July 22, 2021 - This

next observation was me finally realizing that the receiver had a few

problems. When listening in MCW

(Modulated CW) and AUTO (AGC on) mode for AM transmissions the bandwidth is very broad as would be

expected with a TRF receiver operating with AGC. SW-BC stations in the 49M band (late

afternoon,) were quite broad, especially the strongest stations. AM-BC (using the E-Range coil) in AUTO

results is many of the stations over-lapping when using a large antenna.

The AGC does keep all signals at the same output level and the OUTPUT

control has to be set to minimum and even then the signals are too loud. NOTE: AGC wasn't

functional at this time and the RF amplifiers were running a full gain

which resulted in the broad bandwidth.

|

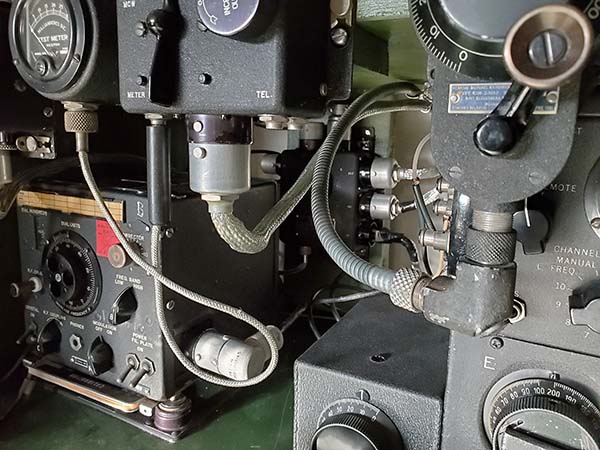

Type-22266 Test Meter Reveals AGC Problems - August 1, 2021

- I was able to find a CBY-22266 Test Meter that cleaned up nicely and

did function correctly. I installed the meter plug into the meter jack on the Receiver

Switch Box. When tuning in signals in AUTO there was no deviation in a meter reading of about

24mA. I switched to MANUAL and could adjust the Test Meter current with

the OUTPUT control. However, all signals are loud in AUTO and the Test

Meter current doesn't change which indicates the AGC isn't working. The type-77 AGC tube tests good. To be able to access test points within the

circuit requires that the receiver be out of its case. All resistors

check within tolerance except #31 and #24 but these resistors measure

much lower than their marked value which usually indicates a parallel path and

not an out-of-tolerance resistor. NOTE: Just to verify, #31

and #24 were isolated and tested,...of course, they were well-within

spec. Further testing requires that the

receiver be powered-up out of its case. I'm not too sure how stable the

receiver will be without the shielding the case provides but for DC

voltage measurements it shouldn't matter.

With the receiver in operation in AUTO, voltage at the grid of the AGC

77 tube is -76vdc and the bias voltage from the dynamotor measures

-89vdc. The grid bias voltage at the RF amplifier tubes is about

-1.5vdc in AUTO and doesn't change with various signal input levels. The grid bias voltage is insufficient for

cut-off of the RF amplifier tubes and therefore, since the cathodes are

grounded in AGC mode, the RF amplifier section is running at full gain.

A DCR test of the RF amp cathodes confirms that, in AUTO, the cathodes

are grounded through the correct value cathode resistors and, when in

MANUAL, the INCREASE LEVEL pot is connected from RF amp cathodes to

ground. The problem appears to be that the AGC tube doesn't develop the DC

voltage since even on the AGC-side of the RF grid resistors, the bias

voltage only is about -1.5vdc. The RF grid bias voltage should be around

-7.0 for complete cut-off (with +250vdc plate voltage.) Since the signal from the RF amplifiers is

coupled through a capacitor to the AGC tube, that capacitor could be

open (it's okay.) It's also possible that the DC filters on the output of the AGC

line are not working (yep!) I need to check alignment of 59C since

this trimmer adjusts the input RF resonance to the AGC tube and to the

Detector. The trimmer does have "undisturbed" GLPT but that adjustment

was last made 80 years ago. I doubt this is a problem because the

receiver works great in MANUAL (GLPT'd adjustment was okay.) The problem is probably a leaky capacitor in

the AGC DC filter which would load-down the AGC/RF grid bias voltage. Partial

isolation is the easiest method to find the bad component. Although a DMM

can't measure capacitor leakage accurately, if the meter shows some DC

resistance, you can be pretty sure the capacitor is bad. The two filters

in the AGC circuit use #218A & B and #4A and B. The DMM didn't show any

DCR on #4A/B but read about 10K on #218A & B (#218 is a triple .5uf 100vdc

with common ground.) I substituted externally connected capacitors which

got the AGC producing RF grid bias voltage and Test Meter reacted as

expected with the cathode current reading about 24mA with no signal and

reading about 9mA with a strong signal from the RF sig gen. However, the

output level can't be adjusted so it seems that the audio output pot is

not working (direct DCR measurement of the pot confirmed that it is

functioning correctly so this problem is probably also leaky capacitor

related.) |

|

Problem Assessment -

Generally, paper-dielectric capacitors were never expected to survive as

usable components over an eighty year time period. There were a few

exceptions such as oil-filled types or paper dielectric capacitors built

with oil-impregnated paper. However, the tub capacitors

in the RU-16 receiver are just the average paper-dielectric types that

are potted

in bee's wax and this results in an average finite life-expectancy. It

seems that all six 0.5uf capacitors exhibit significant leakage current

that is affecting performance. There are also sixteen 0.1uf 400vdc

capacitors that comprise the eight dual 0.1uf tub capacitors. These

capacitors don't seem to show significant leakage but they certainly wouldn't pass a true leakage test (series

resistance) using a LCR-Z-bridge. In fact, when rebuilding these tubs

I found that several had corrosion on the inside indicating

contamination that happened during the original construction of the

capacitor. One 0.1uf dual capacitor was green on

one end with corrosion, so it definitely was necessary to rebuild all

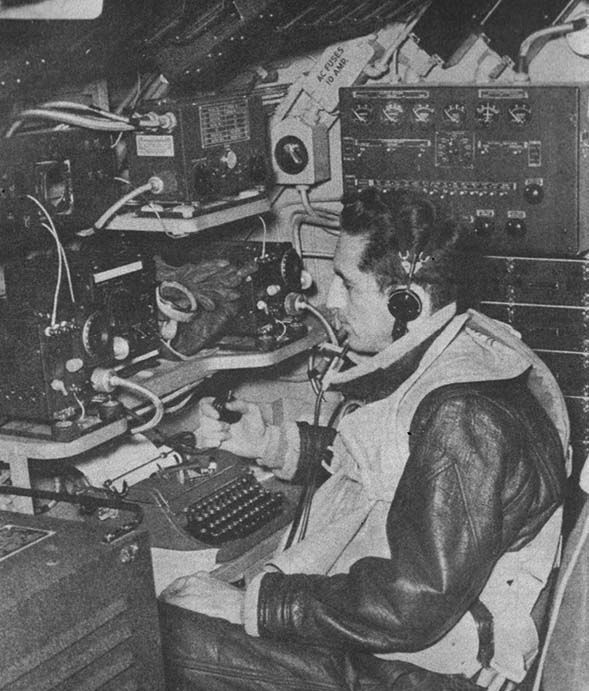

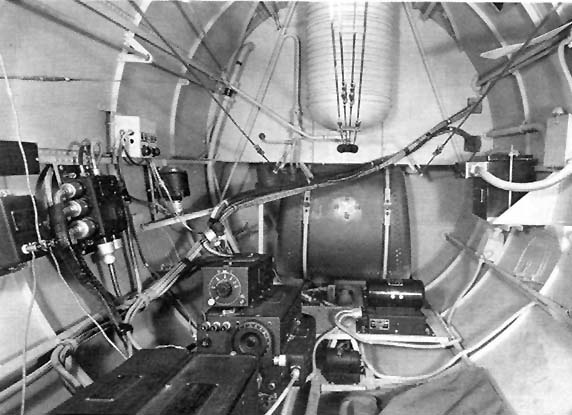

of the tub capacitors. Since I plan on using the RU-16 "on the

air" in a vintage military radio station setup, I would want to have the

receiver performing at its best. Unfortunately, I think that will

require replacing all of the paper-dielectric caps - yep! All of the

paper-dielectric caps are

mounted in metal tubs. To maintain as much physical originality as possible, I'll

have to rebuild all of the tub capacitors using new polyfilm caps that will be

mounted inside the original tubs. |

|

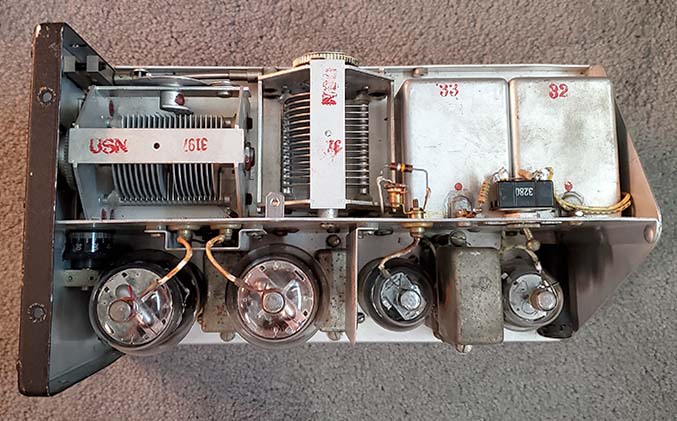

Rebuilding Tub

Capacitors |

Tub #3562 (Qty 1) - contains three 0.5uf 100vdc caps in tall tub with

terminals on the bottom

Tub #1575 (Qty 1) - contains two 0.5uf 300vdc caps in tall tub with

terminals on the bottom

Tub #1573 (Qty 1) - contains one 0.5uf 300vdc cap in short tub with

terminals on the bottom

Tub #1572 (Qty 5) - contains two 0.1uf 400vdc caps in short tub with

terminals on top

Tub #1574 (Qty 3) - contains two 0.1uf 400vdc caps in short tub with the

terminals on the bottom

Total of 11 tubs to rebuild |

Polyfilm Capacitors Required

0.5uf @ 100wvdc - Qty: 3 - Note: actually used 200vdc caps due to tub

size vs capacitor size. Had to order the caps.

0.5uf @ 300wvdc - Qty: 3 - Note: actually used 400vdc caps. Had caps on hand.

Tight fit on #1573 due to small size of tub.

0.1uf @ 400wvdc - Qty:16 - Note: used 400vdc caps. Had caps on hand.

Total of 22 capacitors needed |

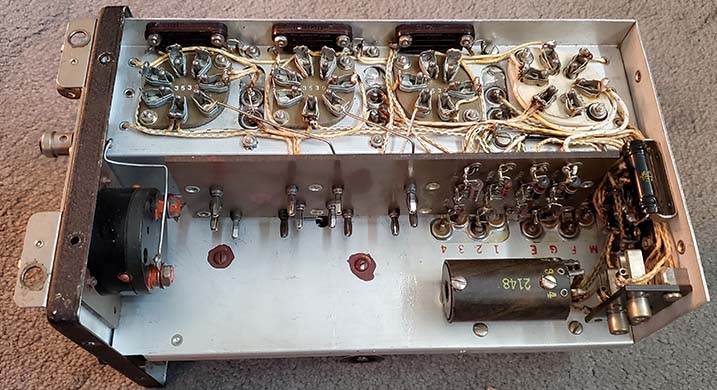

Tub Rebuilding Technique - Once a

tub is disconnected and dismounted it's then clamped in a small bench

vise with the "soldered in place" top or bottom facing up. With a Dremel

tool with a 1.5" diameter cut-off disk installed (E-Z Lock type,) I make a slice

that's right next to the inside edge of the tub on the soldered seam. I had to do one slice and then rotate the tub

to make another slice, then rotate and slice again until I had worked my

way around the soldered seam of the bottom. There were very small

connective metal pieces at some of the corners since the cut-off wheel

sometimes didn't allow going

all the way to the edge. These connective metal pieces can be easily cut with

small wire cutters. I used a small blade screw driver to pry

up the bottom piece (easy to do) enough to see the connecting wires that

need to be cut

with small wire cutters. There's also a common ground wire that needs to be cut.

Now the bottom cover with the terminals can be completely dismounted.

Inside there's a black fiber cover that the capacitor wires were routed

through. The fiber cover can be pried off

easily. Now, the rest of the tub has some bee's wax and the capacitors

inside. I used a

hand-held heat gun to melt the wax out of the tub. The capacitors can

be removed with needle nose pliers or pried out with a small blade

screwdriver. If carefully done, the paper

liner inside the tub will not be damaged and can be left inside for

insulation. On the smaller "short tubs" the paper can't be saved

because it's wrapped around the capacitor body but the paper

really isn't necessary anyway. I used the heat gun to get the residual bee's wax off of the

bottom plate too. Also, I cleaned the residual wax off of the mica insulators

on the terminals.

Next, the new capacitors are connected to have one common lead with two or three

"hot" leads that are connected to the terminals

of the bottom. I used just the

capacitor leads to make the connections to the tub (common) and to the

terminals. I used small sleeving on all the "hot" leads to have the

capacitors well insulated. Since the commons are connected to the tub,

those leads weren't sleeved. The terminals have a central hole through

which the wire leads were inserted and then soldered. The old wire can be

removed from the terminals by heating the terminal to melt the solder

and then pull the old wire out. Then the hole can be "chased" using a

#60 drill bit held in a pin vise. The terminal insulators should be

checked for any solder bridges or other potential problems and again

cleaned with alcohol. There's a hole in the bottom metal

plate for the common wire to be soldered. I pre-test the new capacitors

for value and then proceed with the installation. The capacitor assembly

has the "hot" leads run through the hole in each terminal and then

the leads are clipped and soldered. The common lead is routed out the hole in the bottom

plate. Next, install the capacitor assembly into the tub. Check to be sure

that the "hot" leads can't short against anything (make sure the "hot" leads

are sleeved and as short as possible.) I don't put any filler (bee's

wax, silicon caulk, hot-melt glue, etc.) back in the tub, just the

capacitors and fiberboard insulators. With the bottom plate in place, I next had to

solder one or two corners of the plate to the tub to make sure the

bottom plate was straight and at the proper height which is just below

the rim of the bottom of the tub. Also, I had to make sure the common wire

was soldered into the seam soldering. I used a 250W Weller soldering gun

which was hot enough to allow a smooth bead of solder to be "flowed" around the

perimeter of the bottom to seal the tub. Once the tub has cooled a little,

the terminals can be checked for the proper value of capacitance with

reference to the common tub body. The tub was cleaned with denatured

alcohol. Try to be careful in cleaning and handling of the tubs in order

to avoid damaging the red paint-stamped nomenclature (the red

nomenclature suffers a lot during the rebuilding process.) Then the tub is remounted into the

receiver and wired into the circuit. Originally, there was a coating of

bee's wax on the terminals that probably was "dripped" on after the

wires were installed (the wax actually looks and behaves like

light-brown sealing wax.) Rebuild time per

capacitor tub is about one hour from starting the removal from the

receiver to completing the reinstallation back into the receiver.

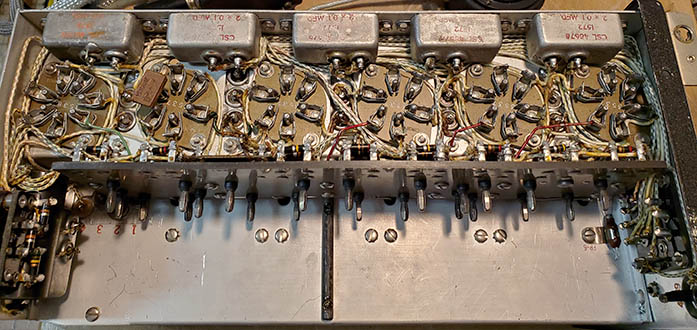

Photos below show the tub rebuild process on a #1574 dual 0.1uf

400vdc capacitor. The other types of tubs used in the RU-16 were rebuilt

using the same procedure with slight variations. Tubs #1572 have the

terminals on the top of the tub and the bottom plate is just a flat

cover soldered in place. These are easier to rebuild since the new caps

can be fit into the tub, soldered to the terminals, etc. and all

that's left is to install the bottom plate. Tubs #3562, #1573 and #1575

use 0.5uf capacitors that are fairly large but 400vdc types will fit

into the tubs, with the exception of #3562 which must use 200vdc types. Tub #1573 is a very tight fit

using a 0.5uf 400vdc cap but it will fit in although I did have to use an

insulating piece of fiber board on the bottom plate since it was right

up against the capacitor body. |