|

A Brief History of Los

Angeles Radio Building in the 1930s |

To understand why Patterson Radio Company built the PR-10 at the Gilfillan Bros.,Inc. plant in Southern California, requires some

familiarity with Los Angeles radio manufacturing history.

Before 1927, radio building on the West Coast was uninhibited and

pretty much any type of radio could be built and sold without very much interference

from the license-holding and patent-owning radio manufacturers located

on the East Coast. California was just too far away and their share of

the booming radio market didn't seem to impact the radio-selling profits

enough to enlist infringement-busting lawyers to pursue those who were

violating patents.

By 1927, RCA was beginning to assert some control over some of their

newly acquired patents. Mainly the "Tuned Radio Frequency" circuit

(not the Neutrodyne configuration though, that belonged to the

Independent Radio Manufacturers) was

important at the time although anything resembling a superheterodyne was

almost certain to be a target for the radio lawyers, too. Although RCA

didn't own the superhet-patent (Westinghouse did,) they handled most of

the legal actions because of their cross-licensing with the members of

the so-called "Radio Group," consisting of General Electric, at the head,

with Westinghouse and AT&T (former member United Fruit Company had

sold their radio holdings to RCA around 1924.)

RCA was beginning

to pressure the Gilfillan Bros.,Inc. (Sennett and Jay Gilfillan,) the only large-scale radio builder in Los Angeles (actually

in the entire West) who also

had other assembly plants around the country. The pressure became intense enough

that eventually Sennett Gilfillan got on a train heading East with the

intention of a "face to face" meeting with RCA officials.

Arriving in New York City, Gilfillan made his way to the RCA

headquarters where he asked to see "the man in charge." At the time,

David Sarnoff, who was general manager, was running RCA because actual

RCA president James G. Harbord had taken a leave of absence to campaign for

Herbert Hoover in the upcoming 1928 presidential election. RCA was still in debt to General Electric and Westinghouse over

patents and RCA's newly acquired Victor Talking Machine Company (located

in Camden, New Jersey) but the

company was beginning to assert itself in the radio industry. Sarnoff

easily avoided meeting with Gilfillan for several hours but that just

seemed to incense Gilfillan more. Finally, in the late afternoon,

Gilfillan got his meeting with Sarnoff. "You're not

going to put me out of business!" Gilfillan shouted at Sarnoff who

thought to himself, "This guy's got some real moxie coming all the way to

New York just to chew me out." Sarnoff cooled things off by asking Gilfillan

to come into his office to "talk things over."

In the meeting Sarnoff told Gilfillan, "We (RCA) don't really care

what you do out West. What we don't like is the Gilfillan plant that you

have in Kansas City. If you would close the Kansas City plant and just

do business in California, we'll give you the exclusive radio

manufacturing licenses for ALL eleven Western states."

Of course, Sennett Gilfillan knew that was an excellent offer and agreed to

the deal. Within a short time, Gilfillan Bros.,Inc. was out of Kansas City and

basically in total control of radio manufacturing in California and the

entire West. >>> |

>>> The "licenses" at the time were the general TRF radio circuit

patents that had

recently been acquired by RCA. By the middle of 1930, after RCA acquired the patent, it included the essential superheterodyne

patent.

The assignment of the exclusive manufacturing license for the eleven

Western states changed how and who built radios in the West. Now, all

legally-built radios had to go through Gilfillan Bros,Inc. Part of the licensing

arrangement with RCA allowed for Gilfillan's license to "protect" non-licensed

radio builders by designating these builders as "sub-contractors" who

were supervised by Gilfillan to a certain extent. RCA insisted that a

protocol be followed that all radios produced had to meet a certain

standard of manufacturing quality which essentially meant that the radio

had to be built, at least in part, in the Gilfillan plant in Los Angeles.

The second floor of the LA plant was not being fully utilized so Gilfillan

set it up as an area for the "sub-contractors" to build their radios. These

sub-contractors could (and did) use all of Gilfillan's tools,

components, materials, supplies, processes and they could also set up their offices

on the second floor. All of the sub-contractors hired their own

engineers, assemblers and other staff they needed. When the prototype

radio was completed, it was reviewed by Gilfillan and, if accepted, it

could then go into production. Marketing of the radio was the

responsibility of the sub-contractor.

Many of the sub-contractors used the 1617 Venice Blvd. address of the

Gilfillan plant as their official address since, for most, that was the

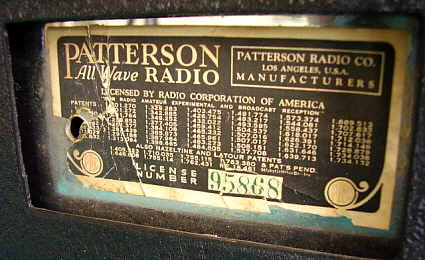

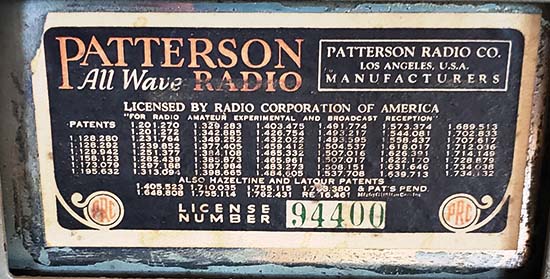

location of their entire operation. Emmitt Patterson and Patterson Radio

Company was an exception. He used a

different location for his office and official address of the company

(1320 South Los Angeles St.)

and avoided any overt connection to the Gilfillan Brothers.

Some of the "wanna-be" radio builders simply couldn't qualify to

be sub-contractors. RCA insisted that a specific number of radios be

produced and a specific minimum production level had to be maintained

in order for qualification. Some LA radio builders just didn't sell

enough radios to qualify. As long as these builders kept their radio building output below a specified level (usually less than

100 radios per week) RCA or Gilfillan wouldn't be at all interested in

pursuing them for patent or license violation.

This sub-contactor license protection lasted through all of the

1930s. During the tough economic times of the Depression it helped a lot of radio builders that just couldn't afford to

buy property, build a factory, buy tooling and essentially spend a

fortune just to get started. The cost was minimal for the sub-contractor

with just 5% of the radio-selling profit taken by Gilfillan who then split that with

RCA. The RCA sub-contractor licensing through Gilfillan only required the builder to hire his own staff and come up

with a good design to then start building and selling radios. Los

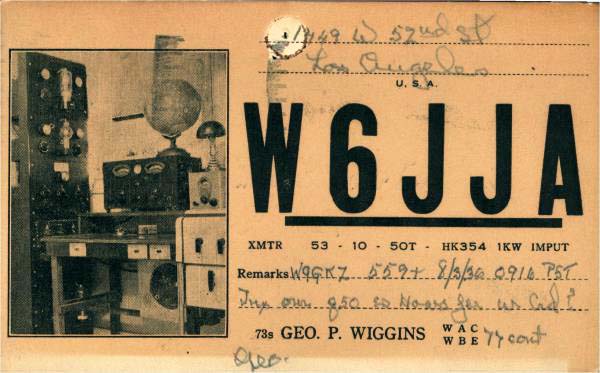

Angeles radio manufacturers that were successful included Jackson-Bell,

Packard-Bell, Kemper Radio Co., Patterson Radio Company, Breting Radio

Company, Pierson-DeLane and many others.

By 1940, RCA was becoming less and less involved with the licensing

and loosened many of the requirements. The major change was now the

license to manufacture could be obtained directly from RCA. This really

only affected the remaining companies that were successful enough to "go

it alone." It spelled the end for Paul Breting who quit building radios

in 1940. Emmitt Patterson had sold his end of Patterson Radio Company to

Karl Pierson in 1937. Pierson partnered up with DeLaplane and continued to build the

Patterson PR-15 under the Pierce-DeLane brand but also eventually

dropped the PR-15 in 1940 and went into building two-way radios until

WWII.

Pierson did start up a short-lived company after WWII that built a

couple of types of ham receivers. Emmitt Patterson

quit radio altogether in 1939.

|