaching position,

which left Krum working with Joy Morton's son, Sterling Morton.

By

1906, Morton and Krum formed the Morkrum Company to develop various types of teleprinter

machines but any serious interest in large-scale usage by major

companies wasn't happening. About this time, Charles Krum's son, Howard

Krum,

joined his father in the teleprinter business. In 1915, the Associated Press decided to try

out a Morkrum machine and that seemed to be the turning point for the

business. However, competition was now coming from Edward Kleinschmidt

who had also been producing various types of teleprinters concurrent

with Morkrum. Both companies had added a "start and stop" pulse to

the code to actually have the teleprinters function correctly and, rather

than spend endless time and money over courts and lawyers, Morkrum company merged with Kleinschmidt

Corporation in 1925 becoming the Morkrum-Kleinschmidt

Corporation. In 1928, that company name was shortened to Teletype

Corporation.

In 1930, AT&T bought Teletype Corp. for $30 million dollars in

stock and placed Teletype Corporation as a division of AT&T's

manufacturing subsidiary, Western Electric.

After the AT&T

purchase, Kleinschmidt's agreements with Teletype Corporation expired

(1931)

and Kleinschmidt went back into the business of building their own

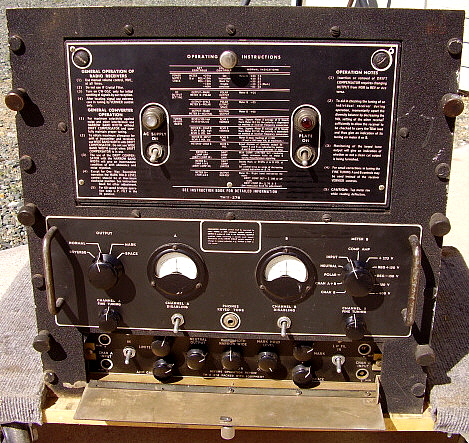

teleprinters as Kleinschmidt Laboratories, Inc. During WWII,

Kleinschmidt demonstrated a portable, 100wpm teleprinter machine to the

Navy. The Navy ended up purchasing the machines which became a standard

for the Navy (along with several varieties of Kleinschmidt and Teletype Corporation

machines.) Kleinschmidt is still in

business as Kleinschmidt Inc., doing business in electronic data

exchange equipment.

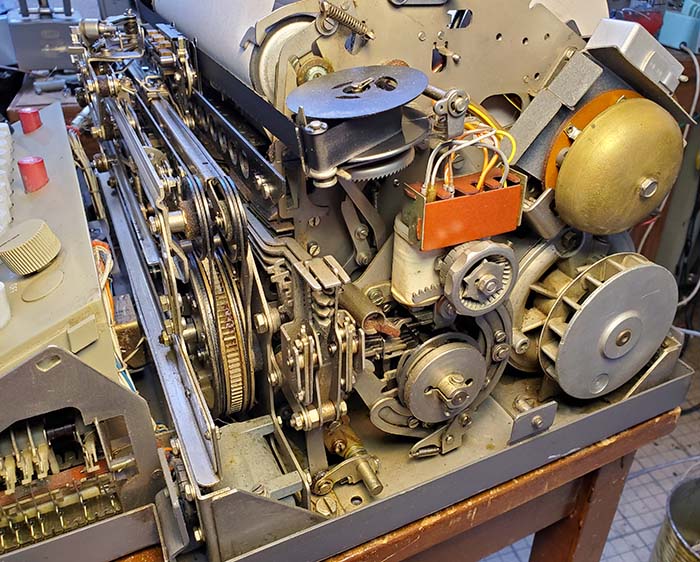

Teletype Corporation operated with a slightly different business

model in that they could sell directly to other companies outside of the

Bell System, which eventually included sales to all branches of the

military. From pre-WWII up into the late-1970s, Teletype machines were

used in almost all business communications for most companies. Most

business product

ordering was by TELEX.

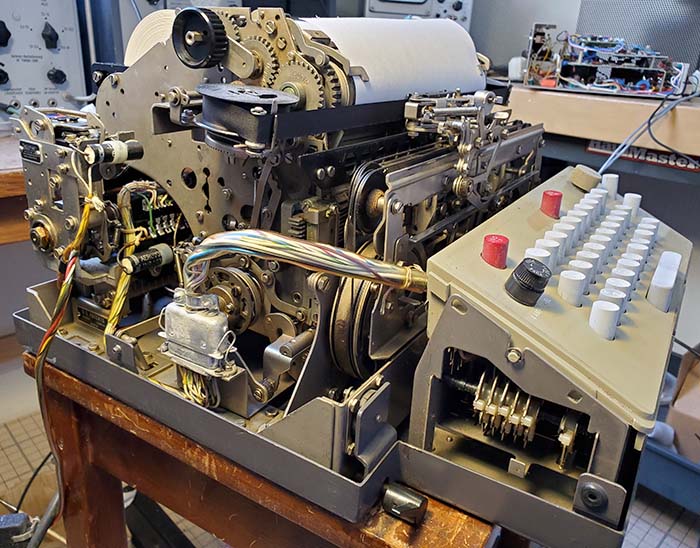

Teletype machines evolved over the years

with several different codes tried but Baudot and then later

ASCII were the main successful codes used. The most popular

speed was 60wpm but 75wpm and 100wpm were also popular and, after about

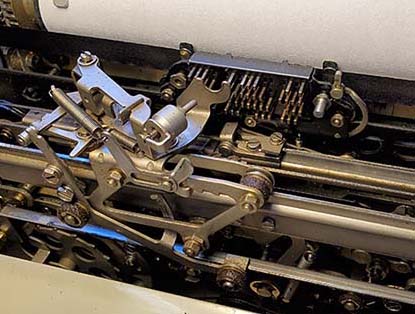

1950, most Teletype machines had a three speed selector switch. Early machines were

generally robust, heavy and usually fairly large. All early machines

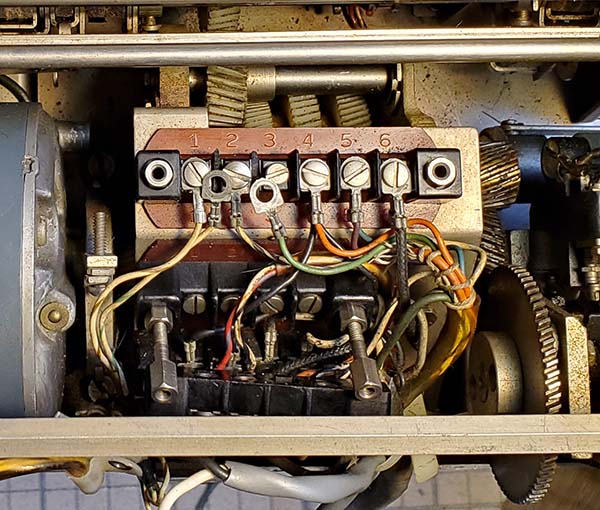

required routine maintenance to keep them running reliably. All wire TTY setups employed

polar relays to assure low noise on the line and reduce printing and

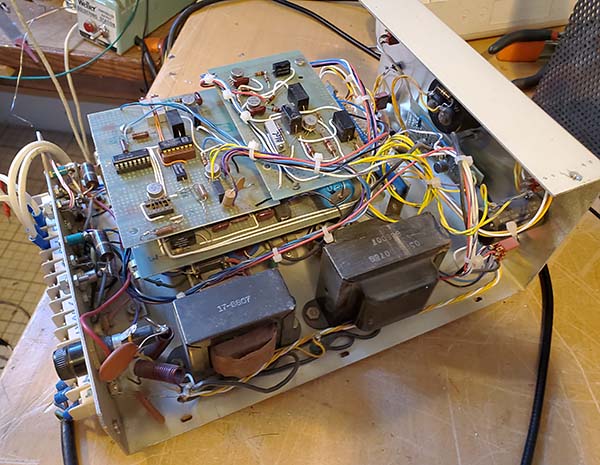

sending errors. Later machines, from the 1960s on, though

smaller and lighter weight, used plastic gears and levers, and were generally not the indestructible

behemoths of the 1940s (in many cases, the plastic hasn't aged well

either, becoming brittle and breaking easily.) As computers became

more and more powerful they were also being installed into much smaller,

light weight packaging. The computers required almost no maintenance

since they were virtually all electronic. By the 1980s, a Teletype

machine for company communications was becoming unnecessary and

ultimately

undesirable. By 1990, Teletype Corporation

was no longer in business.

There were three companies in the

USA that built teleprinters,...Teletype Corporation, Kleinschmidt

Laboratories and

Mite Corporation. Overseas in England, Creed built teleprinters. In

Germany, Seimens & Halske along with Lorenz built teleprinters. In

Italy, Olivetti built teleprinters. |