|

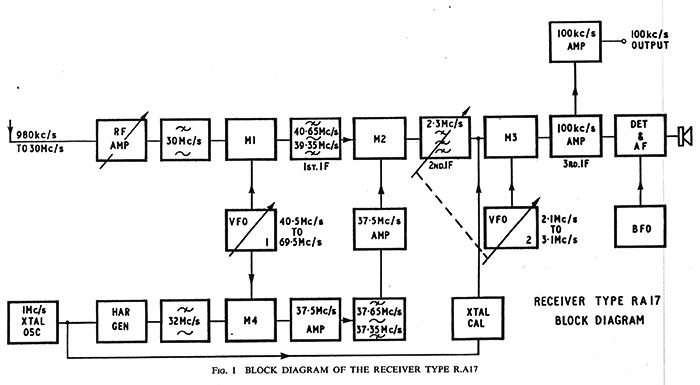

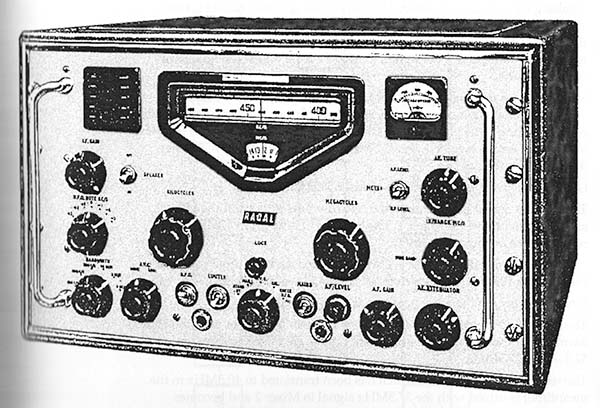

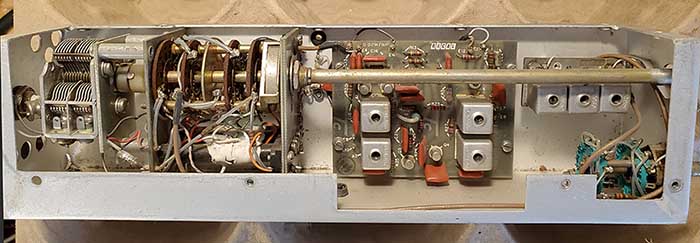

RA-17 Receiver

Alignment Overview

General

Info -

Alignments should follow the basic idea of the instructions in the manual.

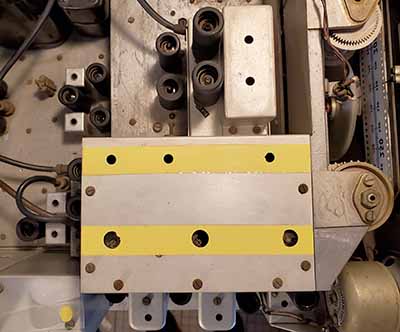

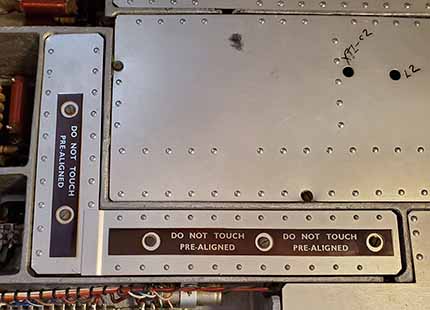

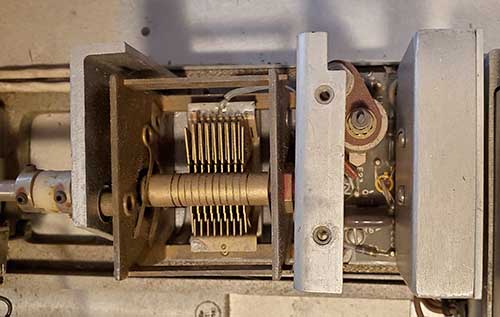

The 40mc BP filter and the 37.5mc BP filter have several

adjustments and the 40mc BP filter requires a spectrum

analyzer with tracking sweep generator (laboratory

equipment) for accurate alignment. Originally, where there

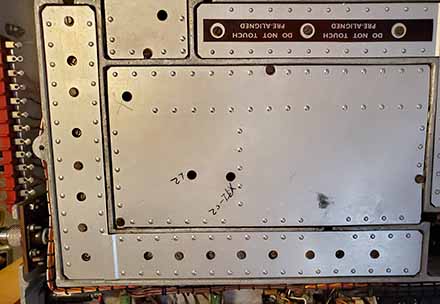

were access holes to the 40.0mc BP filter adjustments, metal labels

were installed (glued) over the access holes that warned "Do

Not Touch - Prealigned." It's very common that

these 40.0mc BP metal labels will be found missing for obvious

reasons. Thoroughly read and reread the instructions before

"diving into" an alignment. You should thoroughly understand

how the RA-17 works before attempting an alignment.

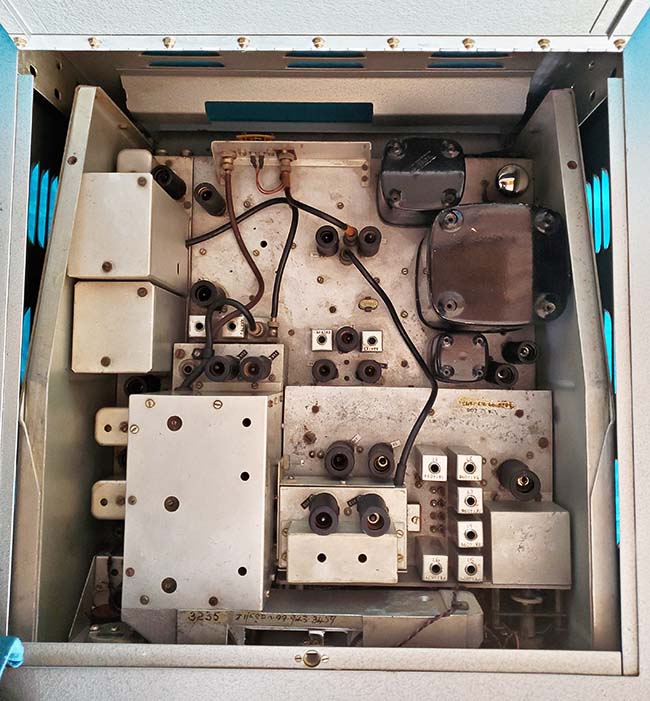

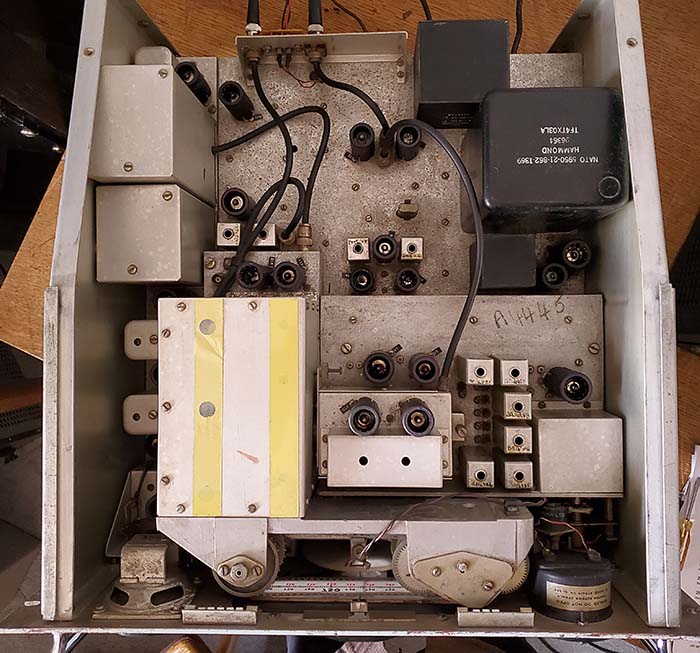

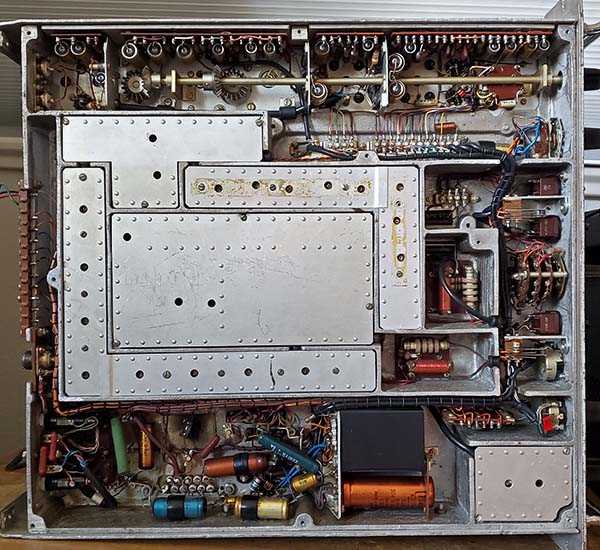

Adjustments are located almost everywhere,...top, bottom and

side of the chassis. Expect to have to move the receiver on

its side or rotate it around the bench for much of the

alignment. Probably placing the receiver on its right side

would provide access to all inputs and alignment adjustments with as

little moving as possible. Since a R-load needs to be

connected into the IF circuitry during alignment, the larger

bottom cover needs to be dismounted. The R-load is necessary

because during the alignment without the load the IF output

presents a "broad double-peak" and if adjusted to one of the

peaks would have the IF slightly misadjusted and trying to

find the exact center of the "dip" (the center between the

two peaks) is difficult. The 4.7K

eliminates the "double-peak" for an accurate adjustment.

Naturally, the top cover also needs to be off for the

alignment but all tubes and circuits are shielded even with

the top cover off. The left-side panel will have to be

dismounted for access to the 100kc LC filter and access

to C-136 (VFO-2 trimmer.) The manual's alignment procedure does

mention that the equipment used should be of

laboratory-quality and that a digital frequency counter will

be needed for accurately aligning the Crystal Filter.

Using a modern synthesizer-type RF signal generator would eliminate

the need for a separate DFC (for checking the

signal generator frequency.) The manual also indicates that

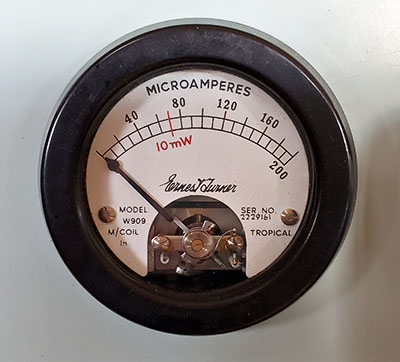

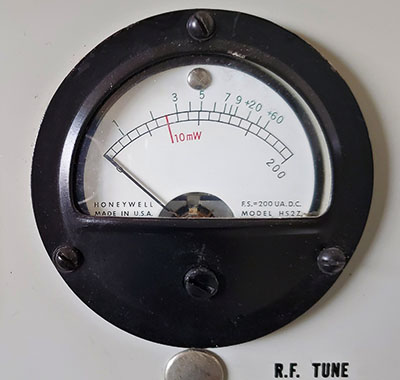

using the Carrier Level meter as an output indicator is

specified in most of the alignment measurements (using the uA scale set to 100 - half scale on the meter) but a VTVM can also be used depending

on what exactly is being measured (the output of the 37.5mc

BP filter requires a VTVM with RF probe.) Also, a heterodyne

frequency meter is specified for alignment of the

40.5mc to 69.5mc VFO 1 but, nowadays, one might think a

digital frequency counter could be used instead but there

are difficulties involved when trying to measure VHF sine

waves with regard to triggering points on the sine wave

causing frequency readout errors. A modern oscilloscope that

can sweep at 0.1u sec per division (10mHz per division)

would show slightly over 4 sine waves per division at 40.5mc and just under seven

sine waves per division at

69.5mc,...some modern 'scopes will also measure frequency in

a digital display somewhere on the screen. Even a modern VHF

receiver

with synthesized digital readout of the received frequency

could be used for the VFO 2 tracking alignment (the VHF

receiver must be able to receive AM signals.)

RACAL's Alignment

Procedure Caveats

- Be prepared,...the alignment procedure is fairly

complicated and it isn't exactly a "step-by-step" procedure. The writing is mildly convoluted making it

somewhat difficult to follow with a casual reading. First, don't be in a hurry to

complete the alignment. Read through the alignment procedure

several times as this will help you to understand what is trying

to be accomplished (this is assuming that this is going to

be the first RA-17 you've aligned.) Like many 60+ year old

instructions for electronic

devices that require periodic alignment, the RA-17 manual

was written at a time when most test equipment used vacuum

tube circuitry and analog dials. Consequently, many of the

steps described in the alignment procedure are due to the limitations of the test equipment of the time. The

heterodyne frequency meter for VFO 1 adjustment is a good

example of a type of test equipment that just isn't used

anymore

(although this might be an easy way to align the VFO

1.) The procedure has some expected measurements and

specifications added into the instructions that are helpful

but do lengthen the instructions quite a bit.

Extra stuff

needed,...a 4.7K resistor is required for loading the

first IF

transformer while it's being aligned. Also, a 1K resistor load is

required for the Ant Tune (Aerial Tune) adjustments and a

0.1uf coupling capacitor and a 12pf shunt capacitor are

specified (for Mk III versions.)

The 12pf shunt is for an external multimeter of a specific

type called out in the procedure. The shunt might not be

required depending on what equipment is actually used for

the measurement. I used a military HP VTVM (Type ME-26D) using a RF probe measuring

RMS and the shunt wasn't needed.

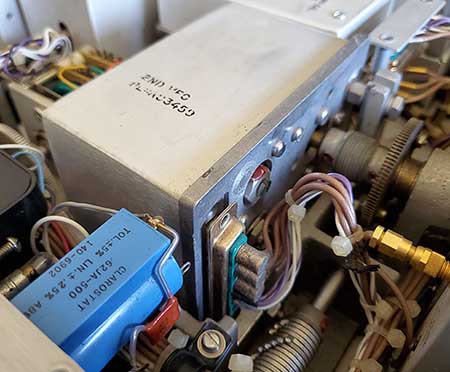

Weird stuff,...the 100kc LC filter has two

unconnected wires

inside the shield-box that must be soldered to terminals

inside the filter box. These wires connect the necessary

built-in damping resistors for alignment (the shield-box

must be remounted for alignment) and the wires are

disconnected after the 100kc LC filter alignment is

completed. The shield-box is on and off four times during

the alignment! And, unexpectedly, to be able to dismount the

100kc LC filter shield-box, the left side panel of the

receiver has to be dismounted! Two access slots are provided

on the left side panel but why they are present when the

side panel has to be removed is just one of those "weird"

things. The Crystal Filter can be aligned through a single access slot provided on the

left-side panel but dismounting the left-side panel has many

advantages during the alignment and it's highly recommended

that the left-side panel remain dismounted for the entire

alignment. The Crystal Filter alignment will require either

a digital frequency counter to set an analog signal

generator accurately (this method is actually mentioned in the later

RA-17C-12 manual) or using a modern synthesizer-type of RF

generator. Using a synthesizer makes setting up the Crystal

Filter very easy since the frequencies are just "punched in"

and the accuracy is unparalleled.

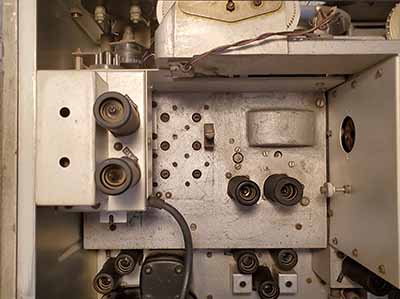

Pains and Oddities - To further complicate alignment, ALL of the adjustments are

referenced by using the

component ID, e.g., adjust L22 or C127, etc. and then

there's no "specifically for alignment" locator drawing

pointing out just where the particular adjustments are. You

have to use several of the component identifier

photos/drawings to locate the actual adjustment specified.

Even then not all of the identifiers are shown. For example,

the 4.7K R-load is referenced to the inductors of the IF

transformers but the actual connections to the IF

transformer terminals aren't mentioned and the terminals aren't identified on the schematic either. You have to trace

the wiring (on your first alignment anyway) to actually know which terminals

to connect the 4.7K R-load to. Another problem is C-195B

C-trimmer on the second IF transformer,...it's not even shown on

the Mark II schematic but it is present in many Mark II

receivers. Additionally, C-195B isn't shown on the component

identifying drawings. One has to just assume that the

unidentified C-trimmer on the second IF transformer must be

C-195B. While carefully doing the read-through of the procedure

(several times,) locate ALL of the adjustments and

mark them in pencil on the component photos/drawings and add

pencil notes to the procedure in the manual (again, assuming this

is your first RA-17 alignment.) That way you'll know

where all of the adjustments involved are located before you

start the alignment. This is just one of several tedious

pre-alignment steps

that are required on just about any complex

receiver on the "first" alignment. Some receivers will have

identifying markings on the adjustments on the chassis from

technicians that performed alignments in the past. They are helpful most of the time.

Since the receiver is

on its side for most of the alignment, clip leads can be

used for connections

under the chassis (ball-clips work best but alligator clips

also work.) For the 4.7K R-load needed, making up the resistor with wire

clip leads in advance will help (although it's only needed

twice.) Using tube extension sockets will make signal input

connections much easier. Most of the tools needed

are standard alignment tools. Non-conductive types might be

needed in the front end of the receiver. If

the receiver has been totally disassembled for a complete

rebuild, the manual's alignment procedure does provide

instructions for setting up the mechanical alignments necessary.

Other Complaints

- Due to the VHF conversion that has VFO 1 operating from

40.5mc to 69.5mc and the 40mc BP filter along with the

37.5mc BP filter, one might find that a lot of their vintage test

equipment just can't operate at those frequencies. Although I

found that my General Radio DFC worked great for measuring

the 1.000mc crystal oscillator, it was totally confusing to

use for measuring the output f of VFO 1 (just adjusting the

trigger would then result in a different frequency display.

This is due to the amplitude of the VFO 1 output changing as

the frequency changes and also there will be some harmonic

content in the output waveform that can also cause

triggering errors.)

The VTVM ME-26D worked fine for HF RMS measurements when

using its RF probe. For all signal frequency requirements below

20mc, the HP synthesizer worked great. For higher

frequencies I used the FNIRSI Oscilloscope with 50mhz

synthesizer RF signal generator combo and that worked fine.

What would be nice additions (for me) to the test gear for

aligning RA-17 receivers would be a good spectrum analyzer

with tracking sweep generator that can operate from LF up to

VHF,

a separate modern sweep generator that operates up to 100mc and

perhaps a VHF AM receiver with synthesizer digital frequency readout capable

of covering 30mc up to 150mc.

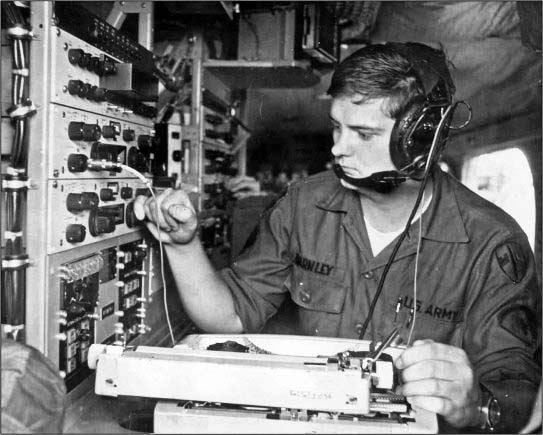

Alignment

Procedures Should be "Marked Up" - The RACAL manual's procedure doesn't "read" like

the typical U.S. Army Technical Manual (TM) instructions that

were written for Army radio technicians to easily follow in

a "step-by-step" method and

accomplish the alignment in a "quick and timely" manner. RACAL's alignment

instructions aren't as difficult to follow as, for example, the Hammarlund

SP-600VLF receiver's "impossible-to-implement" instructions but the RACAL instructions

definitely are not easy to casually read-through unless you

understand exactly how the receiver is designed to work. The

instructions are not written to

allow a "quick and easy" method of alignment

either. But, the more you read the procedure, the easier

understanding it becomes. Don't be in a hurry, re-read the

procedure several times and go ahead and make pencil notes

in the manual. It all helps

on the "first" alignment.

|

Using Modern Test Equipment |

Is it possible to go through the RACAL procedure and

eliminate the 60 year old test equipment references and

substitute modern test equipment? Modern test gear

will normally be easier to

adjust, much more accurate in the set up and give better

results for the alignment. Modern test gear, that can be

easily purchased today, is so far advanced and makes the

alignment tasks so much easier, using 60 year old test

equipment for alignments just doesn't make sense anymore.

The Internet has quite a few examples of "updated"

procedures with hints on using modern

equipment for aligning the RA-17. Some of these instructions are

selected portions of the complete procedure and most of

those are about the

40mc BP filter, the 37.5mc BP filter or tracking VFO 1 with suggestions on aligning

these difficult to adjust circuits. In fact, the RACAL manual's

procedure says that the 40mc BP filter shouldn't be tampered

with unless you have a spectrum analyzer with tracking sweep

generator

which, 60 years ago, nobody had (except for commercial outfits

and the military) since prices for that type of equipment

then were astronomical. Nowadays, good quality spectrum

analyzers with built-in tracking sweep generators are very

accurate, very small and not astronomically priced.

Inexpensive is a somewhat subjective term since spectrum

analyzers with tracking generators (SA+TG) are still somewhat expensive but

what is available today is probably 50X cheaper than similar

spectrum analyzer equipment that was used 60 years ago (and

probably several times more accurate.) There are

quite a few low priced DSA - Digital Signal Analyzer - devices

that would be very helpful in performing other parts of an

alignment. These

devices are made in China and are basically a two channel oscilloscope

with a built-in RF synthesizer signal generator. FNIRSI, a Chinese

company, makes a

tablet-sized, 2 channel 350Mhz oscilloscope with a 50Mhz RF synthesizer generator

and a passive spectrum analyzer, all of about $295

(the DPOS350P,...yes,

I have one and I use it a lot.)

However, the RF synthesizer generator in this particular device

unfortunately doesn't have a sweep function that works with

the spectrum analyzer so sync'ing becomes impossible. This

type of spectrum analyzer is referred to as FFT or Fast

Fournier Transform which

transforms the amplitude vs. time of the 'scope to amplitude

vs. a frequency spectrum. In other words, FFT only shows

basic signal position and strength over a wide frequency

range which is good for harmonic content types of

observations. If you have (or have access to) a SA+TG then

alignment of the 40mc BP Filter becomes possible (although

check performance first using the spectrum analyzer,

adjustment may not even be necessary.) If you

don't have the proper test equipment then don't attempt the

40mc BP filter adjustments. It's possible to check the 40mc

BP filter response with a signal generator but it's not a very accurate procedure

and certainly shouldn't be used for adjustment. The use

of a synthesized signal generator also makes the entire

alignment much easier. The required frequency and amplitude

are simply "punched in on the keypad" and the output accuracy is

unparalleled.

Modern Test Gear Caveat

- There is one very important caveat about using modern test gear

with vintage tube equipment,...most modern test gear wasn't

designed for the high voltages that might be encountered in

vacuum tube

circuits. This high voltage on inputs or outputs of the SA+TG could be the result of hook-up mistakes or just an

accidental momentary contact. In either case, instant and serious damage

could occur to the modern test equipment. Most SA+TG will

have a voltage limit of about 20vdc to 40vdc on the SA and

the TG will be much less than that. Even if the test gear is

capacitively-coupled, that isn't an assurance that damage

won't happen since the capacitor will pass the initial

contact voltage for an instant (as a strong voltage pulse.) Most of the time a 10:1 or 100:1

probe can be used, but not always. Fixed-value inline

attenuators can also be used, sometimes. Another problem is impedance

matching,...most SA+TG are designed for RF transmission line

applications and will have a 50Z input impedance. Many of

the input circuits in a vacuum tube receiver will be much higher Z

and could be "loaded down" when connected to the SA+TG.

Depending on what is being observed in the receiver, whether

voltage levels are accurately shown on the display might be

irrelevant since only the waveform shape is important.

These types of hook-up problems can be corrected, sometimes quite easily, but

always some sort of protection of the inputs and

outputs of the modern test gear is required when interfacing

with vintage tube equipment. The most common solution is to

use an attenuator with a buffer stage. This will provide

good isolation and can even provide impedance matching.

The upshot is when interfacing a modern test instrument with

a vintage tube receiver be very careful and think about what

you're trying to accomplish. Know what the voltages are in

the circuit before connecting the test gear and know what

the RMS voltage levels of signals that are going to be encountered.

Also, remember what the input limitations are for your

modern test gear.

Be aware that sometimes AC line bypass capacitors can "leak"

AC voltage to the chassis if it isn't grounded. This can end

up with AC voltage being connected to the negative input on

"floating inputs." Grounding all test gear and the receiver

chassis is required. Most three-wire AC plugs do ground the

receiver chassis. Of course, AC-DC devices should always be

powered through an isolation transformer and usually the

chassis and B- are separate so always check voltages levels

before connecting any modern test gear.

When the

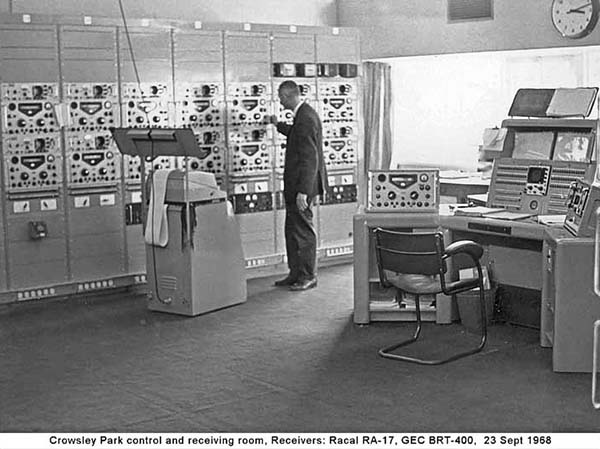

RA-17 was built, RACAL had test jigs with oscilloscope displays

and built-in sweep generators with markers that were mostly

vacuum tube based equipment. Even at RACAL, using this

special equipment for adjusting the

filters was still a fairly time-consuming process.

Modern test equipment is probably ten times more

accurate and fifty times cheaper than what RACAL used 60+ years ago. If you can

afford it, modern test

equipment will ease all of the adjustments quite a bit

provided you know

how the RA-17 is supposed to work and you know how to use the

modern test equipment including protecting its input and

output connections. Check

www.radiomuseum.co.uk

as Allan has multiple pages about working on various types

of problems involving the RA-17 and

details on aligning the RA-17 BP filters and VFO 1 with modern

equipment. Lots of photos

too. Summary

- Like any complex receiver, the

"first one" worked on is

your "learning experience," any that follow become more

familiar and are almost always much easier to

get through. If you've successfully reworked R-390A or 51J

receivers, then you'll sort of know what to expect in a RA-17 or RA-117

receiver. UPDATE NOTE:

Most of what is written above is based on the RACAL manuals

for the RA-17 Mark II and the RA-17L and the RA-17C-12, both Mark III receivers. I've found a

British Military

Technical Handbook for Field and Base Repairs for the RA-17

Mark II and for the RA-17L Mark III (hereafter

referred to the Handbook.) Since this handbook was

written for technicians (I think) it seems to be very direct

in describing each of the steps necessary for alignment

which helps to clarify the tasks. It's basically the same

information that's in the RACAL manuals but presented in a

somewhat easier-to-follow format. However, there are

absolutely no component location drawings provided so the

user has to have component location drawings/photos from

another source (the RACAL manual, probably.) The Tech

Handbook is from 1967. I found this manual/handbook on the

Internet while searching for alternate manuals for the RA-17 Mark II receiver (free download

from VMARSmanuals.co.uk.) As mentioned, the handbook covers

both the Mark II version and the L Mark III version. This

Handbook should be used along with the RACAL manual - it

can't be used exclusively because of the lack of component

location information. |