|

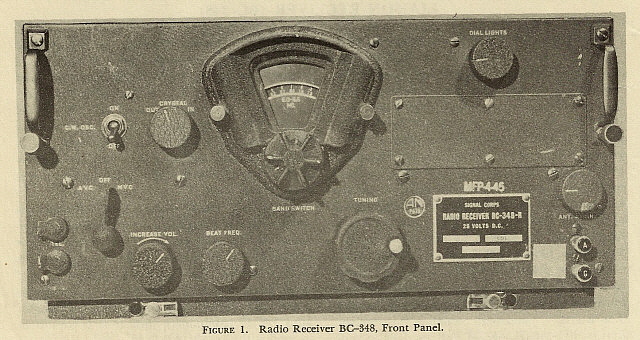

Before the BC-348 came

about there was an earlier version of this famous Aircraft Receiver. It

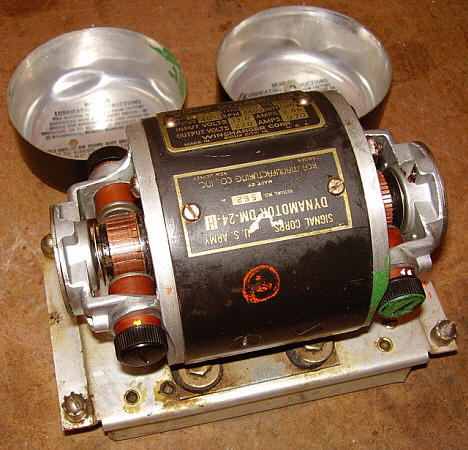

was the BC-224 and it was designed by RCA around 1935. It was a 12 volt DC operated

receiver that provided B+ via an onboard dynamotor. The first BC-224

receivers had the tuning dial at the far left of the

front panel giving the receiver a dramatically different appearance.

When the BC-224 was first produced most aircraft systems ran on 12-14vdc.

However, by the late-thirties, many aircraft systems were beginning to

use 24-28vdc which required RCA to develop another receiver to run on 28vdc

which was designated as the BC-348. Simultaneous with the release of the

BC-348, RCA redesigned the BC-224 to have the same external appearance

as the new BC-348. All versions of these early receivers were built by RCA Manufacturing Co.,

Inc., a subsidiary of RCA that built most of their commercial and

military contracts. Both versions, the BC-224 and the BC-348, were built

up to 1942, when contacts for the BC-224 versions stop. All BC-224

receivers were built by RCA Manufacturing Co., Inc. with the exception

of one contact. The BC-348 contacts continued through WWII with the

greatest quantities built during the 1943-44 time period.

The BC-348 operates on

24-28vdc with the high voltage (~+220vdc) provided by an internal

dynamotor. Over 200,000 BC-348 receivers were built during WWII by many

different contractors building many different versions within that time

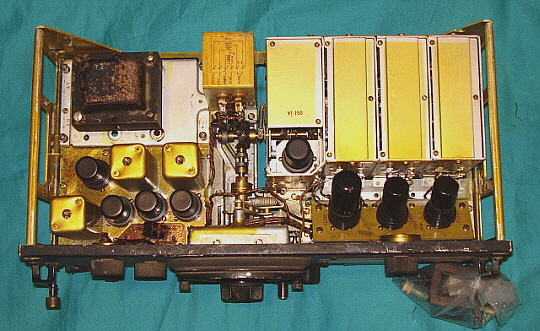

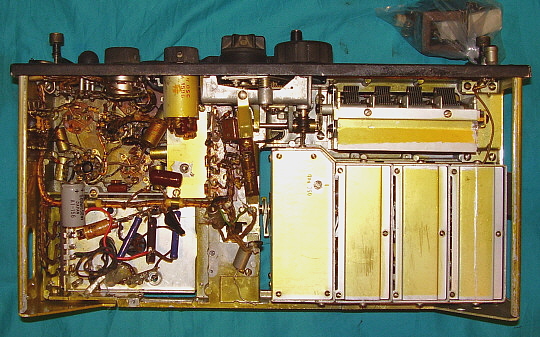

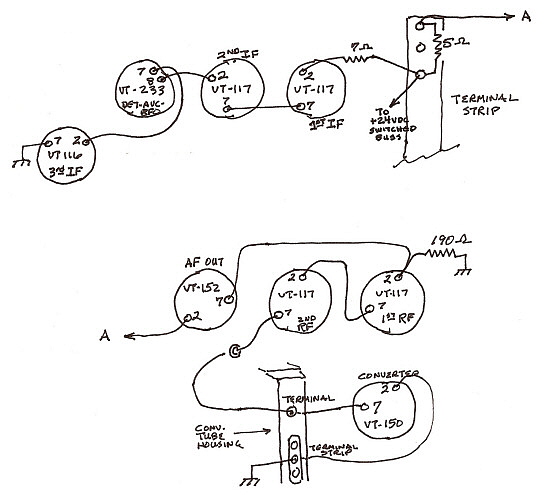

period. The "Early" circuit used eight tubes with the heaters originally wired

in series-parallel for 24vdc operation (two parallel strings of four 6

volt tube heaters in series would operate on 24vdc.) The "early" circuit

provided two RF amplifiers, a Mixer, a Local Oscillator, an IF amplifier

stage, a combination 2nd IF amp and BFO, a combination 3rd IF amp and

Detector/AVC followed by a type 41 audio output stage (this was changed

to a 6K6 in some later versions.) Early versions also will have a 991 neon lamp

acting as a regulator on the local oscillator and will provide

an antenna trim control. A selectable crystal filter was also included

in the circuit. The dual dial lamps were adjustable for brightness and

were wired in series through a potentiometer and fixed resistor.

Frequency coverage was from 200-500kc (not on the B or C version) and

1.5-18mc. The audio output impedance was internally selectable at "low

Z" which was around 300 Z ohms or "high Z" which was around 4000 Z ohms.

Some BC-348s will have a decal on the front panel indicating if the "low

Z" was optioned. During the middle of

WWII, the BC-348-J, N and Q "Later Version" of the receiver was

introduced. This new version had to be interchangeable with the earlier

BC-348 so physically both versions appear almost identical. Inside,

however, several changes were made to reduce the cost of building the

BC-348 but still maintaining its high level of performance. The "later"

version reduced production costs by simplifying the construction and

component mounting which additionally made depot repairs of these

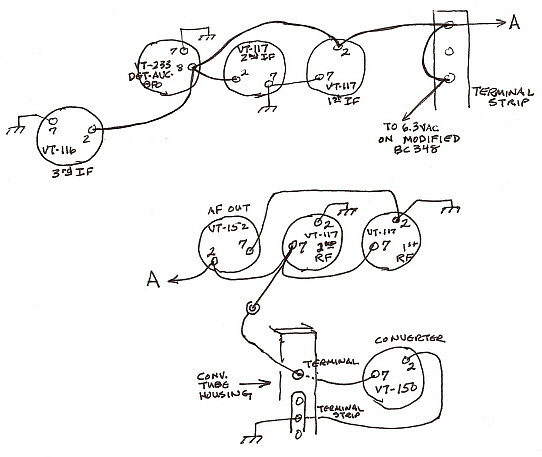

"later" receivers much easier. The "later" circuit used two RF amplifiers, a

converter stage, three IF amplifiers, a duplex diode/triode provided

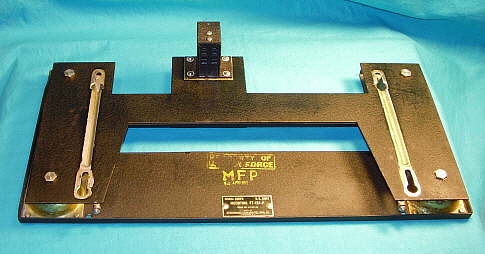

Detector, AVC and BFO functions and a 6K6 provided the audio output.When the receiver was installed on its FT-154

shock mount and installed in the aircraft, an eight pin Jones plug mated

with a receptacle and cable that exited from the rear of the mount

containing the 28vdc input, the remote stand-by relay function and an

audio output line. The BC-348 was generally interconnected with the

transmitter to control boxes allowing the

transmitter's control relay to provide antenna switching, receiver

stand-by and providing side tone monitoring which allowed for full

"break-in" keying.

Since there are so many variations, military

radio collectors have generally divided the BC-348 into two groups,

"early" types (B, C, E, H, K, L, O, P & R) referred to as the "Grid Cap

Tubes" version and the "later"

versions (J, N & Q) referred to as the "Single-Ended Tubes" version. Many different contractors built BC-348s but

Wells Gardner & Co. probably built the greatest quantity of receivers and

is the most commonly seen contractor-manufacturer. Estimated production

of the entire BC-348 line exceeds 200,000 receivers making it one of the

most commonly found WWII aircraft receivers today.

The BC-348 became available as surplus almost immediately after WWII

ended. The typical price was around $100 for a receiver that was in its

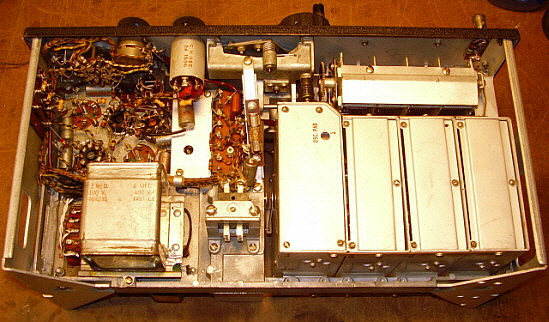

original crate and about $50 for a receiver that was in good-used condition. The dynamotor was

still installed in all receivers offered at the time but many surplus dealers

were offering to replace the

dynamotor with an AC power supply for around $15 extra. The actual AC

power supply conversion was fairly simple and the operation of the

receiver usually wasn't compromised other than probably adding some hum

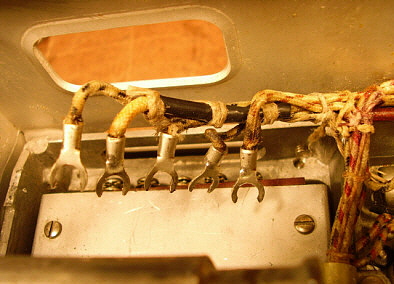

to the audio output. All of the

dealer power supplies were built with the

cheapest parts available, used a simple pi-filter and were undoubtedly

built and installed as quickly as possible by technicians possessing

limited abilities.

Since most surplus dealers added an AC power supply to the BC-348 (and every surplus conversion book

advocated this modification along with many other "ham-type" mods,) nearly every ham-owner

thought they were capable of converting the receiver into anything that was

considered necessary for successful operation. The upshot is today it is

almost impossible to find a BC-348 that hasn't been modified in some

manner.

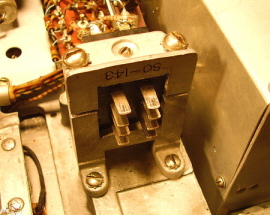

There were at least two

different types of military conversion AC power supplies that show up

occasionally. Hallicrafters produced an AC-operated power supply that could be added

to the BC-348 by the military. It was designated as EP-298. Very few

ever show up so the production quantity must have been very small

(uninstalled examples turn up occasionally.) The

only installed example I've seen photos of was of a BC-348 used by the Navy. It's

likely that the AC-operated BC-348 requirement was post-WWII and was

probably for surveillance or some other ground-based application. The Hallicrafters' EP-298 would have required some conversion rework to the

BC-348 and the installation would have been performed by depot higher echelon level

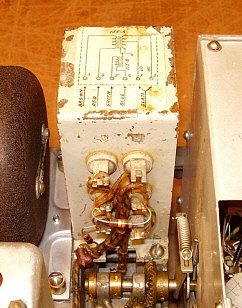

technicians. The second type of military AC-operated BC-348 is the version used

by the Air Force designated as the BC-348-S. The contractor was Belmont

Radio who, apparently, rebuilt BC-348 DC-receivers into a very limited

number of these AC-operated versions for ground use. The contract was

post-WWII.

Many BC-348s

owners actually do want to operate their receiver on the AC house line.

Nowadays, an all-original, dynamotor equipped BC-348 should NEVER

be converted to AC operation. Original receivers are very rare. However,

at least 98% of the surviving BC-348 receivers have already been

converted to AC,...they just need a little help to achieve the great

performance the BC-348 is capable of.

Almost always this must involve rebuilding the existing AC power into a

unit that filters properly and provides the required negative bias

voltage (that many surplus dealers and ham-sters forgot about.) A

well-designed AC power supply must have the following,...dual section

filtering (two filter chokes) for reducing hum to the imperceptible

level. The power transformer CT and negative filter capacitor returns

must connect to B- and B- should not be connected to chassis for proper filtering

and proper bias voltage. The AC power supply must be

turned "ON" by using the AVC-MVC switch (as original.) The proper SO-143

connection must be utilized for the AC input. If possible the PL-103 plug

and FT-154 should be utilized. If these suggestions are incorporated in

the AC power supply design and the receiver is given a thorough rebuild

and a full IF/RF

alignment that includes proper adjustment (or repair) of the Crystal Filter operation, the performance of

the AC-operated BC-348 will be excellent (better than the original

dynamotor operation) and the receiver can become an

easy-to-use asset to the mil-rad station. Plans for dual section

filtered, AC power supplies are in Part 3 of the article.

Today, with the

increasing popularity of hams running completely military radio

stations, the BC-348 is often being used as the station receiver.

Sometimes this is because the original military configuration requires

its use, other times because the operator knows that it's such a great

performing receiver - a receiver that "does so much,

so well, with so little." Fabulous military looks, excellent sensitivity and

good selectivity (when the IF is properly aligned and you actually use

the Crystal Filter) have made the BC-348

a favorite among the military radio enthusiasts, knowledgeable hams and

collectors of WWII airborne radio equipment.

|