| First off,...don't attempt this unless your receiver is

in really, really poor cosmetic condition because IT'S A LOT OF WORK!

However, some BC-348s are poor on the outside and really nice on the

inside, so a repaint is sometimes a necessity. You're going to need

about two or three cans of VHT High-Temp Black Wrinkle Finish Paint. It

is carried at most O'Reilly auto parts stores (also Summit Racing.) Be prepared, it's

expensive at around eleven dollars per can. Use a "spray can handle" as

this allows better control over the spray pattern. Also, use high

quality paint stripper. Remove all of the knobs, the handles, the small

panel, the dial cover and the phone jack "toilet-seat" covers. Unsolder

the wires to the dial lamps and to the Antenna terminal. Remove the

front panel. Keep all of the screws together because they will also be

painted. Drill out the rivets that mount the ID tag to the front panel.

You will also have to drill out the rivets that hold the two dial lamp

sockets to the panel. You can now strip the paint from the front panel,

the handles, the knobs and the smaller access panel.

The front panel, all knobs, the two pieces to the dial cover, the

phone jack toilet seat covers and the small access panel are to be

painted black wrinkle finish. The handles and the screw heads will be

painted black satin finish. Some of the original hardware was actually a

dark bronze finish but this was an oxide finish that is difficult to

accomplish (it's called Brown Patina and will work on brass hardware but

not steel.) Sometimes the brown finish can be duplicated with ink dyes

that combine brown and black to achieve the proper color. Some restorers just paint

the screw heads satin black but this is just a "short cut" that shows a

lack of commitment to originality.

First, though, a word or two on how to successfully paint wrinkle

finish paint. The original paint used on the BC-348 and all military and

commercial gear from the fifties on back was a two-part process that

required a base coat of nitrocellulose lacquer that was allowed to dry.

Then a catalyst was sprayed onto the lacquer base. The panels were then

put into ovens that baked the paint and the wrinkle developed in the

oven. That's why most vintage wrinkle paint jobs have the wrinkle on the

outside and smooth gloss black paint on the inside. The inside wasn't

sprayed with the catalyst.

Today, we use paint that is a one-part process that is heat

activated. I do all of my painting outside so the heat comes from

incandescent lamps. First, DO NOT pre-heat the metal to be

painted by putting in out in the sunlight or in an oven. This causes

activation of the wrinkle almost immediately when the paint hits the hot

surface and will result in very uneven coverage and spotty wrinkling.

Leave the metal at room temperature. Next, the paint has to be applied with very heavy

successive coats separated by just a few minutes. I use a minimum of

three heavy coats applied at different angles for each coat and separate

each application by a couple of minutes. Next, to apply heat I use 100

watt light bulbs in clip-on utility lamps with aluminum shades. These

are available at Home Depot for less than $10 each. I usually use three

lamps suspended over the panel about 10" to 12" above the panel. The

three lamps will heat the paint and the panel and the wrinkle process

will start in about 10 minutes. I now use two 250W brood lamps for

heat. The two lamps provide more heat that the three 100W lamps and are

easier to place correctly. I standby with a hand-held heat gun and

after about 10 minutes, when the wrinkling starts, I use the heat gun to

apply more heat around the corners and places where the lamps don't heat

the panel very well - I still do this and have found it a "necessary"

part of the wrinkling process. For stubborn areas, the heat gun will force the

wrinkle but don't apply too much heat or the paint will "gloss" and the

wrinkle won't match. After about another 5 to 10 minutes the wrinkling

should be complete and now remove all heat and let the panel cool down

for about 30 minutes. When the panel is cool, the paint will be set-up

enough to handle. Let the paint cure at least overnight before mounting any

screws or parts to the panel. If you can wait a little longer, like a

week, the paint will be much harder and resistant to scratching or other

types of damage. Thirty days are required for full curing and after

one year the paint is virtually indestructible.

Now comes the tedious part. You'll notice that the silver

nomenclature on an original front panel is bare aluminum. Originally,

after the panel was painted the paint over the nomenclature was "ground

off." Originally, the nomenclature was much higher and when just

"ground" down slightly, the bare metal showed through as silver

lettering. This time we can't do that since the lettering was already

ground down once and now the lettering is just above the paint level. I

make a small tool that consists of a small piece of an industrial razor blade piece about

.25" wide that is mounted to a small wooden handle. With this tool I can

carefully "shave" the wrinkle finish paint off of the nomenclature but

the lettering still isn't bright.

I also make another tool that is another small wooden handle that has

the end cut at an angle that has a flat surface. I use 400 grit aluminum

oxide paper held to the angled part of the handle with tape to polish

the lettering. This leaves the lettering looking very bright and

original. Sometimes there might be a minor slip-up but I use a small

paint brush to apply Artist's Acrylic Mars Black paint to touch-up

scratches or other blemishes I've caused during the process. >>> |

>>> To remount the ID tag,

you'll have to make "fake rivets." I use 4-40 SS (stainless steel)

binder head slotted screws. I chuck them up in a drill press and file

the head until you don't see the slot but there is still material left

to shape a rivet head. Don't use philips head screws because the slots

are too deep. After you have four good looking "fake rivets" mount the

tag and secure the "fake rivets" using 4-40 nuts on the back of the

panel. There is plenty of clearance for the nuts but don't use overly

long screws. Although you don't have to make "fake rivets" to remount

the dial lamp sockets be VERY CAREFUL about the back clearance when

remounting them with screws and nuts. Mount the binder head screws on

the back side of the panel and use the nuts on the dial lamp socket

side. You still might have to file the head of the screws to be sure you

have clearance. The distance between the back of the front panel and the

tuning dial mask is minimal. Without the clearance, you'll scratch the

dial mask the first time you change bands. Make sure you have the

clearance. Nowadays, I'd use the correct rivets - they are easily

available on eBay including the rivet setting tool. Next, paint the knobs and the other parts that should be black

wrinkle. Use a small scraper made out of a jeweler's file to remove the

paint from the "arrows" on the knobs. An Ex-acto knife with

the proper blade can also be used to remove the paint from the "arrow."

Some versions of the knobs appear that the arrow was engraved and some

version appear to be stamped into the wrinkle finish paint. The engraved

arrows clean out fine but the stamped arrows don't. Some vintage

drawings/photos show the knobs without any arrows. If you have the

stamped type arrows and are having trouble getting them to look correct,

it is acceptable to just leave the knobs black wrinkle and not bother

trying to scrape out the paint. Also, be sure to paint the handles satin

black but

the screw heads should be dark-bronze finish.

For the cabinet, I've had pretty good luck just shooting over lightly

sanded and very clean original paint with the VHT wrinkle finish and

then giving it the heat treatment. You might have to paint one side at a

time depending on your heat lamps. I usually do one side at a time

because I have better control of the wrinkle process that way. I also

use a handheld heat gun to apply heat to corners and edges that the

lamps don't heat enough. I have

stripped the cabinets and wrinkle finished and I suppose they look

slightly better but it's very hard to tell whether a repainted cabinet

has been stripped or just painted over.

What about

the Signal Corps acceptance stamps?

- Without a doubt, the repainted BC-348 looks

incomplete without the orange Signal Corps acceptance stamps. What I did

was to first make full scale drawings of what the typical acceptance stamp

looks like. This will have the square boarder with "SC" at the top, a

random number that was the inspector's identification and then an "A" at

the bottom. Also, I made another scale drawing of the "M1" stamp that is

on 90% of the BC-348s (MWO for Lo-Z audio output.) I then took the scale drawings to a stationary

office supply type store that makes rubber stamps. It costs about $15 to

$20 per stamp. Usually the square boarder on the "SC" stamp costs a

little more but you "gotta have it." Once you have the rubber

stamps, now you can apply your own acceptance stamps on any of your

repainted AAF

gear. I use Artist's Acrylic to mix up the proper orange color and use

water to thin the paint to a very wet mix. I then soak a cloth pad with

the orange paint to create an "ink pad." Be sure to practice on some

scrap pieces for a while. Also, be sure to have the stamp "runny

looking" and be sure to remember - none of the original stampings were

straight. After all, the inspectors were just stamping gear they had

tested or accepted - it wasn't anything special to them. The "M1" stamp

is usually a lighter, almost yellow-orange color ink and done the same

way as the "SC" stamp. In fact, the "M1" stamps are usually even

"runnier" looking. The "sloppier" the stampings looks, the more original

they look.

|

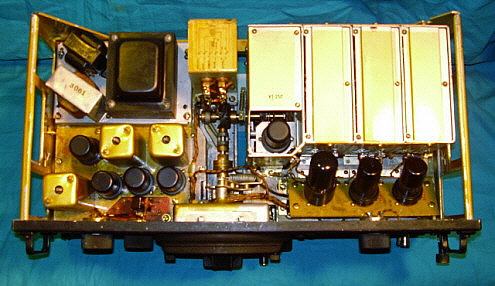

Take a look at BC-348-Q SN 11227 above. This BC-348 has been repainted as described in this section (with

the exception that I used Krylon BWF paint instead of VHT.) Also, the

Signal Corps acceptance stamps are made with reproduction stamps.

Overall, the impression of SN 11227 is that it is an excellent

condition, original BC-348. This is the effect that I want to achieve in

a

restoration. |

|