|

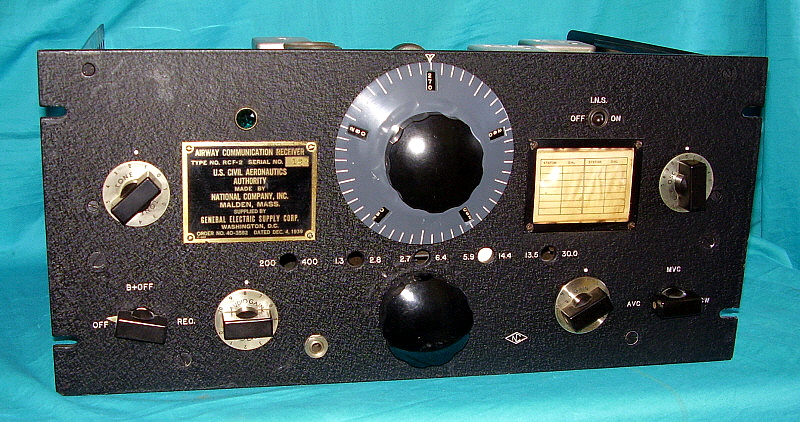

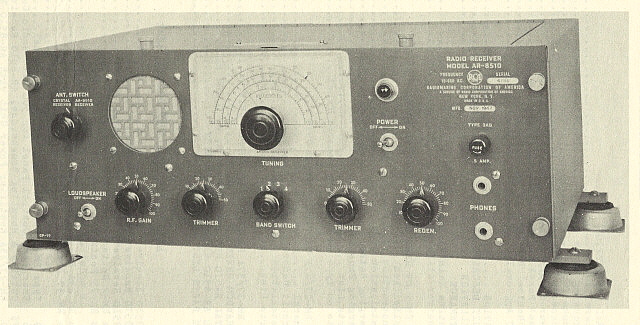

Radiomarine Corporation of

America - Model AR-8516

Circuit Description

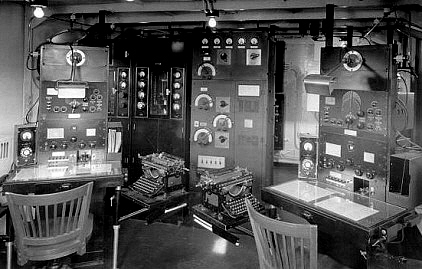

- RMCA introduced the AR-8516 around 1958 and it was

available up into the mid-1960s. It was a

tremendous upgrade from the proceeding commercial shipboard receivers

that RMCA had been providing (those designs dated from the early part of WWII.) The AR-8516 was

a thoroughly modern, complex communications receiver that used 18

tubes in a single, double or triple conversion superheterodyne circuit. The

receiver used a variably-tuned IF covering 1.09 to 3.09mc or 2 to 4mc.

The fixed-frequency IFs were at 455kc and 45kc. Single conversion was

used in the first five bands covering 80kc up to 4mc. Bands 1-4 span

different widths of the LF and MF spectrum and, along with Band 5, these

single conversion bands tune from left to right being from high to low

in frequency. From 2mc up to 30mc is

covered in fourteen 2mc-wide bands. Band 5 (2-4mc) is single conversion

but Bands 6-18 are double conversion. The double conversion bands (Bands

6-18) tune left to right being low to high in frequency. The total frequency coverage is

from 80kc up to 30mc in 18 tuning ranges. Seven crystals are utilized in

the Crystal Oscillator with only two crystals used uniquely. The other

five crystals are used in various fundamentals and harmonics for a total of 13 crystal

oscillator frequencies. The RF amplifier, Crystal Oscillator and Mixer 1

circuit function as the RF input for bands 6 to 18 with the output going

to the Variable IF tuning that then provides a fixed 455kc output. The RF input section is

bypassed when using bands 1 to 5 and the incoming signal goes to the

Variable IF which combines with Mixer 2 and the selected VFO to provide

a 455kc output. Two separate VFOs are used with one

used for Bands 1, 2 and 3 and the second VFO used for Bands 4 to 18.

Main tuning gear reduction is 41.7 to 1 and the SECTOR gear reduction is

another 3.8 to 1. The resulting tuning is a constant "bandspread"

type at almost a vernier tuning rate.

The dial readout is "band-in-use"

and employs a rotating dial drum that is ball chain-coupled to the band switch.

The smaller dial to the right is the kilocycle-logging scale which for Bands 1-4

is a logging scale, but, since

the Bands 5-18 are 2mc linear scales for each band, if the receiver is

well-aligned, then the this dial will readout almost directly "to the kilocycle" for

these bands.

For example, if the slide-rule dial pointer is set in between 14.1 and 14.2 and the

logging dial reads 67, then the tuned frequency is 14.167mc. The

kilocycle dial

index is not adjustable. The accuracy of alignment will determine just

how usable the kilocycle dial ends up being. Spec from 4-30mc is "within

10kc." I was able to achieve an average tracking accuracy of between "dead on"

up to about 5kc off. Below 4mc the accuracy spec is 0.5% which is easily attained

during alignment (at 4mc the spec of 0.5% is 20kc.)

Bandwidth is selectable from 6kc

down to 100hz (five steps) in Bands 3 to 18 but in Bands 1 and 2 the

bandwidth is selectable only from 1.5kc down to 100hz in three steps

(6kc and 3.1kc, if selected, won't change from 1.5kc bandwidth.)

The selectable bandwidths provided are 6kc, 3kc, 1.5kc, 800hz and 100hz. The

3.0kc bandwidth utilizes a Collins 3.1kc mechanical filter. The 45kc IF is

utilized for two purposes. In Bands 1 and 2, 45kc is the IF. In Bands 3

to 18, the 45kc IF is utilized as part of the selectivity bandwidth

operation and results in triple conversion in the IF section if

1.5kc, 800hz or 100hz bandwidths are selected. Two types of

detectors are used with a standard vacuum tube diode detector used in Bands 3

to 18 and a crystal diode detector (heavy duty 1N34 germanium diode) utilized in

Bands 1 and 2. Two BFOs

are also used with the 455kc BFO being adjustable +/- 2kc but the BFO

for 45kc (which is used just for bands 1 and 2) utilizes a fixed-frequency

(adjusted for a 1kc heterodyne or 44kc.) When SSB is

selected the 455kc BFO output is increased (compared to the output in

CW) for better demodulation of suppressed-carrier signals. AGC has

selectable fast and slow time constants. The audio output frequency

response is 200hz to 3000hz (4db down) and the audio power available is

250mW with 3.2Z or 600Z impedance outputs provided. A 500kc Calibration

marker signal is available that functions from the 500kc Crystal

Oscillator that also provides mixing with 455kc IF for the 45kc IF. A carrier level meter (showing db above

1uv) is provided. The ANTENNA (trimmer) control is connected to RF/Mixer

1 and only functions when the receiver is on Bands 6-18 (4-30mc.)

Power Requirements

- Being a commercial shipboard receiver, the AR-8516 is

designed to be powered by various types of ship's power systems. It was expected

that the receiver would be powered by +115vdc. Using

accessories available from RMCA, operation on +230vdc was also possible.

It was also possible to operate the receiver direct on 115vac but the

receiver's power

input section only provides a half-wave rectifier if AC operation

is used. RMCA recommended that the MM-555140-B Isolation Transformer/DC supply be used to

convert the ship's 115vac (or 230vac) to +115vdc for operation of the receiver. In

fact, if the receiver was ordered with the matching table cabinet, then

the MM-555140-B was included and installed inside the cabinet. If the rack

mounted version of the receiver was ordered then the MM-555140-B was

separate and was installed externally (somewhere in the rack.) Since the

AR-8516 is AC-DC in concept, all tube filaments are wired in series.

Most of the tubes are 3-volt filament types, e.g., 3BZ6, 3BE6, 3CD6,

3AL5, etc. but

(2) 5U8, (3) 7AU7 and (1) 12CU5 tubes are also used.

The SECTOR Control

- The unfamiliar control on the AR-8516 is the SECTOR control

which is part of the RF and Mixer 1 tuning in combination with the

Crystal Oscillator. When the receiver is tuning

from 80kc up to 4mc (first five bands) the RF and Mixer 1 circuits are

bypassed and the Variable IF (acting as a RF amplifier, VFO and Mixer 2) tunes the receiver as a single conversion circuit.

When tuning above 4mc, double conversion is used and the SECTOR control

provides the correct tuning for the RF and Mixer 1 (and Crystal

Oscillator) for each of the 2mc wide bands (4mc to 30mc.) Four sets of

coils are used for ranges 4-12mc, 12-20mc, 20-28mc and 28-30mc. When

combined with the selected Crystal Oscillator frequency the result is

2mc wide tuning ranges from 4 to 30mc. The "sector" refers to

each 45 degree quadrant (A, B, C or D) of the RF/Mixer 1 variable tuning

condenser's 180 degree rotation range. Selecting A, B, C or D will

actuate a physical rotation of the RF/Mixer 1 tuning condenser rotor to

the correct 45 degree quadrant required for tuning (plus the Crystal

Oscillator) of the particular 2mc band range selected. The SECTOR

switching is roller-chain coupled to the band switch. The RF/Mixer 1 tuning is gear-coupled to the main tuning

control and the SECTOR selector knob will rotate as the TUNING knob is

rotated. Although the SECTOR knob and RF/Mixer 1 condenser rotate with the main

tuning, the correct quadrant selection is necessary and will require

that the SECTOR knob be set to the "detent" in the correct position. The

"PLACE SECTOR AT" indicator is illuminated and located in the

viewing hole above the band switch. The main tuning dial, logging scale

and meter illumination is also controlled by the SECTOR control in Bands

6 to 18. These lamps will only

illuminate when the correct SECTOR

position is selected.

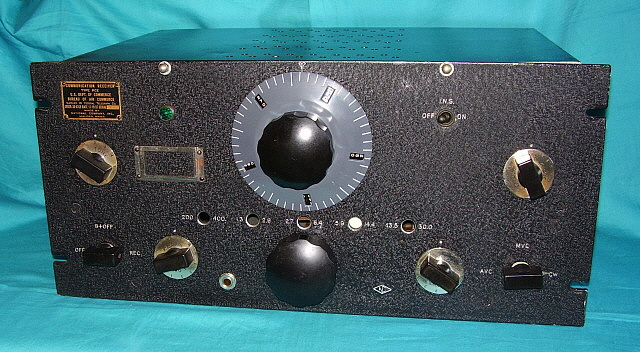

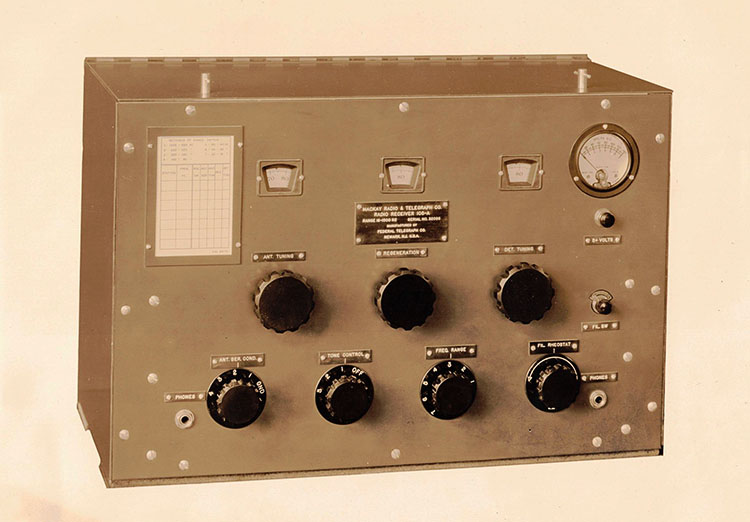

Serial Number and

Cabinet - The serial number of the AR-8516 shown is SN:5830. The

serial number incorporates the year of manufacture in the first two

digits, e.g., "58" is 1958 and the receiver number is "30." There is

also another tag mounted to the rear chassis that gives the month and

year of manufacture, in the case of SN:5830, the tag reads "JAN 1958."

The odd size panel height of 9.5" (rather than the standard 10.5") does

limit the receiver's installation into generic-type cabinets without an

obvious gap. Mounting the receiver in a rack will solve that issue. Of

course the proper RCA cabinet does fit the receiver panel correctly. As

stated in the manual, the AR-8516 was available as a table model

receiver with the cabinet (with the MM-555140-B installed) or it could

be ordered as a rack mount without cabinet (with the MM-555140-B as a

separate accessory.)

|

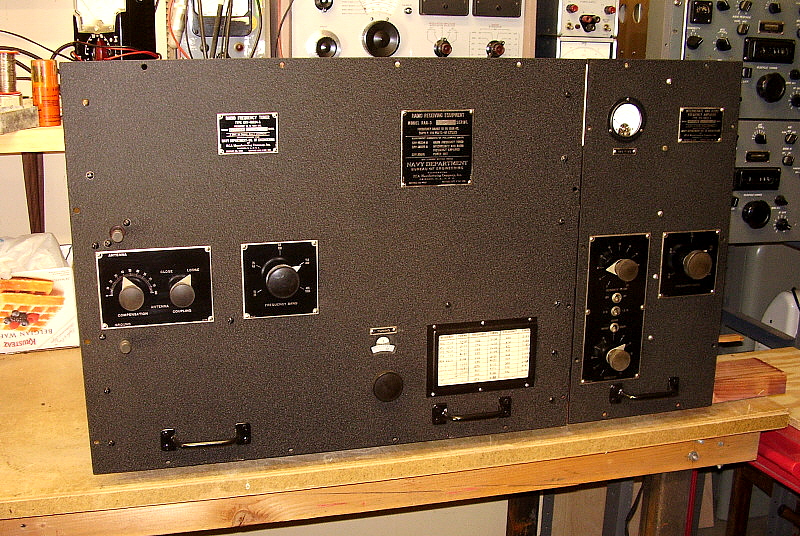

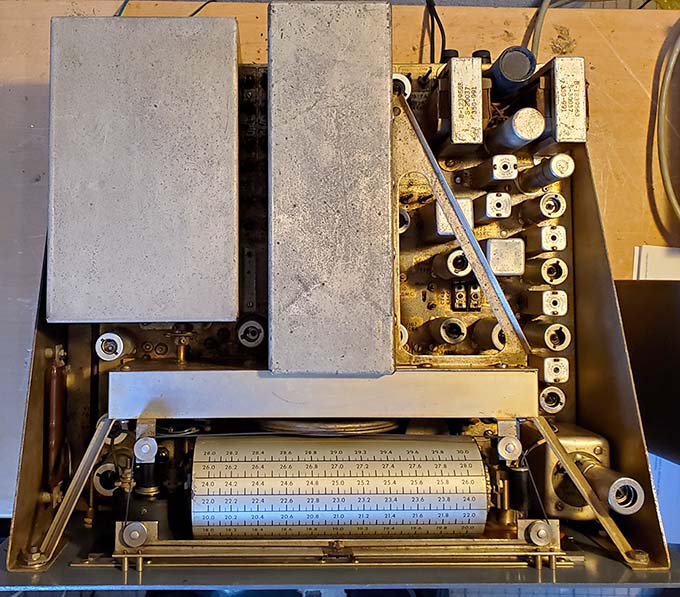

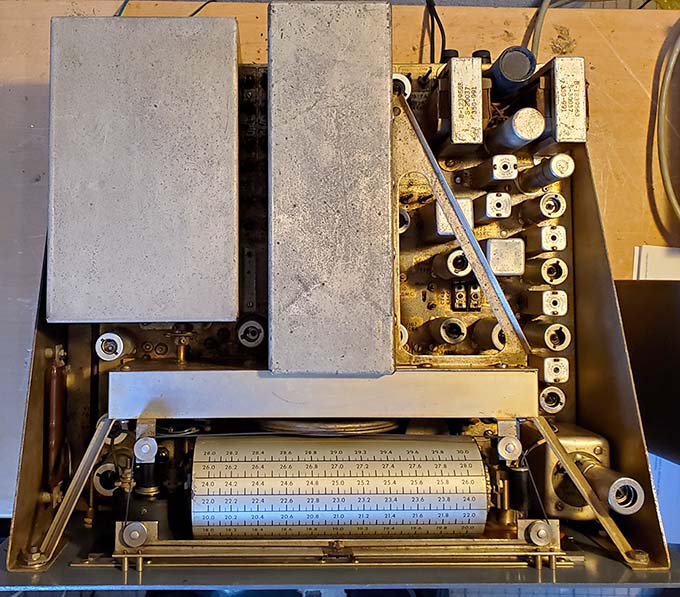

photo above: Top of the AR-8516

chassis |

>>>

Antenna Connections per the Manual - There are four antenna terminals

provided identified as A1, A2, GND and SHLD. The manual warns not to "ground" the SHLD

terminal. This is because in Bands 1-5, SHLD is connected as part of

the antenna input by essentially "shorting" the coax shield to the

center conductor of a coax feed line. This allows the receiver to have a

fairly efficient "T" antenna configuration in the LF and MW ranges. At Band 6, the band switch then connects SHLD to the

receiver chassis allowing the use of a resonant, coaxial fed antenna.

When using the typical unbalanced ham antenna, the center conductor of

the coax is connected to A1, then A2 is jumped to GND and then just the

shield of the coax is connected to SHLD. For the hook-up to work

correctly, the antenna shield can't be grounded anywhere and must only

be connected to the SHLD terminal. For hams the problem with this

hook-up is for 80M (Band 5) and 160M (Band 4) operation.

A More Practical Antenna

Hook-up - If you want to use a resonant unbalanced coaxial fed

antenna for much better reception on 80M or on 160M, then connect the coax shield to GND, A2 also

connects to GND and the coax center conductor to A1. Don't connect anything to SHLD.

If an antenna tuner and tuned dipole antenna combo is used with this

type of connection, then the tuner adjustments will "peak" normally. The

ANTENNA (trimmer) won't function on Bands 1 thru 5 because the antenna

signal is going to the Variable IF (the receiver is single

conversion in Bands 1-5.) |

photo above: Underneath the AR-8516

chassis |

|

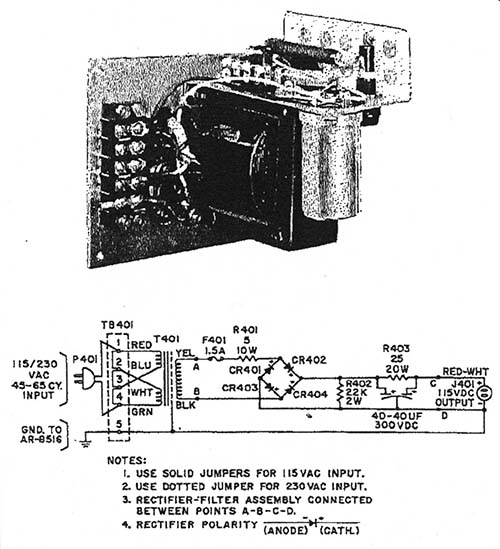

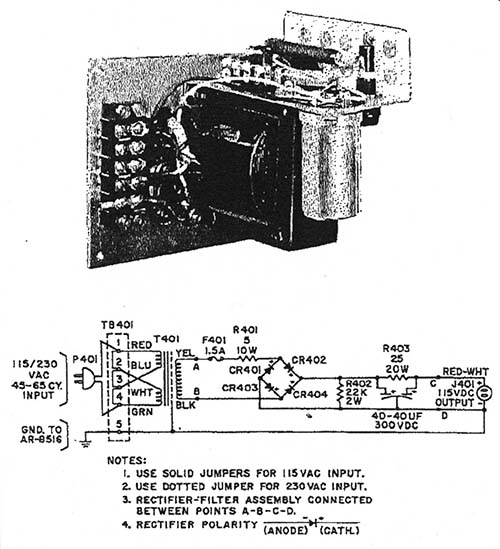

Building a Replica MM-555140-B |

|

The AR-8516 manual states that if a very low hum on the audio

output is desired or necessary then the receiver should be

operated on +115vdc. I decided to build a MM-555140-B since

finding an original would probably take a considerable amount of

time. Luckily, the AR-8516 manual has the schematic for the

MM-555140-B and there really aren't any unusual parts required

for its construction. In fact, everything to build my homebrew

version came from the various junk boxes I have around here.

I used a 150VA 1:1 Isolation Transformer as the main component.

The receiver requires about 80 watts for operation, so there's

lots of reserve capability in the transformer. Other components

were a full-wave bridge rectifier, two 40uf 300vdc electrolytic

capacitors, a 22K 2W CC resistor, a 25 ohm 50W WW resistor and a

6.5 ohm 60W WW resistor. The two large dissipation wire wound

resistors were made up of a parallel combo for the 6.5 ohm 60W

(15+15+75 ohms) and a parallel combo for the 25 ohm 50W (two 50

ohm 25W resistors.) >>>

|

|

|

| >>> These dissipation values are much

higher than the original dissipation values called

out on the schematic but I found that those values

shown on the schematic did get very hot during

operation. This was probably because of the 122vac

line voltage I have. Actually, at the output of the

isolation transformer the voltage is 124vac, versus

the original MM-555140-B design for 115vac input.

Also, the 6.5 ohm value differed from original value

of 5 ohms but that again was due to the higher line

voltage versus the original 115vac design.

The + DC output has to be connected to the

receiver so +DC is routed through CR101 (the

half-wave rectifier in the receiver.) This would

correspond to the LINE (HOT) if the connection was

directly to the AC line. The

-DC corresponds to the AC NEUTRAL connection which is

internally connected to the power supply chassis

(transformer shield.) The B- inside the

receiver is isolated from chassis to allow -DC to be

connected to the power supply chassis The

chassis Ground of the receiver is connected just to

chassis of the DC supply. I used a three-wire power

cable so the power supply chassis and the receiver

chassis go to ground. >>>

|

|

| >>> My version of the MM-555140-B was

installed into a 3.5" x 6" x 8" aluminum project

box. There is a standard single socket grounded AC

outlet on the front panel. Also, two pin jacks are

on the front panel that can be used for monitoring

the DC voltage to the receiver. Other power supply

features are an AC toggle switch and a 120vac neon

pilot lamp. The fuse holder is on the rear panel and

has a 2A SB fuse installed in the Line to primary.

When connected directly to my 122 volt AC line, the

DC voltage at the powered-up receiver is +115vdc +/-

1vac and the +115vdc remains very stable regardless

of the various functional adjustments made to the

receiver. DC voltage measured at the receiver at

initial power-up will start at about +112vdc, climb

to about +117vdc and then settle at +115vdc as the

receiver "warms-up" which takes about 30 seconds.

Hum is non-existent and the audio sounds very clean.

With no load, this power supply output voltage will

measure about +175vdc which isn't over the voltage

rating of the components used but the design output

voltage relies on an 80 watt load being connected

and that's where it operates correctly. The

upper-right photo shows my replica MM-555140-B. Shown to the left is the schematic of the MM-555140-B and also

the artwork of how the RMCA unit looked. |

|

|

AR-8516 SN:5830 Refurbishment |

| When acquired, SN:5830 did turn on and did receive some

signals, but it wasn't fully functional and really wasn't

performing at its design capabilities. Initial inspection found

five of the 18 tubes

were bad with two showing significant leakage (shorts.) The AF

gain pot was internally damaged and no amount of cleaning would

fix it since the carbon track was cracked in several places.

Luckily, I had a NOS 500K A-taper (audio taper) A-B pot to replace the bad original. De-Oxit

was used on the Bandwidth switch which helped it to function

correctly. The receiver was the rack-mount version so it didn't have

a cabinet and for some reason RMCA never offered a dust cover.

I guess they figured that the rack console would protect the

receiver chassis. However, decades of storage in a greasy

environment certainly had the chassis looking terrible. There

was a little minor corrosion but most of the contamination was

dirt, waxy-grease and probably tar-nicotine. The front panel had its share of

"battle-scars," "rack rash" and even some green paint

splatter. The knobs were just plain "grungy" with crud that

seemed waxy-like in all of the flutes and recesses. There was white residue

in the front panel screw slots implying

that the panel and knobs had been

rubbed-down with polish or wax in the distant past.

Thorough

cleaning required major disassembly. The knobs were soaked in

Dawn dish soap for two hours to loosen the waxy grunge after

which they were scrubbed with a short-bristle brush to

thoroughly clean. The knobs were then rubbed-down with a dry

cotton flannel cloth to slightly polish the surface finish. The

RCA meatball badge needed to be dismounted in order to remove

the pitting (600 grit AlOx paper,) cleaned with Glass Plus along

with a

wooden toothpick used to "dig-out" the wax in the

recesses between the letters and finally the badge was polished with Wenol's (British

equivalent of Semichrome.) The chrome handles had minor pitting

that was removed with Glass Plus and 600 grit AlOx paper

followed by polishing with Wenol's. The grunge on the chassis

was removed with WD-40 and an acid brush (with the bristles cut

short.) This was followed by Glass Plus to remove the WD-40

residue. In some stubborn places, isopropyl alcohol would cut

the grime better.

The plastic dial cover was removed, cleaned and polished. The meter

scale, the sector scale and the kilocycle/logging scale were

made of photosensitive phenolic that had darkened but careful

cleaning with Glass Plus brightened up the yellow-amber color

significantly without damaging the nomenclature. The dial scale

was a metalized over-lay applied to the drum. It cleaned up easily because the

material and the nomenclature were particularly durable and could be cleaned a bit more

aggressively than expected. I installed "matching" tube shields.

These were the standard flat aluminum type because the IERC-type

of heat-reducing tube shields are really only necessary when a receiver is going to be

operated 24/7. I matched the original paint on the front

panel (using 5 colors of Testor's model enamel - gray, black,

white, dark blue and brown) and touched up most of the "battle-scars."

The silver dial bezel was touched-up using thinned Testor's

silver paint. A

flat-razor blade was used to remove the green paint drops. The panel

mounting screws were cleaned and painted black before reinstallation.

After cleaning the tops of the two shield covers (RF-Sector

condenser and Variable IF condenser) they both look silver in

the photos. Actually, they appear slightly gold tint, though

much lighter than the chassis. The gold finish is called iridite

and it was a chemical bath that colored the sheet metal during

manufacture and before assembly.

| Disassembly issues not

mentioned in the manual: The BFO pointer is

dual set-screw mounted to the outer coaxial shaft of the vernier BFO

adjustment. To remove the front panel this pointer has

to be dismounted but you can't get at both set screws from the top. The

right side panel has to be removed to access the set screws to

dismount the pointer to allow front panel removal. All of the set

screws in the knobs and couplers are Bristol (spline) types. There

are four shaft bushings, two of which have "C" clips associated

with them (ANTENNA and TUNING.) The Antenna (trim) coupler set screws are easy to

access from the top. But, the TUNING shaft will require removal

of the "C" clip to be able to dismount the front panel. Also,

three of the bushings are standard size but one is much longer

than the others. The long bushing is used for the TUNING shaft for better support of the shaft which does have a large

counter-weight installed on it. The dial string assembly rail for the dial pointer

is mounted to the front panel. When the four screws are removed

this piece can then "flop around" and rub against and mar the

dial scale. Place several paper towels over the dial scale to

protect it during disassembly. Note that the PHONES jack is

isolated from the chassis and panel by two shouldered fiber insulating

washers. This jack should not be contacting the panel or

chassis (problems could result if using direct AC line operation.) Removal of the dial bezel requires removing the front

panel first, then plastic

dial cover piece is dismounted from the rear, then the bezel is dismounted from the

two retaining strips and then the two strips are dismounted from

the back of the panel. This assembly can't be installed or

removed if it is all put together, it has to be installed (or

removed) by dismounting each individual piece.

Sea Trials - Dec 12-15, 2020 -

After reassembly and completion of the DC power supply, I

operated the AR-8516 for a few days to get the "feel" of the

receiver. As acquired, this AR-8516 had already been

meticulously and carefully re-capped so I was pretty confident

that the receiver could operate for long time periods without

any serious problems. The receiver seemed to function pretty well but it was obvious

that some improvement should be possible.

The next day I found a very minor problem that had a significant

effect on reception. The jumper between A2

and GND had been a piece of solder (the lazy tech's jumper) and it

had broken at the A2 terminal. I replaced the solder with a TC

jumper. The signal reception level was greatly improved. I

tuned around 12.965mc and copied one of the Seoul, So. Korea coastal

beacon stations, HGW2. Also, a little lower in frequency and one of the

Chinese coastal beacon stations, XSQ was heard. The next morning, I tried

40M and some of the SSB signals were intensely strong. I tried

HGW2 on 12.965mc (should be at 12.915mc,...more on that problem

in the alignment section) and it was very strong. Fire Drake, the Chi-Comm

jamming signal on 9.85mc (it changes frequency all the time

since it's jamming Radio Taiwan which also changes frequency all

the time to avoid Fire Drake,) was very strong and showed

about 25db over 1uV on the carrier level meter. Trenton Military

Aviation Weather (Trenton, Ontario, Canada) on 15.031mc was

heard with a very strong signal. One other thing

noticed before, with the broken jumper, I couldn't seem to find

a good match with the antenna tuner. With a jumper installed,

now the tuner showed a very positive increase in reception when

the antenna match was "tuned." Also, the ANTENNA (trimmer) on

the receiver would "peak" now. It was also noted that

the best results on SSB or CW was to reduce the RF Gain and

advance the AF Gain which is typical of a receiver without a

product detector. If the RF gain is advanced too far it seems to

"mask" weaker CW signals with excessive background noise, again typical of a

standard diode detector. In AM Voice, the RF gain can be fully

advanced and the AVC allowed to control sensitivity. The RF

tracking is fairly close with the error at 15.000mc

being -6.0kc. The 500kc oscillator is off by about 400hz

and this affects 45kc IF and the 1.5kc-800-100hz

bandwidth performance (which barely worked) and the 500kc calibration marker

accuracy. Although performance seems pretty good, a full IF/RF

alignment will assure that the receiver is at its

design specs. |

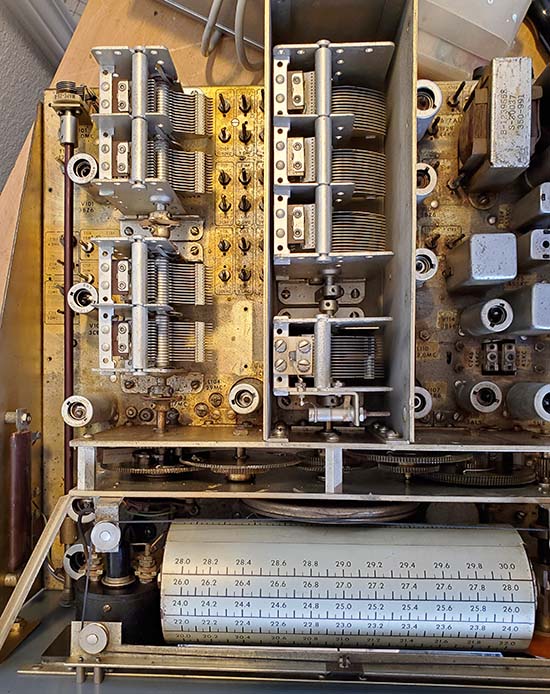

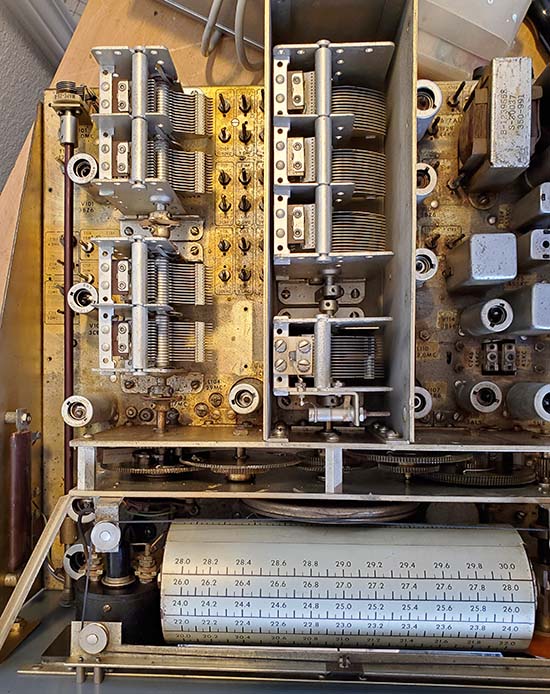

photo above: AR-8516 underneath with the

shield covers

removed from the Variable-IF bandswitch-coils, the RF

bandswitch-coils, the Crystal Oscillator bandswitch along with

the Xtal Osc trimmers and the Variable IF Mixer covers. |

|

| Return to the

Workbench - Dec 18, 2020 - It's pretty much standard procedure

to perform an initial refurbishment to get a set going, then use

it for a while to assess how it's going to work out and then plan what

else needs to be done to complete the rebuild. Although

performance was generally good and it seemed likely that the

AR-8516 could do a very good job as a station receiver there

were other mechanical and electronic things that had to be done

to enhance the receiver's functionality. Here's the list:

1. Mechanically aligned the slide rule dial to more accurately agree

with the kilocycle dial. Pre-alignment necessity.

2. Cleaned with DeOxit and a small paint brush all band switches.

RF sw, Vari-IF sw and Xtal Osc sw.

3. Cleaned rotor grounding contacts on both tuning condensers

with DeOxit and a brush. RF-Sector

and Vari-IF.

4. Cleaned (removed) dried Lubriplate grease from gear box gears

and made sure

backlash split gears were working. Lubriplate is designed for

sliding surfaces not for gears. It dries like concrete if it

isn't constantly in use and routinely cleaned off and reapplied.

This Lubriplate must have been decades old. Light oil

and an acid brush (bristles cut short) were used to remove the Lubriplate. Re-lubed split-gears and bushings with 10w

machine oil.

5. Cleaned and readjusted tuning shaft over-riding clutch. The clutch is a spring-loaded mechanism that had

been filled with Lubriplate - just what you need for a clutch -

it was locked in place!

Cleaned the Lubriplate off with light oil and a brush then washed the

mechanism with Isopropyl Alcohol to remove oil residue. Then

adjusted the clutch to "slip" at the dial end-stops.

6. All tube pins and sockets cleaned with DeOxit and a small

paint brush.

7. Adjustments for 2mc C to 3.9mc L Variable IF tracking had

GLPT lacquer "locking" them. Used lacquer thinner to remove the

GLPT so these two very important adjustments would be moveable.

Overall frequency readout accuracy depends on these two

adjustments. Pre-alignment necessity.

8. Replaced the 30" long power cord with a 72" long power cord.

AR-8516 Manual Alignment Procedure Critique

and Pre-Alignment Preparation - Normally,

pre-alignment preparation isn't necessary but the AR-8516 manual alignment

procedure is not written for "first timers" and assumes that the

alignment tech has been doing a lot of AR-8516 receivers before

and knows the locations of all of the components. I read through

the procedure before starting the alignment and found that I was constantly having to go to

chassis drawings and the schematic to physically locate key

connection points. For example, when aligning the 45kc IF,

the instructions indicate the VTVM should be connected to the

junction of R191 and R192 but no resistor values are mentioned.

There's no component location

drawing showing smaller parts (like resistors.) Small components

have to be located first on the schematic to find the values of these resistors so you

know what to look for under the chassis. You'll know generally

where to look from the schematic. First time is a hassle, that's

why the pre-alignment checkout.

To say the alignment procedure is

lacking details is an understatement. I found it necessary to

make lots and lots of pencil notations about important component values, test

point locations and even drawings of the IF transformer connections.

The 455kc IF transformers pin-outs are important because the

primaries or the secondaries or both have to be "loaded down"

with 10K resistors during alignment. Luckily, the IF transformer

pin-outs are vaguely mentioned in one of the schematic

notes,...no where else,...and even that information is

incomplete requiring a visual and continuity check to verify.

NOTE: IF

transformer pins viewed from

the bottom, green dot is pin 1, go clockwise for pins 2, 3 and 4.

Next, the RF signal generator

input for IF alignment is to the grid of V105 Mixer 1,...no problem,...except that the bottom of the V105 socket is located within a completely

shielded compartment (with more than thirty 4-40 screws mounting

the cover.) I used a seven-pin tube test extender

socket to input the signal to the V105 grid.

>>> |

|

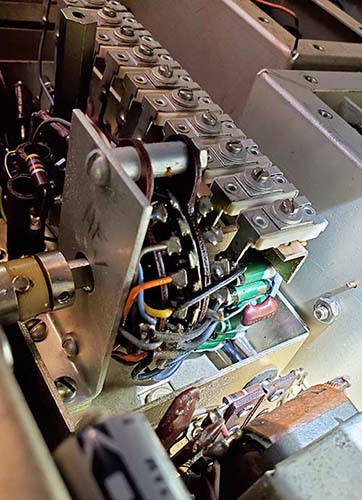

photo above:

Showing the RF/Mixer 1 tuning

condenser (left) and the Variable IF tuning condenser (center) with the shield covers removed.

Also, the gear box cover is removed showing the gear train. |

| >>> Another

complication in the IF and in the RF tracking alignment process is that the receiver has

to be on its side since there are adjustments both on top of and

underneath the chassis along with having to observe the front of

receiver for the dial readout. I had to use a 4"x6" hand mirror

to verify tuning dial readouts and sometimes the locations of

various trimmers to keep from bending over or leaning around the

side of the receiver for every adjustment. I guess I could have

turned the receiver around so the panel was in front but

then all of the difficult to see small chassis-located

adjustments would have to either require a mirror and

bending over and around the chassis or some other

uncomfortable contortions. I think that at

least a couple of days of reading, making notes,

visually locating the important component junctions and

getting all of the resistor loads, coupling caps and

alignment tools together will help to ease the alignment

process. |

|

| IF Alignment

- This starts with the 455kc fixed IF. The only unusual

requirement is the loading down of some of the IF transformers

primaries or secondaries

with 10K resistors. This pretty easy to accomplish if the 10K

resistors are on short flexible wires with small alligator clips

on the ends. The bottoms of the IF transformers are easy to

access for attaching the 10K loads. Two 10K loads are required

because T124 and T125 have both primary and secondary loaded

simultaneously when doing the adjustment. There is a trimmer

capacitor for the

mechanical filter that is adjusted for a relatively equal response between

the 6kc bandwidth and the 3kc MF bandwidth. The 455kc BFO is also

adjusted at this point in the procedure. The 45kc IF does require a signal

generator that will produce RF at that low of a frequency. I normally

use the HP 606B for alignments but its lower limit is 50kc. Luckily, I also

have an excellent General Radio Type 1001A RF generator that

will produce a RF signal as low as 5kc. For the 45kc IF, I had to

use the GR 1001A for the signal source. Four torriod type LCs

are adjusted with trimmer caps and one transformer L is

adjusted. The 45kc BFO is adjusted at this time.

The Variable IF is adjusted to track perfectly (or as close

as possible) from 2.0mc to 3.9mc. This is accomplished with

adjustable L and C and referenced to the kilocycle dial for

maximum accuracy.

This completes the IF alignment. |

RF Tracking -

The single conversion low frequency tuning is aligned first.

This requires adjusting six L and C adjustments per band for a

total of 30 adjustments. Only the 2-4mc single conversion band

(Band 5) can be aligned using the kilocycle dial. Bands 1-4 are

adjusted using the slide rule dial. After the tracking is adjusted on

Bands 1-5, then the 45kc wavetrap is adjusted at 80kc before proceeding

on to the double conversion RF tracking alignment. Bands 5-18

are double conversion and are aligned in four major divisions,

4-12mc, 12-20mc, 20-28mc and 28-30mc. Each Sector A, B, C and D

requires Crystal Oscillator peaking and RF-Mixer adjustments.

Seven crystals are utilized but six are doubled and used on harmonics to allow the

13 bands to operate. There are 23 adjustments plus peaking the

ANTENNA.

I couldn't get "to the kilocycle" accuracy using the

kilocycle dial. It's pretty close and does meet the

specification of dial accuracy of "within 10kc" which

seems to be pretty good (12-14mc is the exception - covered

in the next section below.) For frequencies below 4mc, dial accuracy spec is 0.5%

which is very easy to maintain.

The 500kc oscillator is adjusted using WWV and the beat note.

Since the BFO is on when in the 500kc CAL position, the BFO

should be set to zero so that only the 500kc oscillator and WWV

are heard when listening for the heterodyne zero beat.

There's also two adjustments for the AF feedback that are

adjusted for minimal "ringing" when in the narrow 100hz

bandwidth. Over 75 different adjustments are necessary for a complete

AR-8516 IF/RF alignment.

Errors and Suggestions - There are two obvious errors

or conflicting data in the manual's

alignment procedure. T121 is identified as a 12mc adjustment in

the manual's adjustment drawing. The receiver silk screening and

the manual written procedure are correct indicating that T121 is

for a 2.0mc adjustment. The second error is T115 is correctly

identified in the adjustment drawing as 220kc and the receiver

silk screening also shows the correct 220kc. The alignment

procedure "frequency table" incorrectly calls out 210kc for the

adjustment frequency. Some of the instructions are confusing in

the wording used and require further checking to confirm what

actually is required. The use of the IF 10K loads is a good

example of confusing language. As a matter of poor layout, the

manual has two chassis illustrations dividing the written

alignment instructions. My manual was in a binder and the pages

could be taken out as needed. If only a bound manual is

available then print copies of alignment instructions so the

book pages aren't worn out from flipping back and forth as the

alignment proceeds. |

| Post-Alignment

Performance and Issues - No doubt, the alignment

significantly improved sensitivity and certainly got the 45kc IF

working correctly along with the Bandwidth 1.5kc, 800hz and

100hz working very well. Listening on 20M quickly turned up a

ZS6 amateur from South

Africa. Trenton Military out of Ontario, Canada was easily

found at 15.035mc since their signal was very strong now and the

dial accuracy noticeably improved. WWV 15mc was about 1.5kc off frequency readout and WWV

10mc

was about 1kc off. However, WWV 5mc was off about 10kc (still

within the factory specs.) 40M hams required reducing the RF Gain down

to 4 for the very strong signals. 80M performance was quite good and the tracking on that

band (Band 5) was easily within the 0.5% spec. Just a

note,...there's no noticeable difference in using either a 3.2Z

or a 4.0Z speaker (as expected.) So, that was the good news,...but two problems were noted.

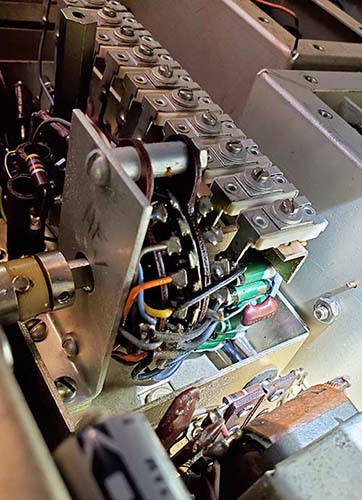

12-14mc Band Tracking

- For this problem I don't think there's any easy solution. The 12-14mc band tracking is off by about 45kc. Since all

other bands are very close in their tracking, I would think that

the Crystal Oscillator is the problem with the crystal being the

most likely suspect. The crystal is Y103, an 8.00mc crystal and

it is used twice, on 12-14mc and also on 28-30mc. A test on

29.0mc revealed an error of about 90kc which seems to confirm

that the crystal Y103 is the likely problem. From what I've

heard, there are virtually no companies that supply newly made crystals

anymore. I checked to see if the R-390A happened to use that

frequency crystal but it doesn't. In addition to finding an

8.00mc crystal there's also the physical access to the crystals

in the receiver which is beyond difficult. Looking at the photo

to the right, the crystals are soldered directly to the band

switch (they have a green coating on the metal housing.) I looks

like replacing a crystal requires extracting the entire Crystal

Oscillator as a unit. It's not a module but note in the photo

that the band switch shaft uses a slotted nylon Oldham-type

coupler which implies the Crystal Oscillator is removable. Since

performance on the 12-14mc band is excellent in all other areas,

I'll probably just have to accept that frequency readout on that band

(and on 28-30mc) is off. Even with a 45kc dial readout error,...at 12mc the

accuracy is still better than 0.5% (0.5% is 60kc at 12mc.)

Note: Used 8.000mc crystals are available from Alltechs in

California - seen on eBay - about $5 plus shipping.

200kc to 500kc Band

Sensitivity - The second issue was poor performance on the 200kc to 500kc band

(Band 2) and this was easily repaired. Low sensitivity on this

band was due to the misalignment of VFO at

220kc. I must have initially set the RF gen to

210kc as indicated in the manual alignment instructions

but actually had the receiver tuned at 220kc as indicated on the

receiver chassis silk screening (after all, I was looking at the receiver dial

in a mirror.) To correct the problem, obviously I realigned with the

receiver tuned to 220kc and the RF generator also tuned to

220kc. The other alignment adjustments (six adjustments, three

for 220kc and three for 500kc) were also peaked for Band 2 and

afterwards the sensitivity was quite good and the tracking was

excellent. In the evening, I set up the AR-8516 with the Pixel

Loop and tuned in several NDBs in the 300kc to 420kc part of the

spectrum. Best DX was LLD 352kc in Hawaii, several Canadian NDBs in

Manitoba and Saskatchewan along with several Mid-west 25W NDBs. With a wire antenna, signals were stronger but so was

the noise which is normal. Dial accuracy was good but the

dial's scaling is fairly vague.

Dec 23, 2020 |

|

Performance as a Station

Receiver - I set up the AR-8516 with the Collins

32V-3 as a station to operate on 75M for the MRCG net and the

Vintage Military Radio Net. A Collins 270G-1 speaker was used as

the audio reproducer. The receiver doesn't have a remote standby

circuit so the front panel standby position of the operation

switch has to be used. Also, with the 32V-3 set up I use a

vacuum relay for the T-R operation for isolating the receiver

antenna input. Since 75M is tuned in on Band 5, the AR-8516 is

operating as a single conversion receiver and because the signal

routing is to the Variable IF, the ANTENNA (trimmer) isn't

functional. However, using a tuned antenna (~50Z for the transmitter) will

be a close match to the receiver input Z. Frequency readout is primarily on the

slide rule dial where the accuracy seems reasonable. Sensitivity

on 75M really isn't ever too much of a problem for just about

any receiver. Selectivity is much more important. 6kc bandwidth

can be used most of the time but it's nice to also have a 3kc

mechanical filter for tough QRM. I run the AR-8516 on +115vdc

and there's no hum at all on the audio output. It's very clean

sounding and voice articulation is reproduced quite well. The

result is easy-to-understand AM QSOs (most of the time.) The only

complaint would be the lack of remote standby that is actuated

with the PTT.

| For the most part, any shortwave transmissions

are easy to receive. CW also is reproduced nicely. SSB uses the

adjustable BFO position to select either USB or LSB and

selecting the "SSB" position

on the operation switch does provide a slight increase in BFO

injection. Stability in the CW or SSB mode is excellent. Using

the narrow Bandwidth will depend on how well the receiver is

aligned. When first tested, this AR-8516 hardly functioned in

the narrow Bandwidth positions since alignment of the 45kc is

crucial for these functions. After alignment, the narrow

Bandwidth selections function great and are a benefit for CW in

crowded band conditions. Also, the narrow bandwidth selections

utilize the 3.1kc mechanical filter at 455kc and then use the

45kc IF to provide 1.5kc, 800hz and 100hz bandwidths. When

properly aligned, the AR-8516 provides excellent selectivity

options. Update: May 2021

- I built a wooden cabinet for the AR-8516. Nothing

fancy. In fact, I built it out of "used plywood" and

from some of the edges, I guess that's pretty apparent.

But, it is square and it does a good job for having a

place for the loudspeaker and other accessories to set.

I painted the cabinet gray and I designed it to conform

to the dimensions of the front panel and the full depth

of the chassis. Overall, the gray paint finish helps to

disguise the fact that the cabinet is made out of wood

(well,...maybe a little, especially in average room

light,...with stuff piled on top.) I think it's a nice

improvement to the AR-8516 "looks" overall and certainly

provides more bench space than the open chassis did.

I've been

using the AR-8516 paired with an ART-13A transmitter and

have found it to be an excellent station receiver with

very nice audio and excellent selectivity. The lack of "remote standby"

can be compensated for by using the front

panel standby switch. With the

generous band and frequency over-lapping, the military radio nets - all being

at the upper end of 75M - can actually be tuned in on Band 6

(4-6mc) to take advantage of the double conversion.

Although not shown in the photo, I'm still using the

Collins 270G-1 loudspeaker with this receiver. |

|

|

|