|

No Receiver is Perfect

The Solution for IF Overloading with AVC Off

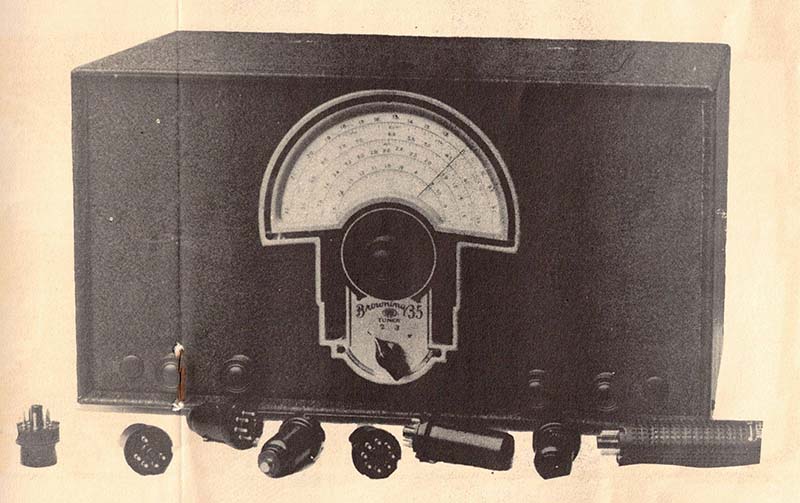

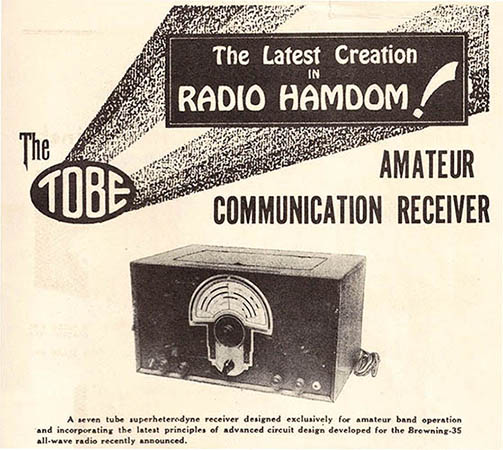

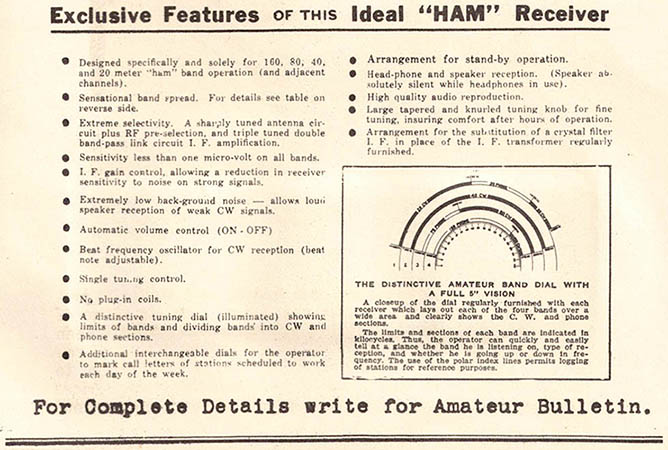

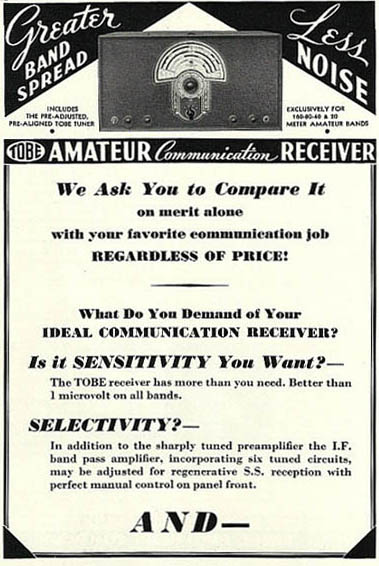

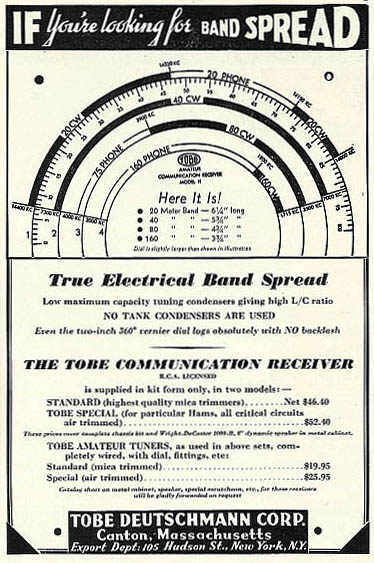

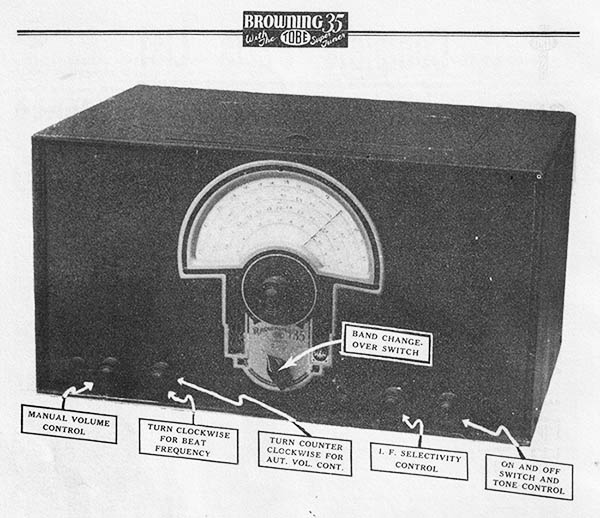

The Problem - The TOBE

receivers have a difficult time when tuning into MODERN

powerful ham signals in the SSB mode when using a large,

resonant antenna. One does have to consider that these receivers were designed in the mid-1930s

when noise levels were low, most ham transmitters were running

CW at

less than 100 watts and most receiving antennas were simple

50 foot long end-fed

wires (remember, the Browning design is almost 90 years old!) Also, one has to consider that

these receivers were kits that had to be fairly easy to build

and the selling price had to be kept reasonable. The original

Browning 35 design was for a short wave receiver that primarily

was for AM reception. When the TOBE receivers are

operated in the AM mode, which forces the use of the AVC control

circuits, modern AM reception is great. The RF amplifier and the IF

amplifier grids are BOTH biased with the AVC voltage that is

inversely proportional to the signal level, that is, as the

signal level increases the AVC bias voltage becomes more

negative. The end result is no

distortion regardless of the level of signal input. BUT, the ham

receivers were almost certainly used primarily in the CW mode (in

the thirties, CW was the dominate mode of ham communication.)

CW reception requires the BFO to be turned on and the AVC to be

turned off. In this set up, the RF amplifier stage runs at

maximum gain and the IF amplifier gain is only controlled

by the variable cathode resistance to chassis-ground, a self-bias type of

control. The level of

apparent grid bias available at the IF amplifier tube is not

capable of controlling the receiver gain when tuning modern CW/SSB ham

signals AND there's no way to

throttle-back the RF amplifier gain that's running at maximum.

The result is extreme distortion on SSB signals due to

signal overload in the IF stage, even with the IF gain set to

minimum. Browning seems to have been aware (from his 1930s

perspective)

of this potential problem, although in the 1930s, CW signal levels

were not nearly as potent then and, MORE IMPORTANTLY, high-power SSB was far in the future.

When in the CW mode, signal overload might have only happened occasionally back then.

Browning did change the IF gain control from 10K

up to 20K to provide better IF gain control (possibly only for the ham

receivers.) For modern CW signals, the distortion isn't nearly

as noticeable due to the nature of the signal (being a keyed

tone) and, additionally, almost all modern CW seems to be at a

power level of about 100 watts or less. Only powerful SSB

signals, of which there seems an abundance, are difficult to

demodulate without distortion.

Possible Solutions

- As an

experiment to confirm my analysis of the problem, I disconnected

the 400 cathode resistor in the RF amplifier circuit and "tack

soldered in" an adjustable 25K rheostat instead. With control over

the RF amplifier gain I was able to easily find a balance of RF gain, IF

gain and Volume (AF gain) that would provide undistorted demodulation of

extremely strong SSB signals when using a resonant large antenna

(tuned collinear array.) I didn't encounter ANY powerful

SSB signal on either 40M or 20M that couldn't be demodulated

with a combination of RF gain, IF gain and the Volume control.

Now, I'm certainly NOT

advocating that this mod be done to any TOBE receiver. My

installation was only a temporary one and it was just done to

confirm my analysis regarding the "fixed-at-maximum gain" RF amplifier

being "the problem" when in the CW (and modern SSB) mode. As stated, if the

receiver is in AVC for the AM mode, the AVC bias controls both

the RF and the IF gain and reception is excellent for all levels

of AM signals - BUT not in the CW mode with the AVC-off

and with a manual gain control that only functions on the IF

amplifier tube and, most importantly, with the RF amplifier

running at a non-adjustable "maximum gain."

Easy, All External, No Mods Solution

- For an

absolutely "no mods" solution, the easiest method

is to be able to control the RF level from the antenna tuner to the receiver

antenna input. Using a "tuned

antenna" set up will allow using the antenna tuner itself as an

attenuator to reduce the level of signal as needed. When maximum

sensitivity can be utilized, then the antenna system can be "in

tune" for best response. And, by a mere adjustment of the tuner, the operator can

reduce the RF level by "detuning" the antenna to cope

with extremely strong signals. A popular device at one time was

the receive-only antenna coupler. This was a small antenna tuner

that allowed adjusting the match of the station antenna to the

receiver only. It could enhance the signal or it could also be

used as an attenuator for strong local signals. This antenna

coupling device method will work most of the

time but extremely powerful SSB signals may still distort.

Also, in a working vintage ham station, it normally does require a

DPDT frame-type relay to switch the balanced feed line from the

transmitting coupler to the receiver coupler. However, for the

vintage approach, the receiver antenna coupler was the method

used by many hams.

Another less-complicated method is to use a simple adjustable voltage

attenuator can be inserted between the receiver antenna input and the antenna

or antenna coupler output.

The attenuator would allow using the maximum antenna response

when weak signals are to be received

and a reduction of the RF level when extremely strong signals

are encountered. Suitable attenuators are fairly cheap at about

$25 and provide stepped attenuation from 0db up to -82db using a 50 ohm

load. They are from China and can only handle 0.25W so they are

definitely for "receive only" use. They have a nice

layout, a small metal housing and the attenuator adjustment by multiple toggle

switches and input/output via SO-239 connectors.

Testing with the Tronson Attenuator Between

the Collinear Array/Matchbox Output and the TOBE SPECIAL Antenna

Input - I bought the Tronson RA-1728A attenuator off of

eBay. I had to pay about $10 more to purchase from a USA-based

seller ($35 with free shipping.) The SO-239 input and output connectors make hook-up

easy. The Collinear Array is the largest antenna I have at 240'

center-fed with 106' of open feed line. There is a slight gain

of a little over +1.5db on 75M and a little more than that on 40M

and 20M. The received signals when using this antenna are

noticeably stronger than with the 130' Tuned Inv-vee antenna. The

attenuator was tested on 80M, 40M and 20M. ALL extremely

strong SSB signals could be easily reduced in strength just by

switching the labeled toggle switches. For example, -20db + -20db

+ -3db would equal -43db of attenuation. The switches allow

selecting any level between 0db and -82db in -1db increments. You

have to add up the total of the db switches thrown to know how

much attenuation is switched in. Most strong SSB signals on 80M

required about -40db of attenuation. One really strong SSB

station required -70db (must have been a local.) On 40M, between

-40db and -20db was typical. On 20M, between 0db and -10db was

typical. The Tronson RF Attenuator is shown in the photo below.

| I couldn't find ANY SSB station

strong enough that the attenuator couldn't reduce the signal

level to where the TOBE SPECIAL easily demodulated the SSB. For

weak signals, the attenuator can easily be switched out of the

circuit by placing all of the toggle switches to the "down"

position. Using the attenuator allows keeping the

antenna resonant (tuned for the received frequency) and

just reducing the signal level of extremely strong

stations as needed BUT

still having the ability to easily return the antenna system/feed

line to maximum response for weak signals. Another observation

was that by

reducing the input signal level before the RF amplifier, it

seems there's much less distortion than with the simple RF

amplifier cathode-type gain rheostat modification. The antenna attenuator is

by far the easiest

and best method to deal with the IF

overloading of the TOBE SPECIAL (and the ACR-35H) when used with

a very large array antenna. |

|

|