|

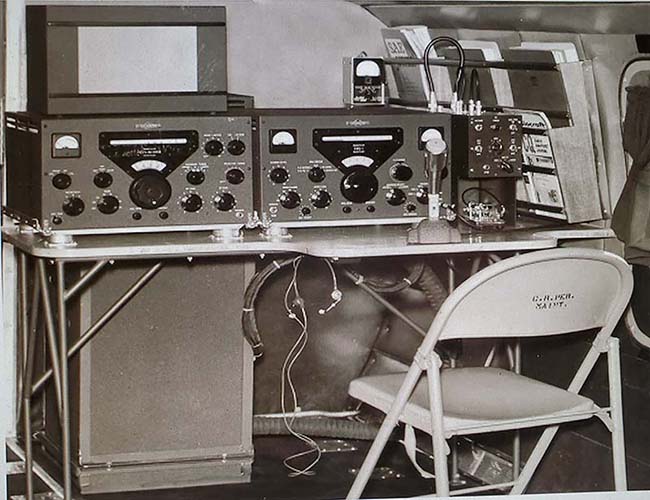

Dummy Load versus Antenna Load Test

15M Test - Full

power into 50 ohm dummy load,...CW no problems, AM no problems

(25% of full power) and SSB no problems, connected to the antenna,

all modes,

full power - no

problems

20M Test - Full

power into 50 ohm dummy load,...CW no problems, AM no problems

(25% of full power) and SSB no problems, connected to the antenna,

all modes,

full power - no

problems

40M Test - Full

power into 50 ohm dummy load,...CW no problems, AM no problems

(25% of full power) and SSB no problems, connected to the antenna,

all modes,

full power - no

problems

80M Test - Full

power into 50 ohm dummy load,...CW no problems, AM no problems

(25% of full power) and SSB no problems. BUT connected to the antenna,...CW

seemed okay, AM and SSB produces

oscillation in the mixer stage and 6CL6 drivers. Since the 250kc

oscillator is reinserted behind the MF, it would be difficult to

distinguish the problem oscillation from normal CW operation. In

AM, this reinserted carrier is adjusted for 150 watts output and

with the oscillation, the CARRIER can't be adjusted to "zero" or

100mA idle PA I to start. Of course, I should go to CW and

adjust the CARRIER LEVEL to zero and see what happens.

Unfortunately, I only have the Collinear Array antenna available

for the upstairs shack. A second antenna that used a coaxial

cable type of feed-line, if it was available, would provide an

interesting comparison.

The KWS-1 has a dedicated, switched into the circuit, 80M

neutralizing set up. The first thing to try is adjusting the 80M

neutralization (this is where I went "off the track" for

a while and seemed to forget that the KWS-1 worked fine into a dummy load

on all bands.)

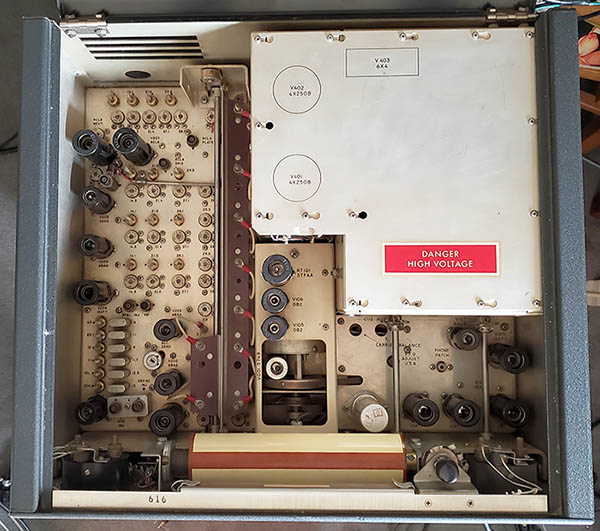

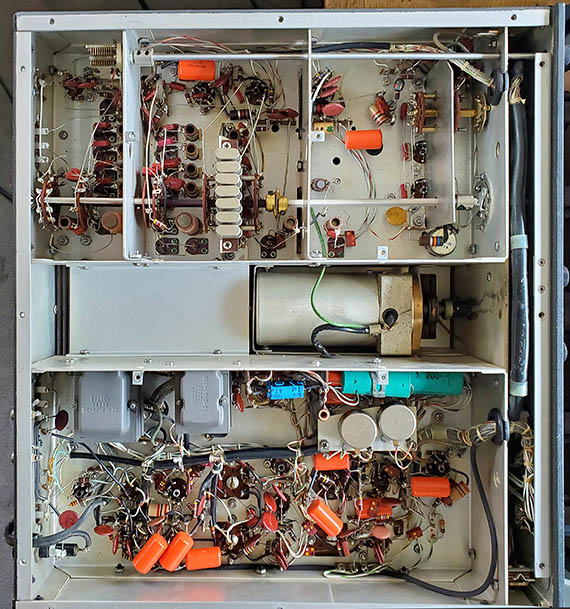

80M Neutralization

-

There are two adjustments involved in the 80M neutralizing. One

is the 6CL6 80M plate tuning and the other is the 80M

neutralizing trimmer. The equipment was set up for neutralizing

and the adjustments were made. It was discovered that while the

6CL6 80M plate tuning would resonate and could be easily

adjusted, the 80M neutralizing trimmer had no effect on

anything. At this point, it looks like the problem is in the

neutralizing trimmer and how it connects into the circuit

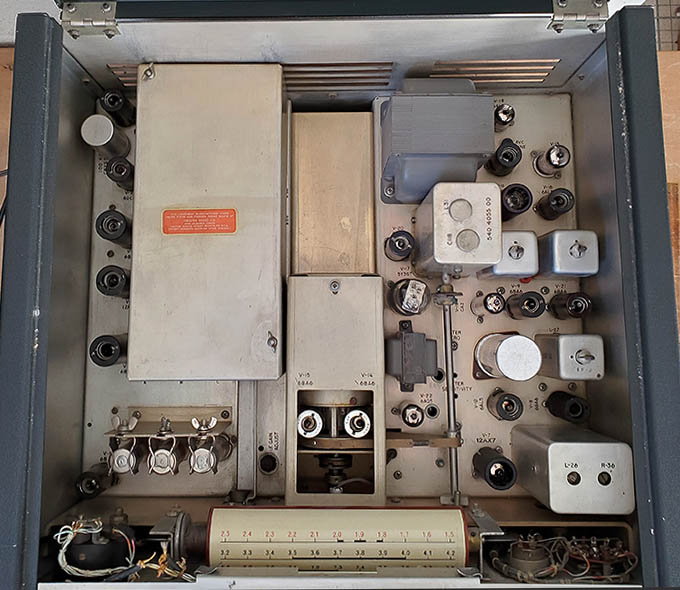

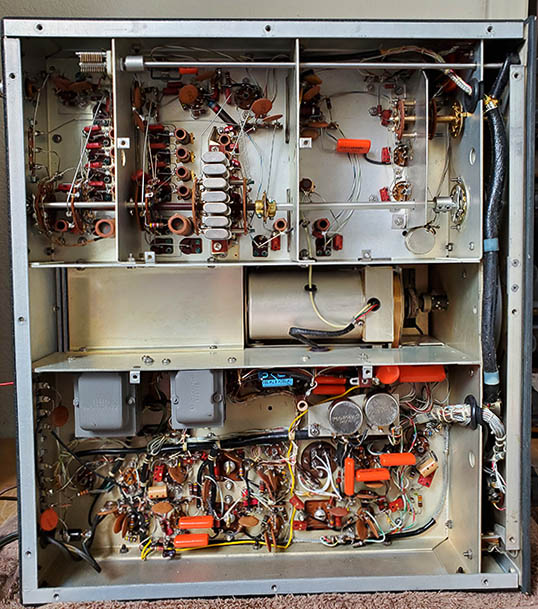

through the band switch. I removed the bottom of the KWS-1 to

inspect this area of the transmitter. Nothing was found. I used

a DMM to check that the switch made the proper connections when

80M was selected. Unfortunately, the switch segment that is used

for 80M is right up against one of the compartment walls and

it's next to impossible to really see the contacts, even with a

small dental mirror. I cleaned the band switch with DeOxit and a

small paint brush just

as a precaution.

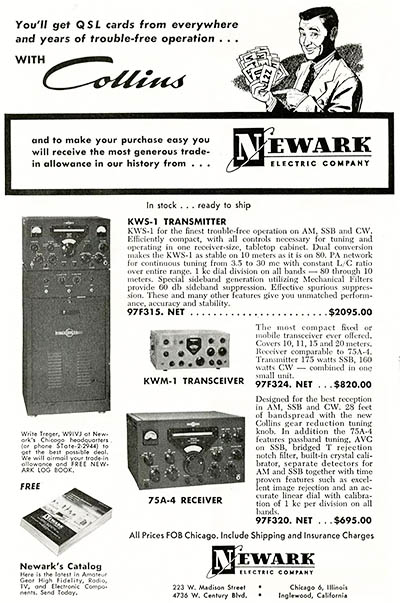

TEST 80M Neutralization

- The KWS-1 manual's 80M neutralizing procedure has you connect a

receiver with S-meter to the 6CL6 output and then monitor the

S-meter reading for an indication of neutralization. I was using

the 75A-4 and to have the S-meter function, the RF gain has to

be advanced and the AVC has to turned on. To have this actually

be sensitive enough to show ANYTHING requires someway to vary

the coupling between the KWS-1/6CL6 output and the 75A-4 input.

It all seems rather crude and it's described that way because in

1955, most hams didn't have access to high-quality

oscilloscopes. Next time, rather than use the crude hook-up described in the

manual, I'm going use an oscilloscope to actually "see" what is

happening as the 80M Neutralizing trimmer is adjusted.

Hopefully, some sort of change might be seen when adjusting the

80M neutralization.

It's NOT the 80M Neutralization

- RFI? Grounds? Counterpoise? -

Using the oscilloscope made finding the neutralization

adjustment on 80M pretty easy. However, it doesn't change the

fact that the KWS-1 on 80M going into a dummy load operates just

fine. No problems at all! I even listened to the signal (leakage

from the dummy load) on the GPR-90 receiver on both 40M and on

80M. The received AM signal sounded great (so did the SSB signal.) However, when operating into the antenna, the

Mixer/Driver stages oscillate only on 80M. A couple of things could be

happening. Radiated RF getting into the transmitter might be a

possibility but everything is fully shielded so RFI seems unlikely.

Also, if it was a RFI/shielding problem, why would it only

affect 80M?

However, good operation on all bands into a dummy load (very

little RF radiation) seems to

indicate that RF from the antenna or feed-line is somehow

getting into the Mixer/Driver somewhere. I never had this

problem in Virginia City but I was on the ground floor and had a

very good earth ground there. Also, in Minden, I had a very good

earth ground on a ground floor. At both of those locations I ran the

same type of antenna, a tuned dipole of 135' CF with open

feed-line to a tuner (I used a Nye-Viking MBV-A then.) Maybe the

lack of a "solid earth ground" for the KWS-1 in combination with

the Johnson Matchbox not being earth grounded either might be a

problem. This is the first time (in 55 years) that I've tried to

operate the KWS-1 from a second floor shack. Maybe it's from

only relying on the "house ground." I've always heard that

operating from a second floor shack makes it difficult to

achieve a good "earth ground" due to the distance involved

"getting to earth" and the same distance is involved with using

the house ground too. I even installed a 1" wide, heavy copper

braid all around the perimeter of the room that was connected to

the house ground to act as a sort of counterpoise (it didn't

help the KWS-1 problem.) The odd thing is the other stations aren't

affected and neither is the KWS-1 on any band other than 80M.

Two Experiments - #2 Might Solve the Problem

Experiment #1 - I suspected that in the CW mode on

80M, the oscillation was actually happening. I went to the CW mode at

full power and then backed the CARRIER LEVEL down to zero. The

oscillation was there and it showed about 300mA PA I, even

though there was no carrier injection. This experiment showed

that the 80M oscillation was happening in all modes.

Experiment #2 -

Next, I had suspected that the problem had to have something to

do with the antenna since the KWS-1 worked perfectly into the

dummy load. The next experiment was to readjust the Johnson Matchbox to something other

than a perfect 1:1 match. I adjusted for a 1.5:1 SWR mismatch.

The oscillation disappeared. I showed only 100mA of idle current

with the CARRIER LEVEL at zero. I readjusted the LOAD and TUNE

for the KWS-1 to match to the 1.5:1 SWR. Still no oscillation. I increased

the CARRIER LEVEL up for 500mA of PA I, no problems. I switched

to AM mode, backed the CARRIER LEVEL to zero, no oscillation.

Increased the CL to 250mA of PA I, no problems.

NOW, how to explain

those results,...although it would be just a guess. At the 1:1 match

there must be some line currents or some type of 80M reactance

or maybe EM radiation from the antenna that allows the coax to resonate with something in the KWS-1 exciter

stages. Changing the antenna match or the matched impedance by

retuning for a 1.5:1 SWR must change something about the coaxial

cable impedance versus the Matchbox and KWS-1 or antenna resonance. Since the dummy load has no

reactance and virtually no EM radiation, because it's just a big resistor, the KWS-1 works

perfectly in that hook-up. I'm not sure if changing the length

of the coax between the Matchbox and the KWS-1 would affect this

80M resonance or the impedance,...BUT IT SHOULD!

I went out to the shop and grabbed a couple

of "made up" lengths of RG-8U coax with PL-259s on each end. One

length was about 25 feet and the other about 10 feet. I

connected the 25 foot length between the Matchbox and the KWS-1.

I loaded up on CW to full power,...no problems. I reduced the

CARRIER LEVEL to zero and the PA I went to 100mA idling current,

so no oscillation. I went to the AM mode and actuated PTT, no

oscillation. I increased the PA I to 250mA and it was stable

with no oscillations. I went over to the Matchbox and adjusted

it for 1:1 SWR, still no oscillation and the KWS-1 seemed to be

running about the same as it did when going into the dummy load.

So, apparently the length of coax that I had been using (since

2021) was in some way resonant on 80M with the KWS-1 output and

the Matchbox input (and it wasn't just the Matchbox since I had

the same problem with the Nye-Viking MBV-A tuner.) Changing the SWR,

changed the impedance

and that made the coax not resonant on 80M. By using a much longer

piece of coax, that increases the cable capacitance and the result is the same as changing the SWR in

that the impedance is different (and the Matchbox is adjusted

to very slightly different settings for the 1:1 SWR) and the reactance changed so as

not to resonate with the KWS-1 output on 80M.

So, why didn't I solve this problem earlier? Maybe I'm

just obtuse but, since the KWS-1 and 75A-4 aren't the only station

equipment around here, there really wasn't any pressing need to

find a solution to this problem since the other stations could

be used. Quite a while later, with an increased interest in my

long-ignored 75A-4 SN:850 along with the possibility of writing

up and expanding its refurbishing process into a

"restoration" article, had me thinking about

setting up and operating the complete Collins station like I had

it over 50 years ago. But,

the KWS-1 still had the oscillation problem on 80M from the 2021 RTTY set-up. I finally had to put together the clues that the

KWS-1 worked fine into a dummy load so it had to be something

with the antenna set up. Changing the 1:1 SWR to 1.5:1 SWR was the

"break-through" since that eliminated the oscillation. It had to

be the coax - that was all that was left.

Other Things - I did find that the housing and mount for the +2000vdc input

to the back of the KWS-1 was extremely loose. I found that the

two screws and nuts that mount the internal part of the assembly

to the chassis had backed-off and were almost ready to fall off

the threads. Retightening these mounting screws and nuts got the

+2000vdc housing secure and now the +2000vdc plug firmly

connects to its receptacle. This has apparently been loosening

up for quite a while since I've been noticing that the +2000vdc

plug was always loose and so was the housing, I just never

checked why.

|