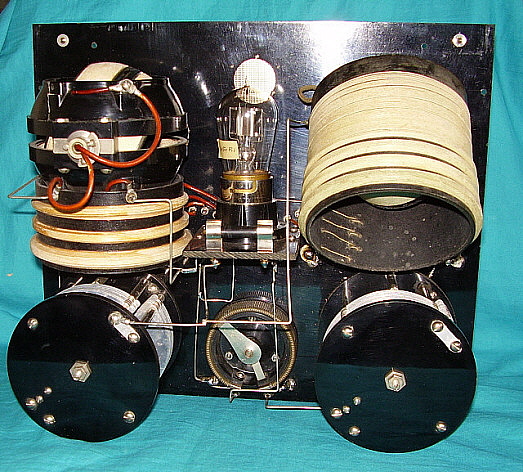

Test Results - On March 17, 2009, from

22:00 to 22:30 PDT, I was able to tune in 25 NDBs from the USA and

Canada. Best DX was ZP on 368kc located at Sandspit, Queen Charlotte

Islands, British Columbia. ZP is not a difficult station to receive as

it is running at least 1KW. Most difficult was probably ULS 395kc

located in Ulysses, Kansas. BBD 380kc located in Brady, Texas was also

tuned in. These both are 25 watt "marker beacons" with a distance of

about 1500 miles from Virginia City, Nevada. Other interesting NDBs

tuned in were WL 385kc in Williams Lake, BC, Canada and MW

408kc Moses Lake, Washington.

Tuning in NDBs is made more difficult because of the hand-capacitance

problem. By tuning the station slightly lower in frequency than

resonance, when the hand is removed the drop in capacitance increases

the tuned frequency and hopefully the station will be then tuned to

resonance. With a little practice it becomes almost instinct to tune

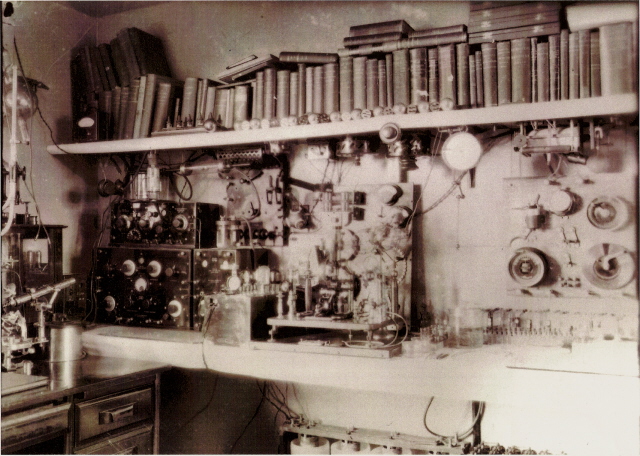

NBDs in this manner when using the Kennedy Universal operating

as an autodyne detector. |

Log of NDBs received March 17, 2009 from 22:00 to 22:30

PDT using Kennedy Universal SN5403 with 525 amplifier.

338kc - PBT - Proberta, Red Bluff, CA

368kc - SIR - Sinclair, WY

338kc - RYN - Tuscon, AZ

371kc - TVY - Tooele, UT

332kc - LBH - Portland, OR

383kc - PI - Tyhee, ID

335kc - CC - Buchanan AF, Concord,CA

385kc - WL - Williams Lake, BC, CAN

329kc - TAD - Trinidad, CO

389kc - YWB - West Bank, BC, CAN

344kc - FCH - Fresno,CA

380kc - BBD - Brady, TX

350kc - NY - Enderby, BC, CAN

395kc - ULS - Ulysses, KS

351kc - NO - Reno, NV

400kc - QQ - Comox, Van.Is.,BC, CAN

359kc - BO - Boise, ID

404kc - MOG - Montegue, CA

356kc - MEF - Medford, OR

408kc - MW - Moses Lake, WA

368kc - ZP - Queen Charlotte Is,BC,CAN

414kc - LYI - Libby, MT

367kc - SX - Cranbrook, BC, CAN

411kc - RD - Redmond, OR

371kc - ITU - Great Falls, MT |

NDB Stations tuned in March 29, 2009LFA - 347kc - Klamath

Falls, OR

CVP - 335kc - St. Helena, MT

DC - 326kc - Princeton, BC, CAN

ONO - 305kc - Ontario, OR

YYF - 290kc - Penticton, BC, CAN

XC - 242kc - Cranbrook, BC, CAN

GLS - 206kc - Galveston, TX

AEC - 209kc - Base Camp, NV

SF - 379kc - SF Int'l AP, SF, CA

|