|

Carbon -

THE BEST! -

I really, really hate to admit that these are "hands down" the BEST

carbon microphones I've ever found. They are becoming increasingly difficult

and expensive to find nowadays but their performance as a

military-radio carbon microphone is unparalleled.

Chinese PLA Microphones (Vietnam War

Era)

- These microphones are the BEST performing of

the carbon mikes providing plenty of response, great sound with

impressive clarity and lots

of modulation when used with WWII-vintage transmitters. However, finding any of these Vietnam

War-era, surplus-People's Liberation Army (PLA) Chi-Comm

mikes these days (that are reasonably priced) will be difficult. These microphones, when stock

original, are in a

metal "Shure look-alike" handheld case that's usually painted

smooth semi-gloss olive drab. I've found one original Chi-Comm "Shure Knock-off" that was painted olive drab wrinkle finish

and another one that was original black wrinkle finish but nearly

all of those that are found will be a smooth OD finish paint (see photo

right for both types of

OD paint finishes.) Rather than the Shure-type slightly-rounded back with a mike-mount stud, the Chi-Comm

mikes have a flat back (this allowed the mike to lay flat on the

desk with the PTT "locked" for "hands-free" operation.) The PTT

switch actually is a rocker-switch that when in the down

position acts like a spring-loaded PTT but if the switch is pushed

to the up position, that's a "PTT locked" and allows releasing

button while maintaining the PTT action (just "rock" the switch to

the center position to unlock and go back to standby.) The

carbon element is hard-wired, so it isn't a "contact" type of

connection. The mike cable isn't a curly-coiled-type and the

"knock-off" PL-68 plug is just very slightly undersized so it will

easily fit into a

standard USA "68-type" three circuit mike jack,...but it isn't a perfect fit. Most

of these PL-68 "knock-offs" fit fine and work great in the

standard "68-type" three-circuit jack but sometimes they can be

difficult to remove from the USA-type jack (probably due to a

minor misalignment due the slight size difference.) If this is a

problem, then the "knock-off" plug can be changed to a standard USA

PL-68. >>> |

People's Liberation

Army (Chi-Comm) "Shure Knock-off" Mikes |

| >>> I own five of these Chi-Comm mikes. Two are Chi-Comm

carbon elements that

I installed into genuine vintage USA Shure 102C metal bodies and another two are all-original

functioning Chi-Comm mikes (shown in the photo above.) The

fifth is an EMS-94 Electret-Condenser microphone element

installed into an original black wrinkle finish Chi-Comm mike body (and it's profiled

further down this write-up in the "Electret" section.) All four of the true carbon

mikes have great response and,

although I hate to admit it, they sound

better than any other carbon mike I've ever tested. I've been using this type of PLA carbon mike over the past 15+ years.

Pseudo-Shure 102C - Shure 102C body with Chi-Comm Carbon Mike Element Installed

- The primary carbon microphone that I use is a vintage Shure

102C metal-body with a carbon element salvaged from a Vietnam

War-era surplus, People's Liberation Army "Chi-Comm" Shure

look-alike microphone. This mike has tremendous response, good fidelity (for

a carbon mike) and provides lots of modulation capability. Since

the Chi-Comm element is "hard-wired" inside the mike body,

it's very easy to remove. >>> |

| >>> The fit into the Shure body is

perfect and the element can be mounted using the 102C

hardware. Since the Shure 102C was a handheld mobile-type

microphone, nearly all examples will have a "curly cord"

installed. Almost none will be fitted with a PL-68 plug so

that has to be changed. The Shure PTT button only functions

as a push-button. I did this retrofit about fifteen years

ago and I've had very good results using this mike with

several different ART-13 transmitters, with the

BC-375 transmitter,

with a GF-11 transmitter and with the

ATD transmitter. I use my other "102C conversion" with the

GRC-19 (T-195

xmtr + R392 rcvr. NOTE: The T-195 uses a very different Type

U-77

twist-lock, ten contact plug so having a second "102C

conversion" with the U-77 connector on the mike cable was necessary.)

Anywhere that a carbon microphone is the proper equipment,

these "102C conversions" work fabulously.

And, unless you tell someone, they look just like the

standard USA Shure 102C microphone. NOTE: I bought these PLA mikes on eBay

15+ years ago. They were cheap,...then,...about $15 each. I

haven't seen any listed on eBay in many years. A

recent 2025 search on the Internet turned up one source for these exact

type of microphones. "Enemy Militaria" has

some of these PLA microphones for sale. However, the price is

staggering,...$208 each! Ouch! |

Vintage Shure 102C

body with Chi-Comm

Carbon Element Installed |

|

Carbon -

A

LOSER - T-38C/RS-38-B WWII Original USN

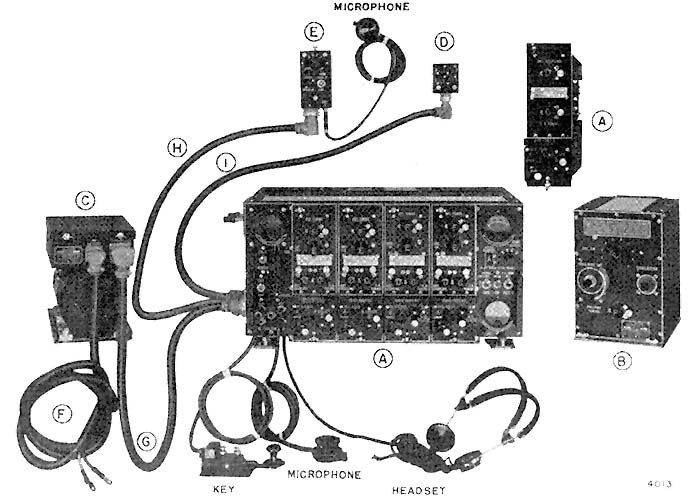

Microphone for the ATD - The T-38C (aka RS-38-B) was a small

handheld mike that fit into the palm of the hand and had a PTT

button on top of the mike body (like a stop watch.) Most

were "noise-cancelling" mikes with three very small voice holes in

the cup although there are some types that were for ground use that

have a multitude of voice holes. I've tried a few of these types of carbon mikes, including NOS examples. I've always found that, if they work at all, the

response is usually very low due to carbon packing or, in the case

of used mikes, maybe fused carbon granules from excessive bias

voltage. To use one of the T-38C versions would involve testing

quite a few to find one that was responsive and then it would

certainly require extreme "close-talking" and an elevated voice

level,...yelling, in other words,...to actually modulate a

transmitter at a level that produced a decent AM Voice signal. I've

never heard an original T-38/RS-38 type of microphone actually being used "on the

air" on any of the mil-rad nets. I tried two different types of T-38/RS-38

mikes with a USN GF-11 transmitter and the response from either one

was way too low for anything other than testing.

The RS-38-B that I disassembled was a Telephonics version and it

was designed to replace the entire mouthpiece assembly for repair. The

two-piece element

can be taken apart and the diaphragm stays attached to the front

mouthpiece. The diaphragm's backside is gold plated,...most

carbon mike diaphragms are in direct contact with the carbon

granules and the gold plating maintains consistent conductivity. The rear part

of the element has the carbon granule cup and the

metal body with the insulated contact button. If you

disassemble the two-piece element upside down, all of the carbon granules will

spill out of the cup (that's not a problem if you plan on

scraping the element anyway.) Installing an electret replacement

element would require destroying the original carbon element to

refit the electret element. Then taking out the spring contacts in the

body would be necessary followed by hard-wiring the electret element to the body. I haven't done this so

I can't say how an electret element would sound in the very small

case that the T-38 and RS-38-B mikes use. There are several versions of this

type of carbon microphone design with slightly different physical

parameters, different designations and built

by companies other than Telephonics. |

Telephonics Corp. -

T-38C aka RS-38-B |

| Carbon -

A TYPICAL WWII-VINTAGE PERFORMER - T-17B WWII USA

"Ground-Base"

Microphone - The Shure T-17

is a very common and therefore an easy to find WWII vintage aircraft

microphone. But, not all T-17s were for use in aircraft. Some were for use

on the ground in buildings. The ground operations type are not noise-cancelling

and will have seven large voice holes in the mike cup. These mikes use

a bakelite body. I've had my "ground-T-17" example for about 20

years and it's an

all-original mike with original carbon element so the carbon granules are probably compacted

somewhat. Response is much better than a typical original T-17 but

much lower than the Chi-Comm mikes (as would be

expected.) Also, lots of noisy crackling sounds and that's a

common problem with

nearly all original WWII carbon elements,...well,...after

all, most of the original elements are 80+ years old.

Nearly all T-17 mikes were for aircraft operations and

are "noise-cancelling" types with three small voice holes in

the mike cup. "Close-talking" is almost always necessary

with any of these types of carbon mikes and speaking loudly also helps. Early

T-17 mikes have metal bodies that are easy to take apart and

work on. The cup is mounted with four, black-wax covered

screws. The carbon element is held in place against the

contacts when the cup is

mounted. The middle variety, A, B and C, are bakelite body

that have a small panel the can be removed for access to the

PTT switch. The cup is mounted with four screws that are

black wax-covered (if the mike hasn't been tampered with.) Very late T-17 mikes (the "D" versions) have

a integral mike cup and element that's a complete, sealed unit. The

entire front of the mike was supposed to be replaced if problems

developed. The handle of the body is molded in "one-piece" with no

easy access to the PTT switch wires unless the mike is fully

disassembled (if that's even possible.) Earlier T-17

mikes can be rebuilt but the "D" versions usually can't. It might be

possible to somewhat resurrect original T-17 carbon elements

by tapping the element against the table to "jar" the

carbon granules loose

but they usually don't ever return to full response (after

all,...remember the 80+ years.) |

Shure T-17B with "Ground-Base

Operations" Cup |

| Carbon -

A RARE GOOD ONE - NOS T-17

"Noise-Cancelling" USA Aircraft Microphone -

I do have another example of the Shure T-17 that's NOS in the

original box. It's a T-17 aircraft version with noise

cancelling cup and with a treated-cloth spit-cover. It's an early T-17 that has

the metal body

with a bakelite cup. Despite its pristine condition, the PTT button

was sticking and wouldn't return to the standby position after being

depressed. I had to remove the button and clean the molding burrs

and then very lightly coat the mating surfaces with light-weight

grease. PTT operation was then normal with no sticking. The DCR of

this carbon element measured about 2500 ohms (I used a

modern DMM for this DCR measurement since the voltage

applied would then be very low.) Most carbon mikes will measure

around 1200 ohms up to maybe 3500 ohms. It's not critical

since the resistance changes with voice (sound) pressure. I connected the T-17 to the ATD. I monitored the output

using headphones on the Reception Set R106 (antenna disconnected)

and also using the Leader 505

oscilloscope as a waveform monitor. I was completely surprised! This NOS T-17

had plenty of response and sounded pretty good (but the

audio was very

"carbon-y.") It provides lots of

modulation (as seen on the oscilloscope.) It was a little

"rough" sounding in the 'phones but I was surprised that placing the

spit-cover on the mike head helped to smooth the rough sound a bit. I think if

this mike was used regularly, it probably would continue to improve.

As it is, it works better than any other "original" T-17 I've ever

used. NOTE: The

EMS-94 Electret-Condenser element will physically fit into the head of

the T-17 mike. I don't have a complete "junker" T-17 and I

don't want to disassemble either of my original T-17 examples.

The mouthpiece screws are covered

with a black wax material on original mikes and if a

T-17 has been taken apart, it's obvious. My two complete T-17s

are original with the black wax in place. The one "junker" T-17B body

that I have is incomplete and has been "gutted" so I don't know how the spring

contacts were installed or if the T-17 even used spring

contacts. If there's a

problem with the EMS-94 not interfacing the spring contacts,

the element can be "hard-wired" for the connections. Other

fitting problems might also be encountered depending on the

depth involved in the body, how the mouthpiece fits and the

thickness of the EMS-94 element. Until I find a "junker"

T-17 that's complete to disassemble and measure, I can only

say the the EMS-94 does fit as far as its diameter fitting

into the T-17B head. |

NOS Shure T-17 early

style with

metal body, aircraft-type "noise-cancelling" cup and spit-cover |

| Carbon

- MINE'S A "BEATER" - BUT

IT WORKS! - Roanwell

RM-15 and Roflan M-15/UR, T-17 "look-alikes" - There's

a T-17 "look-alike" microphone that was designated as

RM-15 that was built by Roanwell Corporation of New York

City, NY. An identical microphone was built by Roflan Company and

was designated M-15/UR. It's probable that somehow Roflan

and Roanwell were connected since the names are so similar,

the mike IDs are so similar and, physically, the microphones

appear to be identical. The microphones date from the 1950s so they appear

to be updated T-17 versions although the handle is built similar

to the early, metal-body T-17. They use the same SW-109 push-button but

with the Roanwell/Roflan logo instead of the Shure logo. The body of

the RM-15/M-15/UR is metal and by removing three screws it will

split-in-half for disassembly (like an early T-17) allowing

easy access to the PTT switch. The black bakelite cup has

seven small voice holes and lettering is embossed on the rim

of the cup states "TALK WITH LIPS TOUCHING MIC." There's a

segmented gap between the back of the cup and the mike body.

The carbon element assembly is made up of the front

mouthpiece behind which the carbon element is

mounted with four screws. Also, the carbon element is hard-wired

through two holes to connect to terminals that are also part

of the back of the element and mouthpiece assembly. The carbon element

can't be dismounted from the mouthpiece unless the carbon

element wires are unsoldered and the four screws removed. The body wires (from the

PTT switch) are also soldered to these terminals. From

disassembling my Roflan M-15/UR, I think the repair

process was to just replace the entire "mouthpiece/carbon

element" as one piece since this only required removing

front four

screws on the mouthpiece and unsoldering the two body wires, connecting up the

new replacement piece and remounting the mouthpiece assembly to complete the task.

This would have been quite easy to accomplish. The segmented

(and open behind the element - like venting)

area behind the mouthpiece assembly is a mystery. It doesn't

seem to have any functional purpose. There are two

capacitors inside the mike head, one for RF suppression on

the mike element and the other for transient suppression on

the PTT contacts. These mikes may have

been used in vehicles or other ground applications.

Interestingly, the M-15/UR shown in the photo was found with a Roanwell carbon element installed (and it fit perfectly

and looked original.) As stated in the title, this

M-15/UR example was a "beater" with missing screws, broken screws, PTT

contacts forced together and many other indicators of

indifferent (or incompetent) rework. I totally

disassembled the M-15/UR, replaced broken or missing screws,

rebuilt the PTT switch, cleaned the contacts, disassembled

the element,...rebuilt

the entire mike, in other words. And, to my complete surprise, after the

rebuild, the

microphone worked. I tested it with the ART-13A monitored

with the FNIRSI 'scope and the Collins 51J-4 receiver with

Trimm 'phones. I was easily able to achieve "cut-off"

although it did require close-talking (and with the

lettering on the mouthpiece, "TALK WITH LIPS TOUCHING MIC."

I suppose that should be expected.) The M-15/UR sounded

like a typical old military carbon microphone,...but I was surprised that

it even worked at all. |

Roflan Co. M-15/UR -

T-17 "look-alike" |

| Carbon -

NORMALLY USABLE - Kellogg/U.S.

Army Signal

Corps T-32 - Gound-Base Use - This is a real

antique dating from the 1930s but T-32s were used by the

Army up into the 1950s because of its durability and decent

performance at ground stations. The carbon element is a

K1-type that was also used in 1930s Army Field Phone

handsets. The K1 is very large with a large diaphragm. The

front mouth piece has lots of small holes for a

better-than-usual pressure transfer. This seems to result in

a good response and

the reproduction is usually seems to have more bass than

expected from a military microphone. The K1 element in

this particular T-32 is dated 1938, so it's pre-WWII. The

interesting thing is that this K1 still has a nice

response and will modulate a WWII transmitter at a usable

level. The small lever on the side of the grip is the PTT

switch and it has "PRESS TO TALK" embossed on the lever. The

plug on the end of the cable is a standard PL-68 (I don't

know how I hid the cable for the photo,...maybe there wasn't

one installed when I took the photo.) The K1 element is held in place by two mounting

screws and then there are two contact clips that are also

screw mounted. The front cover is mounted with four small

2-56 machine screws. The K1 element is actually mounted to

the back of the front cover with the mounting screws and

contact clips on the back of the front cover. Two wires are

routed back to the head connections. Although, with the

amount of space available in the T-32 head, mounting a

modern electret microphone might be easy, the usual K1

element normally will have a very usable carbon mike response

and can properly be used on vintage ground-based

Army transmitters such as the BC-191. |

Signal Corps/Kellogg

T-32 - K1 element dated 1938 |

| Carbon

- Electro-Voice 210-S using a Modern (1987) Aircraft Carbon Microphone Element

- This 1987 aircraft carbon microphone element was in a plastic bag with a

company label stuck to the outside of the bag erroneously indicating

this carbon microphone element was built in 2004. It was NOS in the original packing (the bag) and was

"unused stock" from an aircraft rebuilding company in

Colorado. I've

seen similar elements advertised as being for Beechcraft

equipment but this bag didn't have any indication of what

the carbon element was for. A quick inspection of the

element revealed that the date-code on

the mike element was from 1987, not 2004 (repackaged, I

guess.) The element is much smaller than the typical

WWII carbon mike element so it could easily fit into either

a T-17 or T-38 microphone body. I decided to fit this element into an

Electro-Voice 210-S Carbon Microphone body that I've had for

quite a while. It's a large, beautiful handheld design

featuring a glossy

black bakelite body. The 210-S dates from the early 1950s. The carbon

element that was installed in the E-V was bad and

non-original. This new carbon

element was very close to the original E-V size so it

physically fit into the body fine. I soldered hook-up wires to

the new element and used black dense foam rubber as a shim

to allow using the original E-V element mounting. The "tricky"

part was getting the PTT switch to actually stay together

while the two pieces of the mike body (front and back)

were assembled. I had

to use fine 28ga. wire to hold the PTT switch contacts in

place while assembling the parts of the PTT switch

(including the compressed coil return spring) and once the

switch was together, I pulled out the wire so the two

contacts would "toggle" as the button was pressed. Of course, this

procedure took about three times trying to actually end-up successful.

Then, once the body was together, a test showed that the PTT

switch wasn't making contact, so the whole procedure,

including complete disassembly, had to

be repeated - and that had to be done twice (I wonder how

E-V did the assembly at the factory?) Finally, I got the mike body together with the

PTT switch working. The contacts were tested using a DMM to

confirm that they functioned correctly. Then a PL-68 plug was installed

on the cable. I tested the new carbon element inside the

E-V 210-S case using the ART-13A connected to the Collinear

Array with the signal monitored on the FNIRSI DPOS350P

'scope and the 51J-4 receiver. I had lots of response and

the waveform showed ample modulation with cut-off happening

every so often. The signal modulation sounded very good in

the 51J-4 receiver. I did notice that the element is

somewhat directional and I had to speak directly into the voice

holes of the mike body. That's probably the design and

results from how the mike element sets directly behind the

holes and perhaps the thickness of the bakelite case and

how that thickness relates to the depth of the voice holes

causing some directional characteristics. It's not a

problem, just something I noticed. The E-V mike works quite

well and is a really nice-looking microphone. It's now an

example of how a fairly modern carbon mike element can be

successfully installed into an older mike body and, of course,

this procedure can be applied to WWII-vintage microphones

that need a physically smaller type of new carbon element,

such as the T-17 and T-38. |

Electro-Voice 210-S, a "Beauty" from the 1950s |

|

Dynamic-Magnetic Microphones |

| Dynamic/Magnetic

- THE BEST - Astatic D-104

with TUG-8 Amplified G-Stand - Without a doubt, if

you don't like the "carbon mike sound," the D-104/TUG-8

combo is the BEST for providing a clean-sounding, high-level

audio output. It has no peers! - Well, this isn't a

"military" microphone,...it isn't even a dynamic

microphone,...but it will perform very well with

just about any military transmitter that provides the option

of using a dynamic or magnetic microphone. The Astatic

D-104 with TUG-8 stand is actually a crystal microphone element

driving a battery-operated transistor amplifier with adjustable gain. The output

impedance of the transistor amp will usually work well with military

dynamic inputs. Lots of audio highs with generally low

distortion and excellent articulation. Also, a high

modulation capability can easily be attained because of the adjustable gain feature. For a dynamic (crystal+amp) type

this is the BEST type and using it will avoid the typical "sound

characteristics" of a carbon mike. However, don't use a crystal mike directly

to a dynamic input since the crystal element impedance is very high

and won't provide very much response. You MUST use

the TUG-8 base with the transistor amplifier for proper

interfacing of a crystal mike with a WWII military transmitter. NEVER connect a

crystal mike directly to a carbon mike input,...the bias

voltage will destroy the crystal element. When using the Astatic

TUG-8 stand always select "DYNAMIC" or "MAGNETIC" as the

microphone type (the switch is part of the transmitter controls.) The TUG-8 amplifier has a fairly low output impedance

that

seems to be very compatible with most military transmitters that

were designed to use a dynamic microphone. It's also possible to use

a dynamic mike "head" such as the Astatic 10-D on the TUG-8 stand to allow easy

interfacing and impedance matching of a ham-type, hi-Z dynamic microphone to a WWII military transmitter.

The D-104/TUG-8 that I use has an original Astatic crystal

microphone element in the head. I bought two new D-104 elements

back in the early-1990s when they were still available from Astatic. Thinking that these elements would

always be

available, I installed one into a D-104 head and then sold

that mike (what a dummy!) Fortunately, I kept the other D-104 head with the

1990s Astatic element installed. That mike has done service

here for over 30 years now. It has excellent response in

an Astatic G-stand for direct-to-grid use with a Collins

32V-3 transmitter and I will swap stands to a TUG-8 if I

want to use this D-104 head with a military transmitter.

Crystal microphones are delicate and need to be treated

gently. Don't drop the mike on the floor. Don't expose the

mike to temperatures exceeding 125º F. The military NEVER

used crystal microphones because of their fragile nature.

More info that's specific to D-104 mikes,...read on,... |

Astatic TUG-8

solid-state, battery-operated amplifier that is located in

the base of the stand. The PCB is the amp and the potentiometer controls the

audio gain. The 9-volt battery and the amplifier are

only "on" when the grip-bar is pressed. |

| IMPORTANT

NOTE: KOBE-TONE CRYSTAL ELEMENTS INSTALLED in D-104 HEADS

- Be

aware that many D-104 microphone heads no longer have their

original Astatic crystal element. When Astatic was sold in

2001, the new company stopped making D-104 mikes and

elements. After that, the only "newly-made" crystal

microphone elements available were from Kobe-tone (a

Japanese manufacturer.) These crystal elements were easy to

purchase from Mouser Electronics for about $5.00 each. Not

surprisingly, these were used as replacement elements for

quite a large number of D-104 mikes that had bad crystal elements. The problem

was that no two Kobe-tone elements sounded the same. Some

were okay but many were terrible sounding and none of them sounded

like the original Astatic crystal element. The original

Astatic D-104 crystal element was about 2.5" in diameter and

the thin aluminum diaphragm was the same size, covering the

entire front of the bakelite case used for the

Rochelle-salts crystal element. This diaphragm was covered

with a thin fibrous pad that was glued directly to the rim

of the diaphragm for

"breath noise" suppression. This almost direct exposure of a

large diaphragm to the screen on the mike head

(that had black grille cloth installed) provided excellent high-end audio

frequency and very high output voltage (piezo-electric

effect.) The Kobe-tone

element was available in two sizes, one at 1.9" diameter

and one that was about 1.25" diameter,...both quite a bit smaller

than the original Astatic element. Also, the Kobe-tone

element had a metal cover over the diaphragm with 13 sound

holes (in the larger element.) Since the Kobe-tone was so different in design than

the Astatic, it's not surprising that they didn't sound very

much alike. Most Kobe-tone

crystal elements, if used direct-to-grid, lacked any bass

response (even with a 5meg grid shunt) and also had a much lower

output than would be expected from a crystal element. BUT, if the Kobe-tone was

used in a D-104 head with the TUG-8 base, the

transistor amplifier usually compensated for most of the differences

in output level. On a TUG-8 stand, the Kobe-tone could

produce decent audio at a high output level. The Kobe-tone

crystal elements are no longer being produced, so all that's

available nowadays would be NOS stock Kobe-tone

elements from private individuals or an extremely rare,

original, NOS Astatic D-104 element (or even an old working

original D-104 Astatic element.) |

|

Kobe-tone

Crystal Microphone Element |

Original

Astatic D-104 Crystal Microphone Element |

|

| Dynamic/Magnetic -

A LOSER - Turner U9S Multi-Impedance Dynamic

- It's fairly difficult to find true dynamic

microphones with a low impedance option of between 150Z to

250Z. They're around but they usually are professional mikes

used in broadcasting or public address. Many types require

some wiring changes inside the mike body to select various

impedance options. Some early

dynamic mikes had switches that allowed easy changing of the

impedance. The Turner U9S was a

small early

dynamic

mike with an impedance switch that had color-coded indicators. Blue

was 25-50Z, Red was 200-250Z, Black was 500Z and White was

Hi-Z with the slot of the switch shaft pointing to the Z

selected. I had to make a cable for the U9S with the proper

three-pin connector to fit the mike head. A PL-68 was

installed on the other end of the cable. The U9S doesn't

have any type of PTT. The ATD manual has a paragraph

regarding microphones without PTT and indicates that the

THROTTLE SWITCH can be utilized for a PTT. This requires a

PL-55 plug and a short two conductor cable with a open and

close position switch. I already had a THROTTLE SWITCH cable

that I use all the time for "tuning up" so one didn't

have to be built. The mike is on all the time but that

shouldn't be a problem. I set the U9S to 200-250Z and connected the

mike to the ATD (the dynamic mike R-load is 300 ohms.) The Turner U9S sounded pretty bad. Very low

modulation. I switched the impedance to 500Z and that was a

very slight improvement but the mike output is just too low (the

ATD doesn't use an audio input transformer for Z-matching,

only resistors, but the ATD does provide a C-coupled dynamic mike preamplifier

stage.) The sound quality was okay. Compared to the

D-104/TUG-8, the Turner U9S really isn't usable. With some searching, finding

a 150Z to 250Z dynamic microphone isn't too difficult but

don't expect great performance.

NOTE: The ART-13A uses an audio input

transformer for both carbon and dynamic microphones. This

U9S was also tested with the ART-13. It performed best when

set at 200-250Z. I was able to hit cut-off if I close-talked

the mike,...loudly,...but the sound quality was not that good. |

|

|

Turner U9S

Multi-Impedance Dynamic Microphone wasn't a good

choice. |

|

|

EMS-94 Electret-Condenser

Microphone "Replacement

Element" for Vintage Carbon Microphones

An Electret microphone is a Condenser microphone that

uses a metallic-coated flexible diaphragm that is in close

proximity to a backplate that has been coated with an "electret"

material. The electret material possesses an almost

permanent low-voltage static charge on it. As the metallic

diaphragm moves, the distance to the charged backplate changes the

value of C and, since there's a fixed-charge on the

backplate, a small varying voltage is generated across the

two plates involved. This voltage level is very low and

requires a transistor amplifier, usually a J-FET, to boost the output to a

usable level and to lower the output impedance to a value

compatible with most uses. In the case of electret

microphones that are used for

carbon microphone substitutes, the voltage to operate the

transistor amplifier can come from the carbon microphone's

bias voltage that is supplied by the transmitter. Since electret microphones don't use carbon

granules as a medium for sound transmission, the electret

output is free from "carbon hiss" and usually has low

distortion with a fairly wide audio bandwidth. |

| Electret -

I'M IMPRESSED - A Modern Mike Element

Installed in a Vintage Housing - Over the past ten

years or so, there have been a few types of electrec microphone modules offered

for sale

that were specifically designed for use in WWII vintage carbon mike

bodies. A popular version that was available a few years ago was built onto a small circuit board that

installed into the mike head. The electret amplifier was powered by

the carbon mike bias voltage. These electret PC board modules were designed

specifically for the T-17 "noise-cancelling" mike and did sound

slightly different when installed in other types of mike bodies. These

modules were available on eBay but are no longer being produced.

However, there's a new electrec mike element available

that's easy to install inside some types of old mike

bodies. G-Tel Enterprises, Houston, TX sells the EMS-94 electrec

microphone element for $7.75 each. These Electret elements are made specifically as replacements for the old Western Electric T1 carbon microphone found in telephone handsets. The

EMS-94 Electret amplifier is powered from the carbon bias

supply (the telephone landline provided a bias voltage for the

original carbon microphone in telephones.) Since this is a "telephone replacement" element,

it was designed to work in and sound like the old WE T1 telephone

microphone. It's also the same (large) size

physically at 1.795" diameter and 0.625" thickness. Since the EMS-94 is in a metal housing like the

original T1, the installation would

require a set of contacts that were like the type used in a telephone handset.

Those contacts would have to be fitted into a handheld mike body (although

it's easy to solder wires directly to the

element contacts for "ease of hookup" if spring-contacts aren't

already part of the microphone body.) For the mike

element to "sound correct" the mike body should

have a cover similar to a telephone handset. Mouthpieces

that are "noise-cancelling" tend to reduce the higher

frequency audio somewhat. |

G-Tel EMS-94 Electret-Condenser

Microphone Replacement Element for Carbon Microphones

|

|

|

Installation - The RS-38-B and T-38 WWII mikes

have too small of a mounting area to accept the EMS-94

without some modifications to the mike body. With contact

modification, the EMS-94 should fit into a T-17 without too

much trouble. The easiest way (for me) to use one

of these new Electret elements was to install it into one of the empty Chi-Comm

Shure knock-off cases I have. There's ample room inside the mike

body for the element plus room for a rubber spacer to allow

using the original spring retainer for the element. Also,

the front opening is quite large and unrestricted allowing

full-range audio response. The rubber spacer was 3/8" thick black

foam. It held the EMS-94

securely in the Chi-Comm case using the original Chi-Comm

wire retaining

clip. I cleaned the contact areas

on the mike element

and the soldered two wires for hookup. I used 400grit AlOx

paper to clean the metal surface and then the solder flowed

quite well allowing the wires to be easily attached. The

wire connections

eliminate the hassle of trying to come up with spring contacts.

In the mike body, the wires were connected to case ground and

to the PTT switch. The reassembled PLA mike with the EMS-94

element

was tested with the ATD transmitter. It seemed to have the

response of a good working-condition carbon mike and full

modulation was easy to achieve. The mike sounds something like a carbon mike

but that could just be the ATD audio components or my method

of testing. The response wasn't as intense as the PLA Chi-Comm

mikes but I was still able to easily fully modulate the ATD

(without

yelling.)

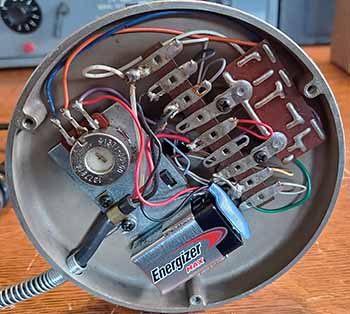

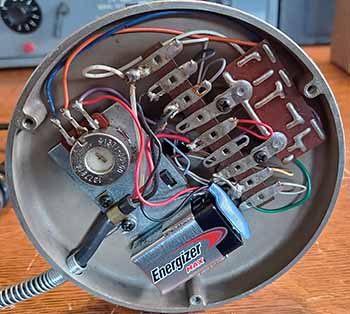

photo left: W7MS

decided that a look inside the EMS-94 would be informative. Mike used the tool

shown in the photo to unwrap the crimp of the front metal

piece of the EMS-94 to reveal "what's inside." As can be

seen, a circular PCB with nine components and the electret-condenser

mike glued to the PCB and wired into the circuit. Note that

the contacts have the connecting wires soldered directly to

the center contact button and to the inside of the metal

shell. Thanks to Mike, W7MS, for this interesting

photograph.

|

|

Electret in

an original Black Wrinkle Finish PLA body but the

grille cloth isn't original |

|

Inside the

Electret showing the spring clip hold-down and the

rubber spacer |

|

ART-13 Test

Turns Up Something Unexpected - I did an "on the air" test with ART-13A modulated with

this Electret mike. I noticed that the modulation was fairly

low on my monitoring oscilloscope but audio reports from the

other net participants were "sounded great" but

that's normally the way "on the air" microphone tests go

when operating in the "net" environment.

Luckily, Wavelength Radio recorded the NV-Mil-Rad Net (on

youtube) and I

was able to (later) listen for myself. I had made two

transmissions

using a D-104/TUG-8 mike and two transmissions made with the Electret mike. With the D-104/TUG-8 modulation was superb

and at a very high level resulting in a really nice audio presence. The Electret was at a very low

average modulation level of about 30% and this could be easily seen

on the recording's panadapter. There were times in the

recording play-back that I literally couldn't hear my audio but

the carrier was remaining strong. This was weird since the

Electret mike seemed to work fine with the ATD.

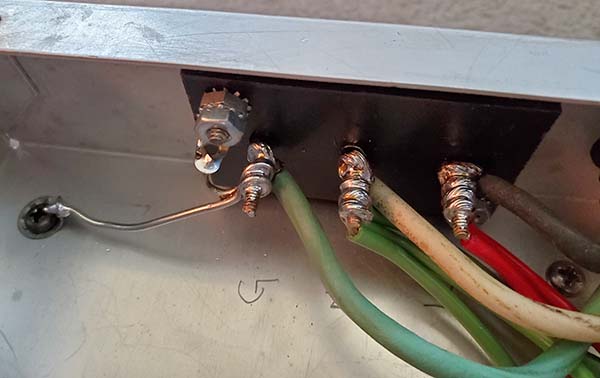

Why I Only Had 30%

Modulation Using the ART-13A - After the mil-rad net problems, I decided to retest the Electret. I again set-up the ATD

with the Electret mike. I was easily able to achieve full

modulation with the Electret as seen on the monitoring

oscilloscope. Obviously, the problem was with the ART-13.

This reminded me that the ART-13 carbon mike bias can have a

potential problem. If the particular ART-13 Audio Module never went through a military depot then it might still have the

original R203, a 15K

bias resistor, that results in a very low bias voltage that just about prevents using any type of carbon

mike. The value of R203 was changed in the later ART-13s to

a value of

4.7K (about 1943) and was usually changed if an

ART-13 went through one of the mil-depots. This lower

resistance increased the carbon mike bias voltage to allow

full modulation when using just about any good

condition carbon mike. This

ART-13A had been through SAAMA so I assumed the resistor

change had been made. But, I only used the D-104/TUG-8 on this

transmitter, in the DYNAMIC position, so the carbon mike bias

resistor

was never in the circuit until I tried the Electret. When

removing the Audio Module, I was surprised to find the

original 15K bias resistor was still present. I had

obviously worked on this Audio Module because some of the

capacitors had been replaced. I don't really know why I

didn't change R203 to 4.7K,...probably something in my mind

about maintaining originality (and not really needing the

carbon bias to be useable.) Since R203 wasn't used,...it

wasn't ever a

problem,...until now. So, I installed

a 4.7K 1W 10% CC as original (well, the original military MWO fix) and I was ready to test again.

Local Testing

-

This time the ART-13A no problem achieving 100% negative cut-off

using the Electret mike. Full modulation was very apparent on the

oscilloscope. I listened on the R106 receiver with no

antenna connected and using 'phones. The audio sounded like

a good dynamic mike, not as many highs as the D-104/TUG-8,

but still very good audio quality. I retested with the PLA

carbon mike and the response was somewhat more than the

Electret, but not by much.

The upshot of this ART-13 testing shows that the output of

the Electret mike is definitely dependent on the level of

the bias voltage from the transmitter. So, if the EMS-94 has

low response, check you transmitter's carbon bias level to

be sure it's providing a sufficient voltage level. Verify

the value and functionality of the bias circuit components

if there's a problem.

UPDATE: Oct 12, 2025 - I was NCO of the NV

Vintage Mil-Rad Net today and I used the ART-13A with the

Electret EMS-94 in the PLA body as the microphone. I

monitored the signal waveform locally on a FNIRSI DPOS350P

oscilloscope. The modulation showed cut-off was being

achieved fairly often and the level of modulation was quite

good. All went Q5 on the net but I was interested in

the Wavelength Radio recording of the mil-rad net on YouTube.

This time, on the recording, I was sounded much better with

lots of presence but I really

wanted to see the panadapter display. The panadapter showed

the signal

was about 10kc wide and that indicated that the audio response was

easily at the 4000hz upper audio frequency spec that the

ART-13 is rated for and the

upper-end audio frequency wasn't limited by the EMS-94 (or the PLA

body.) The

spectrum was full of audio indications out 5kc each side of

3.9745mc (net frequency is 3.974mc.) The vertical panadaptor showed a good level of modulation that again

looked about 10kc wide. The EMS-94 sounded excellent with a

good representation of my voice characteristics with lots of

presence. 100% better

than the last "on the air" test.

|

|

CONCLUSIONS: - The EMS-94 Electret-Condenser

mike element is an excellent replacement for a defective

carbon mike element. It sounds good and modulates very well if the carbon mike bias

voltage of the transmitter is at a sufficient level. It's

large size (1.795" diameter and 0.625" thickness) might limit what

WWII mike bodies it can be installed

into. Since the EMS-94 easily fit into the PLA mike body, I

would think it would be easy to fit into the USA Shure 102C body

or any similar size metal handheld mike body. Also, soldering

wires to the contact button and the shell doesn't do any

damage since the EMS-94 is actually a circular circuit board

inside the housing that has the electret-condenser mike and nine other small

components mounted on the PCB. Two wires are soldered to the

contact button and the shell inside the housing, so

soldering wires externally is okay and definitely makes

installation easier.

Ordering the EMS-94 from G-Tel is easy. The elements are

$7.75 each and because of the minimum order requirement,

you'll have to order at least two EMS-94 Electret elements.

There's also a very small shipping charge. You can pay with

a credit card or PayPal. You can order the EMS-94 Online from:

www.payphone.com/EMS-94-Electret-Condenser-Microphone.html

|

|