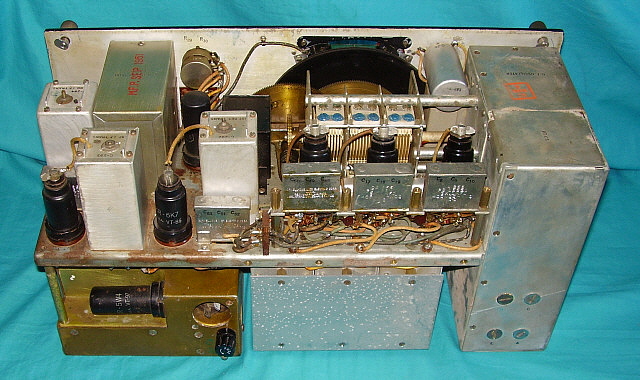

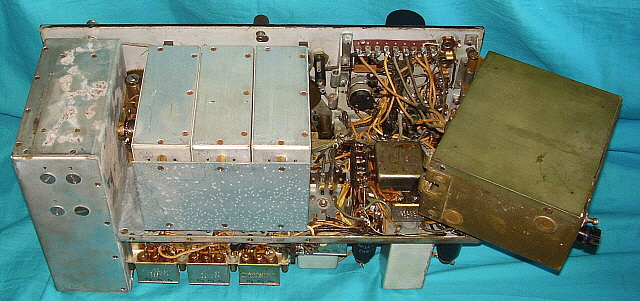

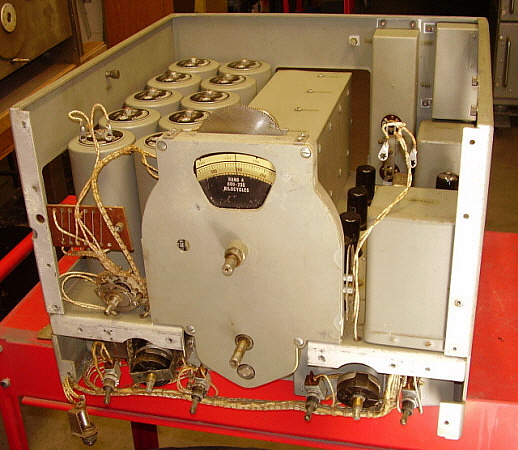

| The RBA-6 shown is from a 1945 contract. This version is

identical to the RBA-5 internally but the RBA-6 is a rack

mounted configuration only and is painted smooth Navy gray

rather than black wrinkle. Judging by the condition of this

receiver, it is unlikely that it was ever put into service. It

is all original except for the substitution of an SO-239 UHF

connector in place of the Navy coax connector for the antenna

input. The RBA-6 is an impressive performer with ample

sensitivity, direct dial read-out with illumination and a

tracking BFO rather than regenerative-autodyne detector. The

tracking BFO actually works quite well for finding the carrier

on weak NBDs. The dial accuracy is excellent and allows tuning

the NDBs by frequency rather than constantly referring to charts

or graphs. The LP filter does limit the audio frequency response

on BC stations but not to the point where the voice is

incomprehensible. The O.L. works quite well at limiting the

maximum output (which is usually due to static bursts) while not

distorting the signal. The RBA-6 is a first-class longwave

receiver capable of receiving any of the signals found below

500kc if used in an RF-quiet area with an appropriate antenna.

RBA-6 Performance

- I have been using this RBA-6 during the morning hours for late

September through most of October 2009 and have found the

receiver to be a phenomenal performer. I can usually separate

LLD 353kc in Hawaii from local Reno AP NDB NO 351kc and this is

using just a wire antenna and not relying on the directional

characteristics of a loop antenna. That's amazing selectivity

for a TRF receiver. I've probably tuned in well over 100 NDBs

but so far only two were new copies and they were West Coast

NDBs. The wire antenna I'm using is the 135' center-fed dipole

with 43' of open feed line that is shorted together at the

receiver antenna terminals. This antenna, while not really

something I designed for LW, seems to work quite well with all

of the LW receivers. Radio Rossii 279kc is received every

morning coming in very strong - Russian LW station located on

Sakhalin Island. JJY also can be received every morning on 40kc

coming out of Japan. Noise is the only limitation on reception

and for better noise reduction I have to run a loop antenna. |

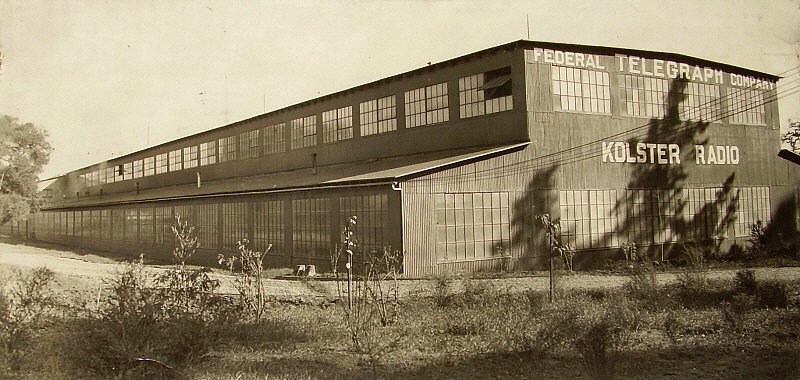

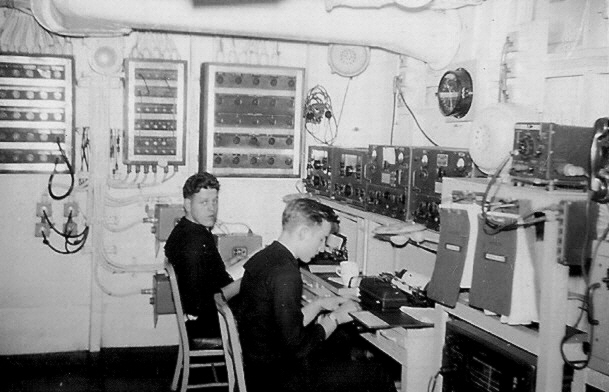

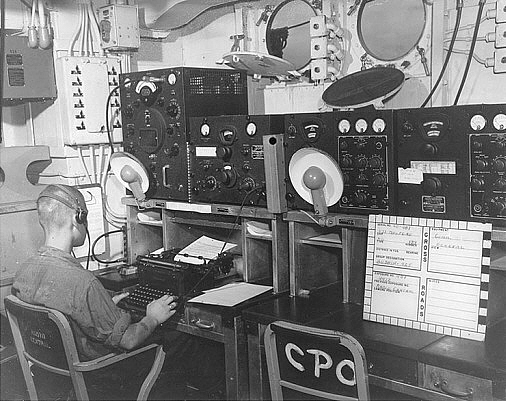

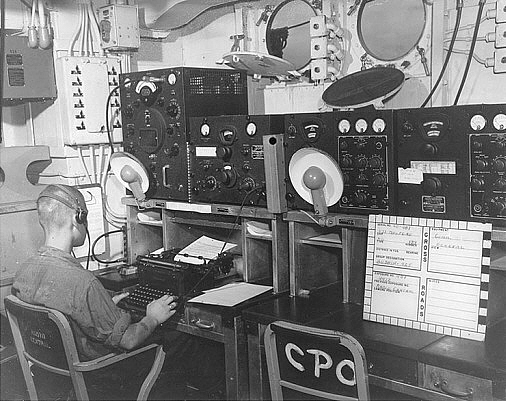

photo above: This USN radio op is

listening to the RBA receiver and is ready to copy on the mill.

Other equipment is the General Radio LR-1 Frequency Meter, the

RBB and RBC receivers. This photo of the U.S.S. Mugford in 1946 |

|

|

January 21,2010

- I finally got the RBA-6 up to the top floor of the house where

it can be used with the six-foot loop antenna. I had tried using

the loop antenna in the basement but the concrete floor and the

rock foundation were a serious detriment to the loop's

performance. The top floor of the house is actually about 30

feet above ground level and allows the loop to function quite

well even though it is located indoors. The performance of the

RBA-6 on the loop is amazing. The signals just jump out of a

fairly quite background noise level. Much quieter than running

on the wire antenna. Most frequencies seem to have at least

three NDBs active and by tuning the loop I can usually enhance

one or the other to allow copy. Quite an improvement in

performance. November 7,

2013 - QTH is now Dayton, Nevada and the antenna is a

300 foot long end-fed wire up about 50 feet. This antenna works

quite well with the RBA-6 although the noise level is probably

higher than using the loop. However, the actual ambient noise

level is so low in Dayton that the 300 ft wire seems to provide

better signal levels than the loop ever did in Virginia City.

More info to come,... Nov. 8, 2013 0615 PST tuned in JJY at

40kc, very loud signal.

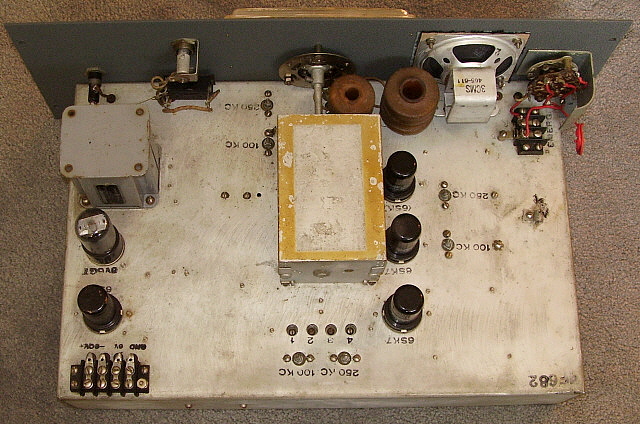

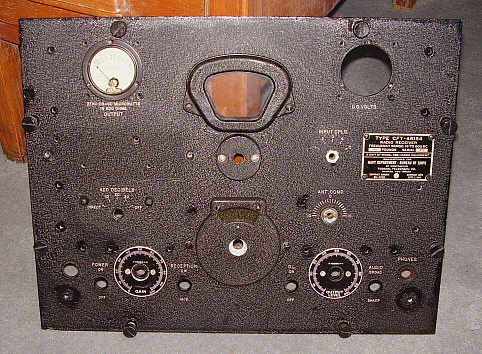

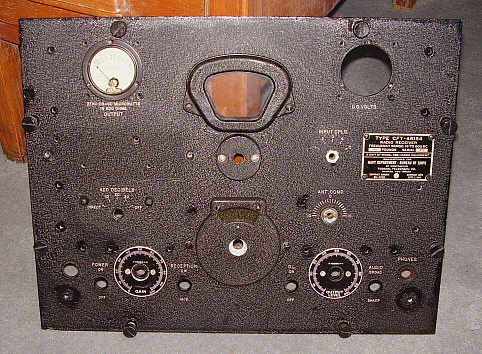

RBA-1,

CFT-46154 - I had the receiver shown to the left

for a short time. It's the early table top version RBA-1, the

CFT-46154. This particular RBA-1 has had a common Field Change

Modification Contract installed that changes the toggle switches

for Reception mode and Output Limiter to knob-type controls.

There are additional changes internally. The B+ meter has been

replaced on this receiver. Additionally, like many receivers

that have gone through a field rebuild, the cabinet is black

wrinkle (it is for an RBA-1) while the receiver's panel has been

repainted gray. This RBA-1 was traded off in 2015. |

|

RBA-1 CFT-46154 SN:

972 - Restoration Log |

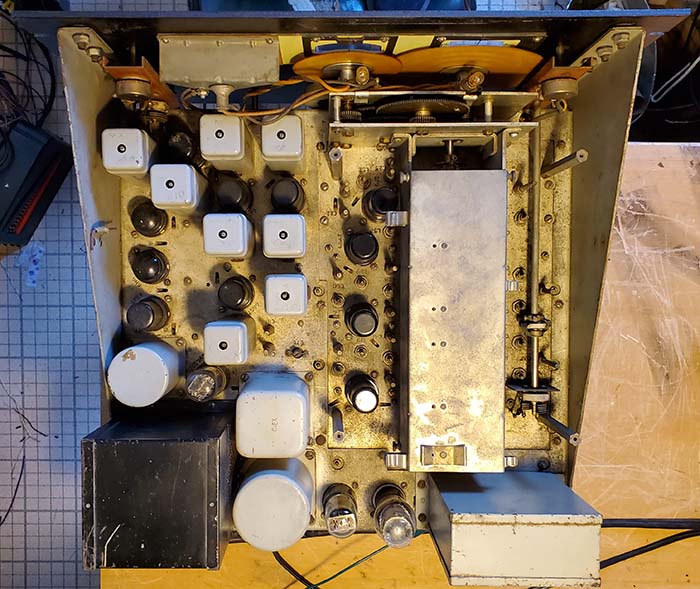

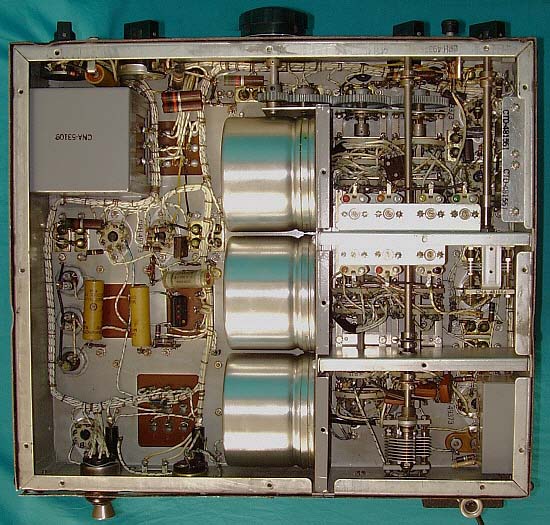

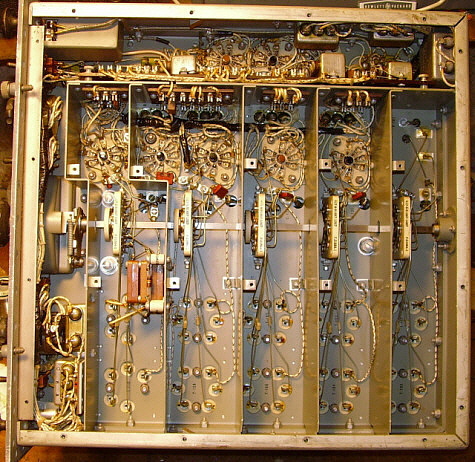

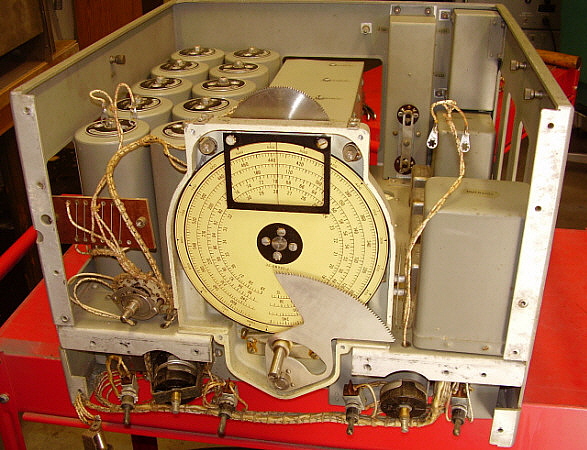

| I acquired RBA-1 CFT-46154 SN: 972 (shown to the

right) from a fellow in Texas in October 2017. It was shipped to

Nevada via UPS. No damage was sustained during transport. I

purchased this particular RBA-1 because it was the first

all-original, black wrinkle finish, complete example that I had

ever come across. Most RBA receivers found around here look like

the RBA-1 shown in the photo above. That is, most have the Field

Change modifications and have been repainted gray. Not that SN:

972 didn't have problems. For example, the DB meter glass was

cracked to several places. The meter, however, worked fine. Band

switching from Band 1 to Band 2 was normal. To Band 3 felt

rough, like fine gear teeth meshing and switching to Band 4 was

stiff but it would switch. All toggle switches seemed to

function okay. There was a little bit of dial drag on the

logging dial which was slightly rubbing against the housing.

Inside was very nice with all shields present. Some very minor

corrosion in just a few locations - nothing serious. Even the

antenna input was still the original Navy coax fitting.

Cosmetically, the cabinet was very scratched up with quite a bit

of paint missing, especially on the top. Front panel was very

good with some minor blemishes and old touch-ups. The dial mask

on Band 4 needs some attention as there are some "pin points" of

corrosion present. All knobs were present but the spinner was

missing from the tuning knob. The two nomenclature panels were

in good condition. All tags were present and in good condition

on both the panel and cabinet. The original tuning chart was

present with NSS (WWII Radio Central USN, Annapolis, MD,) shown

at 18kc. This RBA-1 didn't come with the CVR-20130 power

supply or the armored power cable. Fortunately, I had a spare

20130 and a spare cable to apply power to this receiver.

Normally, I wouldn't apply power without a thorough check out

first, but the seller told me he had the receiver operating, so

there was some confidence that nothing serious was going to

happen. I did check all of the tubes first and ended up

replacing three. I had SN:972 out in the shop, so I connected my

275 ft CF dipole with the 77 ft of feed line shorted to act as

the antenna. Upon power up and warm up, the receiver was

receiving KTHO 590kc up a Lake Tahoe quite loud. I had a 600Z

ohm modified LS-3 connected to the phone jack on the front

panel. Further tuning had MOG 404kc, a NDB from Montegue, CA and

FCH 344kc from Fresno, CA coming in strong. This was about 3PM,

so no DX NDBs were heard. However, when switching to Band 3 the

output was nil, same for Band 2. Switching to Band 1 the

receiver again had output. NAA on 24.0kc was strong but NLK on

24.8kc was extremely strong. NPM on 21.4kc was strong from

Lualualei, Hawaii. So, this RBA-1 is somewhat functional. The

most serious problem is the non-operative Band 2 and Band 3,

however since the receiver works on Bands 1 and 4, the problem

is certainly in the RF stages ahead of the

detector. Additionally, repairing the mechanical issues

of the band switching "roughness" and logging dial drag

will be necessary. The DB meter glass repair will be

accomplished by replacing the entire housing - it's a

Weston Type 506 and they're common. Finally, when fully

functional, a complete alignment. Cosmetics will be

necessary too but that looks to mainly consist of

cleaning and touch-up. |

photo above: RBA-1

SN: 972 "as received" Oct. 11, 2017. Note the bubble-wrapped

tubes piled up on the RF coils. Some of the cabinet can be seen

to the right. This photo was taken before the power-up test. |

|

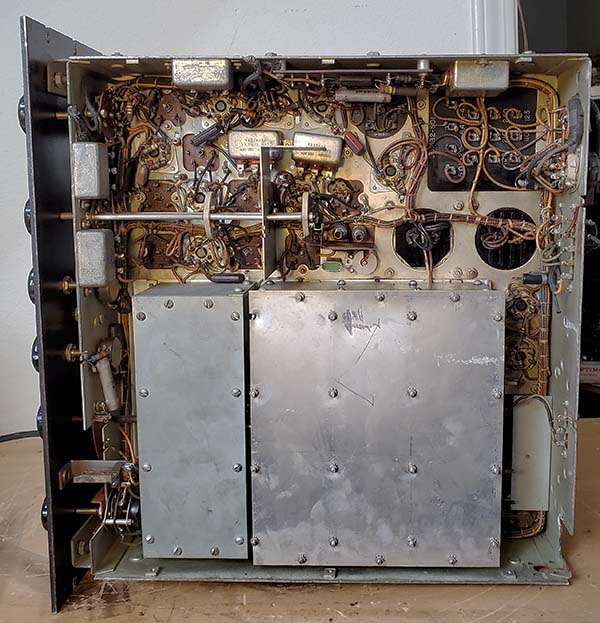

Dismounting the Front Panel - This is an arduous task

that is not well-described in the manual, at least in the

NAVSHIPS 900,708 manual I have. In order to repair the logging

dial drag, the rough feeling band switch and restore the dial

mask, I had to access the cast metal housing that has the dial,

the dial mask and the band switching inside. The only access to

into this housing is from the front and the entire front panel

has to be dismounted to even see the front of this housing. To

get the front panel off I first removed all of the knobs. The

ANT. COMP. and INPUT CLPG. control shafts needed to be removed

by loosening the set screws at the flexible coupling for each

control and withdrawing the shafts out the front panel. All

controls that have panel nuts needed the nuts and washers

removed. The bottom cover needed to be removed. Then the two

chassis-withdrawal knobs needed to be removed. The meter covers

needed to be removed so the meter leads could be disconnected.

The meters can stay mounted to the panel. The tuning chart frame

needed to be taken off. The screws underneath mount a resistor

board to the rear of front panel and these screws had to be

taken out. The PHONES jack nut has to be removed and the shield

around the phone jack itself has to be dismounted by the four

screws on the side of the chassis. The dress nuts and the hex

nuts that mount the four toggle switches had to be removed. I

had to dismount the housing around the logging dial. Underneath

there are two set screws that mount the logging dial to the

tuning shaft. I loosened the set screws to remove the logging

dial. The spacer around the band switch shaft had to be removed.

Now came the difficult part,...there were six screws across the

front panel that secure the front panel directly to the chassis.

These had nylock nuts on the inner chassis side. I had to use a

3/8" open end wrench to hold the nut while the screw was

removed. Two nuts are difficult to access because of the harness

prevents seeing the nut but it can be done by "feel." The four

vertical screws on the left side also had nylock nuts to mount

them. On the right side, two screws had nylock nuts and two had

pem nuts. The pilot lamp assembly had a 5/8" nut on the back

side. When loosened, then the red jewel front could be unscrewed

and dismounted. Now the front panel could be removed. Photo

right shows the RBA chassis with the panel removed. All

removed parts were "bagged and tagged" in small plastic bags.

This "bagging" method is extremely helpful to prevent loosing

any parts and for easing reassembly. Oct 16, 2017 |

|

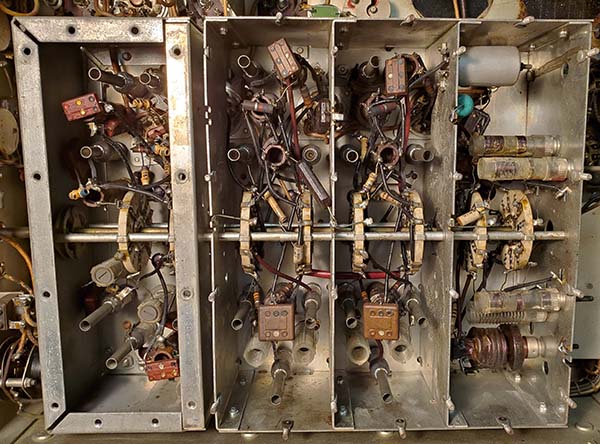

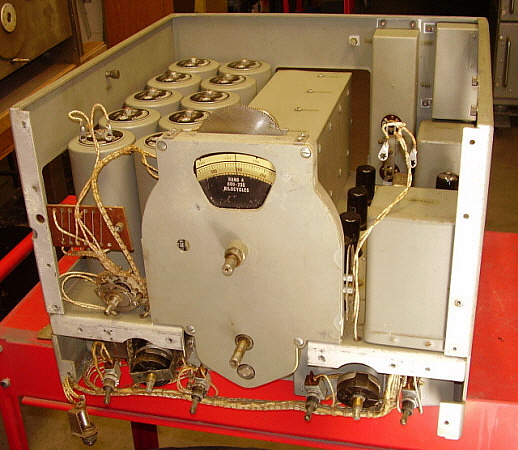

| Accessing

the Dial Mask and Band Switching - With the front

panel off, I could see the housing was a two-piece assembly. The

front part of the housing was mounted with four screws. The next

step is to remove the four screws and lock washers that mount

the front cover of the housing. Now the front cover can be

removed and this exposes the tuning dial and the band switch

arced gear. The dial mask is mounted to the front cover. In

addition to the dial mask there is also a gear on the back side

of the mask that engages the band switch arced gear and actuates

the band changing function. However, since the mask needed to be

restored it had to be separated from the front cover. This

required removal of the retaining collar that was mounted to the

band switch shaft. The set screw wasn't a hex like all the other

set screws had been. This set screw was a spline or

Bristol-type. Also, just to make removal difficult, the collar

was pinned to the shaft. This required driving out the securing

pin with a proper size punch. If done correctly with the proper

tool, the pin comes right out. The collar has to be placed on a

large vise that has the jaws slightly open. With a long thin

diameter punch, the pin can be driven out. The set screw was

only to keep the collar in place while the pin hole was drilled

and the pin driven in. It doesn't have much of a purpose now and

was easy to loosen. This allowed the collar to be removed and

the dial mask, band switch shaft and drive gear could be

separated from the front cover.

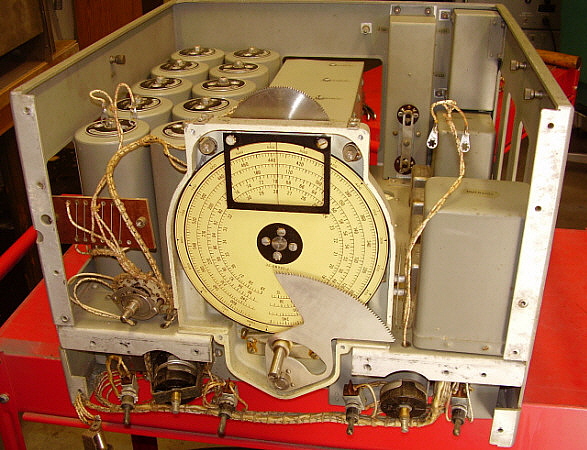

Painting the Dial Mask

- Once the dial mask was removed its condition seemed a little

worse than I thought. The minor flecks of corrosion were

numerous but most of them seemed to be around BAND 4. I removed

the black paint with stripper and wiped everything down with

denatured alcohol. I worked over the surface with steel wool to

be sure it was smooth and no blemishes would show when

repainted. I used Krylon Flat Black for the paint as the initial

coat.

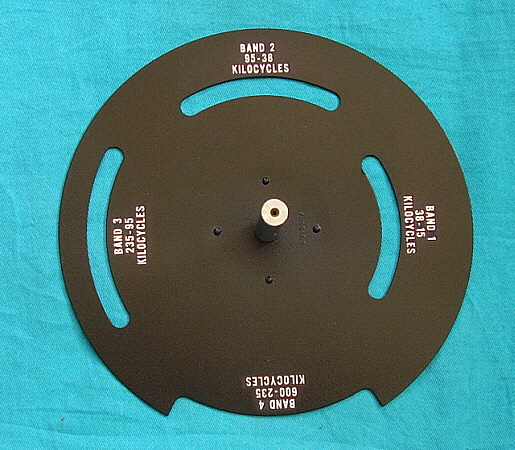

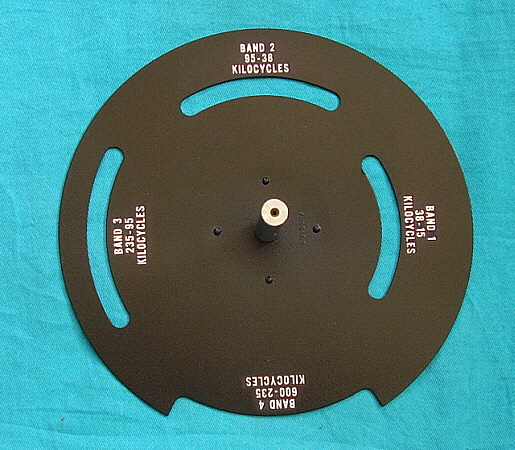

photo right : The dial

mask/cover assembly removed exposes the dial and the arced band

switch gear. |

|

| Restoring the Mask

Nomenclature - Of course, painting the dial mask

covered up the frequency band nomenclature. These letters and

numbers are embossed so they are somewhat higher than the flat

surface of the mask. To restore the nomenclature requires

carefully removing the paint just from the top surface of the

letters and numbers. I had to do the nomenclature recovery in

two steps. After the initial paint in flat black, I used a

special angled tool (that I made) that could hold a very small

piece of 320 grit Al-Ox paper. This was used to carefully remove

the paint just from the nomenclature. Of course, there was some

slight scuffing and other minor blemishes that happened to the

paint surrounding the nomenclature. The next step was to

carefully cut masking tape pieces to exactly cover only the

nomenclature. It sounds time-consuming but it only takes about

25 minutes to do. Next, I applied a coat of Satin Black, which

is much darker black than flat black. When this paint had dried,

I removed the masking tape. Now, only very small areas between

the letters and numbers had the flat black paint showing. These

areas were so small that I touched them up using a "ultra-fine

point" Pilot pen with black ink. The entire mask was then wiped

down with a clean cotton cloth to even out the paint surface. It

sounds like a lot of work and it is fairly time-consuming but

the results are worth the effort since the dial mask is quite

visible, directly in front of you, on all bands, whenever you're

using the receiver. Oct 19, 2017

Dial Mask and Band Switch

Reassembly - I put a small dab of grease on the mask

shaft and installed into the front cover of the housing. The

washer and collar were then installed onto the shaft and the

collar pin installed. The spline set screw was tightened. The

band switch was set on Band 2 so the mask was rotated to show

Band 2 also. The front cover was carefully placed in position

and moved slightly until the gears meshed while the mask

remained showing Band 2 centered. The four screws were

installed. The adjustment for the gear mesh clearance is

accomplished by moving the front cover upwards (reduces mesh)

and tightening the screws. Testing switching showed that the

mesh was correct as the switching was ultra-smooth and not

binding.

photo right: Dial mask

after restoration |

|

| Front

Panel Restoration - This is really just a thorough

cleaning with a brass wire brush (suede shoe brush) and Glass

Plus to remove all dirt, grime and cigarette residue. The

original wrinkle finish is very tough and can take this type of

cleaning but you can't be real aggressive. You just want to

remove the dirt not the paint. The front panel had been stripped

of all tags and the two dial covers. The silver (engraved)

nomenclature needed substantial cleaning. The front panel must

have been pretty dirty as it took about five cleanings until the

paper towels didn't turn gray with dirt and stayed fairly white.

After this many cleanings, the nomenclature was very legible

now. Next is the touch-up. I've been using jet black

nitrocellulose lacquer for the last year or so. This method

replicates how the USN did "touch-ups" on equipment that was

being repaired but was not in the depot for an echelon-type

rebuild. The lacquer looks too dark when being applied but with

the final wipe down with 10W machine oil, the jet black matches

the original wrinkle paint color quite well. The touched-up

front panel is shown to the right.

DB Meter Repair

- The meter glass was broken in this meter. Luckily, it was a

Weston Type 506, which are very common meters. The mechanical

zero mechanism on a 506 is mounted in the glass making

replacement glass difficult, if not impossible. The easiest

method is to find a similar 506 meter that has the meter case

with mounting flange. It doesn't matter what the meter scale

is,...all I wanted was the metal case front with the glass. I

dug around in the junk boxes and found a good candidate. The

swap of the cases is easy only requiring removal of the three

mounting screws on each meter, aligning the meter zero

adjuster-pin with the adjustment slot while sliding the new

housing glass in place and then reinstalling the screws. The

only difference in the meter I used was that the glass was

standard while the original USN meter glass had a "non-glare"

treatment. Other than that, the transplant was perfect.

Oct 20, 2017 |

|

| Plastic

Used in Logging Dial Window and Tuning Chart Cover -

These transparent plastic pieces are made of a celluloid-type of

plastic that is very sensitive to water. Just plain old H2O will

"fog" the plastic. The more water added, the worse the fogging

gets. With enough water, the surface of the plastic will begin

to dissolve. The only way to clean the plastic used in the

Logging Dial cover and the plastic used for the Tuning Chart

cover is to use oil. I used 10W machine oil (3 in 1 oil,

actually.) The oil cleaned the plastic surface and didn't cause

any change in the transparency. Another note on the Logging Dial

window, if this piece is dismounted only leave it dismounted for

enough time to clean it and the dial housing. This plastic piece

is fairly thick and if not secured by mounting screws it will

quickly begin to warp. I noticed the warp starting in about 15

minutes, so I remounted the plastic to allow it to retain its

proper shape. |

Front Panel Remount

- I had to touch-up all of the panel mounting screws with black

lacquer. Several were missing all of their paint but most just

had chips of missing paint. I mounted the two meters after I had

touched-up their mounting screws (and washers.) The most

difficult part of the front panel remounting is installing the

two chassis shims. These two pieces are mounted by the six

horizontal chassis screws. I had to have the six screws

protruding thru their respective panel holes to hold the two

shims in place while I guided the front panel into the proper

position to fully seat against the chassis and the side panels.

I also had to guide the four toggle switches along with the Gain

control and the Output Level control thru their respective panel

holes in order for the panel to fully seat. Once the panel is

seated all of the other panel screws were installed. All but two

of the panel to chassis mounting screws have nylock nuts that

complicate the panel installation, especially the six horizontal

chassis screws that have four of the nuts difficult to access

with a wrench. I first installed the other panel screws and nuts

but didn't fully tighten them. They were holding the panel in

place but allowed for minor movement. For the six horizontal

screws, the easiest method was to have the receiver upside down

as this allowed the best view of where the nuts had to go. Once

the nuts were installed I still didn't fully tighten the screws

yet. I still had to install the screws that mounted the chassis

withdrawal knobs. Once I had all of the panel mounting screws

and nuts installed and threaded together, then I could go ahead

and tightened all of the panel screws.

Each toggle switch had an flat washer, a hex nut and a dress

nut for their mounting. The switches and two controls use

external star locking washers that are mounted on the back side

of the panel and flat washers and hex nuts are used on the

front. The phone jack uses a special fiber insulator that has a

locating pin that has to be inserted into the mating hole in the

back of the panel. The phone jack body front just fits into the

recessed channel which keeps the phone jack from turning when

the panel nut is tightened. I had to make sure that two fiber

washers and one metal dress washer were used when installing the

phone jack nut. This was to provide the correct chassis

insulation and the proper spacing so the phone jack nut would

tighten up. |

| Reassembly

Notes - When I installed the metal spacer for the

band switch shaft I had to make sure that the spring washer was

mounted on the band switch shaft with the "fingers" facing up so

it pressed against the recessed area behind the spacer. This

spring provides a thrust load on the band switch shaft. When

installing the logging dial, it also had a spring that mounted

on the tuning shaft and loaded the logging dial. To synchronize

the logging dial, I first had to set the main tuning to the

minimum frequency on any band. I noted that the logging scale

actually is a little longer than the tuning scales but I had to

set the main dial to "0" on its logging scale. I then installed

the logging dial on the tuning shaft with the load spring in

place. I set the logging dial to read "0" on its scale and

pressed the logging dial firmly as far back onto the shaft to

load the spring and then tightened the set screws. I installed

the logging dial cover and checked the operation for any rubbing

or binding while tuning. I also checked that each 100s segments

on the main dial's logging scale matched the logging dial at "0"

or within a couple of divisions of "0." I then installed the

meter covers and then cleaned and installed the knobs.

I was pretty sure that during reassembly, with tightening up

the panel screws and the other mounting screws, some paint chips

were going to "pop off." I ended up with two fairly large chips

and several smaller chips. These were touched up with black

lacquer.

With everything back in place, retesting and troubleshooting

the Band 2 and Band 3 problems could begin. Oct 22, 2017 |

Minor Troubleshooting

- Problem one was with the DC Voltmeter reading very low.

Pressing on the meter face gently would result in the voltage

reading going up to normal, +220vdc. The problem was that I just

reinstalled the lug connections and didn't clean them first.

Cleaning with a brass wire brush got the terminals and lugs

clean and when reassembled, the voltage reading was normal.

Problem two was that the ANT. COMP. control wasn't indicating

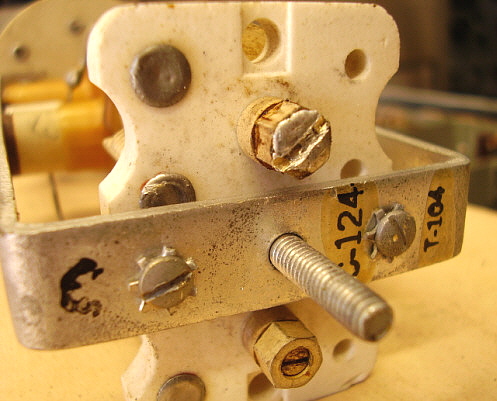

the air variable position correctly. The ANT. INPUT shield has

to be removed (easy to do - only four screws) to see the plates

of the condenser. I set the condenser per the manual,...full

mesh is 10 to the right side of the scale. There's a rotation

limiting pin on the extension shaft thru the front panel that

only allows 180 deg. of rotation so the air variable position

has to match the panel scale.

On to the serious problems,... |

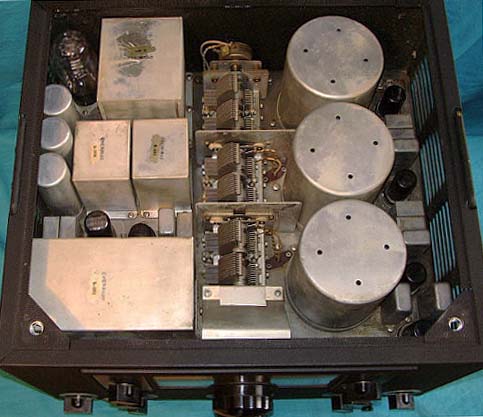

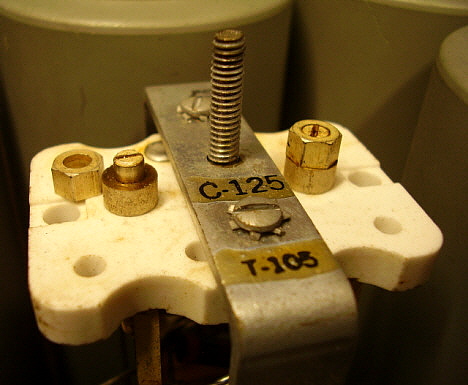

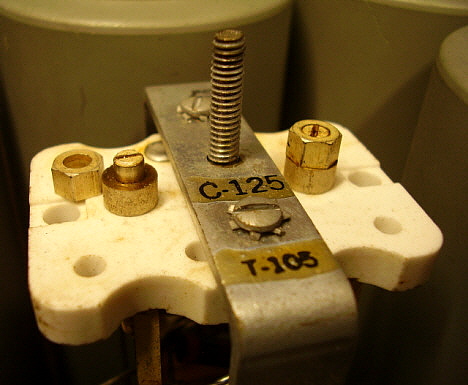

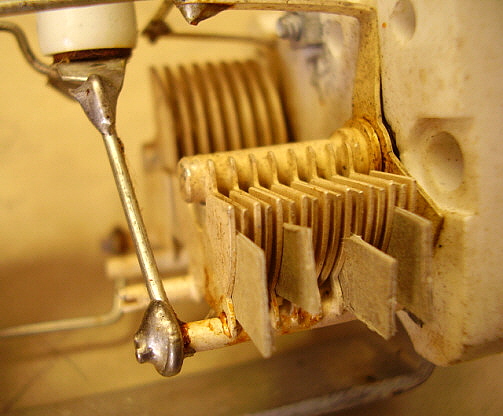

| Repairing

Split Hex-Collars on Air Variable Trimmer Capacitors

- So far, the problems had been minor stuff. I was now going to

find out why Band 2 and Band 3 were inoperative. I could hear a

few signals on Band 3 but they were very weak. Band 2 was dead.

I used a RF Signal Generator to inject a RMS voltage into the

Antenna Input to act as a steady, high-level signal. When

adjusting the trimmers to resonate the RF coils, the problem

became "painfully" obvious,...on Band 2, two of the air variable

trimmers had split hex-collars and the trimmer rotor had dropped

down and was "shorting" the rotor to stator plates which shorts

the RF coil which in turn takes the grid of that RF amplifier

tube to ground. I adjusted the rotors until they were fully

un-meshed which removes the short circuit but leaves that RF

coil "not tuned" and the rotor too low to mesh with the stator.

Enough signal leaks thru to tell that these are the defective

components keeping Band 2 from operating. I found that Band 3

had one split hex-collar trimmer that was already un-meshed.

This was why Band 3 seemed to work but had weak signals. Only

Band 1 and Band 4 had all good trimmers.

The repair of these split hex-collar trimmers requires the

removal of the defective RF coil assemblies. First remove the

shield-can by removing the top nylock nut and the four screws at

the base of the shield. Removal of the actual RF coil assembly

can be fairly difficult due to the 16 gauge buss wire used for

connections. This requires a fairly large soldering iron (or

gun, I used a Weller 250W gun.) On most of the buss connections

the wire is wrapped a half turn around the terminal. On some

wires, the joint can be heated and the buss wire lifted off of

the terminal with large needle nose pliers. Other joints may

require the use of a small pointed tool (like a small awl) to

get the buss wire bend started once the solder was molten. At

this point, long needle nose pliers can slightly unwrap the buss

wire from the terminal and then it can be lifted off of the

terminal. There are four buss wires and two stranded wires per

coil assembly that need to be removed. Once desoldered, then the

nylock nuts can be taken off and the coil assembly removed. Be

careful when doing the reinstallation of the buss wire onto the

terminals. If the buss wire was unwrapped too much it may break

when bending it back into position. Try to only unbend the buss

wire slightly when removing and then no problems should be

encountered when reinstalling. |

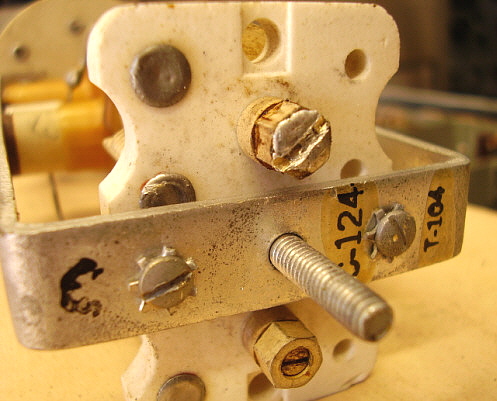

photo above: The hex-collar on the right is correct and not

split. The hex-collar on the left is split and has been taken

off to show the trimmer rotor shaft.

|

|

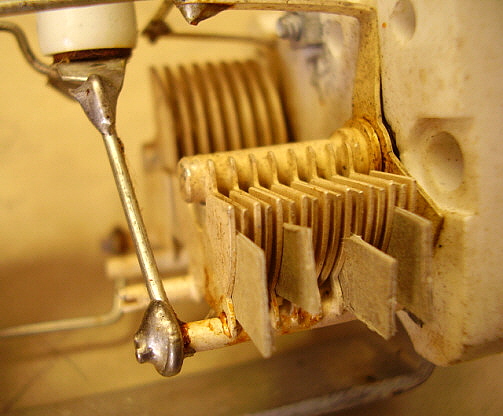

photo above: Cardboard shims are

installed between the rotor and stator plates to maintain proper

spacing for repair |

An ideal hex-collar repair would require access to a machine

shop to make a new hex-collar from 1/4" brass hex stock. The

shaft on the trimmer condenser is slightly tapered from 0.152"

up to 0.154" and this requires that the hex stock have a slight

taper also. The height of the collar is also important since the

press fitting of the collar will stop when the adjusting slot of

the rotor is at the top of the collar. This fit then has to

result in the proper spacing of the rotor and stator plates.

Original dimension for the height of the hex-collar was ~0.190"

and the new collar would also have this same dimension. The

final measuring involves having the hole perpendicular to the

top and bottom surfaces of the hex-collar to allow even movement

of the adjustment without binding. It's also possible to

correctly position the split hex collar on the shaft and then

drill and pin the collar to the shaft. The split should be

perpendicular to drill hole for highest strength. A very small

diameter steel pin will be necessary since the shaft is only

about 0.154" in diameter. The pin should be an easy "press fit"

since it's only holding the collar in position on the shaft.

Either of these two repair methods are

impractical for most restorers because we don't have access to a

machine shop. The next repair method described doesn't require

any special tools.

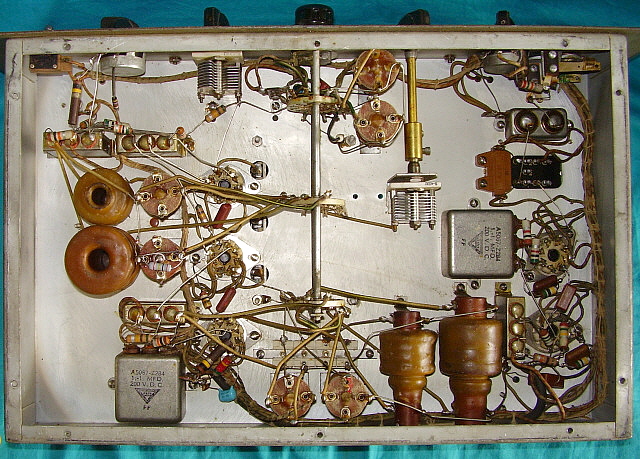

An easier repair of the split hex-collar is

to use solder to hold the hex-collar in place with the proper

spacing for the trimmer plates. Cardboard shim stock installed

between the rotor and stator bottom plates will provide a firm

stationary spacing for the plates. A minimum of four shims

should be used for best support of the rotor plates. I used

.022" thick cardboard that can be salvaged from small boxes or

the cardboard backing from tablets or from many other sources.

As long as the shim thickness is about .022" the plate spacing

will be correct.

The first step is to remove the RF coil assembly from the

receiver. I've tried to do this repair with the coil assembly in

place (just the shield-can removed) and it is almost impossible

to get the cardboard shims installed. There's just not enough

space for access and there's limited visibility, making the

whole operation impossible. Although it's difficult to unsolder

the 16 gauge buss wiring to remove the RF coil assembly, it's

easier than trying to do this procedure with the coil assembly

still mounted in the receiver. |

| Once the RF coil is removed, installing the

shims is easy. I use a pair of channel locks to gently lift the

rotor (with the hex collar installed so it will only move just

high enough.) I then slide in four shims. Now, release the

channel locks and remove the hex-collar. The slotted end shaft

will be at the correct height (for the hex-collar to be

sweat-soldered in place.) The slotted end of the shaft has to be

cleaned with a small jeweler's file but don't clean all the way

down to the stationary spacer. Just the upper half of the shaft

should be cleaned. Add some slight grooves with the file for the

solder to adhere to better. The inside of the split hex-collar

must also be cleaned with the small file. I used a large

soldering iron to "tin" the slotted shaft (250W Weller.) If the

hex-collar now won't fit on the shaft then file off some of the

solder until the hex-collar does fit entirely onto the shaft

with the bottom of the hex-collar flush with the stationary

spacer. Heat the hex-collar and shaft with the soldering iron

until it's hot enough that a very small amount of solder can be

melted. This solder will be wicked between the hex-collar and

the shaft and should provide a very strong bond. Add a little

more solder to the top slot area and create a slight solder

"dome" on the top. Let the solder cool and remove the shims.

I used a Dremel tool with a small cut-off wheel to make a slot

in the solder. This slot has to be widened by gently using a

hacksaw blade (blade alone - not the entire hacksaw.) Test the

trimmer rotation using a blade screw driver. It should now

adjust correctly. Check all of the wires and components on the

RF coil assembly to make sure there's been no damage during the

repair. If it looks okay, then reinstall the RF coil assembly

into the receiver. Oct 27, 2017

photo right: Finished

hex-collar repair showing the slot cut to allow adjustment of

the trimmer when RF coil is fully assembled. |

|

| Another

Problem with Band 3 - Band 2 was performing very well

after repairing the two defective trimmers. However, Band 3

still seemed to be lacking sensitivity. Injecting a modulated

signal into the Antenna Input revealed that the RF trimmers were

all working correctly on Band 3. Switching off the modulation

and switching to CW (BFO on) should have resulted in a

heterodyne signal but no change was noted in the signal. I

adjusted the frequency to the top end of Band 3 (sig gen and

receiver) and adjusted the BFO trimmer and what happened wasn't

unexpected. Of course, the trimmer rotor dropped as soon as it

was unmeshed. The non-operational BFO had seemingly reduced the

sensitivity because no signals could be demodulated. To repair

the BFO on Band 3 is very similar to repairing the split

hex-collars on the RF coils since it's exactly the same type of

trimmer. >>> |

>>> The BFO coil assembly for Band 3 and Band 4 was

removed from the receiver. The trimmer was repaired per the

procedure shown above. After the BFO assembly was reinstalled,

the BFO didn't work on either Band 3 or Band 4. This could only

have been caused by the common return for both trimmer

capacitors. I ended up removing the BFO coil assembly again,

just to check it over closely. I found a questionable solder

joint on the common buss wire return that looked like it might

have been cracked but that should have only affected Band 3.

Before I reinstalled the coil assembly, I carefully resoldered

all of the coil wire wraps to the terminals as a precaution. I

installed the coil assembly and soldered the four buss wire

connections and the stranded wire return connection. Upon

testing, both BFOs worked. The problem was probably due to the

coil wire wraps around the terminals as these looked like

questionable solder joints. The shield cover was installed and

then the BFOs adjusted for 1kc above the tuned frequency on Band

3 and Band 4. Oct 29, 2017 |

| Trimmer Capacitors

Split Hex-collars - Notes - This splitting of the

hex-collar on this style of trimmer condenser is fairly common.

This type of trimmer was very popular in the mid-thirties up

into the mid-fifties. They're found in Hammarlund Super-Pro

receivers (they are a Hammarlund part - "ACP" Trimmer,) all BC-348 receivers other than Q, N and J versions,

Navy RBB and RBC receivers, on and on. It's likely the problem

is due to poor storage conditions and metal fatigue due to age.

When the metal was new the hex-collar could expand and contract

with varying temperature cycles. However, years and years of

thermal cycling will cause the metal to become brittle and

eventually it will crack. Poor storage in garages or sheds only

results in thermal cycles that are even more extreme and rapidly

cause the metal to become brittle. There isn't much that can be

done today except to repair the trimmers as they are

encountered. |

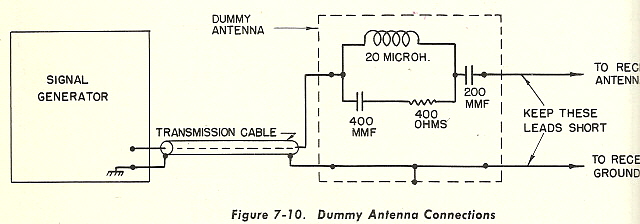

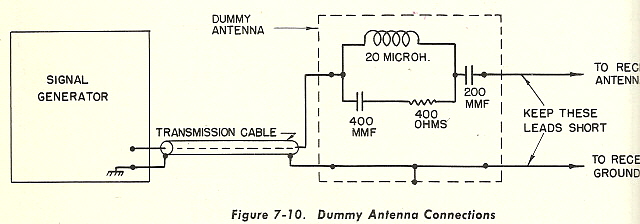

| Alignment

- The hex-collar trimmer repairs resulted in the RBA-1 now being

fully functional. The receiver requires a specific "dummy

antenna" to load the input regardless of the impedance of the

signal generator. Luckily, the schematic of the "dummy antenna"

is included in the NAVSHIPS manual. The parts required are one

20uH inductor, one 400 ohm carbon resistor, one 200pf capacitor

and one 400pf capacitor. The schematic is shown to the right.

The trimmers are all adjusted at the top end of each band. For

example, on Band 4, set signal generator to 600kc. Set receiver

to 600kc. With signal input to antenna input thru dummy antenna,

adjust all Band 4 trimmers for maximum deflection of the DB

meter. Reduce the GAIN control to compensate as the signal level

increases. Use lowest signal input that gives an indication on

the DB meter set at the lowest scaling. This is repeated for

each band.

The BFO is aligned at the top end and the bottom end of each

band. With 600kc unmodulated input and receiver tuned to 600kc,

switch on BFO. A 1kc heterodyne should be heard. Adjust BFO 4

trimmer to 1kc heterodyne, if necessary. Tune to 235kc and set

generator to 235kc. A 1kc heterodyne should be heard. >>> |

| >>> There are adjustments for the BFO inductance

for each band that are "thru the front panel." Two holes

are under the tuning chart (Left = BFO 3 and Right = BFO

1) and the two other holes have acorn head screw plugs

that are removed to access the holes (Left = BFO 4 and

Right = BFO 2.) Adjust BFO 4 inductance for a 1kc

heterodyne, if necessary. Check both the upper and the

lower frequencies to verify that the BFO is actually 1kc

higher than the tuned frequency. Tune the receiver up

about 1kc higher in frequency and the BFO should be zero

beat if it is set 1kc higher than the tuned frequency.

Repeat the adjustments until BFO tracks. Repeat the

procedure for each band. |

|

|

|

| Is the Dummy Antenna

Really Necessary? - When the RBA-1 was in service and

being aligned at a USN depot, it was unknown to the radio repair

technicians what type of antenna was going to be connected to

the receiver. Shipboard antennae were quite different from USN

land station antennae. What the Dummy Antenna does is provide a

somewhat constant impedance load to the receiver that behaves

more like a typical antenna would than a direct connection to

the Signal Generator output would. The variability of what type

of signal generator was used probably also entered into the

alignment problems. Using the Dummy Antenna generally ensured

that every RBA would come thru alignment with the same

performance specification regardless of where it was going and

what type of antenna it was going to be used with. Today, most

of us are going to use one specific antenna with the receiver.

If it's an end-fed wire of considerable length, it might be

better to align the receiver with this antenna connected. Couple

a signal generator output to the receiver's antenna input by

using a small "antenna" on the signal generator output

consisting of a three foot wire that's near the receiver. This

will provide a frequency specific signal that can be adjusted

for amplitude, frequency and modulation (if needed.) This

simulates the receiver actually "picking up" a transmitted

signal and aligning the receiver for the best operation with the

antenna the is going to be used. In this type of set-up, the

load of the antenna is just as it is when the receiver is in

operation. This then provides an alignment that is exactly for

the actual antenna that is going to be used. Tuned loops are a

bit more difficult and experimentation would probably be best

with these types of antennae. Usually, the loop can be tuned for

the highest frequency on the band and then the receiver aligned

to that impedance load. Since there is no alignment adjustment

for the low end of the band, check to see if when the loop and

the receiver are tuned to the low end of the band that the

performance is the same as the upper end. When experimenting

with various antennae and alignment, only the antenna coils will

be affected and only those coils will require adjusting. |

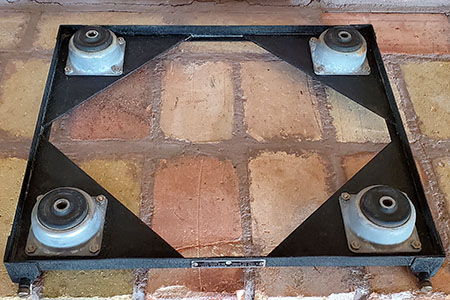

| Cabinet

Restoration - I really didn't want to do an entire

respray of the cabinet. If I did, it wouldn't match the receiver

front panel. There was a lot of paint missing, especially on the

top. The first step was to remove the two data plates and then

to clean the cabinet's remaining paint with a brass wire brush

and Glass Plus. I then used black nitrocellulose lacquer to

repaint all of the areas that were bare metal. I let this set

for a day. The next step was to mix a very thin batch of lacquer

and thinner - about 2:1 ratio. With gloves on, I then used a

cotton pad saturated in thinned lacquer to "go-over" the entire

cabinet. This hides the "touch-ups" and ends up with the cabinet

looking in good original (although "touched-up") condition. I

then reinstalled the data plates and installed the receiver into

the cabinet. |

Antenna Connection to

Navy Coax Fitting - These Navy coax fittings are not

common making them difficult to find. There are two easy ways to

connect an antenna feed line to the RBA (or the RBB or RBC) that

allow use of coaxial cable and provide a good connection to the

receiver. Use a double female SO-239 adaptor. The outer diameter

will just fit into the Navy coax barrel. It will slightly

"thread" itself and make good electrical contact. However the

pin at the bottom of the Navy fitting is too far away to make

positive contact with the center conductor of the SO-239

adapter. I usually roll .010" thick brass or copper sheet metal

into a tube. The tube can then be inserted into the SO-239

adapter center barrel. The other end of the tube should be about

a .375" extension and the open end of it will fit over the Navy

center conductor pin. Another way to connect coax is to use a

female banana pin plug (these do fit onto the Navy center

conductor pin.) The coax center conductor can be soldered to the

female banana plug. The shield can have a drain wire soldered to

it and it can be connected to the ground lug on the back of the

RBA cabinet. |

|

Performance - Since I had the RBA-1 set up out in the

shop, I had to use the 270 foot long, center fed dipole. Since

the antenna is fed with open transmission line, I just

disconnected the two wires from the antenna coupler and, using

clip leads, shorted them together and then used a single 14

gauge stranded wire to connect the feed line to the receiver.

Perhaps this acts like a large "T" antenna that has the 77 feet

of feed line acting somewhat as a vertical with a large 270 foot

long "top hat." The "T" configuration was a popular antenna

during the early days of radio. During some of my initial

testing and troubleshooting I tuned in BO 359kc, the NDB from

Boise, Idaho - and this was during the day! Quite a

surprise,...but when I aligned Band 3 to the antenna, I tuned in

HDN 211kc in Gooding , ID, HLE 220kc in Hailey, ID and TCY 204kc

in Tracy, CA - during mid-day! Additionally, the normal daytime

copy of FCH 344kc in Fresno, CA, MOG 404kc in Montague, CA and

CC 335kc in Concord, CA were all present. None of these were

newly copied NDBs but I've never heard BO, HLE, HDN or TCY

during the day. The next day, I tuned in DC 326kc in Princeton,

BC, Canada. Incredible! This was at 13:30 in the afternoon and I

was hearing British Columbia. Another note, these stations were

being copied on loudspeaker, not 'phones. More experimenting

with other LW receivers will be necessary to determine if this

is RBA-1 performance (unlikely) or if it's antenna

performance (likely.)

Other daytime copies included the USN MSK stations NLK 24.8kc

in Jim Creek, WA, NAA 24.0kc in Cutler, ME, NPM 21.4kc in

Lualualei, HI and, although substantially weaker, HOLT 19.8kc in

Exmouth, Australia. These are very strong stations that are easy

copy, day or night.

The INPUT CLPG and ANT COMP. controls are very important and

must be adjusted for each band. In fact, the ANT COMP. should be

peaked every 10kc or so.

The OUTPUT control and OL switch are used as an audio AVC.

Once set, the audio output won't increase beyond the level set.

When there's a lot of static crashes or "popping" noises, the

OUTPUT (limiter) control helps keep your ear drums intact when

using 'phones. Nov 1, 2017 |

|

| The following is a log of the stations tuned with the RBA-1

using the 270' CF with 77' of ladder line with wires shorted

together. There are six listening sessions within about a seven

week period that include both daytime and nighttime listening

periods. With the six sessions, I tuned in 100 different NDBs of

which six were newly heard stations. Greatest DX was DDP 391kc

in Puerto Rico which isn't unexpected since it runs 2KW. Other

DX (for a western US location) was FIS 332kc in Key West, FL,

YMW 366kc in Maniwaki, Quebec and DB 341kc in Burwash Landing,

Yukon. Daytime copy of British Columbia stations YZA 236kc and

DC 326kc was unexpected but was certainly due to the time of

year. Best LW reception is usually in November and December. The

large antenna was probably also a factor. Maybe the RBA-1 was a

factor, too. |

|

RBA-1, CFT-46154,

SN: 972 NDB Log

Antenna is 270' CF with 77' ladder line

with feedline wires tied together. Height is 30 feet.

Stations are listed in "as heard" order. Pacific Time. Newly

Heard NDBs - Maroon with asterisk. Unless otherwise indicated, all

reception is using 600Z ohm 'phones as audio reproducers.

|

Nov. 3, 2017 05:55-06:35 - Cndx Xlnt,

Quiet |

Nov. 9, 2017 19:10-19:40 - Cndx Poor,

Noisy |

Nov. 18, 2017 13:30 - Cndx Xlnt |

Dec 23, 2017 19:05-19:50 Cndx Xlnt |

1. UAB -200kc - Anahim Lake, BC, CAN

2. IP - 201kc - Mobile, AZ

3. YBL - 203kc - Campbell River, BC, CAN

4. TCY - 204kc - Tracy, CA

5. HDG - 211kc - Gooding, ID

6. LU - 213kc - Abbottsford, BC, CAN

7. QU - 221kc - Grand Prairie, AB,

CAN *

8. HLE - 221kc - Hailey, ID

9. YKA - 223kc - Kamloops, BC, CAN

10. LWG - 225kc - Corvallis, OR *

11. CG - 227kc - Castlegar, BC, CAN

12. VG - 230kc - Vermillion, MB,

CAN *

13. OKS - 233kc - Oshkosh, NE

14. BR - 233kc - Brandon, MB, CAN

15. OJ - 240kc - High Level, AB, CAN

16. AVQ - 245kc - Tucson, AZ

17. YCD - 251kc - Vancouver Is., BC, CAN

18. LW - 257kc - Kelowna, BC, CAN

19. HCY - 257kc - Cowley, WY

20. SLE - 266kc - Salem, OR

21. YK - 269kc - Castlegar, BC, CAN

22. XS - 272kc - Prince George, BC, CAN

23. GYZ - 280kc - Guernsey, WY - USCG

24. CEP - 278kc - Ruidoso, NM

25 QD - 284kc - The Pas, MB, CAN

26. EKS - 286kc - Ennis, MT

27. YYF - 290kc - Penticton, BC, CAN

28. TOR - 293kc - Torrington, WY

*

29. TV - 299kc - Turner Valley, AB, CAN

30. ONO - 305kc - Ontario, OR

31. UNT - 312kc - Penticton, BC,

CAN *

32. DC - 326kc - Princeton, BC, CAN

33. POA - 332kc - Hilo, HI

34. RYN - 338kc - Tucson, AZ

35. ZU - 338kc - Whitecourt, BC, CAN

36. DB - 341kc - Burwash Landing, YK, CAN

37. BKU - 344kc - Baker, MT

38. FCH - 344kc - Fresno, CA

39. SBX - 347kc - Shelby, MT

40. NY - 350kc - Enderby, BC, CAN

41. AL - 353kc - Walla Walla, WA

42. MEF - 356kc - Medford, OR

43. BO - 359kc - Boise, ID

44. YQZ - 359kc - Quesnel, BC, CAN

45. RPX - 362kc - Roundup, MT

46. 6T - 362kc - Foremost, AB, CAN

47. DPY - 365kc - Deer Park, WAWH2XVN copied on 183kc

at 05:57 |

1. ZQ -

410kc - Sir Wilfred Laurier CCGS, BC, CAN

2. MW - 408kc - Moses Lake, WA

3. MOG - 404kc - Montegue, CA

4. QQ - 400kc - Comox, Vancouver Is, BC, CAN

5. SB - 397kc - San Bernardino, CA

6. ULS - 395kc - Ulysses, KS

7. DDP - 391kc - San Juan, Puerto Rico

8. YWB - 389kc - West Bank, BC, CAN

9. JW - 388kc - Pigeon Lake, AB, CAN

10. WL - 385kc - Williams Lake, BC, CAN

11. PI - 383kc - Tyhee, ID

12. GC - 380kc - Gillette, WY

13. OT - 378kc - Bend, OR

14. EHA - 377kc - Elkhart, KS

15. EX - 374kc - Kelowna, BC, CAN

16. LV - 374kc - Livermore, CA

17. MF - 373kc - Rogue Valley, OR

18. HQG - 365kc - Hugoton, KS

19. DPY - 365kc - Deer Park, WA (2nd copy)

20. RPX - 362kc - Roundup, MT (2nd copy)

21. BBD - 380kc - Brady, TX

22. AP - 378kc - Active Pass, BC, CAN

23. MR - 385kc - Monterey, CA

24. HAU - 386kc - Helena, MT

25. CSB - 389kc - Cambridge, NE

26. PNA - 392kc - Pinedale, WY

27. DQ - 394kc - Dawson Creek, BC, CAN

28. FN - 400kc - Ft. Collins, CO29. MM - 411kc -

not on Navaid (MW w/o the dit?)

30. INUU - 395kc - I've copied this beacon many

times but have never found it on any Navaid. Oil Rig?

NOTE: Conditions were particularly noisy due

to a passing storm front and wind causing severe antenna

static. One of the problems with using an outdoor

antenna. Even indoor loops will respond to weather

fronts however.

|

Nov. 17, 2017, 19:00 - Cndx

Poor |

1. FS - 245kc - Sioux Falls, SD

2. YZA - 236kc - Ashcroft, BC,CAN

3. XC - 242kc - Cranbrook, BC , CAN

High level of static from passing front. Static was

so bad that OL didn't help. These are new copies for

RBA-1 only. |

As an illustration of how fast signal

cndx can change, I was running the RBA-1 in the early

afternoon on the loudspeaker. Copied for long time

periods the following stations,... 1. HLE -221kc -

Hailey, ID

2. HDG - 211kc - Gooding, ID

3. YZA - 236kc - Ashcroft, BC, CAN

The static level was very low and these stations were

easy copy on loudspeaker. This was at 1:30PM in the

early afternoon!

|

Nov. 22, 2017 21:10-21:40 -

Cndx OK |

1. LU - 213kc - Abbotsford, BC, CAN

2. RL - 218kc - Red Lake, ON, CAN - #

3. QU - 221kc - Grand Prairie, AB, CAN

4. YKA - 223kc - Kamloops, BC, CAN

5. DN - 225kc - Dauphin, MB, CAN - #

6. CG - 227kc - Castlegar, BC, CAN

7. VG - 230kc - Vermillion, MB, CAN

8. YZA - 236kc - Ashcroft, BC, CAN

9. AVQ - 245kc - Tucson, AZ

10. YCD - 251kc - Van. Is, BC, CAN

11. HCY - 257kc - Cowley, WY

12. LW - 257kc - Kelowna, BC, CAN

13. YK - 269kc - Castlegar, BC, CAN

14. GUY - 275kc - Guymon, OK - #

15. CEP - 278kc - Ruidoso, NM

16. YYF - 290kc - Penticton, BC, CAN

17. TOR - 293kc - Torrington, WY

18. ONO - 305kc - Ontario, OR

19. VC - 317kc - LaRonge, SK, CAN - #

20. MA - 326kc - Midland,TX - #

21. DC - 326kc - Princeton, BC, CAN

Static level was moderate even though weather and

wind were calm. Most are repeat copy but five new

stations to this receiver (marked with #.)

Total NDBs copied with this RBA-1 = 100

Total newly heard NDBs = 6

|

|

1. GDV - 410kc - Glendive, MT #

2. MW - 408kc- Moses Lake, WA

3. QQ - 400kc - Comox, BC, CAN

4. ENS - 400kc - Encenada, BCN, MEX #

5. FN - 400kc - Ft. Collins, CO

6. DQ - 394kc - Dawson Creek, BC, CAN

7. YWB - 389kc - West Bank, BC, CAN

8. WL - 385kc - Williams Lake, BC, CAN

9. HAU - 386kc - Helena, MT

10. YPW - 382kc-Powell River, BC,CAN#

11. GC - 380kc - Gillette, WY

12. K2 - 378kc - Olds-Didsbury, AB, CAN#

13. EX - 374kc - Kelowna, BC, CAN

14. YK - 371kc - Yakima, WA#

15. YBV - 370kc - Berens River,MB,CAN#

16. SX - 367kc - Cranbrook, BC, CAN#

17. YMW - 366kc - Maniwaki, QC, CAN#

18. HQG - 365kc - Hugoton, KS

19. AA - 365kc - Fargo, ND#

20. BF - 362kc - Nolla-Seattle, WA #

21. PTT - 356kc - Pratt, KS#

22. IN - 353kc - International Falls, MN #

23. PG - 353kc - Portage, MB, CAN #

24. SBX - 347kc - Shelby, MT

25. MNC - 348kc - Shelton, WA #

26. FCH - 342kc - Fresno, CA

27. RYN - 338kc - Tucson, AZ

28.

LF - 336kc - LaSalle, MB, CAN *

29. FIS - 332kc - Key West, FL #

30. DC - 326kc - Princeton, BC, CAN

31. MA - 326kc - Midland, TX

32. YQF - 320kc - Red Deer, AB, CAN #

33. VC - 317kc - LaRonge, SK, CAN

34. YYF - 290kc - Penticton, BC, CAN

35. EKS - 286kc - Ennis, MT

36. CEP - 278kc - Ruidoso, NM

37. XS - 272kc - Prince George, BC, CAN

38. YK - 269kc - Castlegar, BC, CAN

39. ZSJ - 258kc - Sandy Lake, ON, CAN #

40. ZYC - 254kc - Calgary, AB, CAN #

41. YCD - 251kc - Vancouver Is.,BC, CAN

42. FS - 245kc - Sioux Falls, SD

43. YZA - 236kc - Ashcroft, BC, CAN

44. FOR - 236kc - Forsyth, MT

Xlnt cndx. One newly heard "LF 336kc" and 19 new

copies for this receiver marked with #. |

|

|