| References: 1.

Hammarlund Owner's Manuals for

SP-10. SP-110L, SP-200-X and SP-400-X - These provide information on design intent

and expected performance in addition to schematics, alignment and other

information.

2. Rider's Perpetual

Troubleshooter's Manuals - Various volumes contain

information on the Comet -Pro, SP-10, SP-100 and SP-200. Many times this

is the exact same information from the owner's manuals.

3. U.S. Army Signal Corps -

TM11-866 - This Army manual contains a wealth of information

on the SP-200 series, specifically the BC-779, BC-794 and BC-1004

receivers. It also includes the various power supplies, the R-129/U

receiver and detailed circuit descriptions and drawings.

TM11-896 provided details

on the 1948 Wickes' modified BC-794 receiver.

Instruction Book for Super Pro

for Signal Corps, 1935 SPA receiver -this is the Hammarlund provided

instruction book that came with the SPA receiver. The contents are

almost identical to the later Hammarlund SP-10 manual.

4. QST - Various issues from

1936 to 1948 - Contain original ads that provide a time line

for engineering and model changes, company performance expectations,

sometimes interesting users.

5. Communications Receivers -

The Vacuum Tube Era: 1932-1981. Raymond S. Moore - The best

reference book on communications receivers, provided Hammarlund history

and general specifications on the receivers.

6. The Hammarlund Historian -

Website - Provided the Oscar Hammarlund history. The website

provides a lot of information on the SP-600 series.

7. Popular Mechanics

- December 1937 issue contains the article on the SP-100SX - shown in

its entirety above in the SP-100 section.

8. BAMA - Boat Anchor Manual

Archives - source for Hammarlund Super-Pro manuals on-line -

source of the manual for the SP-100-LX (although it's listed as SP-110L.)

9. Thanks to Todd KA1KAQ, Steve

W8TOW, John W3JN for their help and detailed information on

their Pre-war Super-Pro receivers and variations they've encountered.

10. Thanks to Steve Bringhurst

for providing info on these websites showing the foreign military Super

Pro copies, the Australian AMR-200,

http://www.royalsignals.org.uk/photos/vk4kdp.htm

and the Russian KV-M,

http://www.oldradio.cqham.ru/war/KV-M.html Thanks to Karl-Arne

Markstrom, SMŘAOM, the the information on the Swedish MRM-5/SP-100

receivers.

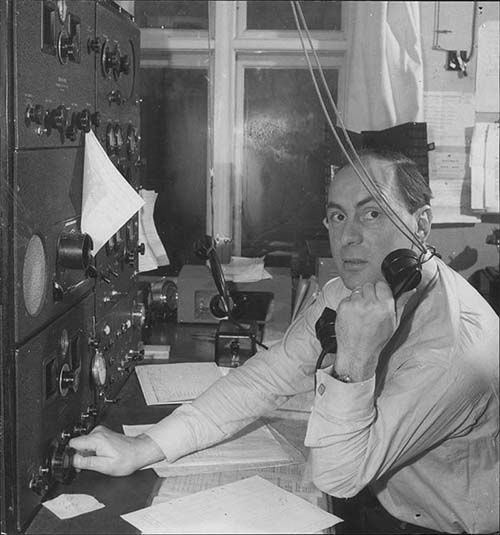

11. Thanks to Inland Marine

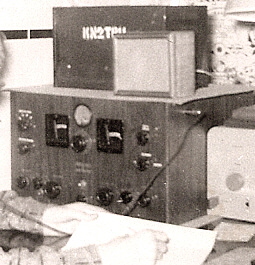

Radio History Archive for the photo of WMI in 1937. Here is

their website URL:

http://www.imradioha.org/WMI.htm

|