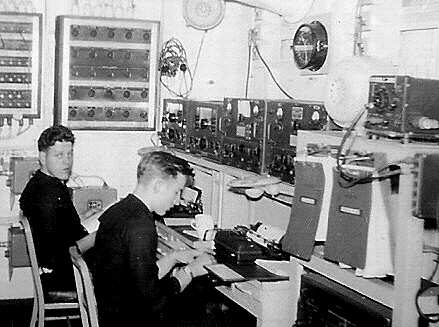

|

The 2021

Wells Gardner & Co. RAO-3 Restoration

The almost impossible to solve problem of

missing data plates on my old RAO-3 suddenly became solvable when a

"parts set" RAO-3 with data plates showed up on eBay. A close

examination of the photographs revealed that not only were the

data plates present but almost ALL of the non-original or

compromised parts that were

present on my old RAO were original and present on this parts

set. Having owned my old RAO-3 for over fifty years and having

repaired it a couple of times in the 1969-1970s time frame along

with a major cosmetic restoration in 2006, I now had the

opportunity to actually perform a complete restoration of the receiver and have it not

only look like a good condition original but "up the level" of

restoration to "museum quality" with a total electronic rebuild.

There's nothing better than having a good, useable "parts set"

for a restoration project. This restoration will allow the receiver to function correctly for long time

periods as

originally intended and to perform ideally as a vintage military

receiver in an amateur vintage military radio station. |

|

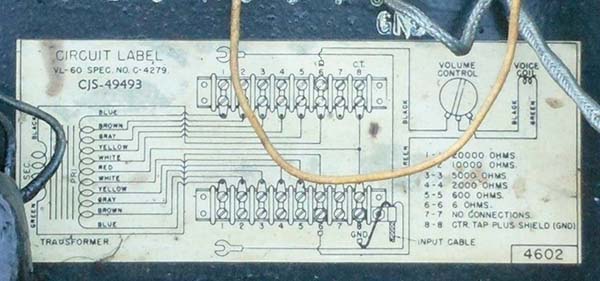

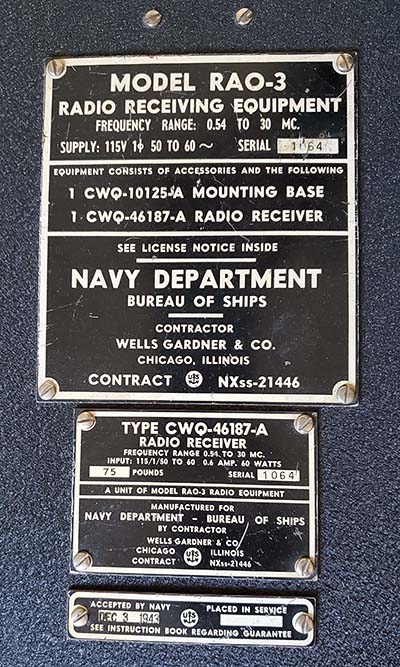

photo above: The eBay photo of the "parts

set" RAO-3 |

January 9, 2021 - I

happened onto an eBay listing of a "needing restoration" RAO-3. What was

interesting was this receiver had all of its data plates. I had never

come across a RAO-3 that still had its data plates installed and I actually

thought that the reason might be that Wells Gardner had dumped a lot of receivers

(that

hadn't been used to fulfill contracts) onto the surplus market,

naturally without tags. In

addition to the data plates, this RAO had the original audio output

transformer, the original WG power transformer cover, the original dial

lamp sockets and harnesses and the original cover for the first RF

amplifier tube with retaining nuts. Additionally, all of IF transformer

cans still had the silk screened identifications. The receiver chassis

inner threaded metal pieces for the shock mount thumbscrews were

present. Besides the overall "rough condition," what probably made the

receiver a "parts set" was about half of the knobs were gone and the bottom cover

was missing

(parts I didn't need.) Also, a hamster mod had added a toggle

switch to the left of the S-meter ruining the front panel. The really "good" thing was the

seller was located only about 450 miles away (The Sisters, Oregon) so FedEX

Ground shipping wasn't too expensive. The auction was won ($59) and in

preparation of the restoration, my old RAO-3 was extracted from the shop

storage and brought upstairs for testing.

"Parts Set RAO-3" Inspection -

Arrived Jan. 15, 2021 - Good data plates, good audio output transformer, all

four threaded adapters for the shock mount are present, first RF amp

housing cover present, original power transformer cover present, almost

all of the silk-screened identifications are present on chassis

components.

Unfortunately, the Antenna input was a hamster'd RCA phono jack. The

S-meter scale was the typical "no red" faded and darkened plastic. AF Gain pot was a later replacement part and it was

an incorrect linear taper type pot. Should be an audio taper. A check in

my spares "pot box" turned up four 500K audio taper pots, so no

problem. Overall, 95% of the parts needed were present and in good

condition. I had an original Navy coax receptacle and I had an original NOS Marion Electric

"for Wells Gardner RAO" S-meter to use in this restoration. |

|

The "Old RAO-3" Quick Test - I'm not

really sure if I'd applied power to the old RAO-3 since the 2006 "on the

air" testing which took place in Virginia City. Since that time there

had been a move to Dayton and further storage. Sometime in the past 14

years, I did pick up a correct and original RAO-3 shock mount for the

receiver but I don't remember operating the receiver at that time, just

mounting it to the shock mount and photographing it. Well,...fourteen

years of storage did require a slight bit of prep before the power up. I

needed an AC power cable. I had always used some type of hamster power

cord that would have a molded end that could be forced into the

"twist-lock" AC receptacle. This time I made up a "correct" power cable

with the proper twist-lock plug, an excellent condition vintage power

cable and vintage AC plug. After that, a 600Z ohm speaker was plugged

into the PHONE jack (Hmmm,....I guess I got ahead of myself and forgot that I still had

the replacement 8Z audio transformer in this RAO receiver, oh well,...)

A ten foot long test wire antenna connected and, using a Variac,

I ramped up the AC input voltage to 115vac in about 15 seconds. The AC line

here is 122vac, so the Variac lets me adjust the input voltage to the original spec

of 115vac. The receiver audio reproduced lots of ambient background noise and a few ham

signals on 40M. I disconnected the 10 foot wire and attached the 135'

Tuned Inv-Vee ham antenna. Big boost in signals and lots of 40M activity.

With the CWO on, I tuned

some higher frequencies for testing and I found HLO, a Korean Frequency Marker

Beacon around 12.9mc besides all of the normal SW BC in the 25M band. Sensitivity seemed reasonable but the following

problems were noted,... 1. The Crystal Filter although somewhat

working didn't really seem to have a variable narrow notch. Might be alignment but could also be a crystal

problem.

2. Any slight change in the RF Gain would cause a significant change in

BFO frequency. This is a common problem in "original 75+ year old

components" HRO and NC-100 receivers.

3. A slight hum was noticed in the loudspeaker if listened to in close

proximity. Could be many things. The filter caps are oil-filled paper

dielectric.

4. Wrong tube in the audio output - had a 6V6 installed, should be a

6K6. 6V6 is a beam-power pentode while the 6K6 is just a pentode. 6V6s

sound "shrill" when replacing 6F6 or 6K6 tubes.

5. The Tone control had a "dead spot" - nothing serious since the Tone

control does work. Might need De-Oxit treatment. Mostly cleared up with

use.

6. This issue has been this way

since I got the receiver,...only one fuse is

connected to the AC line. Fuses on both Hot and Neutral are original

(though not necessary.) Originally, some USN installations had

"floating" AC power so both fuses were necessary. With the

grounded neutral used for house AC power only the hot "needs" to be

fused. F102 fuse holder is broken at the rear connection (it's missing.)

7. With longer operating time, the receiver seems to require more and

more gain. When first in operation, 40M hams can have RF Gain at 5 or 6.

After 20 minutes or so, the RF Gain has to be at 9. Defective 6J5 tube. |

Further

Inspection of the "Old RAO-3" 1. All tubes tested good except 6J5 LO

tested odd. Decreasing gm as test button held down which usually

indicates a tube at the end of its life or possibly a gassy tube. Might have caused

the decreasing sensitivity (it did.)

2. Measured all resistors in circuit. All are JAN Allen-Bradley

resistors. Most measured within 10%. One measured higher than marked

value which indicates actual value drift. Several measured lower but

this can be parallel resistance within the circuit. JAN Allen-Bradley

carbon resistors are just about the most reliable and stable vintage

types of carbon resistors. Only long term heat caused by leaky bypass

capacitors usually will affect the value. Later testing the suspect

resistor that appeared to be 10K but measured 70K - a schematic check

indicated the resistor IS a 70K and the violet color band had faded to a

brownish color. So, all JAN A-B resistors were okay.

3. Three of the original mica capacitors had been replaced with dipped

silver mica capacitors. I'm sure I didn't do this, so these replacement

parts are from before 1969.

4. Three of the original paper capacitors were replacements. All three

are different brand paper wax caps and the soldering job indicates these

were probably the result of a pre-1969 junk box repair work.

5. AF Gain pot is an A-B replacement pot. It appears to be a linear

taper type since most of the gain adjustment is from 0 to 3 and above about 5 there isn't

any increase in audio

gain. The A-B pot measures 275K at 50% and the manual indicates that 25K at 50% (which is

an audio taper) is the original spec for the pot. Overall output level

during this test was undoubtedly affected by the 600Z loudspeaker. Taper

not affected, still needs audio taper.

6. Paper capacitor count is .01uf-600vdc = 9, .1uf-400vdc = 13,

.05uf-600vdc = 2, .1uf-600vdc = 4, 1.0uf-200vdc = 4, that's a total of 32

capacitors. OEM was John E. Fast & Co. in Chicago. Capacitor shell only

has CBV, which was John E. Fast & Co. Navy contractor identification

along with a part number, value and working voltage. Also, a letter-type

date code.

7. Under the 1st RF Amplifier (the metal box mounted to the back wall of

the cabinet) are three paper-wax capacitors. All are .1uf 400vdc. These

capacitors are next to impossible to see unless maybe a dental mirror is

used. They are also impossible to remove and replace with the RF Amp box

mounted to the back wall of the cabinet. Also, it's next to impossible to dismount and

extract the RF box unless the 3rd IF transformer is also removed from the

chassis. To extract the box also requires unsoldering three wires. The

almost fully hidden capacitors and the difficulty in doing a replacement

has probably resulted in many "recapped" RAO receivers having

"originals" of

these three caps still in place.

Initial Rework Necessary on the "Old

RAO-3"

1. Quite a bit of surface rust in one area inside the "back porch"

chassis. Wire brushed to clean and then applied 10W machine oil to

protect. After a few days the oil dried up, then the area was cleaned

with lacquer thinner and painted to protect the surface. I'm sure the rust has been there all the time I've had the

receiver. The receiver has been in Nevada since 1973 and has always been

indoors since 1969, so the moisture that caused the rust was from before

I owned the receiver. Inside the "back porch" there was some rust in the

joints which was cleaned and repainted with black nitrocellulose

lacquer.

2. The seven pin "battery input" socket had been rewired and doesn't

agree with the schematic. I thought initially that someone had rewired

it for remote standby. Five out of seven wires were moved to different

pins and the A+ wire was connected to chassis externally (hamster job

with the wire wrapped under a screw) instead of through the socket with

ground lug connection to chassis. Unfortunately the wire insulation is

white with barely perceptible colored tracers. Also, at least one wire

isn't original. Found a "cut and splice" taped with masking tape hidden

by the rectifier wiring harness that was part of the one non-original

wire. Since the CT or the B+ switch weren't part of the changes, it's apparent

that the changes weren't for remote standby. All wires had to be traced

using a DMM (in ohms) to confirm

what the wires were and where they should be connected. This required

unsoldering all of the wires from the socket, tracing the wires and then

applying a masking tape numbered identification. After all of the wires

were identified then the socket pins were cleaned and the wires soldered to

the proper pins. The mating plug had to

also be reconfigured to have the proper connections within. The two

jumpers in the plug are for AC input and for tube heaters. While a remote standby

function might be convenient, none of the RAO receivers originally had

it and almost all RAO users know that the front panel standby

has to be used when the receiver is paired with a transmitter. Also, for

the future, it

makes it much easier to work on a receiver if its wiring agrees with the

manual. This socket was originally for emergency battery operation of

the receiver which was a Navy requirement at the time of the contract. I

believe that the mod-changes were to allow remotely applying AC power to

the receiver (maybe an external timer to turn the receiver on or off at

specific times.)

3. Replaced the SO-239 flanged UHF receptacle that had been installed in

place of the original Navy coax receptacle. Luckily, no holes drilled

(flange was on the inside and retaining nut on the exterior.) Rebuilt the antenna input to match

drawings using an original Navy coax receptacle. Almost all RAO

receivers have had their original Navy coax receptacle replaced with a

UHF receptacle. This really wasn't necessary and is just another "hamster"

modification. On some Navy coax receptacle the internal pin is exactly like a

male banana pin and a female banana receptacle will fit inside the Navy

receptacle allowing direct connection for the coax center conductor and the

coax shield can be connected to the screw ground just above the receptacle.

Other Navy coax receptacles are slightly larger and a double female UHF adapter

can be used. The threads have

to be filed down slightly on the side that will fit into the Navy

receptacle. Once the adapter fits, the center conductor of the adapter

is the correct size to fit the Navy receptacle pin. Just push in the

adapter and then screw the coax PL-259 to the other end of the adapter

and the antenna is connected without ruining the original (and hard to

find) Navy coax

receptacle. There are two different types, so you have to check which

one you have. I had to do the banana plug receptacle type of connection,

(receptacle change was with the RAO-7/9 introduction although it's

possible that some RAO-6 receivers also may have the later receptacle

installed.)

Transplanting Parts -

After removing all of the cabinet pieces from the old RAO-3, I noticed that the

front of the BFO can and the front of the Crystal Filter housing were

moderately bent as if the receiver was hit in in front near the Crystal Filter and BFO

area. I do remember that when I found the receiver the Crystal Filter phasing control shaft was

broken off and the original paint had two significant scratches down to the bare metal in that area. It might be an easy

transplant to R&R the BFO can and the Crystal Filter assembly from the

parts set into the old RAO. My old repair of the phasing shaft was

slightly off-center and although it worked it did result in an obvious

"off-center" rotation of the Phasing knob. |

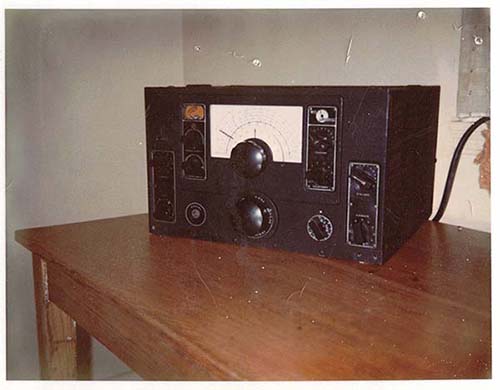

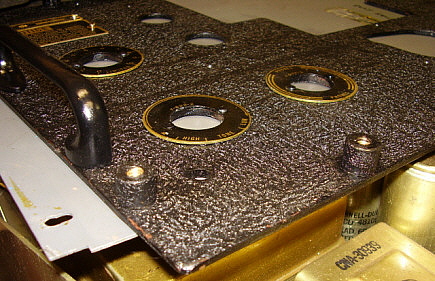

photo above: The "parts set" data plates shown now installed on

my old RAO-3 using the original hardware from the "parts set."

These original data plates are the celluloid plastic type of

data plate rather than the etched metal tags. |

|

Jan 17, 2021 - R&R the

power transformer cover. Removed the original four adapters for the

shock mount thumbscrews. Five bar knobs and the tuning knob are present on the parts set and

they are original WG knobs. Will have to soak the set screws with

penetrating oil as they are really stuck. R&R the 1st RF amplifier tube

cover. Removed the replacement audio output transformer from the old

RAO-3 and removed the original audio output transformer from the parts

set. Installed the original audio output transformer in the old RAO.

Installed a reconditioned Centralab 500K audio taper pot for the AF Gain

control and installed.

Jan 18 - Worked

with stuck set screws on the six original knobs on the parts set.

Penetrating oil and heat worked on all but one set screw that

unfortunately had the hex rounded so it was impossible to remove with

the proper tools. A reverse flute drill bit might be able to break the

set screw loose to save this original bar knob. The 2006 restoration replaced all but two WG bar knobs with

National bar knobs. Fortunately, the tuning knob and the band change

knob are original WG knobs. At any rate, if I can salvage all the WG

knobs on the parts set, I'll only be short one WG bar knob with all

other knobs on the receiver being the correct WG types.

Jan 19 - Removed the

three oil-filled filter capacitors from the parts set. All three tested

at 4.6uf with cap checker. Removed the two

dial lamp harnesses from the parts set.

Jan 20

- The set screw from the last bar knob wasn't going to come out so I

used a Dremel tool with cut-off disk to cut the shaft of the NL control.

With the knob removed now the brass shaft can be drilled out easily and

the knob salvaged. With the last knob removed the entire front part of

the cabinet was dismounted. This allowed easy access to the chassis

components I needed to dismount. Removed Crystal Filter assembly.

Removed BFO coil-capacitor assembly. Removed 2nd and 3rd IF

transformers.

Jan 21- I removed the

side cover on the soon-to-be transplanted Crystal Filter for a close

inspection and to clean the Selectivity switch with De-Oxit. No problems

were seen. Transplanted the Crystal Filter assembly into the old RAO-3.

From the wiring wraps, it looked like the old Crystal Filter had been

removed at some time in the past, hmmm. Also, the front bend was causing

a misalignment of the Selectivity switch shaft. The replacement assembly

sets "square" on the chassis and the two shafts are straight. When I was

removing the old BFO can, I noticed that the BFO tube socket was badly

broken. From the top it looked like just a hairline crack but from

underneath a large section of ceramic was missing and one tube pin

receptacle was hanging loose. I guess it has been that way all the time

I've had the receiver. At any rate, I replaced the broken socket with

the BFO tube socket from the parts set. Then transplanted the BFO can.

The bend in the old BFO can was severe and looked like it stressed the

variable condenser although it did function okay. |

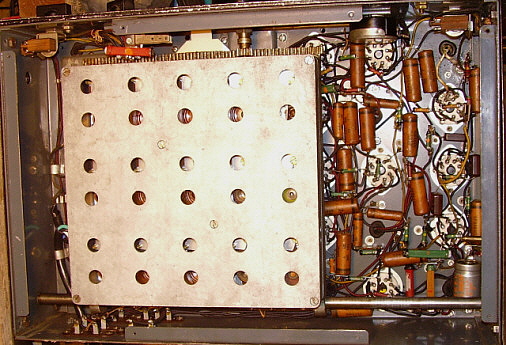

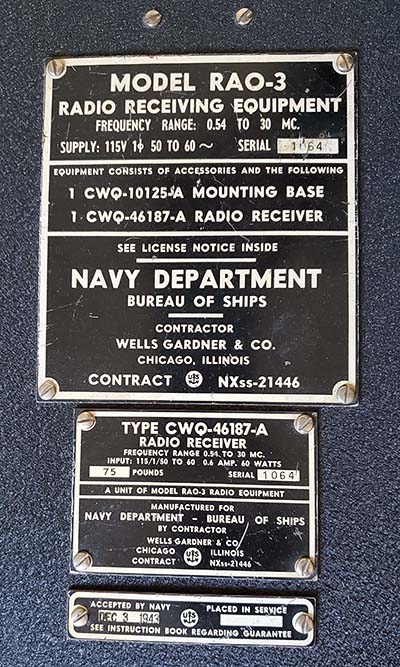

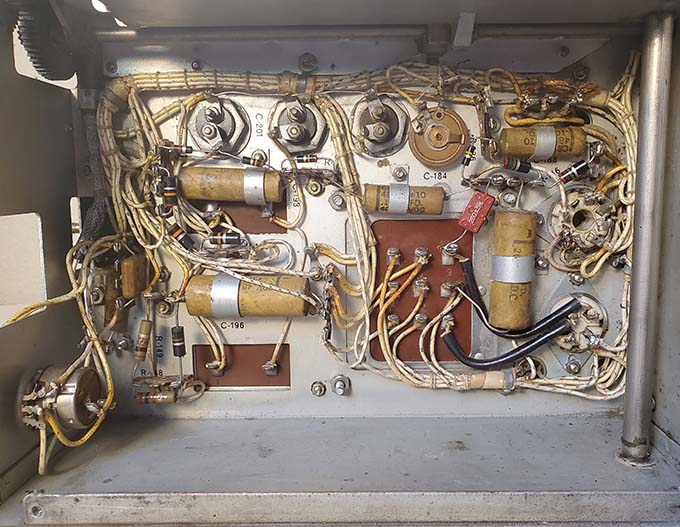

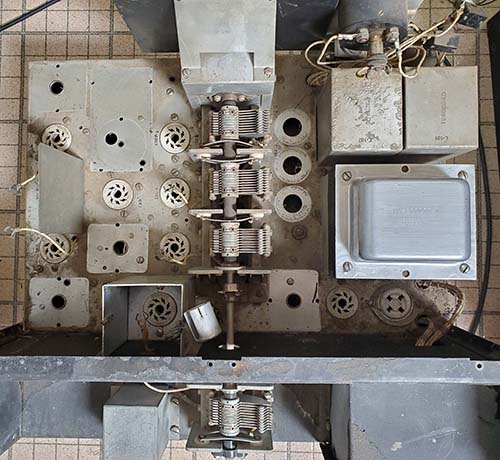

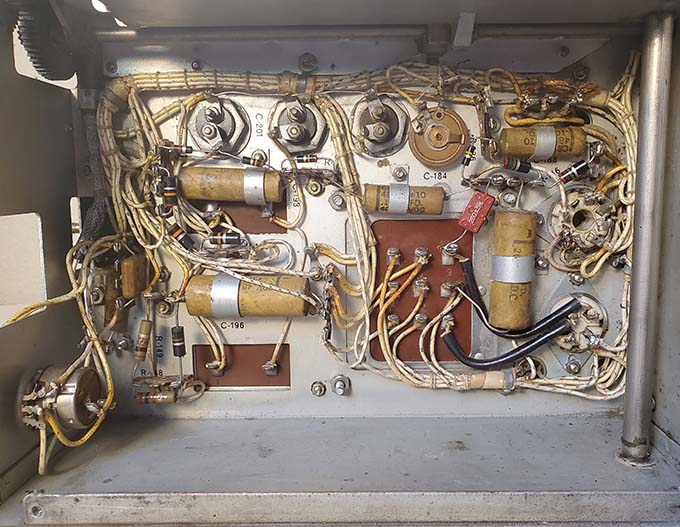

photo above: The RAO

"parts set" with most of the major parts removed for

reinstallation into the "old RAO-3." Parts that still need

extraction are the RF Amp box and the 6C8 shield. The power

transformer cover shown is the non-original from the "old RAO-3." |

|

Jan 22 - Installed 2nd IF

transformer. Removed 3rd IF transformer from old RAO-3.

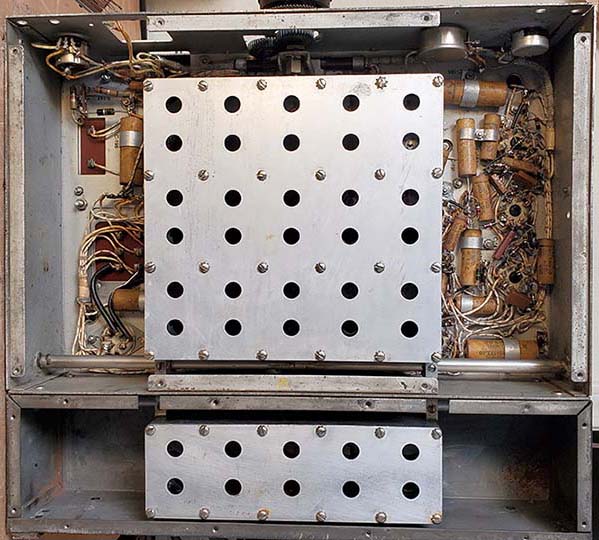

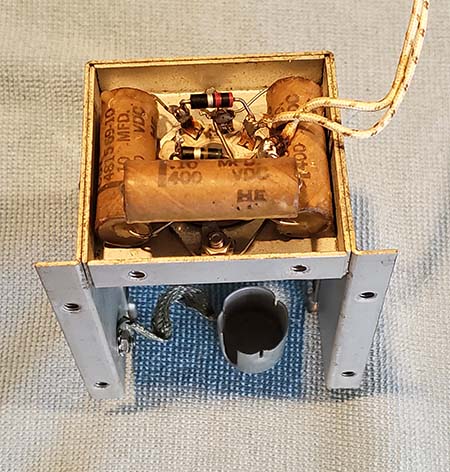

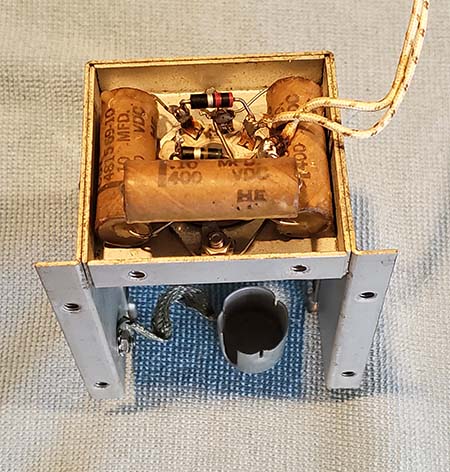

IMPORTANT NOTE: When cleaning

the chassis to install the replacement 3rd IF, I noticed that under the

1st RF Amplifier tube socket there were some paper-wax capacitors

installed. These are impossible to see unless the 3rd IF transformer is

removed (maybe a dental mirror might help

to see them,...if you know they're there.) These three capacitors can't be replaced unless the entire

1st RF Amp assembly is first dismounted and removed from the receiver. There are three wires that need to be

unsoldered to remove

the entire 1st RF Amp assembly (besides the six screws that mount the

assembly to the back vertical cabinet wall.) Additionally, the 3rd IF

transformer has to be dismounted to allow the RF Amp box to be tilted

over so the plate connection can be unsoldered. Even with the 3rd IF

transformer removed the space is very restricted. If one knows about the

RF box caps and is also planning on removing the IF transformers then, with

the 2nd and 3rd IF transformers extracted, the space to remove the RF box

is much larger making the job easier. Once the RF Amp box is dismounted,

then access to the capacitors is not restricted. I had to rebuild the three

paper-wax caps in order to be able to then remount the 1st RF amp

assembly and then the 3rd IF transformer could be reinstalled. Photo to

the right shows the bottom of the RF Amp box with the rebuilt original

paper-wax capacitors (new polyfilms inside) installed.

Brief

Capacitor Rebuilding Description - Restuffing caps consists of first

using a hand-held heat gun to melt the wax in order to remove the old

capacitor from the shell. The shell is wiped (while still hot) with a paper towel to

remove the excess old wax which results in a clean empty original

capacitor shell. Next a polyfilm capacitor is "sized" by wrapping it

with masking tape until it fits into the shell without falling out. Then

the ends are filled with hot-melt glue leaving about .125" to .250" gap

at the ends. The ends are then filled with melted bee's wax. When the

end cap wax has set-up, then the entire exterior of the capacitor shell

is coated with melted bee's wax. When completed, it's very difficult to

tell the rebuilt from an original. Polyfilm cap orientation shouldn't

matter but I always install the caps with the left lead as the "outside

foil" when holding the capacitor in the right hand and the value writing is

viewed as "rightside-up."

Jan 23 - Cleaned the tray

area under tuning condenser with denatured alcohol. This area always

collects all of the debris that makes it into the receiver cabinet over

the years. Lots of greasy dust type dirt that cleaned easily with the

denatured alcohol using small long handle paint brushes and long handle

Q-tips. Detailed cleaning on the tuning condenser was also

done. Cleaned the chassis ground connections and then installed the

three oil-filled paper-dielectric filter capacitors. The three

oil-filled caps were apparently removed sometime in the past (before

1969) and not reinstalled correctly. The insulating washer was next to

the capacitor body and the grounding washer was next to the chassis. The

grounding washer should be next to the cap body to connect it to chassis

ground (not an electrical connection but for shielding) then the fiber

washer is next to the chassis. Not a serious mistake but still not

correct. I'm beginning to discover that my old RAO-3 had been worked on

extensively and not by any Navy depot. While the rework is generally

okay, it wasn't at a professional level that would indicate depot rework. |

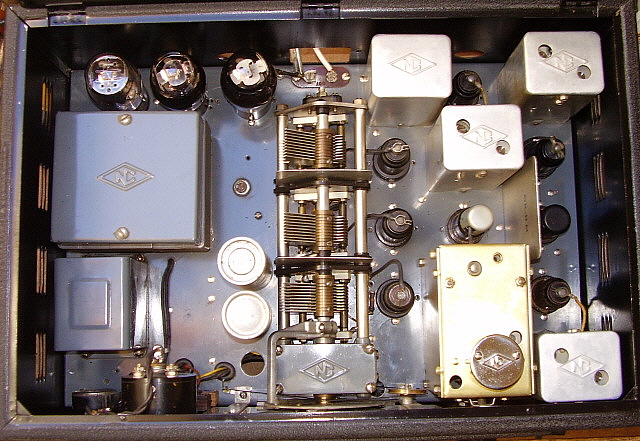

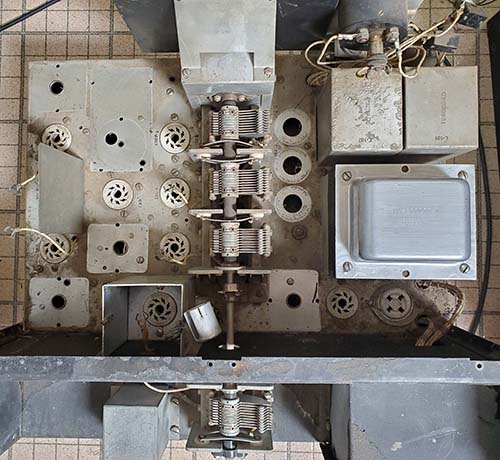

photo above: The 1st

RF Amp box showing the three rebuilt capacitors installed on the

underside of the assembly. |

Jan 24 - Started

rebuilding the paper-wax capacitors. I'm removing a small quantity of

original capacitors from

the "parts set" and then rebuilding those. Once that

quantity is finished I then remove the same value caps from the old RAO and

then install the rebuilt ones. I rebuilt the six paper-wax caps on the power

supply side of the chassis. These along with the three under the RF box

total nine caps rebuilt and installed so far. Both the "parts set" RAO

and the old RAO have a few non-original capacitors so a few of the same

value caps from the old RAO will need to be rebuilt and then reinstalled

into the positions that had non-original maker caps. The end-result will

be that all paper-wax capacitors will appear to be original CBV types

but will have modern polyfilm capacitors inside.

|

Jan 25 - Rebuilt the two

1uf 200vdc caps, the two .05uf 400vdc caps and the three 0.1uf 600vdc

caps. Then installed them into the old RAO-3. 16 caps rebuilt so far.

Jan 26 - Rebuilt eight

.01uf 600vdc caps.

Jan 27

- Installed all of the .01uf 600vdc rebuilt caps. 24 caps

rebuilt and installed. I removed the remaining .1uf 400vdc caps

from the "parts set" with the exception of C189

that has a unique clamp mount. For C189 I used the

original from the old RAO-3. These eight caps were rebuilt and

then installed bringing the complete total of rebuilt paper-wax

caps to 32.

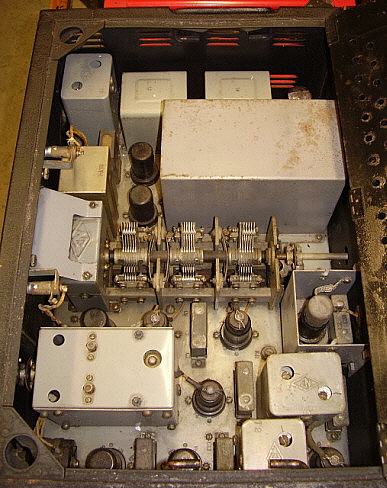

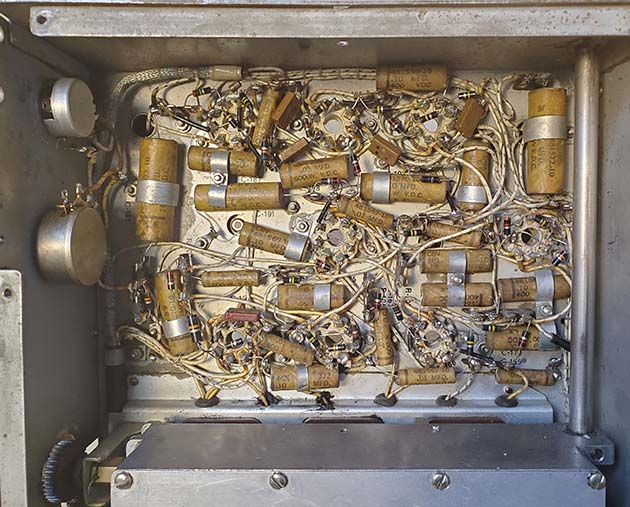

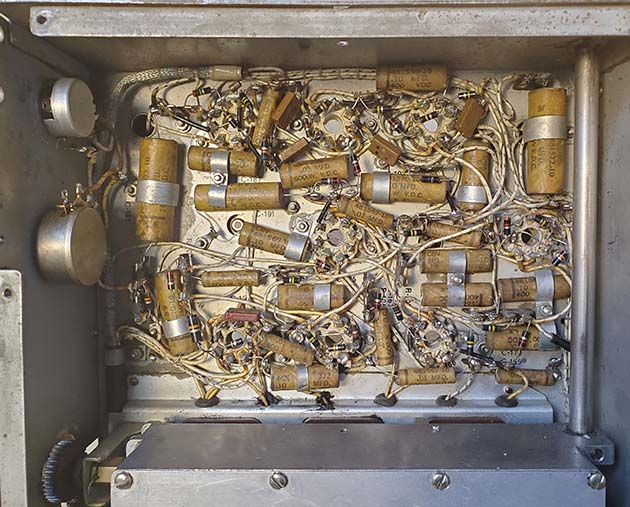

photo left: Under the IF/AF side of the chassis

showing how the rebuilt paper-wax capacitors are difficult to

tell from the original CBV paper-wax capacitors. Note that only

the .01uf paper-wax capacitors and one .05uf capacitor and one

.1uf capacitor don't have clamps to secure them

to the chassis.

photo right: Under the power supply side of the

chassis showing the rebuilt CBV paper-wax capacitors located there.

|

|

Jan 28 - Replaced the

three newer style dipped mica capacitors with original

style, tested vintage mica caps (this was for under-chassis

appearance only.) Some of the original mica capacitors used in both WG RAO-3

receivers seemed to have defective leads. The lead wire seems to be very

brittle and easily breaks when trying to extract the capacitor. One

of the original receiver problems back in 1969 was due to a broken lead

on a mica capacitor. It's probably why the three dipped mica caps were

installed. My thought is that if an original mica cap can be extracted

from the "parts set" without damage then the leads are probably not

defective. About 50% of the mica caps in the WG RAO-3 receivers seem to

be affected. Part of the "test" besides measuring the value was to

determine that the lead wasn't brittle.

Replaced the grid leads to the 6C8G and the 6F8G tubes. The "parts set"

wires were in better condition than those in the old RAO. I was going to

replace the S-meter lamp wiring because the two wires were "friction

taped." But, the wires are within a laced harness and removal of the

wires would probably break the laces. Instead, I replaced the friction

tape with original black spaghetti tubing which looks more convincing as

original. The wire from the S-meter switch to the meter also had

friction tape on it so I used the good condition wire from the "parts

set" as a replacement. Grid connection wire to the 2nd RF amp had friction tape so repaired with black

spaghetti tubing. Installed the NOS S-meter and installed original lugs

for the meter connections, also used original meter stud nuts and washers. Installed

the original type of S-meter lamp socket. I had a screw base #40 lamp

installed,

should have been bayonet base #47. The rubber grommets on the lamp

socket are to prevent pushing the lamp into the S-meter too far which

can overheat the meter scale and discolor it.

I added two fiber washers between the back of the logging dial hub and the

front of the gearbox hub to take up some clearance that had been

allowing the

tuning shaft to have about .090" thrust end play. Mechanically set the

logging dial to be accurate.

Functional Test -

Installed the tubes and cleaned the pins with brushed on DeOxit and then

plugged in and out a few times. Connected 600Z ohm loudspeaker, the AC

power cord and a test antenna. Power applied with variac with no

problems. Full scale S-meter indication in AVC and no signal (AVC at max

negative bias, apparently.) Loud signals in MVC, tested three bands with loud

ambient noise levels, tested Crystal Filter OK, tested BFO OK, tested

Tone OK, tested NL OK, RF and AF gain OK. Receiver is almost fully

functional with just an AVC problem. When the AVC problem is repaired,

then the receiver will be reassembled.

Jan 29 - Even

though the coupling capacitor from the detector/3rd IF transformer to

the grid input of the AVC amplifier tube (a 50pf mica) seemed to measure

okay on the cap meter, it apparently was open. Installed another vintage

50pf mica and that got the AVC functioning. Synchronized the band

indicator to the catacomb position - it has to mesh with the pinion gear

on the correct "tooth" of the drive gear in order for the correct band

indicator to be in the 12 o'clock position when that band is engaged at

the catacomb pin receiving contact blocks. Installed the combination front panel-side panels part of

the cabinet. Installed the lid, the band change bezel, the dial

escutcheon and the "back porch" cover. All original screws and lock

washers used in all of the mountings. Most of the black wrinkle finish

truss-head screws needed cleaning and touched-up. Installed the four

threaded adapters that are for mounting the receiver to the shock mount. Lightly lubed (with

grease) the two round rods that the two catacombs ride on.

Jan 31 - Operated the

RAO-3 yesterday and this morning to allow any unusual issues to turn up

but the receiver performed quite well. I was thinking about not doing an

alignment because the sensitivity was okay and the tracking was very

good. Luckily, I did do a full IF/RF alignment in the afternoon. The IF

was slightly improved with the alignment. Tracking also was very

close but Band C did need the lower end slightly touched-up to be

accurate on the 40M band. Audio is very good although it is

"communications grade" but the bass response isn't lacking, it just

isn't emphasized. The problem of the slight frequency change in the BFO

as the RF Gain is adjusted in MVC is now only encountered on Band A and

even there it's just barely noticeable compared to what it was prior to the

rebuild.

| RAO-3 Performance

- There's no doubt that after 50+ years of ownership,...it was

about time that I rebuilt this receiver correctly. As I mentioned

somewhere earlier, this RAO-3 was only a 26 year old piece of

equipment when I found it in 1969. I had always run it on its

mostly original parts that were now over 75 years old. So,...was

improvement noticeable after all of the rework was finished?

Absolutely! Here's what I've observed as definitely better

performance: 1. Audio response

- certainly replacing the "universal" audio output transformer

with a good original RAO-3 audio output transformer was the

major reason for the improved audio. A second improvement must

have also been the replacement of the incorrect "linear taper"

AF Gain pot with an "audio taper" pot that now results in a

fully adjustable audio gain. Of course, slightly leaky

capacitors can also skew bias voltages and affect low frequency

coupling, so the capacitor rebuild also added to the much

improved audio. Additionally, I had been running a beam power

pentode 6V6 as the audio output tube and the correct tube is a

pentode 6K6. NOTE: I

didn't change any values of C, the values I used are original to

the receiver design.

2. Selectivity - this

improvement is due to the replacement of the damaged

Crystal Filter assembly. The old unit had a severe "crunch" in

the front that was putting stress on the Selectivity switch and

the Phasing condenser with the misaligned wooden shaft prevented

smooth adjustment.

Accurate alignment of the replacement Crystal Filter also must

have helped. The Crystal Filter is now fully operational and a

valuable tool to combat QRM.

3. Sensitivity - when

listening to 40M SSB nets the RF Gain is now at 4 or 5 with the

AF Gain at 8. 20M SSB stations are normally between 5 and 7 for

the RF Gain. Trenton Military on 15.065mc is easy copy. TAH

(Marker Beacon, Istanbul, Turkey) copied on 8.35mc. All of the

marker beacons from Seoul, Korea were easy copy at 12.9 mc. Nice

improvement.

4. Dial Accuracy -

this was always pretty good but is even better now with the

recent RF tracking touch-ups.

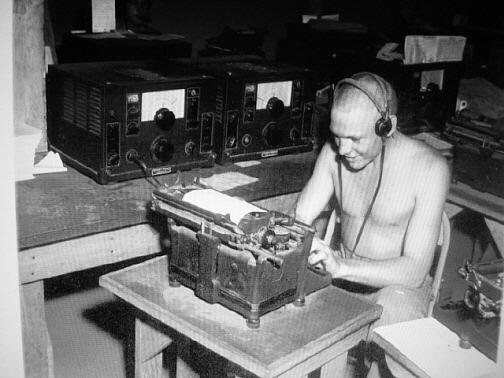

The best compliment for a receiver rebuild is to actually be

able to enjoy using that receiver in a vintage military station

while it successfully and repeatedly provides reliable

communications with fine articulate audio,...just as

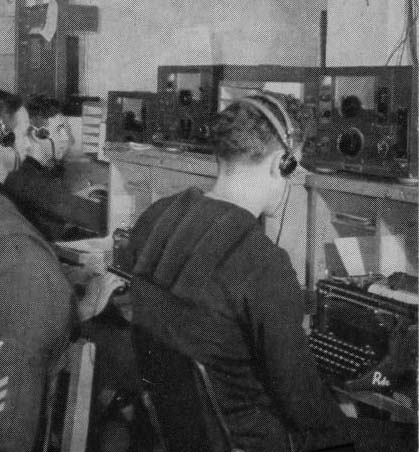

seen in the photo to the right. This setup has been in use weekly use since

early February 2021. |

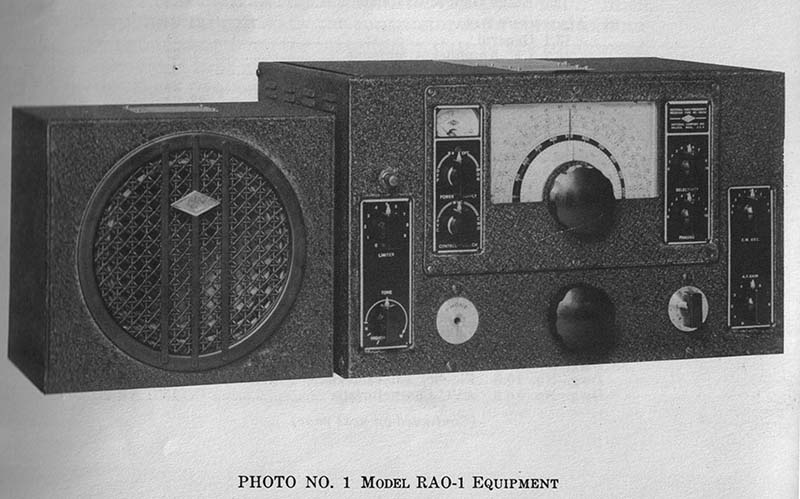

photo above: Left to

right - WWII Underwood SII "Mill" typewriter, Navy-Collins T-47/ART-13

transmitter on top of the vacuum tube power supply (homebrew,)

Navy RAO-3 receiver with a National MSC-10 speaker cabinet with 10"

PM speaker with a 600Z matching

transformer, Shure 102C carbon mike, a Hi-Mound HK-710 handkey and,

on top of the ART-13,...a Vibroplex Original "bug."

|

| UPDATES:

Dec. 16, 2021

- I'd been operating

the RAO-3 directly on the 124 volt AC line which will slightly increase the

tube filament voltage and also increase the B+ somewhat. The RAO

was designed for 115vac input and the easiest way to adjust the

AC line is to use a "bucking transformer." I looked through the

filament transformer box and found a 6.3vac 6A transformer made

by Triad. I wired it up to "buck" the voltage and the resulting

AC input to the RAO was now 116vac. I just use power cable for

wiring with an AC plug and an AC cable receptacle. All

connections to the transformer leads are soldered and insulated

then tie-wrapped to the mounting flanges for security. The

bucking transformer just sets behind the RAO and is connected to

the power strip that powers up the station. With that way of

connecting the bucking transformer, it's only powered up when the strip

is turned on and that only happens when the station is in use.

No real obvious difference in RAO operation but the filament

voltage is now 6.3vac and the B+ is around +200vdc.

Oct. 11, 2022

- I've been listening to the RAO-3 lately and I'm beginning to

wonder about the AVC. When switched in, the AVC throttles-back the RF/IF

gain to the point where it seems that the AVC bias is dependent

on the received noise rather than the signal. There doesn't seem

to be very much change in the AVC bias in relation to the signal

level. Although the S-meter appears to be working, on higher

frequencies tuning off signal and back on signal doesn't really

change the S-meter indication (responding to received noise) that might be reading S-6 or so.

Performance in CW is great with good sensitivity easily up to

20mc. In reading the original Instruction Book for the RAO-3, nowhere in the manual is the reception of "voice" or "music"

mentioned. Only CW or MCW modes are shown. AVC is an option for

measuring signal strength in CW with the BFO off or for Sensitivity control in

MCW. This implies that the RAO-3 receiver was normally

operated in the MVC position and AVC was only used briefly for

checking signal strength. This would seem to be how the RAO-3

works best with the greatest sensitivity, that is, regardless of

the mode, always in MVC, riding the RF Gain control. |

|