| SN 616 was my main transmitter for many years and has

proven to be a super-flexible unit capable of high power SSB and CW with

reduced power AM and RTTY communications. There was a 13-year time

period from 1980 up to early 1993 when the KWS-1 was in storage inside a

fairly large, well-insulated pump house on our Minden, Nevada property back then. It managed to

survive this neglect without any issues since the pump house was

very dry and well-insulated (never got below freezing and never

got any warmer than about 80F - and it was dark, unless I opened

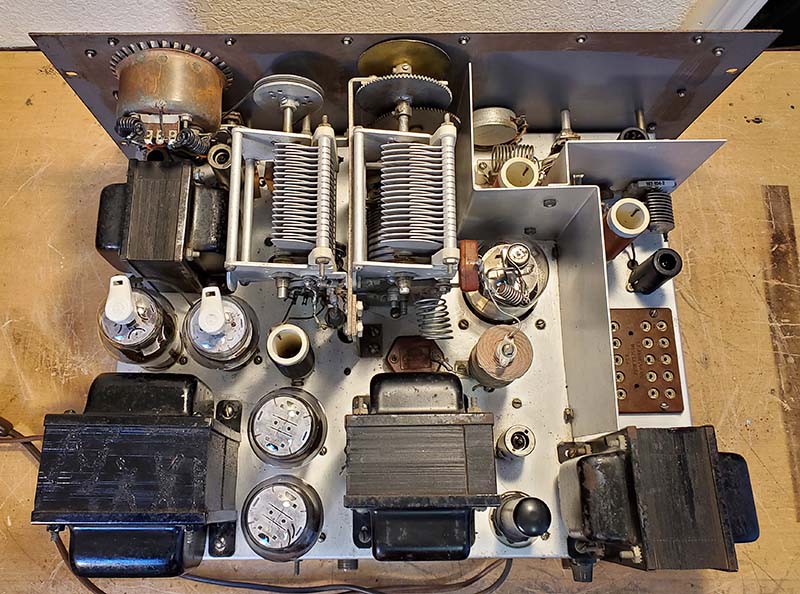

the door.) In fact, the KWS-1 has only had routine maintenance

performed on it over the years (meaning the KWS-1 is mostly all

original.) I did have to repair a broken flex connection on one

of the roller inductors a few years ago, also a broken wire in

the microphone connector. I now occasionally use the KWS-1 on AM on the

Vintage Military Radio Net where it provides a unique type of AM

for enthusiasts to hear - one selectable sideband with carrier.

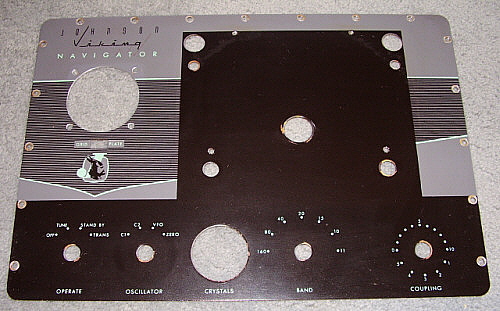

The KWS-1 transmitters have a long association with military MARS stations and, of course, the SSB promotion that involved

Art Collins and the Air Force in the mid-fifties. My last set-up had sn: 616

set-up with a Collins Lab 51J-4 sn: 4723 as shown in the photo

above. The KWS-1

is certainly one of the best from the "Golden Age of Ham Radio."

OPERATIONAL NOTES: AM on the KWS-1 is

not without headaches - mostly in the form of "Critical Audio Reports"

from the BC-audio crowd. The KWS-1 will NEVER sound like

double-sideband AM and it will NEVER sound like high fidelity AM.

No matter how many times you describe the KWS-1's method of

generating an AM signal and the fact that it's a "single

sideband signal with reinserted carrier" you'll still run into

those listeners that expect AM BC Collins 20V-quality audio from

anything built by Collins (I don't know

why,...most of Collins' equipment was for communications.)

However, a few things performed during AM set-up can avoid most

"Critical Audio Reports" when using the KWS-1. Be sure to run

the carrier reinsertion (Carrier Level) so that it results in

about one-quarter unmodulated output power as compared to full power output.

This is usually about 150 watts of carrier and is usually

achieved at about 250mA of PA current. Use a known-accurate inline watt meter to be sure of the

carrier power output. Typical full power output DC on a KWS-1 will be

around 625 watts so one-quarter would be around 150 watts. Be sure to run the Audio Gain very low -

usually about 1 or so - and NEVER use the ALC - always keep the

ALC at full CCW in the AM mode. Be sure to monitor the PA Grid current -

it should never move from 0. Any grid current flowing will

create distortion. Even a minor fluctuation of the Grid Current

meter needle is indicating non-linearity and resulting

distortion. Keep the Audio Gain low (around 1) and avoid

excited, over-animated voice levels (if possible.) Use an

oscilloscope to monitor your modulation and watch the Grid

Current constantly. Following these suggestions will have your

KWS-1 producing "its type of AM" about as well as it can. You'll

still get "Critical Audio Reports" and sometimes you'll just

have to tell the "reporter" that the KWS-1 wasn't designed as a

high-level plate-modulated AM transmitter. It wasn't designed as an AM

broadcast transmitter. It's a high-power SSB transmitter that

can do AM in a method that produces "communications quality"

audio with a narrow bandwidth and THAT was what was important

for hams (and some limited military use) in

the 1950s. One other thing on the Collins procedure for

setting up for AM operation,...Collins really thought that

nobody was going to operate AM at one-quarter power when they

could operate full-power CW or SSB. So, their AM set-up is sort

of "try and see" how it will work. Basically, Collins has you

set-up for full power match to the antenna with the Carrier

Level producing about mid-scale grid current and PA current at

500mA. Then switch to AM and reduce the Carrier Level to show

250mA PA current and set the Audio Gain as required. The problem is how the

antenna load reacts to different carrier wave envelopes that are

produced at about 625 watts DC and 150 watts DC. I've found the

mismatch is noticeable and the efficiency is greatly reduced at

low power. It might be the antenna types that I use, "tuned

dipoles" with Z-matching, but I doubt it. What I do is to follow the Collins set-up but at the

point where I've reduced the Carrier Level for 250ma of PA

current, I then readjust the PA Tuning for the correct "dip" and

then I might adjust the PA Loading slightly and "re-dip" for the

best antenna match (making sure the SWR is still 1:1.) I've found that with the approach of

"retuning" after the reduction of carrier injection the KWS-1 PA

current is very stable and rarely needs to be adjusted after

setting it lower, to about 230mA. I actually have to reduce the

PA current (Carrier Level) for best ratio of Audio modulation to

Carrier Level. This results in an increase in output power to

about 175 watts with with a reduction in PA current to 230mA, in

other words, better efficiency since the PA input power is less

(230mA x 2KV rather than 500ma x 2KV.) Also, much better stability and

the audio modulation is very high with no grid current showing.

However, this is how my KWS-1 tunes using matched "tuned" dipole

antennas. Experimentation will determine if your KWS-1 on AM

with your antenna will react the same way.

More complaints are to be expected in modes other than AM.

Especially nowadays when the majority of hams are using modern

transceivers and expect absolutely no drift. The stock KWS-1

will

drift. In the 1950s through the early 1970s, the slight <1kc

drift that the KWS-1 exhibits during a QSO was not considered a

problem because every ham used separate receiver-transmitter

setups and a slight retuning of the receiver was normal

operating procedure. Besides, the KWS-1's <1kc drift was so much better than most other rigs

at the time. But,

today any frequency drift is unacceptable and you're likely to

receive a "critical frequency stability" report when operating

some modes. Some KWS-1 users will employ a synthesizer as an

external VFO or use a DSO (digitally synthesized oscillator) device at the EXT. VFO input to keep

the KWS-1 at "zero drift." The only mode where the "stock

f drift"

isn't noticed is on AM. SSB will garner complaints and RTTY

using a stock KWS-1 is

impossible anymore (in the 1970s, I ran this KWS-1 at reduced

power doing "real machine" RTTY with no problems. Not anymore!

An attempt at RTTY in 2022 was a disaster because of the "zero

drift" necessity when communicating with modern transceivers

that have a built-in RTTY mode. Nowadays, when operating RTTY, a

drift of 20 or 30 hertz will put your FSK signal out of the

filter's bandwidth, so very little drift can be tolerated in the

RTTY mode anymore. Back in the 1970s, I used to have to keep

retuning the receiver during a RTTY QSO due to the transmitter

drift on the other end. This was NORMAL,...then. That's why ALL

of the TUs had keying indicators for Mark and Space or

oscilloscope displays,...so you could visually see the proper

keying. And, if you had some sense of pitch and did monitor the

signal, you could hear the drift happening. Older RTTY TUs were more forgiving and many

military TUs worked on just one audio frequency and any deviation was

part of the Baudot code being sent, so drift wasn't too much of

an issue.) CW QSOs are so short with very short

exchanges that the KWS-1 doesn't have time to drift much.

Most KWS-1 owner-users believe that excessive heat from the PA box being so

near the PTO is the cause of the f drift. Modifications include fans and adding insulation on the exterior

of the PA box near the PTO (the PA box originally had its

interior lined with fiberglass insulation but in humid

environments the fiberglass took on moisture resulting in

arcing. There was an ECO to remove the fiberglass from inside

all KWS-1 transmitters that were worked on by Collins dealers.

However this original insulation may have kept the PA Box heat

away from the PTO.) What I've found is that the small

function relay is mounted on the same aluminum bracket that's

used as part of the PTO mounting. The vibration of the relay

"clicking" on and off with the T-R function will cause a very

slight "bump" each time in the PTO frequency. That

"bump" seems to add up over the

duration of a QSO. I noticed this when operating RTTY in the

mid-1970s. Careful experimentation showed that the PTO frequency

change only happened on the T-R operation and there really

wasn't any drift otherwise. My solution was to add some rubber cushions to the

mounting of the relay and that seemed to cure the problem.

However, that was then. Nowadays, fifty years later, it seems

other minor problems are

also creeping into the KWS-1's original components and that's

affecting its ability to stay on frequency. The BEST and EASIEST solution to the

drift problem is the use of an external

modern synthesizer device connected to the EXT. VFO input. It's

easy and it's

non-invasive.

|