|

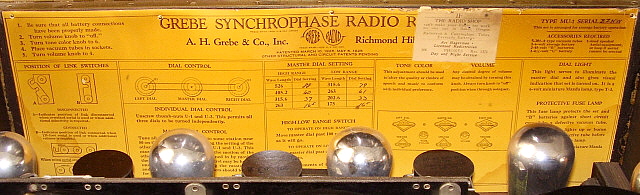

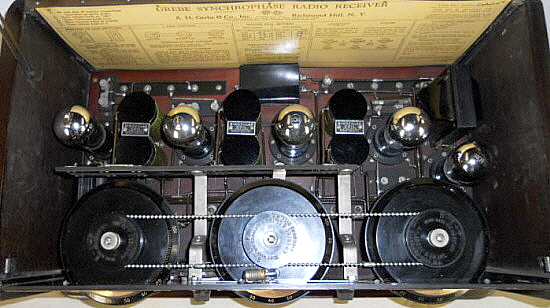

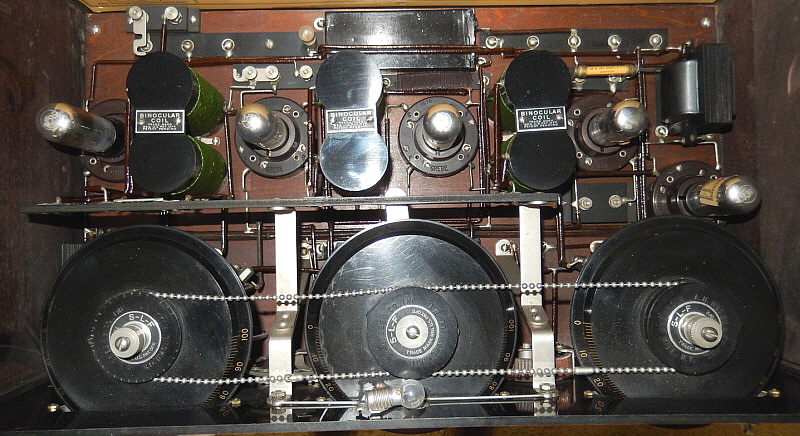

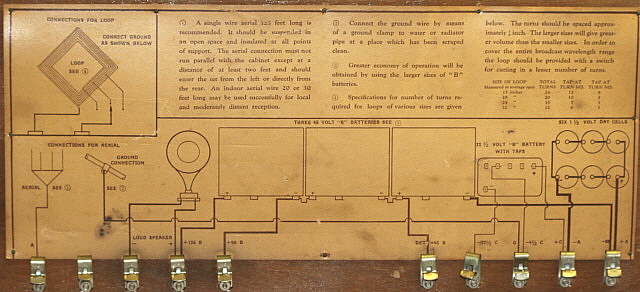

MU-1 Early Production

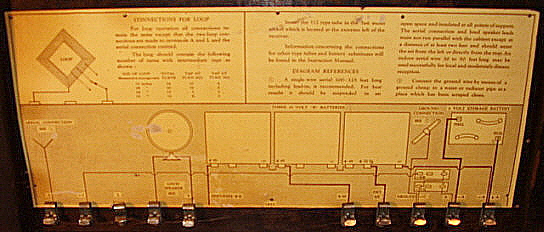

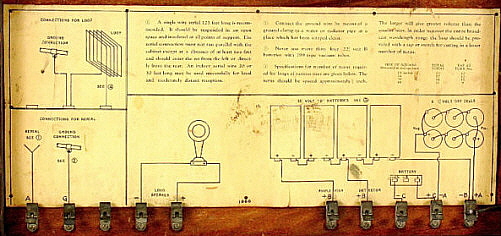

Aug. 1924 to mid-1925 - No Chain Drive, no Band

Switch, four +22.5vdc B-batteries shown on hook-up card |

BLYI - (one lid prop, early type)

CCBU - (early type - no other details)

CTPB - (VOL/FIL on R.E.,with Batt. Base option, 2LPs)

FWWC - (VOL/FIL on R.E, from console model)

HVXD - (early type - Battery Base option)

JRPI - (Two FIL R.E., early type)

JTRC - (INCREASE only on Round Esc., 2 lid props)

LBCO - (VOL/FIL on R.E.)

LYWA - (INCREASE only on Round Esc., 2 lid props)

MPRI - (VOL/FIL on R.E., 2 lid props)

PNBU - (Early type, 2 lid props)

RXJA - (Early type)

STNU - (Early type)

TBRI - (Early type)

VSGB - (Early type w/4 B-batteries shown on card)

WJVX - w/ Batt. Base opt., 2 LPs)

WZJX - (Early Type)

ZDVC - (VOL/FIL on R.E., 2 lid props)

ZLXA - (Early type)

|

MU-2 Early Production

No Chain Drive or Band Switch, 6 Tubes all UV-199 |

BNDU - No Chain Drive, six UV-199 tubes

HSGC - No Chain Drive, six UV-199 tubes

VLZX - No Chain Drive, six UV-199 tubes

VYVA - No Chain Drive, six UV-199 tubes

|

|

MU-1 Intermediate

Production

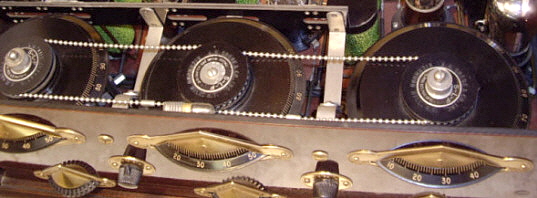

mid-1925 to mid-1926 - Chain Drive, Band Switch, both xmfrs

the same size, +90VDC B+ w/two +45vdc B-batteries |

BZNW - (Long B+, C- Caps)

CSPY - (Short B+, C- Caps)

FYJH - (Short B+, C- Caps)

GLYW - (Short B+, C- Caps)

GNPX - (Short B+, C- Caps)

JBBR - (Short B+, C- Caps)

JPSO - (std. mid-production)

KKKH - (std. mid-production)

LSRY - (std. mid-production)

MFSS - (Short B+, C- Caps)

MPCY - (std. mid-production)

NZCW - (std. mid-production)

PGNY - (Short B+, C- Caps)

PPSN - (std. mid-production)

PYLP - (std.mid-production, except has all Cushion Sockets)

RJNA - (Long B+,C- Caps, has 1926 Factory Upgrades)

SRSS - (Short B+,C- Caps)

TPTN - (std. mid-production)

VZLR - (Short B+,C- Caps)

WGXD - (Long B+, C- Caps)

XFGI - (std. mid-production)

XHHP -(std. mid-production)

YKYG - (std. mid-production)

ZYLC - (std. mid-production)

ZYXG - (Short B+, C- Caps)

|

MU-2 Late Production

Chain Drive, Band Switch, 5 Tubes, both xmfrs the

same size, Cushion Sockets, +135vdc B+ |

DMJA - Chain Drive, four UV-199 and one UX-120

SKHX - Chain Drive, four UV-199 and one UX-120

WKYA - Chain Drive, four UV-199 and one UX-120

|

|

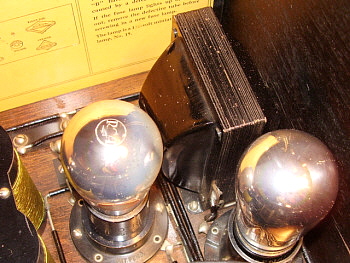

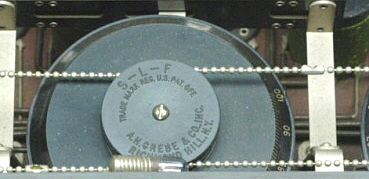

MU-1 Late Production

mid-1926 to mid-1927 - Large 1AF Xmfr, UX-112 tube, +135vdc

B+ w/three +45vdc B-batteries and Cushion-type Tube Sockets |

BPZI - (UX-112, no other details provided)

BXVD - (Late version)

CCYI - (All Cushion Sockets, S-L-F embossed)

CFFI - (UX-112, no other details provided)

CMCP - (UX-112, cushion sockets)

CRZD - (No detailed data available)

DJJU - (S-L-F embossed)

DTCM - (Late Version)

FSPG - (All Cushion Sockets, S-L-F embossed)

HLLY - (UX-112, cushion sockets)

HZFP - (UX-112, cushion sockets, red/black mottled dials)

JMMT - (All Cushion Sockets, S-L-F embossed)

JVFR - (All Cushion Sockets, S-L-F embossed)

KBZT - (All Cushion Sockets)

KVWY - (All Cushion Sockets)

LGYS - (All Cushion Sockets, S-L-F embossed)

LSHR - (All Cushion Sockets, mottled dials)

MFPA - (All Cushion Sockets, S-L-F embossed)

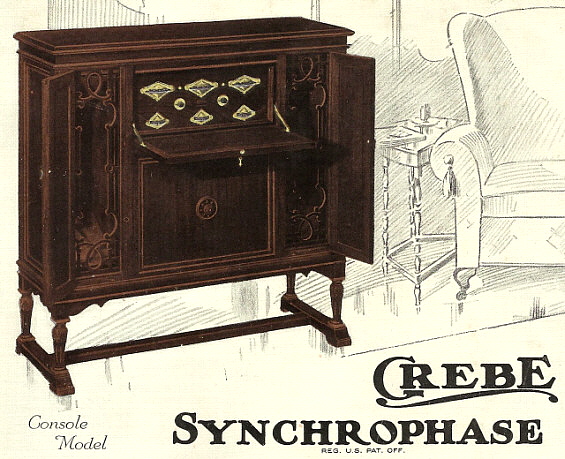

MHSA - (All Cushion Sockets, S-L-F embossed - Console)

MNZC - (Det Cushion Socket, S-L-F embossed)

NBLL - (All Cushion Sockets, late version)

NCSO - (Det Cushion Socket, S-L-F embossed)

NLCH - (All Cushion Sockets, S-L-F embossed)

NRFM - (All Cushion Sockets, S-L-F embossed)

NSHR - (All Cushion Sockets, S-L-F embossed)

PMMA - (All Cushion Sockets, no other data)

PVPA - (Det Cushion Socket, S-L-F embossed)

RDBD - (Det Cushion Socket, S-L-F embossed)

RGZL - (All Cush Sckts, S-L-F emb, Mottled Dials)

RPVA - (Det. Cushion Socket, S-L-R embossed)

SGDR - (All Cushion Socket, S-L-R embossed)

SLZR - (All Cushion Sockets, S-L-F embossed)

TNZS - (Det Cushion Socket, S-L-F Metal Rings)

TPBO - (Det Cushion Socket)

VCGY - (Bayonet Sockets, S-L-F Metal Rings)

VNDX - (UX-112, large 1AF xmfr)

VVGH - (Det Cushion Socket, Older style Clutch Caps)

WGGN - (no details provided)

XBLW - (All Cushion Sockets, S-L-F emb'd, red/black mottled dials

)

XCPT - (All Cushion Sockets, S-L-F embossed)

XNYB - (Det Cushion Socket, large 1AF xmfr)

XPDP - (post 8-26)

XVRN - (Cushion Sockets, large 1AF xmfr)

YFTI - (All Cushion Sockets, S-L-F embossed)

YPND - (post 8-26)

ZRDT - (Det Cushion Socket, S-L-F embossed)

ZXZL - (All Cushion Sockets, S-L-F embossed) |