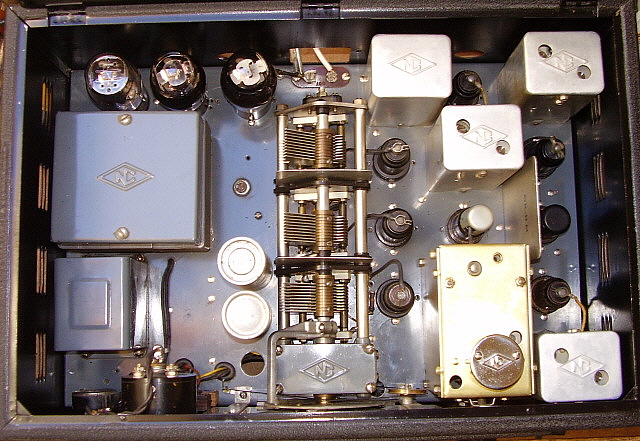

My initial goal was to just re-do the electrolytic capacitors to appear original, re-install original Sprague paper-wax capacitors where needed and to do a cleaning. I thought I'd just have the Silver Anniversary as a "shelf-queen" because,...who needed another restored "moving coil" receiver anyway?...,...right?

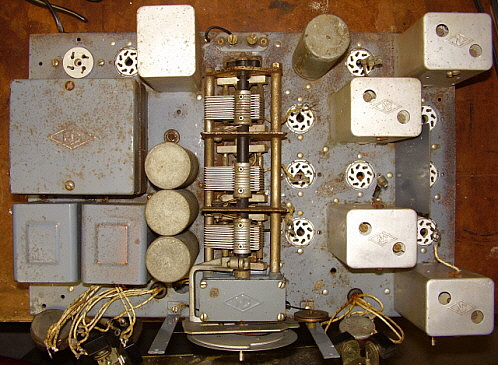

Rebuilding the Electrolytic Cans - This required removal of the plastic pill bottles and new electrolytic caps and accurately trimming the cut that had removed the tops. I then looked in the junk box for some defective can electrolytics (easy to find) and accurately cut the tops off of two of the cans. Since both the original cans and the new tops were the same outside diameter, as long as the cuts were accurately accomplished the seam joining the two pieces together should be minimal. I installed a dual 10uf 450wvdc in the can that originally was a dual 8uf and I installed a 40uf 300wvdc in the can that originally was a 40uf at 200wvdc. The new tops were then mounted using epoxy with a cardboard tube inside (to hold the epoxy.) The finished caps looked nearly perfect and, other than the new caps inside and the new tops, they were essentially the original cans for the receiver.

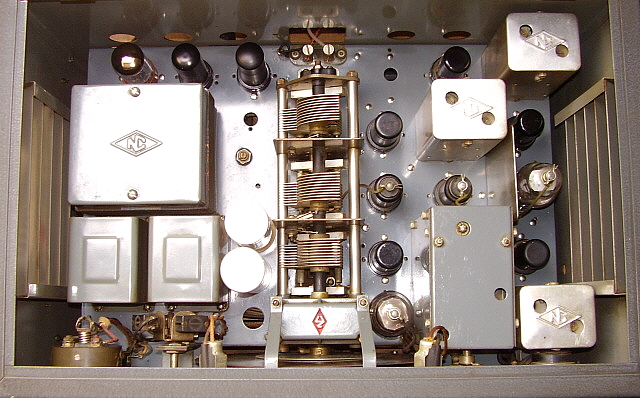

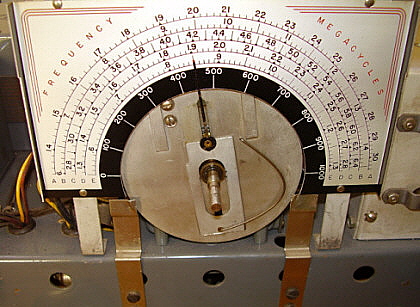

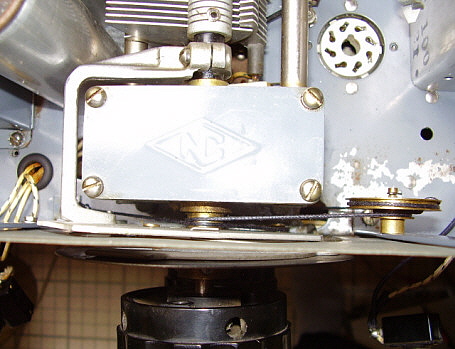

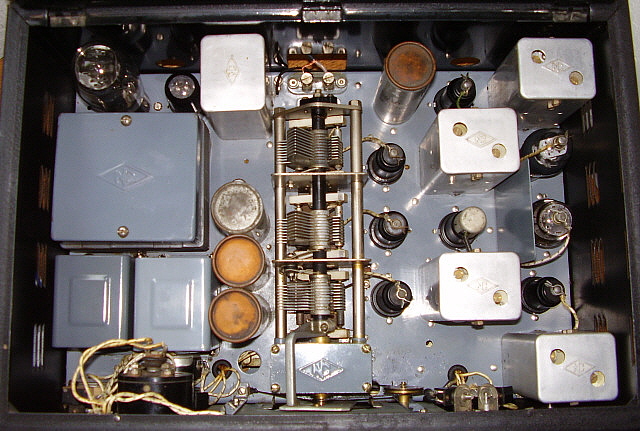

photo above: The Silver

Anniversary NC-200 as received. Dirty, no NC diamond and an ultra-dark

S-meter scale.