| Preliminary

Inspection - June 18, 2017 to June 23, 2017 - No doubt, this is a formidable

restoration project.

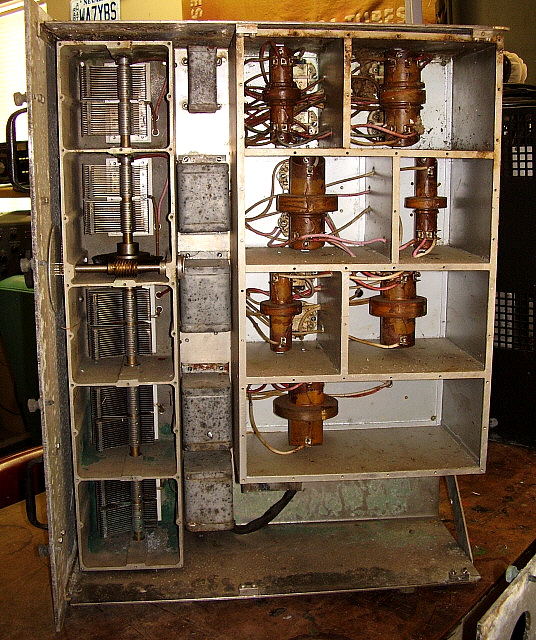

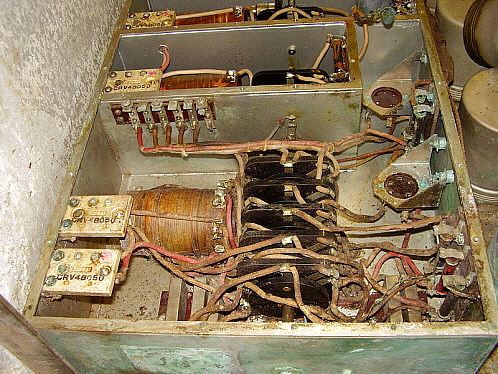

There is a lot of damage due to poor storage conditions. This damage is

both cosmetic and electronic. With a project that requires this much

work it helps to create a list of problems and observations that will help to formulate a restoration plan. Here's the obvious,...

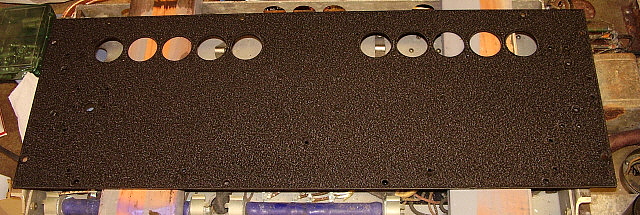

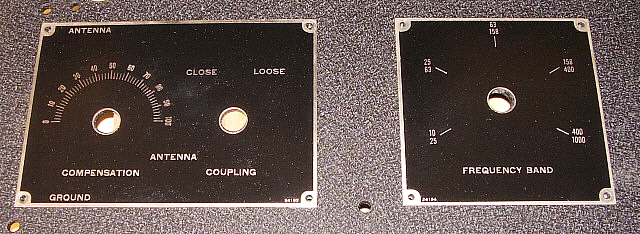

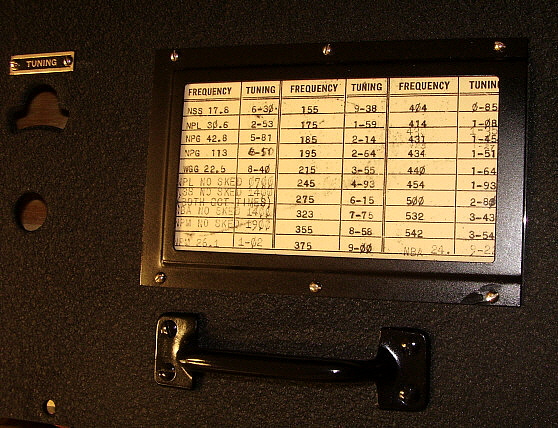

1. Entire repaint will be required. Black wrinkle finish - I'll have to

contact VHT to see if I can buy a quart and then thin to spray using the larger

paint equipment I have (the type for painting cars.)

2. Cabinet straighten and repair. Whatever the mounts were, they are

missing.

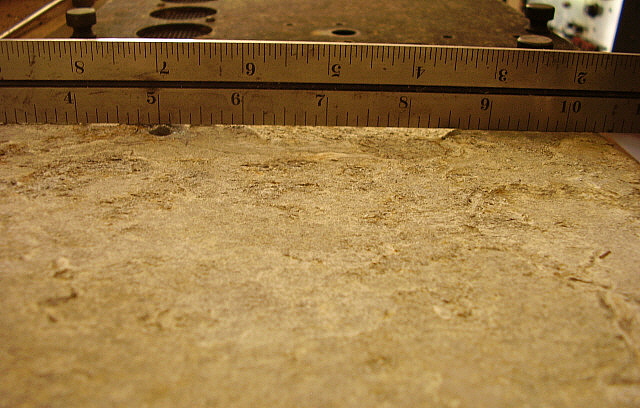

3. Corrosion removal. Most is surface corrosion however some erosion

is noticeable on the inside of the front panels where the mounting

brackets contact the aluminum. Erosion on the back of the Tuner panel

is pretty serious.

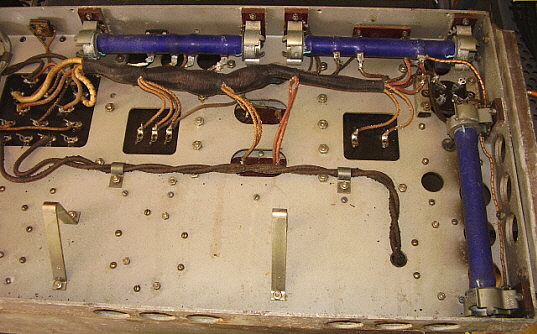

4. Wiring harnesses will require rebuilding. I'll try to use as much

of the original wire as possible but it's probably going to be necessary

to replace a lot of wires.

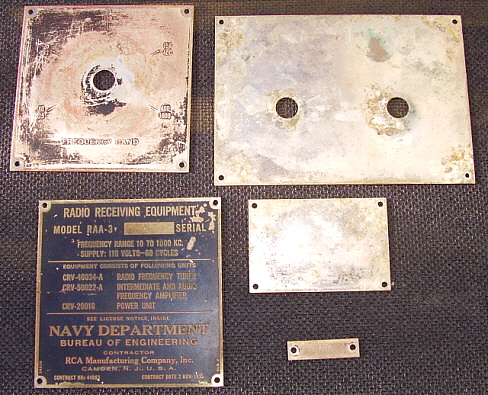

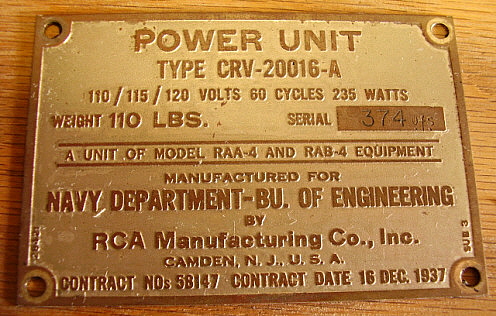

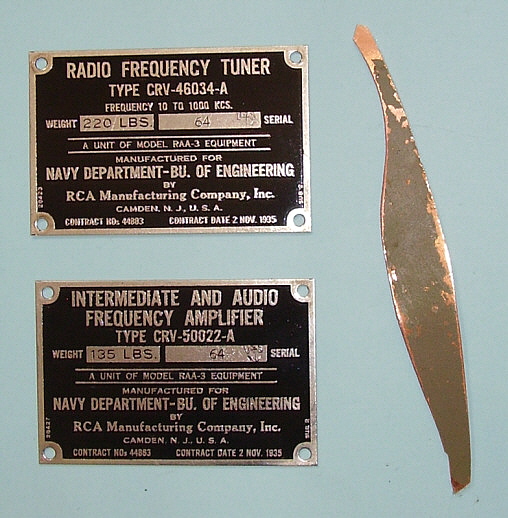

5. Data plates and nomenclature plates need restoring. Fairly easy.

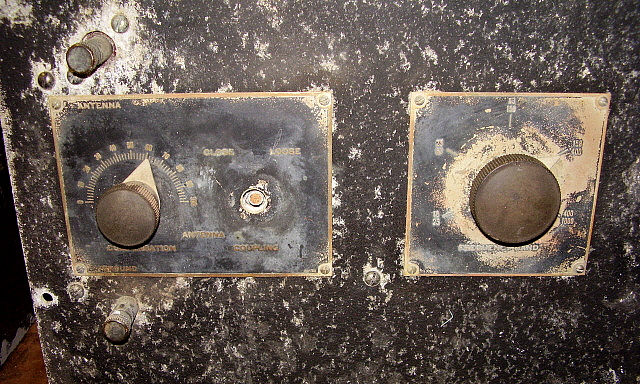

6. Dial doesn't rotate although tuning mechanism works. Shaft turns

so dial set screws are probably loose. Dial is held by a threaded

boss and nut. The nut was loose.

7. Missing Plate Voltage meter - wiring to meter cut very short. Same

Plate meter that's used on the early RBA, RBB or RBC receivers. The

metal housing versions of the meter. 8. Broken shaft on Coupling

switch control. I have the original broken shaft and knob. The shaft is

made of wood (fiber material) so a replacement is fairly easy to construct. Here's some of the other problems,...later update notes are in

italics.

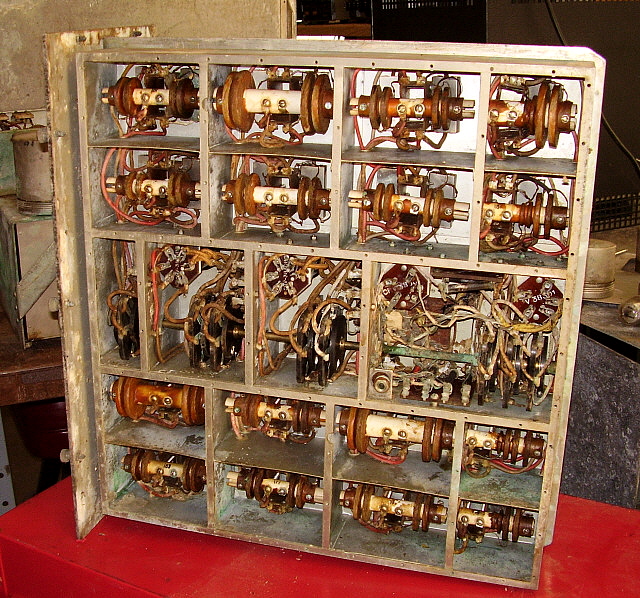

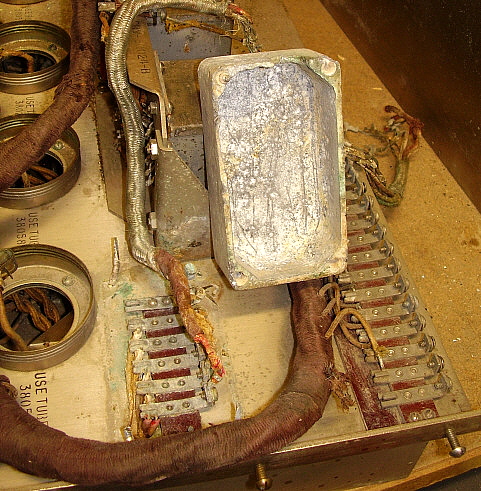

1. Several IF transformers are damaged, some minor,...one major.

Appears that mice running around in the compartments broke several wires

from the coils to the terminals of the IF transformers. One coil on one

of the 238kc IF was bitten into and about 20% of the coil is missing.

This one will need to be rewound or a replacement coil from a 200kc IF

trimmed to work. Too bad someone removed the bottom shields years

ago.

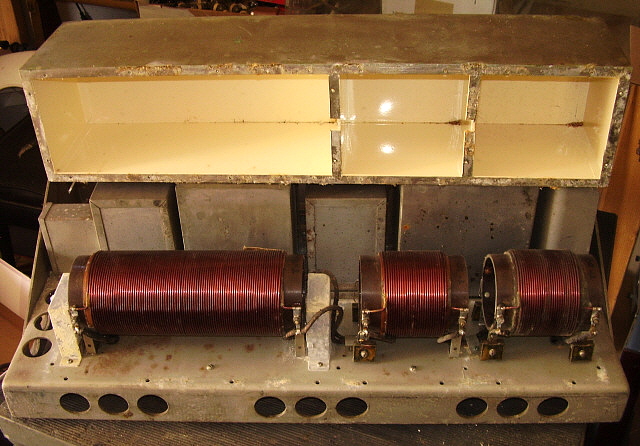

2. Severe nut and seed storage in LO section of tuner - no apparent

damage after removal. Used a shop vac (there was a lot of seed/nut

debris - see photos below.) One terminal on the bandswitch is broken. 3. IF Bandswitch doesn't rotate - appears shaft is corroded in one

bearing - WD-40 and slight pressure defeated the corrosion and the IF

Bandswitch is now operational. After the WD-40 had time to seep into

the bearing the switch operation is very easy and requires very little

effort to effect band changes now. >>>

|

>>> 4. Phone jack in IF-AF appears to be missing insulator spacer, wiring

shot to jack. This appears to be an output from the detector. It must be

for testing since access to this jack would be difficult if the receiver

was installed into the cabinet. No access hole in the cabinet where the

jack is located. This jack is for alignment and is for installing a

detector plate current meter for measuring peak current during

alignment. Though the bottom shields are missing, there was a hole in

the shield to allow access to this jack. 5.

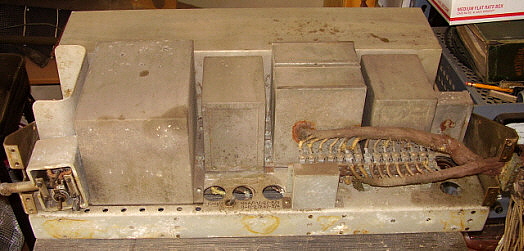

Severe surface corrosion on all transformers and chokes (due to steel

cases.) These components will need repainting after the corrosion is

removed. Most of these components are actually bypass capacitors. 6. Generally, the Tuner and Power Supply are in better

condition than IF-AF unit which has the most damage and will be the most

difficult to restore to functionability.

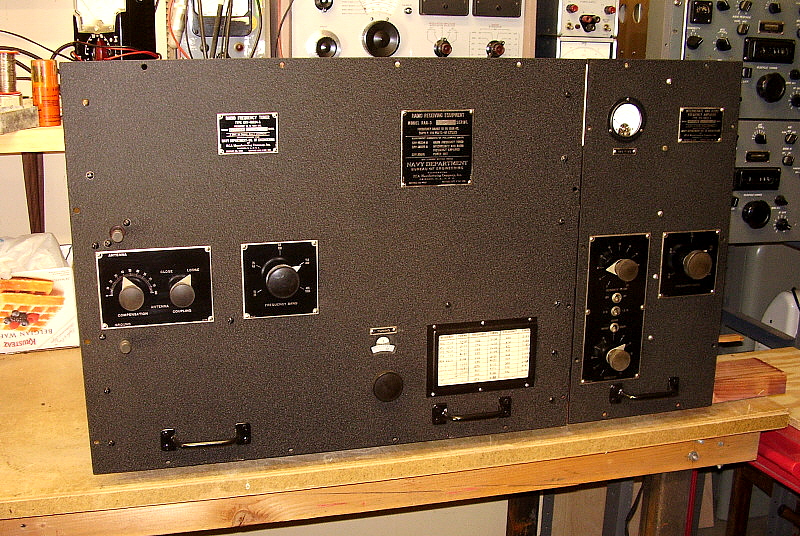

The Tentative Restoration Plan - Though a restoration can

usually be accomplished without a manual or schematic, it's much easier

and ultimately much more complete and accurate with a manual for

reference. The first step is to get some documentation (manual found.)

During disassembly, all removed parts, including hardware, will be

"bagged and tagged" in individual, identified plastic bags. This will be

a tremendous help during reassembly since all parts will be easy to find

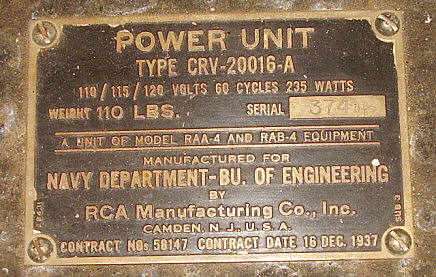

and easy to identify. Since the Tuner and the PS are

fairly heavy they will have to be restored in the shop. The PS will be

restored first since it appears to be in the best overall condition. The

Tuner will be restored next since it's better than the IF-AF unit. Both

of these pieces can be worked on in the Summer out in the shop. The

IF-AF unit is about 75 lbs out of the cabinet and can be brought into

the upstairs lab for repair. This can be done during the Winter, if

necessary. Cabinet repair will be done last after the RAA is operational

and the Tuner, the IF-AF unit and the PS panels have been restored. If

the cabinet restoration ends up being a Winter project, painting may be

postponed until it warms up. One caveat,...this plan is subject to

change depending on what unforeseen problems are encountered during the

restoration process (and we do expect to find many more problems than

those listed so far.)

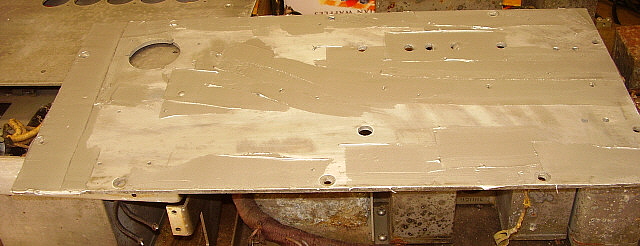

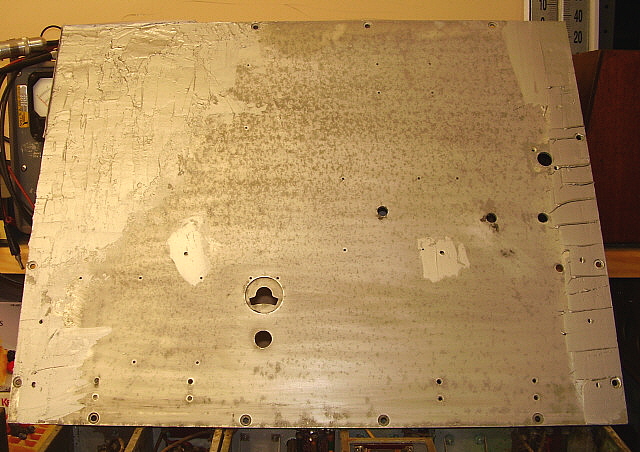

UPDATE to the Plan: December 1,

2017 - As mentioned, the above plan was tentative. I've

already changed the plan after some careful thought. Rather than restore

each unit, one at a time, I decided to go ahead and do all of the

cosmetic restoration work first. This was mainly to be sure that as I

progressed through the restoration, I would already know that the

finished RAA-3 was going to "look good." This meant I had to do all of

the panel repairs, the painting with black wrinkle finish of the Tuner

panel, the IF-AF panel and the Power Unit panel. The Tuner panel had

significant erosion damage on the back that had to be repaired. This

panel is huge and having its wrinkle finish paint job turn out fantastic

was a major relief. The added advantage of painting the wrinkle finish

on the panels early during the restoration is that the panels can be set

aside and the wrinkle paint allowed to fully cure and become the tough,

hard finish it can be after a month or two (or maybe a year.) Once all the panels, the

panel data plates and the panel hardware are finished and can be set

aside to "cure," I'll then do the electronic restoration. Power Unit

first because I'll probably need the power supply to restore, test and

troubleshoot the Tuner and the IF-AF Unit. Once I have the complete

receiver chassis together and operational, then I'll restore the

cabinet. The cabinet is extremely heavy and will need to be sand

blasted, so this type of operation is probably best done in the summer.

Of course, plans always are subject to change and hopefully the changes

make sense and will help in the ultimate completion of this restoration. |