|

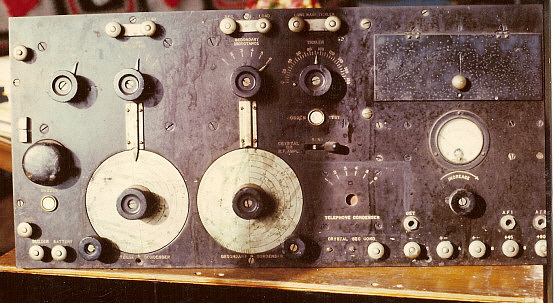

Circuit Description

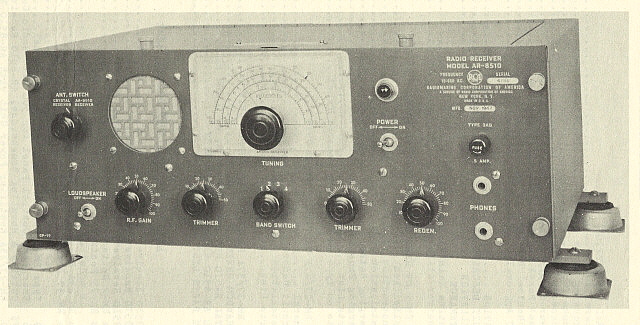

- The AR-8516 was

a thoroughly modern (well, for the late-fifties,) complex communications receiver that used 18

tubes in a single, double or triple conversion superheterodyne circuit. The

receiver used a variably-tuned IF covering 1.09 to 3.09mc or 2 to 4mc.

The fixed-frequency IFs were at 455kc and 45kc. Single conversion was

used in the first five bands covering 80kc up to 4mc. Bands 1-4 span

different widths of the LF and MF spectrum and, along with Band 5, these

single conversion bands tune from left to right being from high to low

in frequency. From 2mc up to 30mc is

covered in fourteen 2mc-wide bands. Band 5 (2-4mc) is single conversion

but Bands 6-18 are double conversion. The double conversion bands (Bands

6-18) tune left to right being low to high in frequency. The total frequency coverage is

from 80kc up to 30mc in 18 tuning ranges. Seven crystals are utilized in

the Crystal Oscillator with only two crystals used uniquely. The other

five crystals are used in various fundamentals and harmonics for a total of 13 crystal

oscillator frequencies. The RF amplifier, Crystal Oscillator and Mixer 1

circuit function as the RF input for bands 6 to 18 with the output going

to the Variable IF tuning that then provides a fixed 455kc output. The RF input section is

bypassed when using bands 1 to 5 and the incoming signal goes to the

Variable IF which combines with Mixer 2 and the selected VFO to provide

a 455kc output. Two separate VFOs are used with one

used for Bands 1, 2 and 3 and the second VFO used for Bands 4 to 18.

Main tuning gear reduction is 41.7 to 1 and the SECTOR gear reduction is

another 3.8 to 1. The resulting tuning is a constant "bandspread"

type at almost a vernier tuning rate.

The dial readout is "band-in-use" and employs a rotating

dial drum that is ball chain-coupled to the band switch. The smaller

dial to the right is the kilocycle-logging scale which for Bands 1-4 is

a logging scale, but, since the Bands 5-18 are 2mc linear scales for

each band, if the receiver is well-aligned, then this dial will readout

frequency almost directly "to the kilocycle" for

these bands.

For example, if the slide-rule dial pointer is set in between 14.1 and 14.2 and the

logging dial reads 67, then the tuned frequency is 14.167mc. The

kilocycle dial

index is not adjustable. The accuracy of alignment will determine just

how usable the kilocycle dial ends up being. Spec from 4-30mc is "within

10kc." I was able to achieve an average tracking accuracy of between "dead on"

up to the greatest error being about 5kc off. Below 4mc the accuracy spec is 0.5% which is easily attained

during alignment (at 4mc the spec of 0.5% is 20kc.)

Bandwidth is selectable from 6kc

down to 100hz (five steps) in Bands 3 to 18 but in Bands 1 and 2 the

bandwidth is selectable only from 1.5kc down to 100hz in three steps

(6kc and 3.1kc, if selected, won't change from 1.5kc bandwidth.)

The selectable bandwidths provided are 6kc, 3kc, 1.5kc, 800hz and 100hz. The

3.0kc bandwidth utilizes a Collins 3.1kc mechanical filter and the

1.5kc, 800hz and 100hz bandwidths are also derived through the 3.1kc

mechanical filter going then to the 45kc IF which is

utilized for two purposes. In Bands 1 and 2, 45kc is the IF. In Bands 3

to 18, the 45kc IF is utilized as part of the selectivity bandwidth

operation and results in triple conversion in the IF section if

1.5kc, 800hz or 100hz bandwidths are selected. Two types of

detectors are used with a standard vacuum tube diode detector used in Bands 3

to 18 and a crystal diode detector (heavy duty 1N34 germanium diode) utilized in

Bands 1 and 2. Two BFOs

are also used with the 455kc BFO being adjustable +/- 2kc but the BFO

for 45kc (which is used just for bands 1 and 2) utilizes a fixed-frequency

(adjusted for a 1kc heterodyne or 44kc.) When SSB is

selected the 455kc BFO output is increased (compared to the output in CW) for better demodulation of suppressed-carrier signals. AGC has

selectable fast and slow time constants. The audio output frequency

response is 200hz to 3000hz (-4db down) and the audio power available is

250mW with 3.2Z or 600Z impedance outputs provided. A 500kc Calibration

marker signal is available that functions from the 500kc Crystal

Oscillator that also provides mixing with 455kc IF for the 45kc IF. A carrier level meter (showing db above

1uv) is provided. The ANTENNA (trimmer) control is connected to RF/Mixer

1 and only functions when the receiver is on Bands 6-18 (4-30mc.)

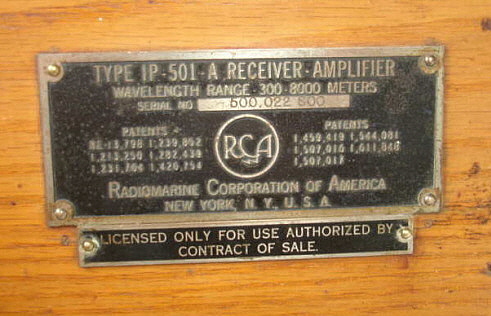

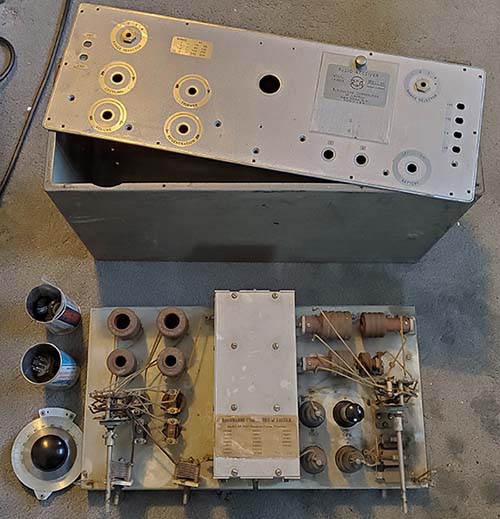

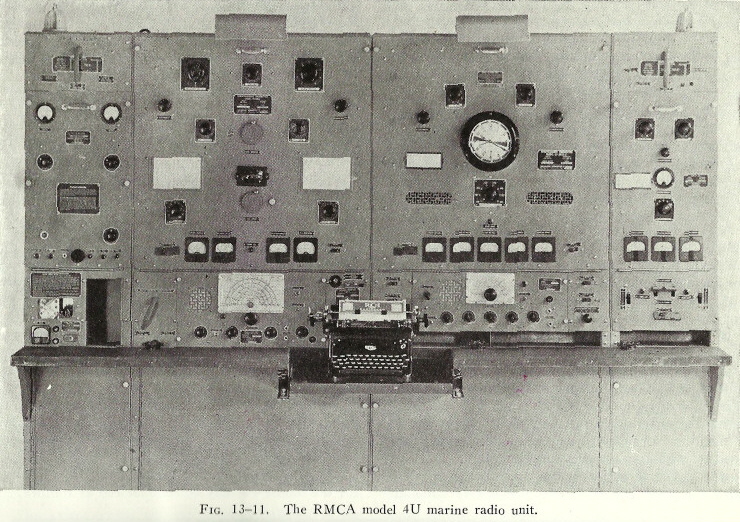

Radiomarine also offered a very similar receiver that

was designed for AC line power application at any land-based

communications operation (like RMCA Coastal Stations.) The

CRM-R6A has many slight differences but it's basically the same type of

design as the AR-8516, both electronically and mechanically.

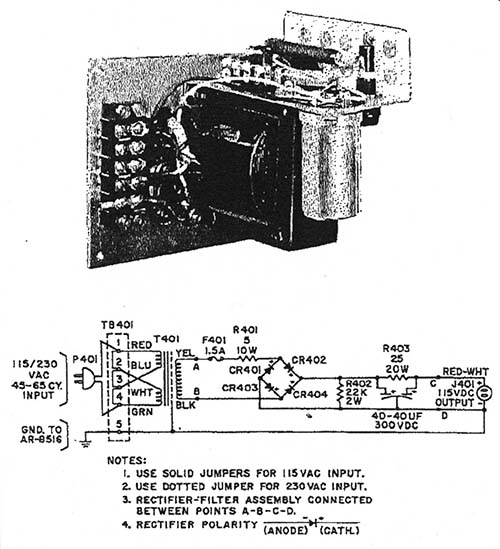

Power Requirements

- Being a commercial shipboard receiver, the AR-8516 is

designed to be powered by various types of ship's power systems. It was expected

that the receiver would be powered by +115vdc. Using

accessories available from RMCA, operation on +230vdc was also possible.

It was also possible to operate the receiver direct on 115vac but the

receiver's power

input section only provides a half-wave rectifier if AC operation

is used. RMCA recommended that the MM-555140-B Isolation Transformer/DC supply be used to

convert the ship's 115vac (or 230vac) to +115vdc for operation of the receiver. In

fact, if the receiver was ordered with the matching table cabinet, then

the MM-555140-B was included and installed inside the cabinet. If the rack

mounted version of the receiver was ordered then the MM-555140-B was

separate and was installed externally (somewhere in the rack.) Since the

AR-8516 is AC-DC in concept, all tube filaments are wired in series.

Most of the tubes are 3-volt filament types, e.g., 3BZ6, 3BE6, 3CD6,

3AL5, etc. but

(2) 5U8, (3) 7AU7 and (1) 12CU5 tubes are also used.

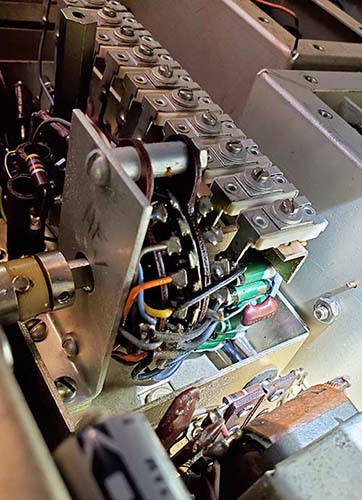

The SECTOR Control

- The unfamiliar control on the AR-8516 is the SECTOR control

which is part of the RF and Mixer 1 tuning in combination with the

Crystal Oscillator. When the receiver is tuning

from 80kc up to 4mc (first five bands) the RF and Mixer 1 circuits are

bypassed and the Variable IF (acting as a RF amplifier, VFO and Mixer 2) tunes the receiver as a single conversion circuit.

When tuning above 4mc, double conversion is used and the SECTOR control

provides the correct tuning for the RF and Mixer 1 (and Crystal

Oscillator) for each of the 2mc wide bands (4mc to 30mc.) Four sets

of coils are used for ranges 4-12mc, 12-20mc, 20-28mc and 28-30mc. When

combined with the selected Crystal Oscillator frequency the result is

2mc wide tuning ranges from 4 to 30mc. The "sector" refers to each 45

degree section (A, B, C or D) of the RF/Mixer 1 variable tuning

condenser's 180 degree rotation range. Selecting A, B, C or D will

actuate a physical rotation of the RF/Mixer 1 tuning condenser rotor to

the correct 45 degree section required for tuning (plus the Crystal

Oscillator) of the particular 2mc band range selected. The SECTOR

switching is roller-chain coupled to the band switch. The RF/Mixer 1 tuning is gear-coupled to the main tuning

control and the SECTOR selector knob will rotate as the TUNING knob is

rotated. Although the SECTOR knob and RF/Mixer 1 condenser rotate with

the main tuning, the correct section selection is necessary and will

require that the SECTOR knob be set to the "detent" in the correct

A, B, C or D

position. The "PLACE SECTOR AT" indicator is illuminated and located in

the viewing hole above the band switch. The main tuning dial, logging

scale and meter illumination are also controlled by the SECTOR control in Bands

6 to 18. These lamps will only

illuminate when the correct SECTOR

position is selected.

Serial Number and

Cabinet - The serial number of the AR-8516 shown is SN:5830. The

serial number incorporates the year of manufacture in the first two

digits, e.g., "58" is 1958 and the receiver number is "30." There is

also another tag mounted to the rear chassis that gives the month and

year of manufacture, in the case of SN:5830, the tag reads "JAN 1958."

The odd size panel height of 9.5" (rather than the standard 10.5") does

limit the receiver's installation into generic-type cabinets without an

obvious gap. Mounting the receiver in a rack will solve that issue. Of

course the proper RCA cabinet does fit the receiver panel correctly but

finding one is next to impossible. As

stated in the manual, the AR-8516 was available as a table model

receiver with the cabinet (with the MM-555140-B installed) or it could

be ordered as a rack mount without cabinet (with the MM-555140-B as a

separate accessory.)

|

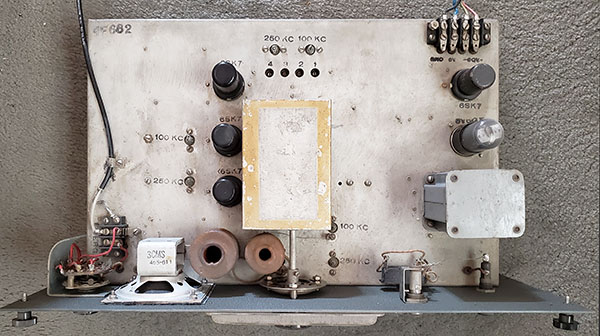

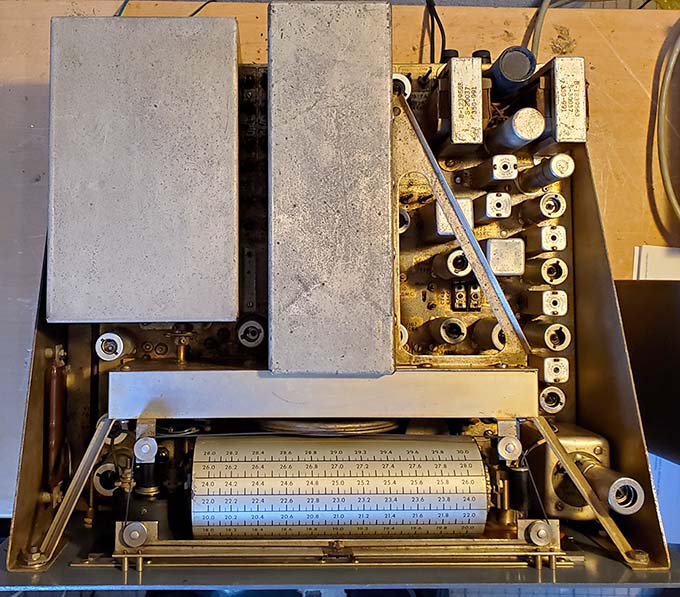

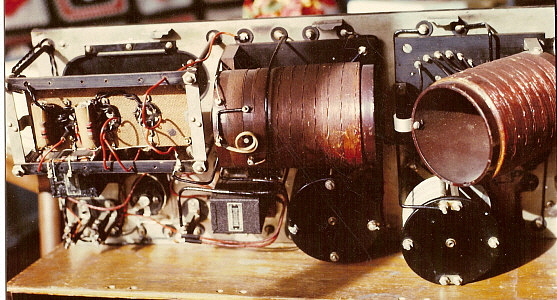

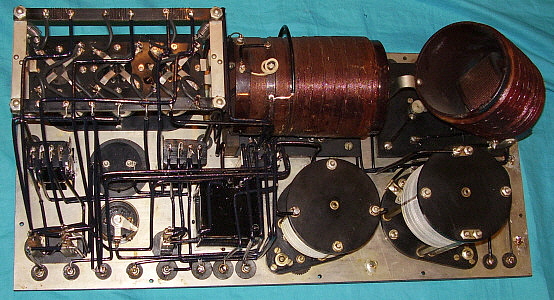

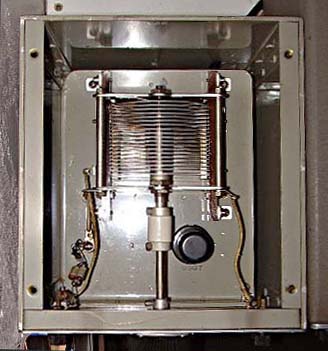

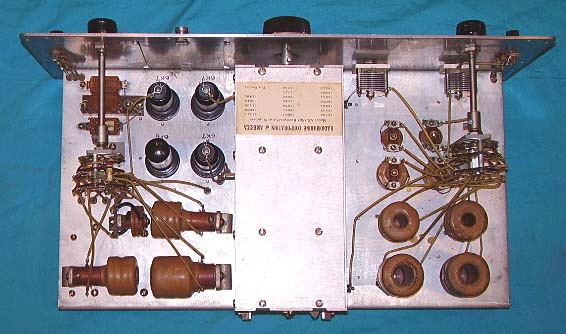

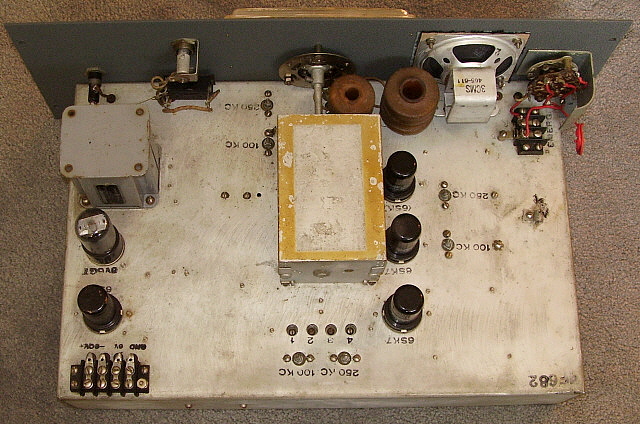

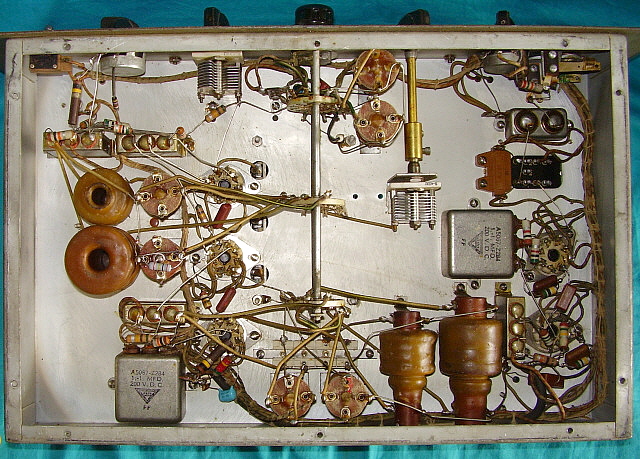

Under the chassis showing the bee's

wax impregnated coils.

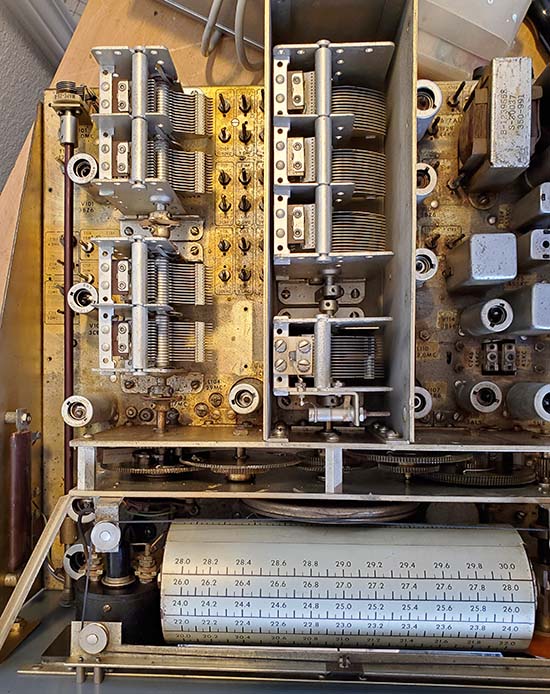

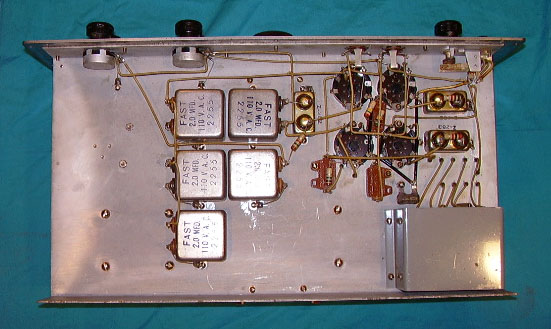

Under the chassis showing the bee's

wax impregnated coils.