|

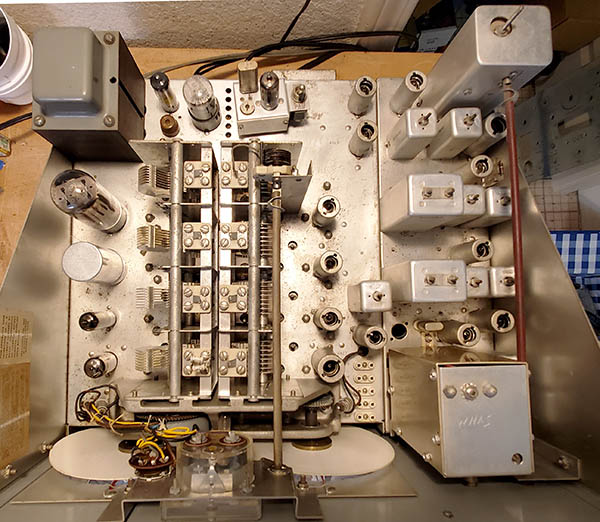

The receiver does have to be mounted in

the cabinet to achieve the best stability. How NC-400

receivers were ever used rack-mounted is a mystery (probably

with side rails.) The cabinet

frame and

screw-mounting provides the support the flexible chassis

requires. The NC-400 can pull in weak signals quite well, especially after a

careful alignment. It probably will take a bit of listening and working

with

the receiver to eventually get the most out of it. The NC-400 can be a

sensitive receiver. It can be selective enough when necessary

and also can be set-up for a broad IF passband to enjoy some of

the quality SW BC stations - are there any left? Ownership and

actually operating the NC-400 for a while will go a

long way toward one's overall appreciation of the NC-400 and

certainly its electronic performance is at the forefront of that

appreciation. The audio quality is a pleasant surprise considering

it's just a single-ended 6AQ5 that's producing the very natural sounding

reproduction. However, the Tone switch is next to useless since it just

reduces the high audio frequencies slightly by switching in a

bypass capacitor (for $895, one

would think National would have installed a true adjustable Tone

control.) For the best audio reproduction, use a good

quality, moderately large diameter speaker, 8" to 12" is

sufficient, installed in a decent housing and the NC-400 audio

will sound great. Finding the matching loudspeaker, the NTS-2,

is difficult. I run my NC-400 using the balanced 600Z output to

a good quality eight-inch speaker in a large wooden cabinet with a 600Z to

8Z matching transformer. The sound quality is pleasant. There

already is a 22 ohm load resistor on the 3.2Z output so nothing

has to be connected there when using the 600Z line. Also, the

phone jack is on the 3.2Z output but since there's the 22 ohm

R load any impedance phones can be used.

That being said, the NC-400 has many, MANY quirks.

First, the good quirks,...the

multiple IF selections will take getting used to. You can

receive CW and SSB signals (even AM signals) several different ways with

combinations of the Mode switch and the IF Selectivity switch.

Once it's determined that SB1 is LSB and SB2 is USB, then

selecting the proper sideband isn't difficult but a slight

adjustment of the BFO will be necessary on either LSB or USB for best

demodulation of the SSB signal (an easy way to remember USB

versus LSB is that SB2 is the "higher number" and is the "upper

sideband.") You can use SB1 or SB2 in the AM

mode for an interesting type of AM reception. For exalted

carrier AM, you have to switch to CW and adjust the BFO for

zero-beat (no AVC in this position.)

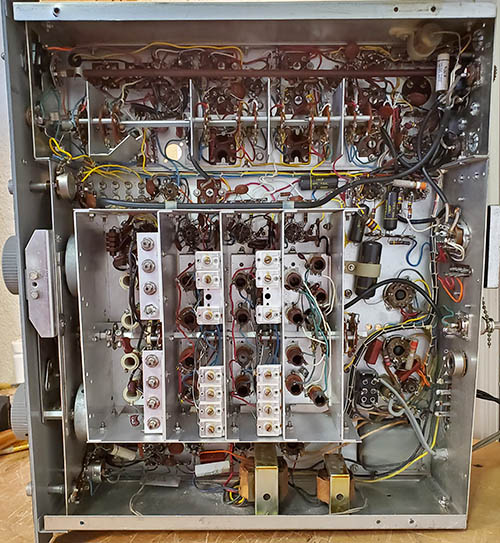

It's important to remember that when you're in B, M or S

bandwidths, you're using a different IF section in the receiver

with only six tuned circuits. But, you can run the AM signal

through the 14 tuned IF circuits by using SB1 or SB2 for a fixed

3.5kc bandwidth. Or, you can run the AM signal through VS and

have 10 tuned IF circuits and also use the Crystal Filter. CW

signals or SSB signals can also be run through the various IF

circuitry. There are many methods to try, which does seem to

backup National's advertising claim that the NC-400 was "the

most versatile receiver available."

Now, the bad quirks,...the insolvable problems

are all mechanical in nature. Like the flexible chassis and

component mountings that cause frequency excursions whenever

certain adjustments are made. Or the vague frequency readout

that gets worse as the tuned frequency gets higher and higher.

When actually using the NC-400 "on the air" most vintage ham

gear operators will have a digital frequency counter set up to

read the transmitter frequency. The NC-400 can be "zero beat"

against the "tune" or "spot" function from the transmitter and

the receiver will be "on frequency." But, those crappy "band-in-use" indicators that stick and never seem to

point to the band you're actually on, or the "mega-torque" band

switch that causes shockwaves throughout the chassis as it's

operated and the cheap knobs that give the controls a flimsy feeling

are other irritations that you'll eventually have to accept. The sheer size of

the receiver and its 75+ pounds of bulk weight requires a

lot of bench real estate but that could be viewed as a "commanding

bench presence" and that might compensate for the lack of table

space. In many vintage amateur radio station installations the receivers aren't moved

around very often, either physically or even tuned frequency.

Sometimes many of the adjustments are only made once and then

left alone. So, perhaps most of the mechanical problems really

won't be that much of an issue (unless you have an OCD nature

and want everything to be "perfect!")

I have used my NC-400 connected to my 75M

collinear array antenna. This is a 240' center-fed

dipole with

108' open feed line to a 1KW Johnson Matchbox tuner that's operated

on 75M (two half-waves in-phase.) This is a

substantial antenna that does exhibit a little gain (~1.9db) and

does allow hearing very weak signals. But, the NC-400 noise

floor is pretty high with this antenna so for the best sounding

signals I'll reduce the RF gain from maximum until the S-meter

reading just begins to drop. At this point the signal is still

creating AVC voltage but the background noise is greatly

reduced. I think that SSB signals actually sound much better

with the RF gain reduced slightly in this manner. CW signals

will require reducing the RF gain somewhat since the AVC is turned off

by selecting CW but the CW signal is still routed through the

Product Detector. Also, you can listen to CW in the SSB position

and then have AVC, if desired. Strong AM signals, with using a

diode detector and a different IF section, can do

rather well with full RF gain but, with weaker AM signals, better results

(especially with QRN

present) will be with the RF gain slightly reduced. As mentioned

above, you can route AM, CW or SSB signals though any of the

various IF bandwidth or Mode options to experiment with what

works best for the receiving conditions.

For signals outside the 75M ham

band, the Matchbox allows "tuning" the antenna for a good match

anywhere from 3.5mc up to 25mc. I listen to 20M a lot since it's

a daytime DX band and I do most of my listening during the day. Listening to the Chinese CW Coastal

Beacons is pretty easy on 16.9mc in the later afternoon. Any of the SW

BC stations sound

pretty good but the best broadcast audio quality signals seem to be coming

out of China these days. The Chinese are producing powerful signals

with lots of modulation and a wide bandwidth (well, maybe not

Firedrake, but most other Chinese stations.) Radio Havana is strong

too but their

modulation is a little

rough sounding and their announcers are annoying to listen to.

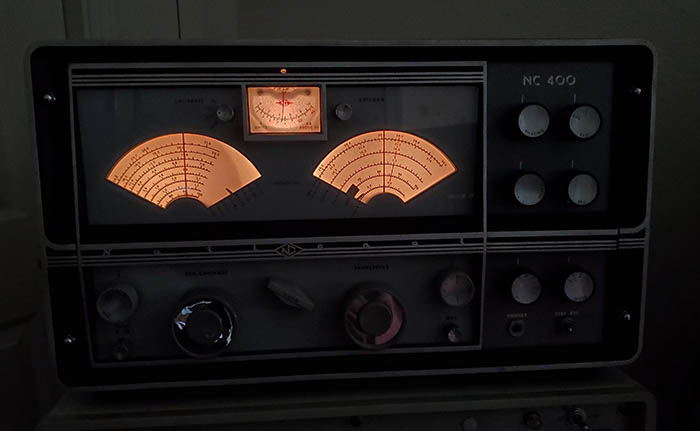

So, despite the mechanical quirks, give your NC-400 a little time. Experiment with the many different

methods to demodulate signals. I think when

you get used to those "good" quirks and when (or if) you get used to its

unique appearance, the NC-400 can become a fine station

receiver,...one that isn't seen all that often and at least you didn't have to pay the 1959 $895 cost in

2023 dollars (9200 of 'em.) I can't really say that I've

followed my own advice though. I always find the performance of

the NC-400 lacking and I just can't wait to replace it with a

decent performing receiver.

|

I had my NC-400 set up with the W6MIT homebrew

transmitter, shown in the photo above. Though W6MIT's transmitter

might be a little short on "good looks"

just the opposite is true of its incredible audio quality on AM. A

really stellar homebrew transmitter. At only 75 watts of carrier

power, I find that using the 75M collinear array antenna is a big help. Most of the

time, the "1625 Rig" with the collinear produces a good signal that is Q5 with most check-ins to

the Vintage Mil-Rad Net. And, the gain of the antenna also helps with the

received signals (gain is about 1.9db.) I have to admit though,...I've had this

particular set-up on two different occasions and neither time did using the

NC-400 result in a long-term relationship. I just couldn't wait to replace the

NC-400 with a decent performing receiver. |