|

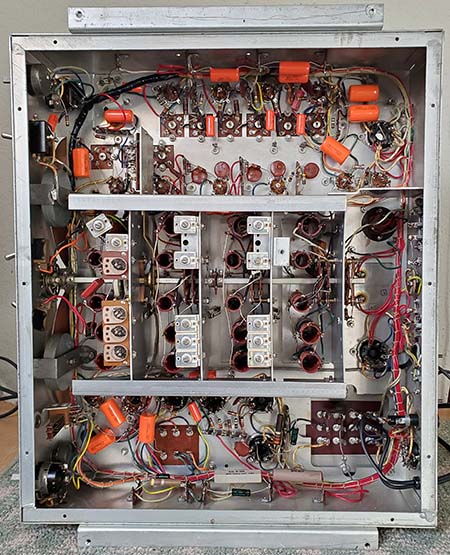

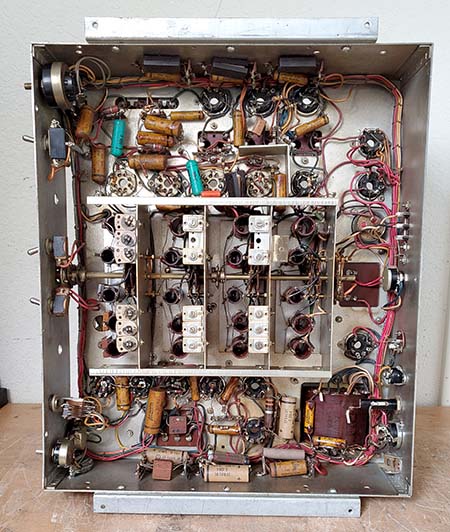

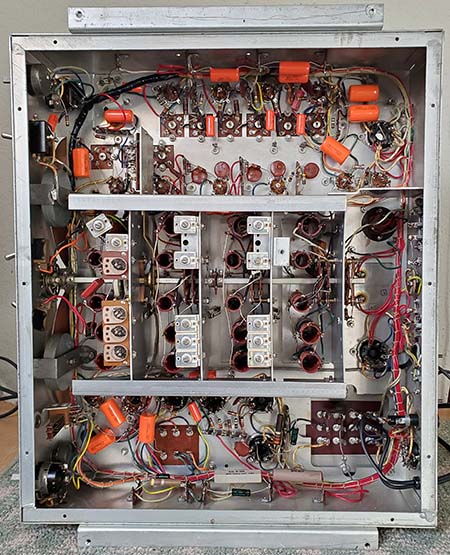

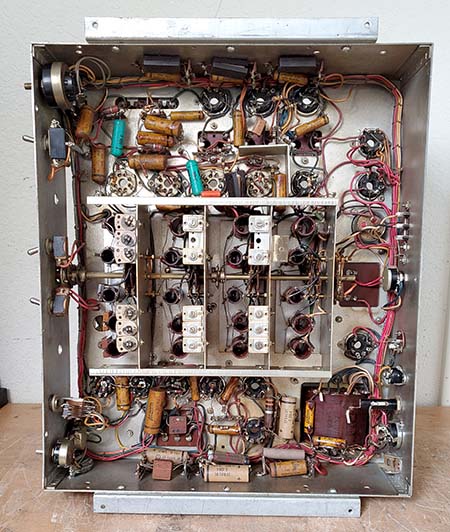

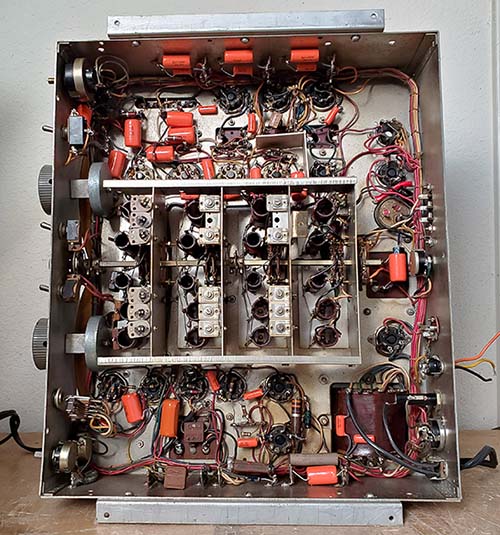

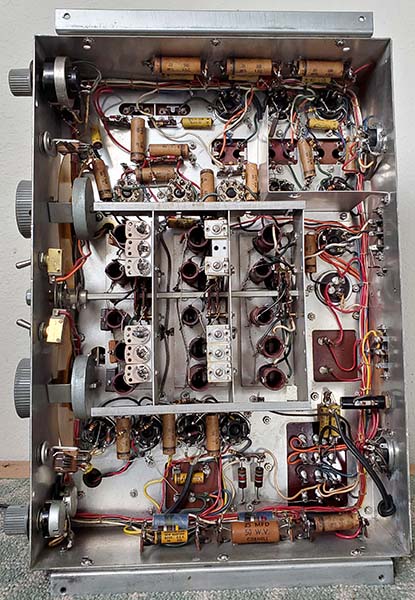

NC-183D Top of Chassis

SN: 430 0135

The first "three in a row" IF cans are for the 1720kc IF.

The first five of the "six in a row" IF cans are for the 455kc IF.

The rear-most can is for the Amplified AVC. Late production

NC-183D receivers will have a potted power transformer

identified as S461 as this receiver has. |

Other Details

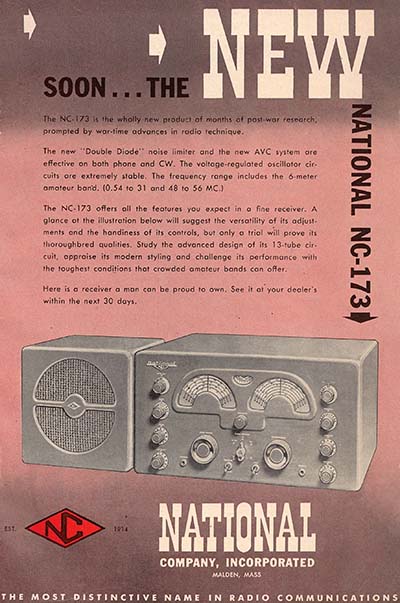

- The NC-173, NC-183 and the NC-183D all featured a five-position

Crystal Filter that allowed for a wide range of adjustability

to the received bandwidth (from the normal IF passband

down to about 100hz selectivity.) The Crystal Filter was

also able to null heterodynes that were very common at a

time when all ham voice transmissions used the AM mode.

The Crystal Filter could also improve CW reception by

enhancing almost any selected heterodyne tone. To further aid IF

selectivity, three stages of IF amplification were used

in the NC-183D. National claimed that the NC-183D IF system provided

3.5kc passband

selectivity. This IF system was also employed in the

HRO-50-1 and HRO-60 for the same reasons. Good

selectivity was essential to cope with the congested ham

bands of the 1950s and 1960s and

to allow reliable communications. An 8 Z ohm and a 500 Z ohm audio outputs

were provided from an odd-ball three-pin socket on the

NC-183 (the NC-173 and the NC-183D used a standard three screw terminal strip.) The

three-pin mini-socket was probably replaced late in the

NC-183 production with a standard three screw

terminal strip. The Tone control only reduces the upper

audio frequency response leaving the lower end

unchanged. National indicated that the Tone control was

to improve reception for weak signals or noisy

conditions and not necessarily to enhance the audio

spectrum for listening pleasure (even though it does.)

Specifications indicated that with the Tone control at

10 the audio frequency response was 60hz to 12khz and

with the Tone control at 0 the audio frequency response

was 60hz to 1000hz. |

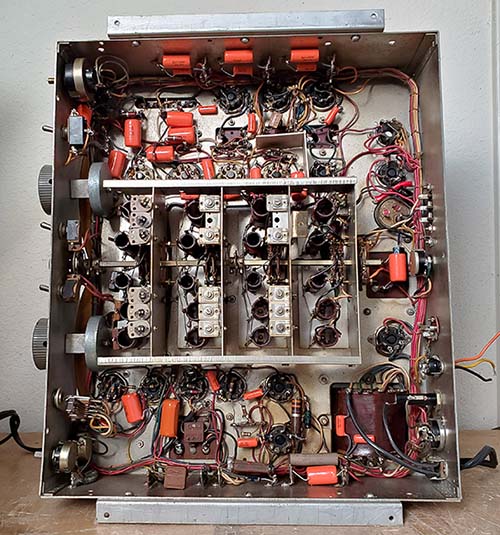

NC-183 Top of Chassis

SN: 241 0262

Behind the Crystal Filter are the two 455kc IF cans.

The rear-most LC (in

can) is for the amplified AVC. Note the numerous

WWII style metal-octal tubes. The power

transformer is the SA3901 used in the NC-183 and

in early NC-183D receivers. |

|

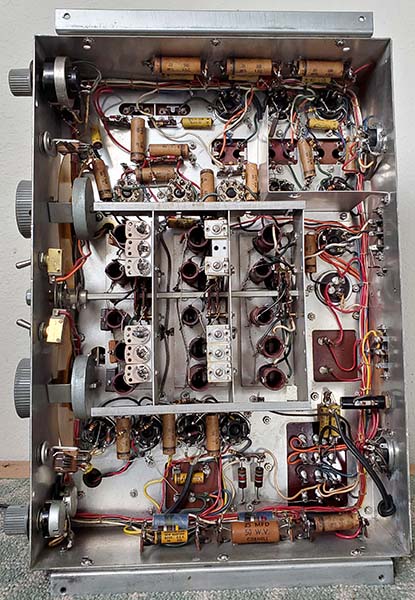

NC-173 Top of Chassis

SN: 173 2821

Note the different style power transformer that was

used on all NC-173 receivers. The pattern metal venting on

the back panel that was added by late-1947. Note how short the tuning condenser cover is compared to the NC-183. |

The Physical

- The cabinets on early examples of

the NC-183 and NC-173 were painted a light-gray color

that had a slightly silver undertone. This was a

semi-gloss, smooth-finish paint that was very durable

but had a tendency to show any nicks and scratches quite

well. The knobs used on these receivers had gray plastic knob

grips with bright silver skirts and the tuning knobs had

bright silver "knob-brights." The earliest

NC-173 and NC-183 builds had have vertically

oriented toggles switches as shown in early advertising.

Also, the earliest NC-173 didn't have an accessory

socket (the accessory socket was probably added by

late-1947 when the NBFM adapter became available.) Early examples

of the NC-183 had a punched pattern metal

screen spot-welded in place on the rear panel (see

photo right.) The earliest NC-173s (about the first

1000 receivers) had a solid back cabinet that didn't

have had any rear venting at all. Later NC-173 cabinets have

the patterned metal screen venting. By

1949, the NC-183 rear panels had horizontal-rectangular vents

that were punched into the sheet metal before cabinet assembly.

Probably around 1951 or so, the cabinet paint on the

NC-183 was changed to a dark gun metal silver-gray and

the knob grips were changed to black. During the last of the NC-183 production, in 1952, other

minor upgrades were beginning to

be incorporated into the receiver. The gunmetal

silver-gray color and black knobs were carried over to

the NC-183D cabinet introduced in late-1952.

Late versions of the NC-183D replaced the standard

SA3901 power transformer with a potted power

transformer identified as S461. The older style filter

choke was replaced with a potted filter choke identified

as S-669.

|

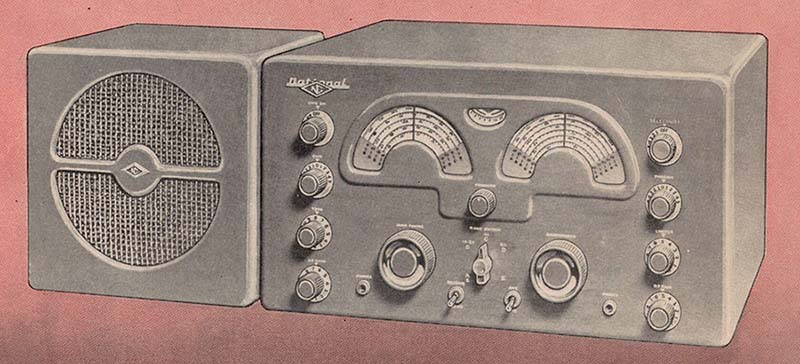

This is an Early NC-183

showing early style cabinet rear venting and

the lack of a "punch-out" hole for the Select-O-Ject

accessory. To the left of the fuse holder cap is

the three-pin speaker socket. Serial number is

202 0442 (built while the HRO-7 was still being

produced.) Interestingly, SN 202 1318 does have

the "punch-out" hole. Also, the first

1000 NC-173 receiver cabinets had no venting at

all.

photo from eBay |

|

NC-183R Rack Mount Receiver

Version

The rack mount

version used a standard 19" front panel that wasn't an

integral part of the cabinet like the table models used.

The flat front panel allowed for engraved nomenclature

that was cut into the panel after the wrinkle finish

paint was applied. In this method, the nomenclature will

show the base metal, aluminum, through the paint as

"bright silver nomenclature" - well, when it was new anyway. Though

missing on this receiver, normally the rack mount

versions had a dust cover that protected the chassis.

Receiver pictured is ca: 1951-52

|

The NC-173 was a physically smaller receiver compared

to its bigger brothers measuring 20"W by 10"H by 12"D

and it also weighed at least ten pounds less. The NC-183

and the "D" were 20"x10"x15" with a weight of

approximately 65 lbs. Other Versions

- Like its predecessors, the NC-183D was also available

in a rack mount version designated the NC-183DR. The

earlier NC-183 had used a dark gray, almost black

wrinkle finish, panel but the NC-183DR used a gunmetal

gray smooth finish front panel. There was a military version

NC-183D, the NC-183MR that also had the military designation

R-651/URR-39. This receiver was installed in a 30" tall table rack

that included a matching rack mount speaker. The

complete

military-version receiver was designated as the AN/URR-39 and that

consisted of the R-651/URR-39 receiver, the LS-228/U

rack speaker and the MT-1529/U table rack (with shock

mounts.) This version

eliminated the 6M coverage and provided a LF

band (50kc to 150kc) instead. The band spread wasn't

calibrated for ham bands and just had a logging scale.

|

Artwork for the

NC-183D showing the yellow scale S-meter that

probably was never used in production |

|

AN/URR-39 Receiver

photo from

navy-radio.com |

|

The NC-183D Legacy -

The production of the NC-183D ended in 1958. If there

was a continuation by National of the "big and heavy receiver with dual

dials separated by the S-meter" physical layout and

design, it would probably have to be the 1959 NC-400

receiver. Besides the similarity of the front panel, the

chassis also had a layout similar to the NC-183D. National

decided they would entirely update and redesign the NC-183D style

of the continuously available band spread type of

receiver and then add in a lot of military-type features

(some that required accessories) with the goal of producing

an exorbitantly over-priced equipment package. National

then tried to entice the military as

customers but the NC-400 was a cheaply-built

receiver with anemic audio and a litany of mechanical

issues due to the flimsy sheet metal used for the

construction of such a heavy receiver. The military

wasn't interested in purchasing another expensive receiver since

they already were buying the infinitely superior Collins-designed

R-390A receivers (even at over three times the cost of the

over-priced

NC-400, everybody loved the R-390A receivers.)

The hams weren't interested in the NC-400 either since the asking price

was nearly $900 without any accessories. When it came

right down to it, there wasn't anything about the NC-400

that could entice any of National's regular customers to purchase

the receiver. NC-400 production ended quickly with

only one run of less than 1000 receivers. The

NC-400, the NC-183D's successor, ended up being

purchased by a few big-budget commercial users and by

the U.S. tax-payer supported FBI where they were used as field-office receivers.

The NC-400 shown was originally sold to WHAS, a

commercial radio-TV station in Louisville, Kentucky, as a

monitor receiver for their tech department (luckily,

they seldom used it and never worked on it.) For

more details and a critical analysis of the quirky

multiple IF sections and the multitude of

mechanical

issues that plagued the NC-400

receiver you can go to the "National NC-400"

article on this website. Use the Home/Index link at the

bottom of this article for navigation. |

NC-400 SN: 543 0006

from 1959 |

|

Summary of

NC-173, NC-183 and NC-183D Receiver Features |

|

NC-173

Produced from 1947 to 1951

Orig.

Price - $199

Circuit - 1 RF Amplifier, 2 IF Amplifiers, 1 Audio

Output Amplifier

Tubes used: RF-6SG7,

Mix-6SA7, LO-6J5, IF-6SG7 (2), Det-6H6, AVC Amp-6AC7,

NL-6H6, BFO-6SJ7,1stAF-6SJ7, Audio Output-6V6, Rect-5Y3,

Reg-0D3

Audio Output Z - 8

ohms and 500 ohms from three-pin mini-socket

Tunes .54-31mc and

48-56mc

Antenna Input -

Three screw terminal strip, 300Z nom.

AM Sensitivity -

<2.0uv 6db s/n ratio (1948 catalog spec)

Selectivity

- ~8kc at -10db w/o Crystal Filter

|

NC-183

Produced from 1948 to 1952

Orig.

Price - $269

Circuit - 2 RF

Amplifiers, 2 IF Amplifiers, P-P Audio Output

Tubes Used: RF-6SG7

(2), Mix-6SA7, LO-6J5, IF-6SG7 (2), Det-6H6, AVC

Amp-6AC7, NL-6H6, BFO-6SJ7, 1stAF-6SJ7, Phase Inv-6J5,

Push-Pull Audio Output-6V6 (2), Rect-5U4, Reg-0D3

Audio Output Z - 8

ohms and 500 ohms from three-pin mini-socket

Tunes - .54-31mc and

48-56mc

Antenna Input -

Three screw terminal strip, 300Z nom.

AM Sensitivity -

<1.5uv 6db s/n ratio (1948 catalog spec)

Selectivity - ~8kc

at -10db w/o

Crystal Filter

|

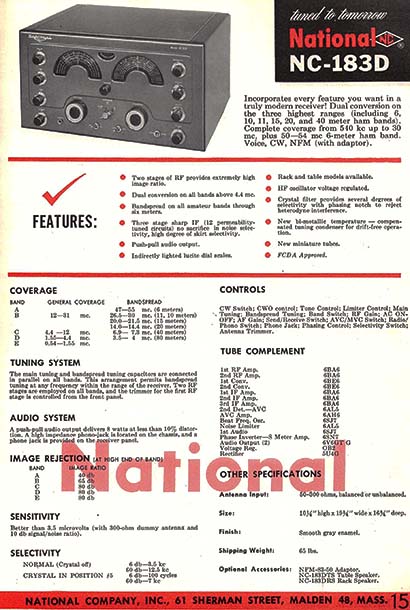

NC-183D

Produced from 1952 to 1958

Orig.

Price - $369.50

Circuit - 2 RF

Amplifiers, 3 IF Amplifiers, Double-Conversion, P-P

Audio Output

Tubes Used:

RF-6BA6(2), 1720kc Conv-6BE6, 455kc Conv-6BE6, IF-6BA6

(3), Det-6AL5, AVC Amp-6AH6, NL-6AL5, BFO-6SJ7, 1stAF-6SJ7, Phase

Inv and S-meter Amp-6SN7, Push-Pull Audio Output-6V6

(2), Rect-5U4, Reg-0B2

Audio Output Z - 8

ohms and 500 ohms from a three screw terminal strip

Tunes - .54-31mc and

48-56mc

Antenna Input -

Three screw terminal strip, 50 to 300Z nom.

AM Sensitivity - <3.5uv at 300Ω 10db s/n ratio

(1956 ARRL HB Ad spec)

Selectivity - 3.5kc at -6db w/o Crystal Filter

|

|

NC-173, NC-183 and NC-183D Serial Number Log

Serial numbers are very helpful for determining when

a particular receiver was built. The NC-173, NC-183 and

the NC-183D all use the standard post-WWII National

format of a seven digit serial number. It's fortunate

that National incorporated the specific "production run

number" as the first three digits of the serial number.

The production run numbers were assigned

chronologically. Each run produced a certain quantity of

receivers that were assigned a four digit number that

included "leading zeros" to identify specific receivers.

For example, HRO-5A1 serial number 184 0009 would be run #184

and this receiver was the 9th off the line. The serial numbers collected from later post-war HROs

and NC-2-40D receivers have already provided several

examples of the chronological issuing of many of the run

numbers. However, I really don't have anything specific to the

NC-173, NC-183 or the NC-183D. So, I'll start collecting

serial numbers on those types of receivers and see what

can be determined.

UPDATE: So far, it looks like ALL NC-173

receivers used #173 as the production run identification

and the four digit serial number provides the

chronological build-date information.

SN Locations:

The NC-173 serial number is usually stamped into the

metal chassis at the top-rear-center of the chassis just

above and between the filter choke and the filter

capacitor. The NC-183 serial number and the NC-183D

serial number are located above the accessory socket

and have "SER. NO." stamped

into the metal chassis (or silk-screened) proceeding the actual seven digit

number that is stamped into the metal chassis. The three photos

to the right show the locations of the

serial numbers for each receiver type.

Report Your SN:

If you have examples of these receivers, please e-mail

the serial number of each receiver. Be sure to

mention if your receiver is original and has any

significant differences from what's described in this

article or anything unique (and factory original)

about the receiver such as cabinet paint color used, cabinet

rear vent type, power transformer type on 183D, factory circuit changes,

etc. I'll add the serial numbers to the log and after a

while the log should produce

some interesting information. The variations tied to

serial numbers will help date when the changes happened. Here's an e-mail link

below or just use the e-mail link on website Home Page

(both links are the same e-mail address.)

Send your NC-173, NC-183 or NC-183D serial number to:

Serial Numbers

173-183, National, WHRM |

NC-173:

173 0212(vots,nas,SBC), 173 0912(vots, nas,SBC), 173 2155, 173 2821(pmrv), 173 4204(pmrv),

NC-183:

202 0248, 202 0442(eB,pmrv), 202 1318(pmrv), 241 0128, 241 0262, 241 0377,

305 1423(T), 309

0159(R),

309 0368(R),

309 0785,

NC-183D:

328 0584(ST,sM), 357 0271(NOT), 357 0363, 357 0668(ST,PS-J), 372 0538(PT), 372 0574(PT),

396 0086(PT,PS-J), 430 0135(PT), 430

0174, 430

0478 (R, Black Wrinkle panel)

R= Rack Mount

PS-J = Parts Set that was Junked

ST= standard pwr transformer SA3901 (on NC-183D)

PT = potted pwr

transformer S461 (on NC-183D)

NOT = Non-original pwr transformer

eB = seen on eBay

sM = seen at swap meet

pmrv = pattern metal rear vent

vots = vertically oriented toggle switches

nas = no accessory socket

SBC = solid back cabinet (NC-173)

If no notations are shown then just the serial number

was reported

|

|

Receiver

General Information |

|

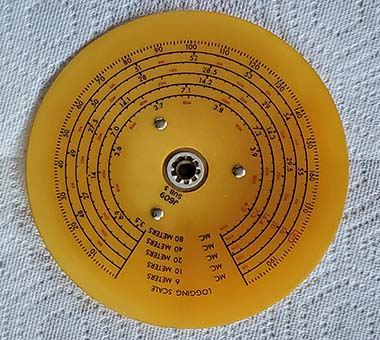

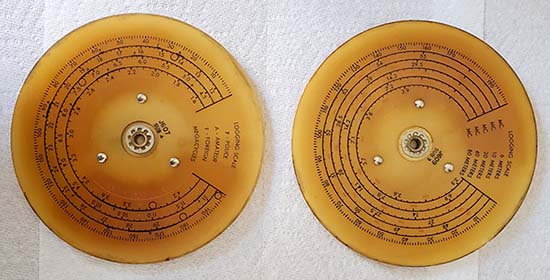

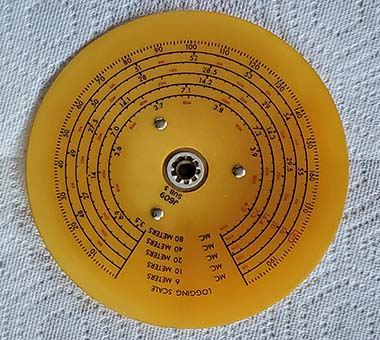

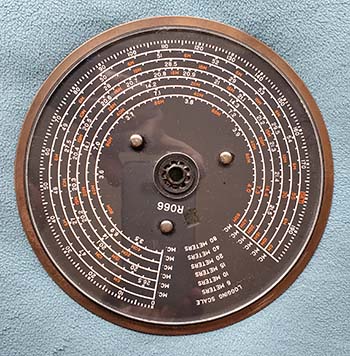

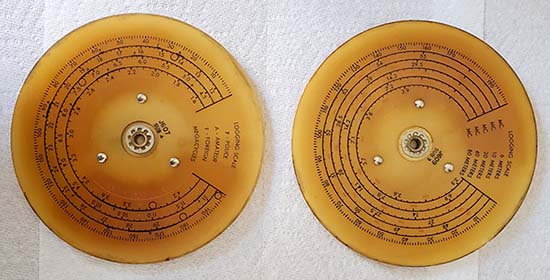

NC-173 and

NC-183 dials are a plastic disk that is riveted to the metal hub.

This type of material will darken as it ages and with

its long-term exposure to light and heat. The NC-173 and

the NC-183 used the exact same dials. |

NC-173 & NC-183 Yellow Phenolic-Acetate Dials versus the NC-183D

Lucite Dials

- The NC-173 and the NC-183 used acetate-based phenolic plastic

dials that were pale yellow when new but nearly all of

these types of dials have darken considerably to an

amber-color due to the photosensitive nature of the type

of plastic. These dials along with the S-meter scale

were backlit resulting in one source of intense light

near the dials as long as the receiver was on. Bright

sunlight directly on the dials also contributed to

intense darkening of the dials. There were also

indications that age and possibly heat from the receiver (if operated for long hours)

also contributed to this darkening.

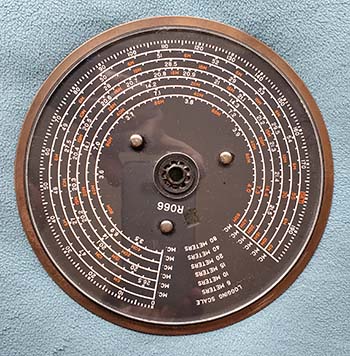

The NC-183D addressed this dial material problem by

using copper metal-backing plates that had a Lucite dial

riveted to the front of the metal plate (Lucite is a

high quality-type of crystal-clear Acrylic that won't

yellow or crack and is very strong but lightweight.) The Lucite was

reverse-side silk-screened with the dial nomenclature. This gave the dial

scale the appearance of "depth." These dials had to be illuminated from the

perimeter edge with the lamplight going through the

Lucite which makes the

silk-screened numbers very bright and visible (it requires the

position of the lamp be as far forward as possible for optimum illumination.)

Since Lucite was used the NC-183D dials, they are almost always in excellent condition (something

that, unfortunately, can't be said for the NC-173 and

NC-183 dials.) Dirt, debris and staining can get

behind the Lucite if the dial is subjected to a very

humid or wet environment. Extreme moisture behind the

dial will deteriorate the silk-screened nomenclature

causing it to crack and flake resulting in partially

missing numbers and tiny flecks of white silk-screen

paint.

NOTE:

As a restoration hint,...the dials from the NC-173 and

the NC-183 are identical with the same part numbers so

they can be interchanged if necessary.

NOTE 2:

It's interesting that while the NC-173 and NC-183 Band

Spread dials don't have the 15 meter band, the Main

Tuning dial does have 21.0mc to 21.5mc highlighted as an

amateur band. Although the IARU had approved a 15M band

and it was known that a ham band was going to be created

in and around 21mc starting around 1946, it wasn't an

officially usable ham band until 1950. Late in NC-183

production (and probably NC-173 production) the

bandspread dial was changed to have 15M calibration. Notice that the

NC-183D Band Spread dial shown to the right does have

the 15M band calibration (actually, 19.8mc to 21.56mc.)

|

NC-183D dial

showing the metal rim of the copper-plated backing plate and the

Lucite front dial. Lucite was used for airplane cockpit

covers and aircraft windows because of its strength and it will not yellow or crack with exposure

to UV or weather. |

|

This Marion

Electric meter is actually for a National NC-100 Series

receiver but it's the same phenolic material that was

used in NC-173 and NC-183 receiver dials. |

NC-183D

S-Meter - The S-meter

scale was changed for the NC-183D to a black field with linear scale

and numbers that were translucent yellowish-orange up to S-9 and

translucent red for DB above S-9 when backlit. These type of S-meters also seem to age quite well

(most of the time.) While the "red" on the

NC-183D S-meter for the <NC> and "over S-9" was "bright red" when illuminated, the "red"

used on the Lucite dials was a "brick red" color.

Original NC-173/NC-183

Dial Color - The S-meter shown to the left

is a NOS example that has been kept inside a box and

has never been exposed to sunlight, illumination lamps

or heat. It shows the correct color that the

acetate-based phenolic dials were when new. The red

numbers and letters show how vibrant the red was when

new.

Reproduction Dials and

S-meter Scale - Radio Daze, the major

supplier of reproduction plastic dials, in their online

catalog show that they offer reproduction dials for the

NC-173/NC-183 (same dials) and also for the S-meter

scale. But, before ordering, I would contact them to be

sure that the material they are using to make the dials

is the light yellow color shown in their online depictions.

A few years ago, I ordered a RCA ACR-136 repro dial that

was shown as the correct light yellow material online but what was

delivered was a dark reddish-brown material that was as dark

as the darkened dial I was trying to replace. According to

Radio Daze, the reason for the dark color was that was

the only phenolic material available (at that time,...2021.) Since the cost

for the NC-173/183 repros is over $70 (the complete set of

two repro dials is $47 and

meter scale is $24) I'd check with Radio Daze prior to ordering

to confirm what color material is going to be used. Be sure to also

realize that you'll only receive the plastic repro dials.

You have to remove the old dial from the hub and mount

the new repro dial on the old hub. You don't need to use

rivet mounting (as original) since there's a lot of

clearance for screw and nut mounting. Also note, Radio

Daze has a six week

lead time for delivering repro dials (they blamed

COVID in 2021, I don't know what the problem is now.)

|

| Analog Dial Accuracy - As for the dial accuracy, it's fairly good considering that it's an analog dial

that's electronically coupled with bandspread tuning with both dials having

limited resolution. By using either received known "marker" frequencies or an

external crystal calibrator reasonable

dial accuracy for the ham bandspread tuning can easily be achieved. Many

hams in the 1950s had surplus heterodyne frequency

meters like the BC-221 or they had a device called a Frequency Standard

that was a crystal oscillator for 1000kc, 100kc and then

a multi-vibrator circuit for 10kc. At the time, most

manufacturers felt that the vague frequency accuracy of

the receiver's tuning dial was normal considering it was

an amateur receiver and extreme accuracy could always be

provided externally with the operator using a frequency

meter or similar device and then using the logging

scales provided for accurate frequency resetting. |

|

There's Only One Accessory Socket

- Only one accessory socket was provided for either the optional NBFM adapter or for the optional

National Select-O-Ject (not both, and not for a National Co. plug-in Crystal Calibrator.)

The earliest versions of the NC-173 didn't have any accessory

socket. The accessory socket was probably added when the NBFM

adapters became available around August 1947.

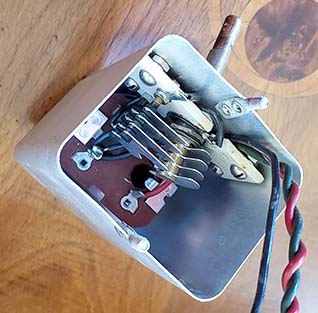

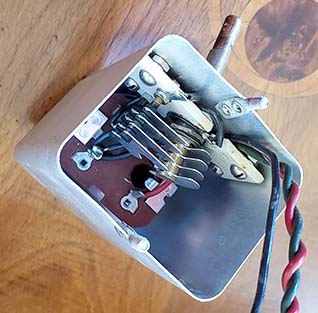

The Select-O-Ject - SOJ-2, SOJ-3

- This accessory was connected to the NC-173, NC-183 or NC-183D accessory socket via a

cable with plug connector on the end from the Select-O-Ject for

power and routing of the signal lines. The SOJ-2 was

the version that had to be used with the NC-173, NC-183. There was a

"punch-out" hole in the rear cabinet panel to provide access to the

accessory socket for the SOJ-2 cable (the "punch-out" wasn't on the

earliest 1947

NC-183 models, but was added by SN 202 1318, and the NC-173 didn't need the "punch-out" because it had the accessory socket on the rear

chassis apron.) The NC-183

accessory socket had to be rewired to work with the SOJ-2 (per

the National instructions but one would think it would be more

prudent and easier to purchase the SOJ-01 version the came without a

plug wired to the cable allowing the user to add a plug wired for

his particular receiver) and the

Radio/Phono switch on the receiver was used to place the SOJ-2 into

operation (the NC-173 had to have a "dummy" phone plug inserted

into the front panel PHONO jack since it didn't have a Radio/Phono

switch on the front panel.) The NC-183D used the SOJ-3 that didn't require the

accessory socket be rewired. The NC-173 also didn't require

accessory socket modification to work with the SOJ-2. As mentioned,

the SOJ-1 came without a plug installed to allow it to be adapted to

any receiver (instructions included.) The Select-O-Ject was a tunable audio frequency

peaking or nulling circuit usable mostly for CW but able to enhance

other types of signals also. Nowadays,

Select-O-Jects seem to be in the "seldom-seen" category of National

accessories but, perhaps that's because the current owners just don't want to part with

a versatile and usable device like the Select-O-Ject.

|

NBFM Adapter - NFM-73, NFM-83

-

Starting in the late-1940s and going through most of the 1950s, Narrowband FM was

thought of as a practical solution to the ever-growing problems of AM TVI and also for

RFI-QRN

reception problems in some locations. Since FM eliminated the

amplitude variations of the signal that caused most of the TVI

issues and replaced the amplitude variations with frequency variations that seemed

invisible to TV watchers, NBFM seemed perfect for Voice

communications for hams. The problem was that NBFM took up just

about the same bandwidth, maybe a little more depending on the

modulation f-deviation, as the standard AM signal. So, although TVI and

QRN issues might be gone, there was the possibility that the HF ham

bands couldn't accommodate a lot of NBFM users in competition with

the AM users. As a result, the FCC decided to gather some data on

NBFM in the HF amateur bands. For a period of one year starting in

late-1947, NBFM was

allowed anywhere in the normal HF amateur phone bands. All of the

manufacturers knew this and responded by introducing adapters and

NBFM capabilities in their gear produced in 1947 and 1948. At the

end of one year (about the end of 1948,) the FCC determined that

NBFM was going to have negative impacts on ham phone operation on

160M, 80M, 40M and 20M and operation of NBFM was not going to be

allowed on those bands. The FCC allowed for

limited the operation of NBFM to frequencies above 27mc, relegating

NBFM to 11M and 10M ham bands below 30mc. Though several manufacturers offered a NBFM

function on their receivers, it never became a popular mode of

transmission below 30mc. This was partially because of the

transmitting frequency limitations imposed by FCC regulations that

prevented wide-spread use of NBFM in the HF region of the spectrum. However later on, NBFM did become the popular voice

mode on VHF, especially on the 2M band. Currently, NBFM on HF is authorized

for 29.2mc to 29.3mc in the 10 meter band and this small portion of

the spectrum is the only HF authorization for NBFM communications. When the NFM-83 adapter is installed into

the Accessory socket, the adapter receives its operational voltages from the

receiver. Two tubes are used in the adapter, a 6SK7 IF amplifier and a 6H6

discriminator/detector. The

signal input is from the IF output and AVC line via the Accessory socket and the

NFM-83 output is

via the Accessory socket to the receiver's audio input. The NFM-83 is essentially "in

operation" whenever the receiver is turned on but the output utilizes

the PHONO-RADIO switch to route the NFM-83 output to the receiver's audio

system. When installed, PHONO is used for NBFM operation and RADIO is used for

normal receiver operation. The NFM-73 has a different configuration

that allows it to be plugged into the NC-173 accessory socket that's

on the rear chassis apron on the back of the receiver. The NC-173 didn't have a PHONO-RADIO

switch so a dummy phone plug was inserted into the PHONO input on

the front panel to actuate the jack-switch which then disconnected

the AM detector and routed the NFM-73 output to the audio amplifier

stages. Withdrawing the dummy plug returned the NC-173

to AM-CW reception. No modifications to the receiver were required

for using the NFM-73 adapter. The NFM-73 and NFM-83 are fairly easy

to find. Either of the adapters are

usually cheap and they should be since they are completely useless devices nowadays. |

NFM-83

Narrowband FM Adapter

Is it really a useless device?

Since NBFM on HF is only authorized on

29.2-29.3mc, finding any HF-FM activity today

would be a challenge. |

Kit-type 100kc Crystal Calibrator

- I don't know of any reason that National didn't provide for using

their

onboard Crystal Calibrator other than economics. Certainly, had

National included their typical 1000kc/100kc plug-in calibrator,

that would have been the most useful of the commonly available

National plug-in accessories but it would have required additional

wiring for an additional accessory socket and front panel switching

to operate the calibrator switching from the front panel of the receiver.

That's why the HRO-50/60 receivers have two accessory sockets - to

allow using a Crystal Calibrator with front panel switching plus either the NBFM adapter or the

Select-O-Ject that were operated with a separate rotary mode switch

for FM and the panel switch for the Select-O-Ject for its operation.

On the NC-183 series, since the dial indexes are not movable, the

calibrator could be used to set-up the Band Spread dial accurately

by minor adjustment of the Main Tuning. Conversely, the Main Tuning

dial could be set up accurately using minor adjustment the Band

Spread tuning.

Since regulated +150vdc and 6.3vac are available at

the NC-183 or NC-183D (or even the NC-173) accessory socket, any

100kc crystal calibrator kit could be built to use the accessory

socket of the receiver. Generally these kits will have a toggle

switch on the calibrator to turn off the B+. The output can usually just

be electrostatically coupled to the antenna

input and provide sufficient signal level. The hassle is that the lid of the receiver has to be lifted

to turn the calibrator on or off or, for the NC-173, one would have

to reach around

behind the receiver to turn the calibrator on or off. National, along with

most of the other receiver manufacturers, certainly

thought that any ham would have had either a surplus Heterodyne Frequency

Meter

or a ham Frequency Standard (an external, self-contained crystal

oscillator providing 1000kc, 100kc and 10kc markers) for accurate frequency

measurement of a received signal or for determining ham band edges

so an "onboard" 100kc crystal calibrator wasn't considered

a necessity. Additionally, the logging scale provided on each dial

is 0-200 and that provided a lot of resolution for accurate

resetting to known "logged" frequencies. Using any sort of

calibrated signal source (a borrowed Frequency Meter, for instance)

it would have been possible for a ham to "log" all of the ham band

edges and any specific ham schedule frequencies using the Main

Tuning Log setting and the Band Spread Log setting. This was an easy

and convenient method for accurate frequency reset that didn't

require an on-board Crystal Calibrator. As an example, on my NC-183

receiver, the Nevada Vintage Mil-Rad Net on 3.974mc is tuned by

setting the Main Tuning to Log 168.0 and the Band Spread to Log

170.5. It's a quick setting of the two dials and the receiver is "on

frequency."

|

|

Phono Input

-

Although the Phono circuitry was used via the accessory socket

wiring (pin out for audio varies with model) for the Select-O-Ject output or the NBFM adapter

output,

the Phono jack input could be used for any other sort of audio

amplification as long as the input levels and the impedances

matched. The SOJ-2 had to be disconnected to use the Phono input for a phonograph

cartridge input. The National NBFM adapter instructions don't

indicate that the adapter had to be removed from the accessory

socket to use the Phono input, but it did.

Battery Operation -

The octal socket on the rear chassis

apron allows access to the power supply voltages, remote standby

functions and can allow a

hook-up for battery operation of the receiver. Remote standby was

later routed to its own three screw terminal strip on the NC-183D.

As for battery operation, one famous use of a

NC-173 operated entirely on dry cell batteries was the receiver used

on the Kon-tiki Expedition in 1947. National advertising promoted

this trans-Pacific experimental raft sailing from South America to

Polynesia and its use of the NC-173 in several ads at the time.

Several battery and crank-generator small transmitters were also

used on the Kon-tiki. National advertising in the September 1947 QST

issue implies (but doesn't specifically state) that the Kon-tiki also carried a National HRO-7

receiver that was also dry-cell battery operated, however the

official write-up in Dec. 1947 QST states that the NC-173 was the

main receiver and the HRO-7 isn't even mentioned. It seems unlikely

that the HRO-7 was aboard since it wasn't introduced until August

1947.

|

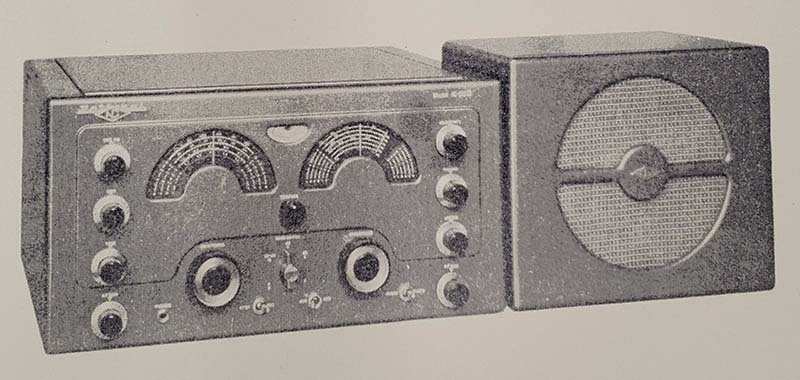

|

NC-183DTS 10" diameter

PM Loudspeaker for

the NC-183D

The NC-183TS was exactly like the "DTS"

but with the light-gray paint to match the NC-183. The

same brown woven cloth was used in the early version

loudspeakers. Be aware that some eBay sellers will

measure the cabinet dimensions and list the smaller MCR

6" speaker as a "National 10 inch Speaker" (this is

actually quite common.) |

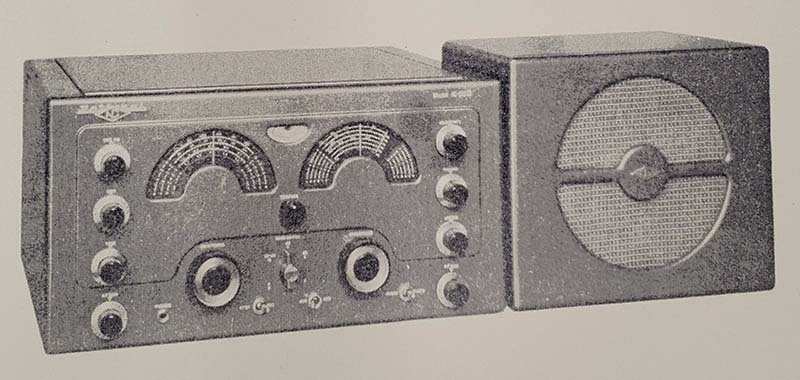

Loudspeakers - The

NC-183 used a 10" diameter PM loudspeaker, identified as the NC-183TS, in a matching table cabinet. The

1948 National Catalog shows that the

NC-183 was

supplied with the 10" loudspeaker however they are seldom found together

nowadays. Even though National specified that the loudspeaker was

included with the receiver, many dealers would offer the receivers

at a reduced price but minus the loudspeaker and then list the

matching loudspeaker for $10 to $14 extra. The 1950 ARRL HB advertisement

for the NC-183 indicates the loudspeaker wasn't

included in the price shown ($14 was the price.) The

loudspeaker impedance was 8Z ohms nominal. There also was a smaller

version of this loudspeaker cabinet that used a six-inch speaker in a light-gray enclosure was

designated NC-173TS. There are other light-gray smaller speakers

that are found equipped with eight-inch speakers

but these were intended for the HRO-7T. The 1947 National catalog states that the

NC-173 loudspeaker wasn't included with the receiver

and was priced at $10. All NC-173 advertising doesn't mention that

the speaker wasn't included with the receiver, even

the early ads in QST. The smaller loudspeaker

was intended for the NC-173 since its audio

output capabilities were primarily for ham communication (although

these smaller speakers do sound much better than

would be expected.)

The NC-183D was supplied with the larger 10" diameter PM loudspeaker and

cabinet. The speaker enclosure paint

color was changed to the gunmetal silver gray that was used on the

NC-183D receiver cabinet. The three-pin plug that had been used on

the NC-183TS was replaced with two

spade lugs to match the NC-183D screw terminals for the audio

output. There's usually a paper string tag on the speaker cord

indicating that it should be connected to the 8

ohm terminals of the receiver. This "DTS" version of the loudspeaker is shown in the photo to the

left. The NC-183D manual back page shows the speaker as model

NC-183DTS. The 10" loudspeaker does have good bass response

and sounds very nice for quality SW-BC reception (but don't have

the speaker only two feet away and directly in front of you. The speaker will sound much better from across the room,...ten

feet, or so,...in my

opinion, this applies to almost all loudspeakers.) |

|

NC-173TS 6" diameter PM

Loudspeaker for the NC-173

Although the assumption would be that an

8" loudspeaker would be installed into this size

cabinet, I've only seen 6" diameter loudspeakers

installed. If these smaller cabinets are found with an

eight-inch speaker installed it was intended for use

with the HRO-7T. The cabinet color is

the light grey with a slightly silver tint. |

|

Cabinet Paint

- The cosmetic department always seems to be problematic

at best. The light gray-slightly silvery paint job on

the NC-173 and NC-183 or the darker gunmetal gray-silver

paint on the "D" were actually

very durable paints but this type of smooth semi-gloss finish paint

always seems to show the "hits"

that the cabinet has taken from just about anything setting on top of

or next to the receiver or whenever it's moved from one place to

another. Part of the problem is that the NC-183 versions

are heavy receivers with "absolutely nothing" to grip

when trying to carry the receiver when moving it to a

new

location. I'm sure a lot of the dents

and scratches are due to the mover dropping the receiver

or the receiver just "slipping" out of the mover's hands.

The upshot is it's almost impossible to find

any of these receiver-types in mint

cosmetic shape. The nomenclature is stamped into the metal so a

repaint might be possible although only

automobile-quality paint that is "custom matched" to the original

color

should be used in any repaint. Almost all "off the shelf" spray-can paint will

contain fillers that act as a sort of primer but using

this type of paint will fill up the debossed

nomenclature. The original paint was very durable but

was very thinly applied

and that's why it seems so prone to damage. If

at all possible avoid repainting the cabinet

since properly mixed paint, special equipment,

correct prep and especially professional spray

areas and professional painting experience are

all necessary for a quality result. Often, if

the receiver has decent cosmetics, a good

thorough cleaning followed by a careful

"touch-up" paint application is all that's

necessary to get the receiver looking acceptable

for a vintage ham station.

NOTE: Shown to the right is an excellent

repaint of the gun metal dark gray used on the

NC-183D. The paint application looks like

power-coating but it's completely even and

looks almost original (just slightly darker gray color.) The filled

engraving looks

excellent. So, quality repaint jobs are possible but it

almost certainly involves professional painters using

quality paint and equipment with the paint job done in a

controlled environment. |

NC-183D - A Quality

Repaint Job

photo from eBay

|

Cleaning

Phenolic Dials on the NC-173 and NC-183 - As mentioned, the acetate-based phenolic plastic dials used on the NC-173 and

NC-183 are always much darker nowadays than they were when new.

Most of the time, the section of dial that was exposed to light

through the front panel dial opening will be much darker than

the unexposed areas. This darkening is inside the plastic

material and is impossible to correct. Sometimes a slight

improvement can result with damp-cleaning the back-side of the

dial. Any cleaning of the front-side of the dial should only be

attempted after a test-cleaning of the part number

that's located near the hub of the dial. If the part

number isn't affected by damp-cleaning then the entire

dial front can be cleaned by that method. I've found

that many plastic dials made after WWII will have very

durable ink that can be damp-cleaned, BUT TEST TO BE

SURE. The NC-183/173 dials used very durable ink on the dials

and they can be cleaned directly using a Glass Plus

dampened paper towel. DON'T EVER USE WINDEX, the ammonia

is a harsh cleaner, use only Glass Plus, don't scrub, don't use a lot of

pressure and watch the ink for any thinning. I didn't

have any ink degrading with Glass Plus when

damp-cleaning either the NC-183 dials or the NC-173

dials yet years of dirt and

tobacco staining were removed. After the cleaning, the dial

will have a "flat" look but lightly polishing with a

dry soft flannel cloth

will impart a sheen to the plastic dial without doing any

damage. This dial cleaning won't change the darkening that has

happened because of sunlight. That discoloration is deep inside the plastic

material. What the cleaning does is remove other types of dirt

on the surface of the dials and that will generally brighten the

dial somewhat and increase the contrast between the dial color

and the nomenclature. Cigarette smoke contamination on the phenolic-acetate

dials is the most common "dirt" that can usually be easily

removed on post-WWII dials, but be sure to test the silk-screened ink on a

non-visible area first.

Cleaning Lucite Dials on

NC-183D - Lucite can be cleaned using

Glass Plus or a plastic foam cleaner. Don't use WINDEX.

I've used Glass Plus with paper towels and had no

scratching occur but some plastic cleaners will suggest

using a soft cotton cloth to avoid scratching. It

probably depends on the paper towel brand used. Avoid

the cheap paper towels that are coarse and stiff

feeling. The most important part of cleaning is to NOT

use WET paper towels or cloths. The excess wetness will

wick down the rivet holes and get behind the Lucite.

Normally, this will dry and not cause any problems but

if there is any dust or a film coating on the inside of

the Lucite dial, then it's possible that some residual

pattern will show in the dust after the wetness has

dried. It's not staining but you can't get rid of it

unless you disassemble the dial which means drilling out

the rivets. That's a major pain that's best avoided by

only using slightly damp paper towels or cloths. Other

than avoiding excessively wet cleaning, the Lucite dials

are very forgiving and easy to clean.

NOTE: If

a little moisture did wick down the rivet holes usually the

"stain" won't show when the entire receiver is assembled

since the rivets are hidden by the shape of the dial

openings in the front panel.

Dial Covers

- The dial cover on the NC-173 and the NC-183 is a

single, thin plastic, rectangular piece that has the

band indicators for both dials applied on the backside

and then covered with gray paint for color and

protection. This piece can and easily does get very

dirty. That adversely affects the dial visibility. The

dial cover plastic is mounted with two aluminum

strip spacers, one on each side. The aluminum strips are

only used on the NC-183 to provide

the proper spacing so the dial cover is the correct

height behind the front panel dial openings. There are two screws,

lock washers and nuts on each side to mount the plastic

piece. The screw heads are on the outside of the front

panel. On the inside is the aluminum strip, then the

plastic, then the lock washer and nut. The nuts aren't

overly tight or the plastic could possibly crack over

time. Once the dial cover is dismounted, it can be

easily cleaned with Glass Plus. Both sides need to be

clean. Usually the gray paint that covers the

nomenclature is in good condition. If it has scratches

or missing paint areas and the lettering isn't affected

then carefully match the paint and apply on the

backside. Remount using the original spacers and

hardware. The NC-173 dial cover mounts the same way but

without any aluminum spacers. Since the front panel's

embossed area is just around the dials and the mounting

screws for the dial cover are in the area of the panel

outside the embossed area, the dial cover ends up being

flush with the inside of the dial openings with no

spacers. The NC-183D uses two Lucite dial

windows that are approximately 0.125" thick and have a

section that has a black background paint applied. The

index line is an engraved line on the interior side

filled with white paint. The mounting edge of each piece

is slotted so the mounting screws only have to be

loosened. The Lucite windows both mount just on one side

with an aluminum spacer and another aluminum strip that has

tapped holes. The side nearest the S-meter isn't

supported except for a metal support guide that is

mounted by way of the Trimmer shaft bearing bracket. The slotted mounting on one side only will

allow for slight position adjustments. The band

indicators are on the exterior side of the Lucite

with engraved nomenclature (actually, I think the

nomenclature was stamped in some way) with white fill

paint. Clean the Lucite pieces with Glass Plus. Be

careful of the band indicator engraving and fill paint

because it's extremely delicate and can easily be

damaged or entirely removed. Putting the band indicators

on the outside of the dial covers was a "BIG

MISTAKE" by

National. If it had been done like the NC-183 or NC-173

with the indicator nomenclature on the interior side protected

with a coat of paint then the following cosmetic problem

would have been avoided,...

NC-183D Band

Indicators - An Insolvable Problem - Another cosmetic problem involves the

Lucite

dial covers and the white paint fill on the band identification

markers used on just the NC-183D. The engraving is very,

very,...well,...extremely shallow and the thin white fill paint can be

easily destroyed by careless cleaning efforts, for example,

using Windex to clean the dial covers,...a common mistake. The

shallow nature of the engraving prevents re-doing the white fill

paint in a normal manner. Any attempt to remove excess fill-paint

is impossible because

the "wiping action" tends to "pull" the fill-paint out of the

extremely shallow engraving. Worn original white fill-paint

seems to be a very common cosmetic problem that seems impossible

to restore, at least, I've never found a successful method to

accomplish it. National

must have had some special process to accomplish the white fill of the nomenclature

on these NC-183D band indicators since the debossed nomenclature

doesn't look like typical engraving. I suspect that National somehow "hot stamped" the

nomenclature and the color simultaneously and that's why the debossed lettering and numbers are so, so shallow (not at all

like true engraving.) Since this was some sort of "special process"

National used that certainly required specialty tools, today it

has become impossible for restorers to duplicate the end results.

Some Things I've Tried -

That Don't Work:

Rubber squeegee

- didn't work. Lacquer Stiks

- didn't work. White Testor's Enamel

painted just on the engraving with as little over-spread as

possible. Let this dry and see if I can remove the excess

carefully with a new razor blade. This was very close to working

with the razor "rolling" the paint off nicely

but the razor blade is too aggressive for the plastic leaving

very fine but noticeable scratch marks. Next, I'm going to try a

Plastic business card

- didn't work. The trick seems to be letting the paint

dry some and then it will "roll" off leaving just a little bit

of paint to be removed later when it's dry enough that it won't be pulled

out of the engraving. How to remove the remaining paint residue

is a problem and thinner seems to easily remove the fill paint,

even though it's fairly dry. I'm thinking about going back to

Artist's Acrylic and using this plastic card procedure. With

acrylic paint, clean up would be much easier using Glass Plus that doesn't react with

the plastic. Well, that

didn't work either...the acrylic paint won't "roll off" like Testor's

does and the plastic business card won't shave off the acrylic paint but

just smears it around. Testor's and

Plastic Card - when Testor's was tried again, the

plastic business card isn't sharp enough to make the paint

"roll off." To sum it up,...Testor's and a new razor blade comes

the closest to working. But, it's far from perfect. If

the original band indicators are faded but can be seen

and read, I wouldn't do anything to them because

anything you do will only make things worse. If the band

indicators are completely gone (like these were that I

experimented on,...from a "parts set") then the Testor's and a

razor will provide some fill to the nomenclature but test your razor technique on a

scrap piece of Lucite or plexiglass first and see how much scratching you get,...it probably will change your mind. Maybe if there was a plastic

razor blade,...maybe that would work. Or, a

very sharp edge using a piece

of plexiglass. It might work,...Tried it,...nope, it doesn't

work very well. It's probably the only option that sort of works

and doesn't damage the Lucite. Then there's this solution,...

The Best Option

- Actually, I've come to the conclusion that finding a "parts

set" that has good dial band indicator/covers is probably the best

solution. Although, unless the "parts set" can be found locally

to eliminate the exorbitant cost of shipping a heavy receiver that's only

needed for parts, it might end up being a very expensive method

to fix this seemly insolvable restoration problem. Hopefully,

there might be other "needed" parts that can be also

be salvaged from a

"parts set purchase + shipping" expenditure. All of these special and difficult to

solve cosmetic issues seem to justify the high prices that a

"near mint" NC-173, NC-183 or especially the NC-183D can garner today. |

|

General Information on Rebuilds

Is rebuilding really necessary? If you intend to use

any of these receivers as a vintage ham receiver in a

ham radio station environment where the receiver will be

turned on regularly, used for a couple of hours and be

depended upon to provide reliable operation, then the

answer is yes. If you want to experience the tremendous

audio capabilities of the NC-183 or NC-183D then a

rebuild will absolutely be required. Most of these

receivers, when in "as-found" condition, have been

stored away and haven't had power applied to their

circuitry in years,...perhaps decades. Defective

components are a certainty and if the receiver is

powered up in this condition it's quite possible to

damage other components in the receiver. The attention

to detail necessary for accomplishing the rebuild will

allow you to examine every part of the radio and this

will result in you discovering many other somewhat

latent problems and to take care of any mechanical

issues found. With a complete, thorough rebuild, the end

result will be a receiver that can be left turned on for

several hours without overheating components, it will

operate to original specifications and it will be a

pleasure to use. With the NC-183 and NC-183D, the audio

produced by these receivers will be impressive when

everything is correct. |

|

Typical "As

Found" Condition - Today's vintage

ham gear enthusiasts appreciate National's combination of robust

push-pull V-T audio with great reception possibilities making the NC-183

and, even more so, the NC-183D very popular choices for vintage

ham station receivers. Additionally, these were very well-built

receivers that used top-quality (for the time)

components. The chassis is high-quality cadmium plated and many of the steel parts are

nickel-plated. Other chassis components have a matte-aluminum

finish. The NC-183D chassis is often found in beautiful

condition, though it does depend a lot on how well-cared-for the

receiver was during its active period and then ultimately where

the receiver was stored afterward. It does seem that finding an

excellent condition, all original NC-183D isn't as difficult

as finding the NC-173 or NC-183 in a similar pristine condition.

The earlier receivers seem to have been used for a much longer

time, so they might have ended up becoming victims of amateur

repairs and seemingly modified more often than the NC-183D

versions. The expense of the "D" might have been another reason

for its better preservation. Also, the NC-173 and NC-183 were

good usable receivers for a much longer period of time than the

NC-183D. When the last of the NC-183Ds were produced, in 1958,

the ham radio market was beginning to change to smaller and

lighter-weight ham receivers. The desire to keep a large, heavy

receiver around perhaps didn't last too much longer. The

NC-183Ds were retired with less total time in active use, so

many were "put away" in excellent condition having been used a

for just a relatively short time. But, just because any of these

receivers might have been retired and put away in good shape

doesn't mean they stayed in that condition. Poor storage

conditions and endless time spent in a humid, rodent infested

environment has irreparably destroyed many of these receivers.

Some retired receivers were traded-in on new equipment to be

then sold by dealers as "second-hand" receivers. These receivers

didn't seem to benefit as much from "new owner appreciation" and

being older gear, many second-hand receivers were soon hacked

for repairs, modified in attempts to modernize the performance,

abused, thrown around, scratched-up and finally ended up

becoming part of a vertical pile of collected gear,...usually

rusting away in a leaky shed or damp basement. The upshot is,...any

NC-173, NC-183 or NC-183D found in excellent physical condition

today is a rarity. But, you're more likely to find a

really nice NC-183D than either of its predecessors (although

I've seen a lot of really poor condition NC-183D receivers too.)

NC-183D

- Many as-found condition NC-183D receivers will have a variety of

operational problems nowadays generally due to poor storage, hamster

rework in the form of "junk box components" used for repairs that

are "hook-spliced" into the circuit. Sometimes unnecessary

and destructive modifications

are incorporated into the circuit. In addition to those

problems, some

original leaky paper-dielectric capacitors can potentially cause heat-related failure of the

power transformer or the filter choke if the receiver is operated for long-hours without

a proper rebuild (power transformer failure seems to be a

moderately common occurrence judging by how often replacement

power transformers are encountered in these receivers.) A

full rebuild and complete alignment are normally

required to obtain the "top performance" that the NC-183D is capable

of providing. If you're planning a NC-183D rebuild, there are 16 (up

to 19 in later versions) molded-plastic-tubular,

paper-dielectric capacitors to replace but, luckily, a large number

(all but five) of the

.01uf capacitors are ceramic disks that won't require replacement. There are 5 electrolytic capacitors

that will probably need replacement. Reform and test at full

operating DC voltage if you plan on using the original electrolytics. All components are

easy to access. Check the carbon resistors for being out-of-tolerance since

any leaky

bypass capacitors can easily over-heat associated load resistors.

Many of the 470K resistors are in parallel with other components in

the circuit and will not measure their actual value "in the circuit"

and will need one lead "lifted" for accurate measurement (if

you feel it's necessary - like if you're having trouble with the

circuit.) On replacement parts, use only new capacitors.

Polyfilm "Yellow Jackets" will work fine but the end

result will look like the cheapest parts available were used for

the rebuild. CDE 715P Orange Drops

are polypropylene dielectric and high quality capacitors that will make the rebuild look

much more professional. Replacement resistors should be NOS

JAN CC types (10% tolerance or better) if possible, and their value must be verified with

an accurate resistance measuring device (some brands of

carbon resistors will drift in value even if they have never

been used. Allen-Bradley JAN types are the best for holding

their value.) Replace any tubes that

don't exceed

minimum acceptable transconductance by a significant percentage (NOS

tubes are best.) Finish with a complete IF and RF

tracking alignment and your NC-183D should become an easy-to-use

station receiver that provides excellent sensitivity, the necessary selectivity

if you use the Crystal Filter and very high-quality audio reproduction

if you use the original National NC-183DTS 10" table loudspeaker or

perhaps even a

better speaker set-up.

NC-173 and NC-183

- These earlier receivers have wax-covered cardboard shell, paper-dielectric capacitors

installed (and there are a lot of 'em - 26 paper-dielectric wax-coated types to

be exact,...plus four rectangular bakelite molded paper caps -

30 paper-dielectric capacitors total for the NC-183. The NC-173

has a total of 26 paper-dielectric capacitors and two bakelite

molded paper capacitors.) In the NC-183, the four rectangular-shaped, brown-molded plastic capacitors look like over-size micas but are actually .05uf 600wvdc paper-dielectric capacitors

and these should also be replaced (these are WWII surplus components that many manufacturers

used post-WWII.) In the NC-173, the molded bakelite

capacitors are .005uf 600wvdc paper-dielectric types (only

two of these are used.) Check electrolytic capacitors for value and leakage

current. The power supply filter electrolytics will almost

certainly need replacing. Sometimes the filter capacitor might

have an

excellent seal and it might function after reforming but be sure to

reform and test at full working DC voltage (but I still don't know if I'd trust it for long hours

of operation. After cutting apart a few of these Aerovox filters

and seeing what's inside,...I'd replace or rebuilt any original

multi-section,...it's a failure waiting to happen!) Also, many times the cathode bypass electrolytics are still good

(low operating voltage, connected in parallel with a low

value resistor and the small size provided excellent sealing

preventing most of them from drying-out. Testing and reforming

will be required - but replacement is certainly a better option for top

performance of the hi-fi audio section.)

Resistors should be checked for values versus tolerance.

Basically, it's the same procedure as with the "D" model but

with a lot more paper-dielectric capacitors to

replace. |

|

NC-183D -

Vintage AM ham users favor the NC-183D primarily because of its

double-conversion, its tertiary component IF system that also provided an

extra stage of IF amplification and its superb high fidelity audio

reproduction. The receiver was supplied with the

NC-183DTS, a 10" PM

loudspeaker in a matching housing but these are rarely found

with the receiver anymore. The original National 10" PM speaker

actually sounds very good, but these large 10" versions

are becoming more and more difficult to find along with its

ever-increasing expense to purchase them when they are in good condition

(not to mention that most of them will have to be shipped to

you adding to the overall expense.)

However, if a larger speaker system is available, the

NC-183D can produce really fabulous audio on AM signals. Lots of bass is

available and the 3.5kc IF passband (at -6db) is sufficient for a

fairly wide-sounding, bass-laden audio

reproduction (at one time, I used a 15" Jensen coaxial speaker housed in a

Jensen KM bass-reflex box - described further down.) The

audio bandwidth specs are a surprise for a communications

receiver and feature a -5db 20hz low end, flat from 50hz to 7khz

and an expected drop off beyond that to -5db down at 12Khz and

there's 8 watts of V-T audio power available and 11 watts peak.

Though it might be thought that by tuning to one sideband or the

other, higher audio frequencies could be recovered, the shape of

the NC-183D IF passband is such that as one tunes "off carrier

center" more and more signal attenuation occurs and that results

in the best audio reproduction actually happening when the

signal is tuned "carrier center." The TONE control can be used

to maximize upper audio response, if that's what's desired. It's too bad that AM-BC programming is so dismal (around

here it's nothing but sports-talk, poli-talk and the aurally torturous

country-western stations on AM )

and quality SW-BC is also a rarity these days.

Well, there's always low power DIY BC-ing. Or, for better signal

quality, you can use a lab-type RF signal generator and feed your

CD-player (showing my age,...sorry,...your MP3 device although

maybe that's obsolete too) output into the EXT. MOD input, adjusting the sig-gen

modulation gain level

for a quality waveform. Then connect the RF sig-gen to the NC-183D

antenna input and decide on a frequency to use. It's like having

whatever programming you want delivered via cable to the

receiver. Of course, audio quality is highly dependent on the

type of external equipment used for this "hook-up" and

the resulting "quality" is

certainly a subjective judgment.

The NC-183D is also sensitive enough and provides

adequate selectivity to deal with most actual ham band reception issues.

I've used the NC-183D as a station receiver on 75M and it's

easily able to cope with all of the QRM and QSB issues along with having a good

ability to provide Q5 copy of very weak signals in the AM mode. It's also

convenient that remote standby is very easy to set up and use.

When examining the specifications one will notice that the

NC-183D has almost all of the features of the HRO-60 but minus the

headache of dealing with plug-in coil sets that have to be

manually extracted from the receiver to change bands or to be switched between general coverage and ham band

spread coverage;

or the expense of purchasing additional coil sets if coverage

other than 1.5mc to 30mc was desired;

or the problem of how to store

unused coil sets or dealing with a PW-D micrometer dial that was

pretty much useless by the HRO-60 production (the PW-D had to be

installed, otherwise it wouldn't have been a HRO.) Maybe you

can't use the plug-in National Crystal Calibrator on the NC-183D but there are other

methods for externally determining received frequency (using

a heterodyne frequency meter was popular in the 1950s but

nowadays it's much easier to use a digital frequency counter, or

just use the logging scales for accurate frequency resetting.) If you want the

performance of the HRO-60 but with less accessories and in a more convenient-to-use form

with features like simultaneous band spread and general coverage operation,

tuning range changes via a front panel band switch or high fidelity audio, the NC-183D is that

receiver. Likewise, the earlier NC-183 was intended to be

competitive with the HRO-7

first and later, the HRO-50.

NC-183 -

The earlier NC-183 is obviously lacking some of the more

sophisticated design features of the NC-183D, but the NC-183 was

from where the "D" evolved. Even though it's the early version,

the NC-183 was considered a "hot receiver" when it was

introduced in 1947,...at least

according to National advertising that stated the NC-183 was the

"deluxe

receiver for optimum reception under all conditions!" Nowadays, when the NC-183 is

fully rebuilt and aligned, it

will perform more or less like the "D" on lower

frequencies but the NC-183D's double conversion and more modern

tubes definitely benefit its reception capabilities above 20mc.

Since the NC-183 only uses two stages of IF amplification using standard IF

transformers, the result will be a broader IF passband that will

tend to favor the hi-fi audio capabilities of the receiver when

listening to quality AM broadcasts (if they exist.) The Crystal Filter can narrow

the passband as needed and will probably only be needed

occasionally. Crystal Filter can easily be used for AM reception

and is excellent for reducing adjacent frequency SSB

QRM. The single-conversion design really only adversely affects

performance on the highest frequencies. Up to about 15 meters,

the NC-183 does a great job. Above 25mc, the NC-183 begins to

show its WWII design roots as the sensitivity falls off somewhat (the 6M coverage requires strong signals,...and

some actual activity on the band.) Mechanically, the tuning on the

NC-183 can have problems since the plastic dials are directly rim-driven

with a pinch-wheel system. If the plastic dials are damaged

along the rim,

they will never work correctly (and these dials can be

damaged easily by careless removal of the chassis from the

cabinet.) The odd-ball three pin loudspeaker socket is a

hassle to find a mating plug for but using just the correct size

metal pin to fit the one large socket receptacle (chassis

ground) and to fit a smaller pin for either 8Z

or 500Z outputs will work fine and eliminates trying to find the

almost unique plug. The NC-183 is difficult to find in excellent

cosmetic condition (I've never seen a near-mint condition original

NC-183) and almost any example will always need some

mechanical rework and definitely will need electronic rebuilding to get it performing up to its original capability. I've

also used the NC-183 (fully rebuilt) as a station receiver on 75

meters and have found

it easily able to cope with all of the normal QRM issues.

Actually, 75 meters isn't

much of a challenge for almost any receiver and selectivity

becomes the most important facet of performance when operating

on this band. The NC-183 Crystal Filter deals with QRM very

well. Because of its wider "bell-shaped" IF passband that's very

different from the "steep sides and flat nose" passband of the NC-183D, I think the NC-183

actually produces a slightly better sounding audio reproduction

of a good quality AM broadcast signal if compared to the same type of

signal received through the "QRM-fighting" 3.5kc IF passband of the NC-183D.

And, with the NC-183, if more selectivity is required,...there's

always the Crystal Filter.

NC-173 - The

NC-173 is a slightly smaller receiver not having the depth that

was required by the NC-183 chassis. Also, the weight is

noticeably less than the NC-183. The Phono

input is on the front panel and includes an internal phone plug-operated

switch that disconnects the receiver circuitry from the audio

section when the Phono jack is used. The accessory socket is on the back

panel. The smaller 6" loudspeaker (NC-173TS) was supplied with

the NC-173 and a

standard three screw-terminal strip was used for the 8Z and 500Z audio

outputs. The National NC-173 advertising always showed the smaller

loudspeaker in a housing that's the same height

as the receiver cabinet where the NC-183TS 10" speaker housing

is noticeably taller than the receiver. The NC-173 receiver used a different style power transformer

(lower voltage B+ winding since less power required for the

single audio output tube is used) and the audio output

transformer was also different since it was for a single output tube. The audio output power

isn't shown in the manual specifications but given that the 6V6

plate voltage is around +180vdc with an average of about -18vdc

grid bias, the power output is about 2 watts. This isn't

implying that the NC-173 has anemic audio,...it doesn't. The

receiver will really sound very good when it's rebuilt and is

used with a decent quality loudspeaker (the 10" NC-183DTS

sounds great when driven by a NC-173 but even the smaller

six-inch speaker sounds pretty good.) NC-173 reception might have problems with images starting around

14mc.

To a certain extent, actually hearing images will be related to the incoming

signal strength so a very large broadband antenna or a long untuned end-fed wire might

actually allow more images to be heard than a simple resonant antenna

system would. As a test, using a ten foot long wire antenna, I

absolutely could not hear the 15mc WWV image on 14.090mc even

though the 15mc signal was S-9+. But the

20mc WWV image on 19.090mc was as strong as the actual signal.

Switching to the Collinear Array antenna and the 15mc WWV image

was easy to find but even with this large antenna I couldn't

hear the 10mc WWV image. One does have to consider (as maybe the

original purchasers did) that the majority of ham operations

would have been on 80 or 40 meters where images wouldn't have

been a problem and the receiver's selectivity was the important performance

requirement. If

frequencies higher than 14mc were of interest and it was thought

that images might cause a problem it was always

possible to add an external preselector to improve image

rejection. On 80M, no problems would be encountered using the NC-173

as the vintage station receiver. Likewise, 40M operation

wouldn't present a challenge. The NC-173 uses the same Crystal

Filter as the NC-183, so it provides

the selectivity needed to cope with QRM. The NC-173 is rarely

found in pristine condition although I've seen a couple over the

years.

NOTE: An observation on using

WWV as an "image test" signal - No HF signal is more

recognizable than WWV. This station almost always provides a powerful

signal but, no matter how weak the signal is, one can always

recognize its unique characteristics. The typically powerful WWV signal with easy recognition skews the "image

test" to a certain extent. A normal ham signal image probably wouldn't even

be heard or noticed. In fact, the only ham images I've ever heard when

using single-preselection receivers on 20M have been from high

power ham stations using high gain directional beam antennas and

excellent propagation resulting in extremely strong

signals. And, the only reason these images were even noticed was

because the ham signal appeared to be way outside the 20M ham

band (so it was obviously an image.) So, even though 15mc or

20mc WWV images can be

received, I doubt that any normal ham signal would be. Even

SW-BC stations in the 19M band are rarely heard as images. So,

although I mention the WWV image test, remember that this is the

absolutely worst case image test if one is using actual received

over the air signals.

No Receiver is Perfect

Though the NC-183D, the NC-183 and the NC-173 can perform very

well when fully rebuilt and aligned, providing fabulous audio

and excellent sensitivity, these receivers were designed during

the post-WWII era. In fact, the early receivers will have

some WWII surplus components used and the metal octal tubes are

mostly WWII design improvements over the late-thirties metal

octal tube designs. The early receivers operate as would be expected

for the time period but, they can still do a fine job on

75M,...almost any receiver can. The later NC-183D has several

circuit design improvements, more modern tubes and some nice mechanical

improvements. But, it still operates like an early-1950s

receiver but with the ability of better higher frequency

performance.

Antennas are very important for top performance. A random

length, untuned wire will not allow any of these receivers to

perform to their maximum specifications. A matched antenna or a

resonant antenna will allow maximum response from these

receivers and, of course, antennas with gain will provide the

very best response.

With any of these receivers you can expect a fairly long

warm-up time. These receivers need at least several minutes at

least to settle down and stabilize. Frequency drift won't

entirely stop but it will slow down considerably within about 20

minutes or so. Although dial accuracy is

excellent, the dial resolution is poor but that's what

would be expected for the time. For example, on Band B, the MT

dial readout resolution is an index mark every 200kc. Even on

Band D (80M) the MT index marks are every 50kc. If you calibrate

the Band Spread, you can get better resolution and better

accuracy but even on 80M BS the resolution is 10kc per index

marker so direct frequency readout still involves a lot of

guessing (or using a frequency meter if accuracy is important.)

National didn't provide a Crystal Calibrator for these receivers

and the National Crystal Calibrator won't work in the Accessory

Socket. Although it would be possible to install a homebrew or

kit 100kc calibration oscillator but it would have to

incorporate its own switch to turn off the B+ to disable the

oscillator when not in use (the B+ can't be turned off at the

Accessory Socket.) MT dial calibration can be sometimes

accurately set by using the BS tuning to offset the MT dial. It

only works if the desired MT frequency is higher than desired

with the BS at 100, then the BS can be used to bring the MT into

calibration.

The Noise Limiter is from the late-forties, so it's designed for

impulse-type noise, like ignition noise. It doesn't work very

well on many of the

modern types of RF noise (although the NL does seem to reduce SCR-impulse

noise quite well, like motor speed controllers used in modern

modulated heating systems.) The S-meter response is very dependent

on the tuned frequency, that is, on 80M with the RF gain at 9.5 the average AM ham

signal will "peg" the S-meter while a SW-BC station in the 19M

band will barely reach S-9. This is typical of S-meter circuits

of the time although the RF gain level can be adjusted to

compensate for "over-driving" the S-meter.

Since these receivers were designed and produced

before SSB came along, the Detector and AVC are designed for AM

reception. CW (or SSB) can be received by adjusting the RF gain

for a proper BFO

injection ratio. This is typical diode detector/BFO design of the time period. The

Amplified AVC circuit can be

left on for CW reception if desired. SSB reception will require reducing the RF gain

control down for proper demodulation of a SSB signal. Expect a lot of drift in the CW and SSB mode

unless the receiver has been turned on for at least 30 minutes.

The NC-183 and the NC-183D are both heavy receivers weighing 65

pounds. When trying to move these receivers the cabinet doesn't

provide anything to "hold on to" and the rolled edges and smooth

paint can limit your grip. Judging by the dents and scratches

found on these receivers today, loosing one's grip and dropping

the receiver must have happened more often than would be

expected.

The sum it up,...the NC-173 and the NC-183 operate exactly like receivers designed and produced in the

late-forties to sell for between $190 and $260. The NC-183D is a slight improvement but overall

behaves with the same minor issues that would be expected from a

receiver produced in the early-1950s (and selling for about $370.)

Although these receivers were expensive, they weren't the most

expensive receivers available. Their design and performance

can't and shouldn't be compared to the Collins-designed military

R-390A. Mentioning Collins, one has to consider that

even though the Collins 75A Series or the Collins 51J Series

were contemporaries of these National receivers and can